Method for fabricating sheet oxygen sensor

A technology of oxygen sensor and manufacturing method, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of difficult sealing, chip defect, fracture, etc., and achieve easy control of the process flow, high one-time pass rate, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

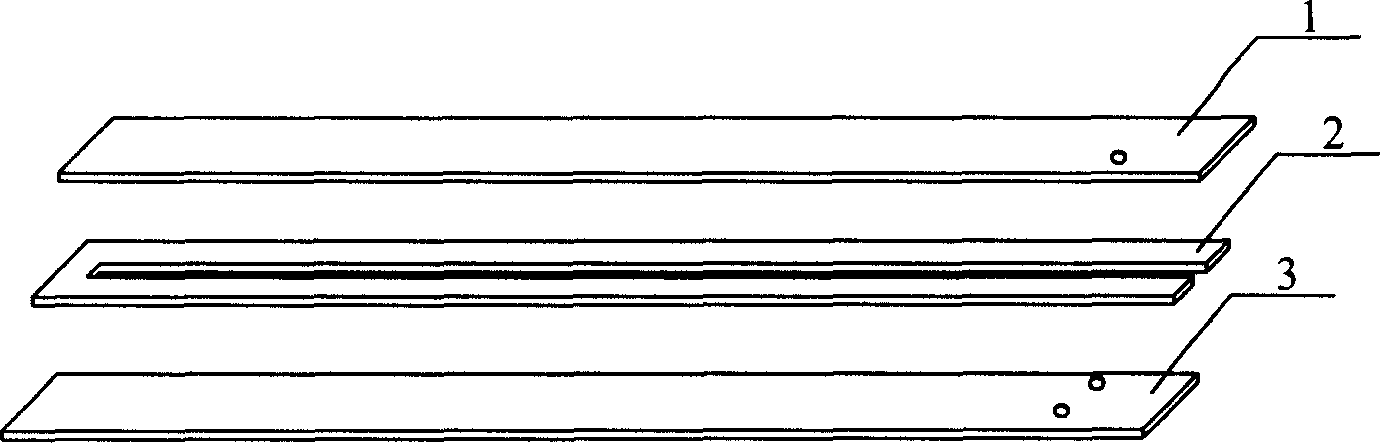

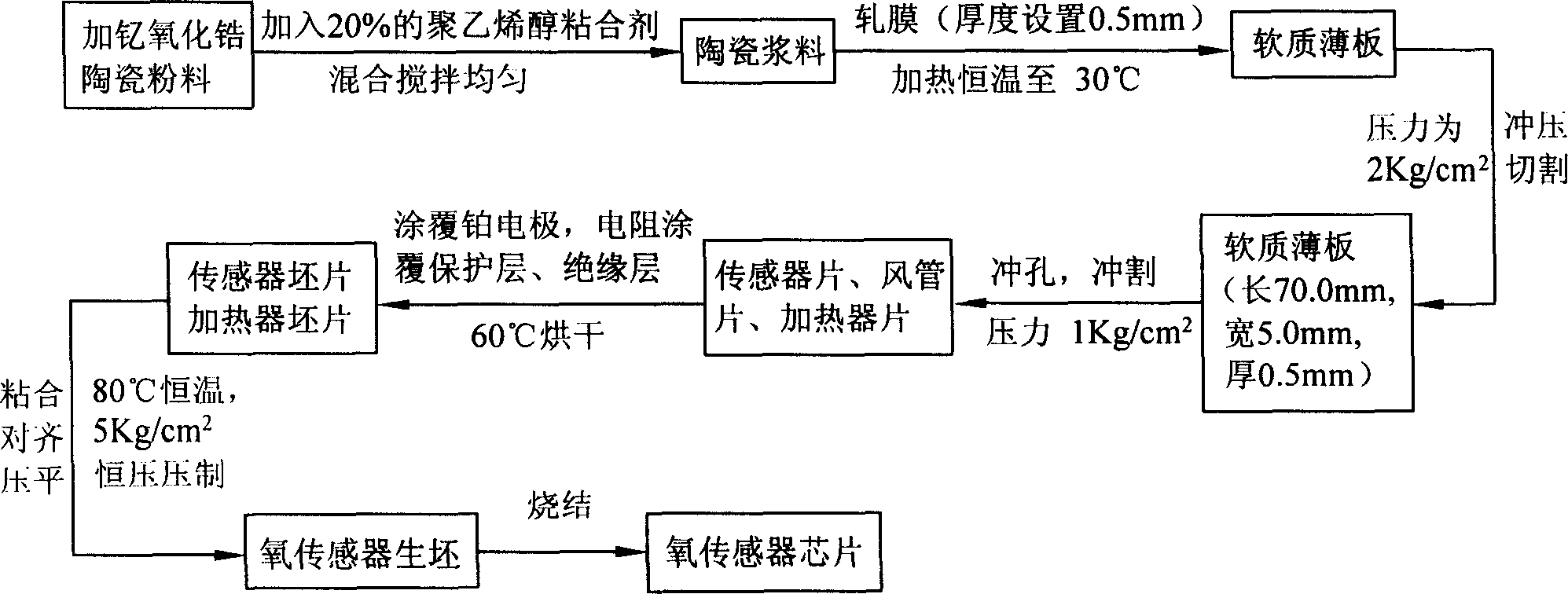

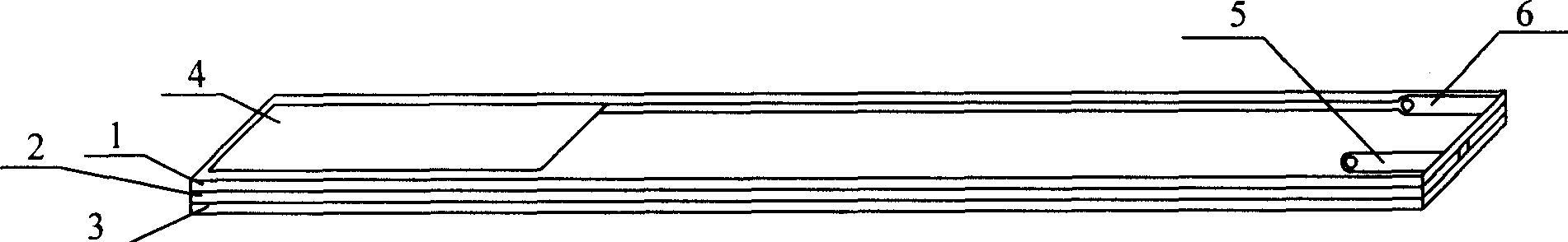

[0040] The present invention adopts three-layer integral sintering method, and concrete operation is:

[0041] 1. Make a slurry: Add 20% polyvinyl alcohol binder to the yttrium-added zirconia ceramic powder and stir to form a paste, and let it stand for 1 to 2 hours.

[0042]2. Rolling film: Set the rolling film thickness before rolling the film. After setting, do not adjust it arbitrarily to avoid uneven rolling film thickness. Slowly pour the jelly between the two rollers of the film rolling machine to roll the film. At the beginning of film rolling, the film rolling speed is relatively slow because the ceramic powder is prepared into a slurry. In order to speed up the film rolling speed, the film rolling roller can be heated, but the heating temperature should not be too high, generally controlled at 30°C. Heating while rolling the film like this, when the paste begins to not completely bond on the rolling film stick, and sticks together in sheet form, stop heating. Knea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com