Microwave ceramic and preparation method thereof

A technology of microwave ceramics and ceramic powder, which is applied in the field of microwave ceramic materials, can solve the problems of low dielectric loss and less research on the temperature coefficient of diversified frequencies, and achieve the requirements of wide temperature coefficient range, high Qf value, and low loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

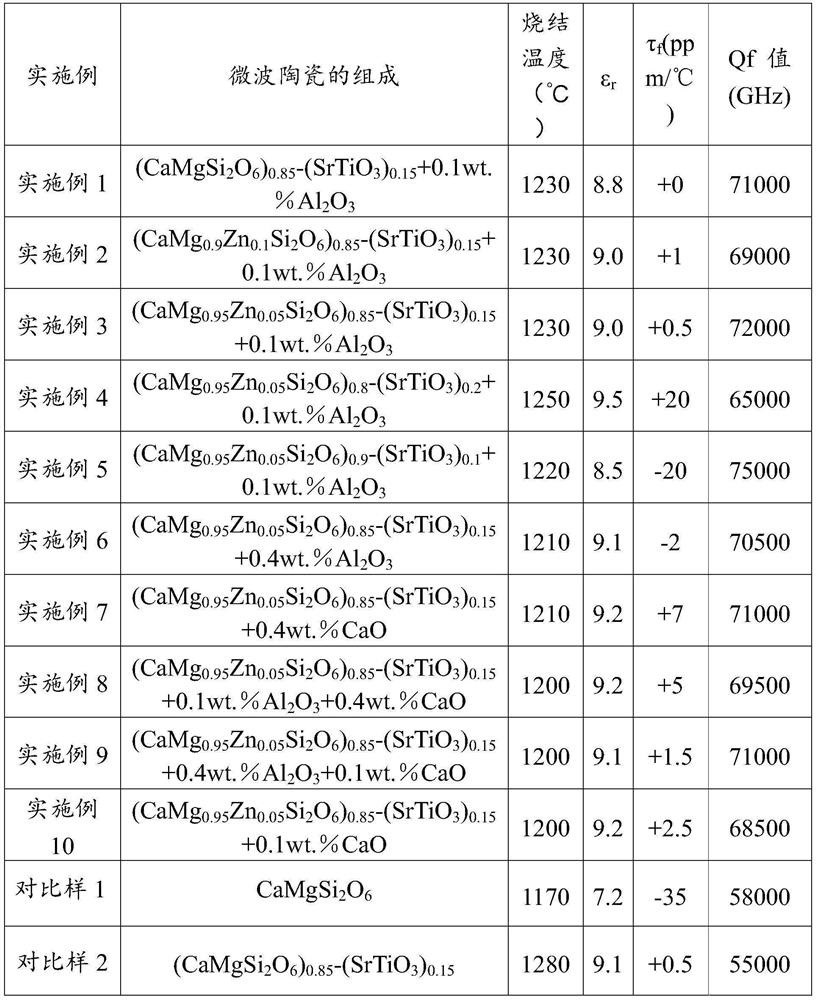

Examples

Embodiment 1

[0017] The concrete steps of this embodiment are as follows:

[0018] (1) Preparation of composite powder: Molar ratio [0.85]: [0.85-0*0.85]: [0*0.85]: [2*0.85]: [1-0.85]: [1-0.85] ratio respectively Weigh CaCO with a purity above 99.5% 3 , MgO, ZnO, SiO 2 , SrCO 3 、TiO 2 The powder is ball-milled in a high-speed ball mill and fully mixed, then taken out, dried, ground, and pre-calcined at a high temperature to obtain (CaMgSi 2 o 6 ) 0.85 -(SrTiO 3 ) 0.15 For the composite powder, the calcining temperature is 900° C., and the calcining time is 3 hours.

[0019] (2) Prepare ceramic powder: add 0.1% by weight (ie 0.1wt%) metal oxide Al to the composite powder 2 o 3 , secondary ball milling in a high-speed ball mill, adding 20% (ie 20wt%) binder of the weight of the composite powder and then granulating to obtain ceramic powder. The composition of the ceramic powder is (CaMgSi 2 o 6 ) 0.85 -(SrTiO 3 ) 0.15 +0.1wt%Al 2 o 3 . The bonding agent is polyvinyl alco...

Embodiment 2

[0023] The concrete steps of this embodiment are as follows:

[0024] (1) Preparation of composite powder: Molar ratio [0.85]: [0.85-0.1*0.85]: [0.1*0.85]: [2*0.85]: [1-0.85]: [1-0.85] ratio respectively Weigh CaCO with a purity above 99.5% 3 , MgO, ZnO, SiO 2 , SrCO 3 、TiO 2 The powder is ball-milled in a high-speed ball mill and fully mixed, then taken out, dried, ground, and pre-calcined at a high temperature to obtain (CaMg 0.9 Zn 0.1 Si 2 o 6 ) 0.85 -(SrTiO 3 ) 0.15 For the composite powder, the calcining temperature is 920° C., and the calcining time is 3.2 hours.

[0025] (2) Prepare ceramic powder: add 0.1% by weight (ie 0.1wt%) metal oxide Al to the composite powder 2 o 3 , second ball milling in a high-speed ball mill, adding 22% of the binder of the composite powder weight and then granulating to obtain ceramic powder. The composition of the ceramic powder is (CaMg 0.9 Zn 0.1 Si 2 o 6 ) 0.85 -(SrTiO 3 ) 0.15 +0.1wt.%Al 2 o 3 . The bonding agen...

Embodiment 3

[0029] The concrete steps of this embodiment are as follows:

[0030] (1) Preparation of composite powder: Molar ratio [0.85]: [0.85-0.05*0.85]: [0.05*0.85]: [2*0.85]: [1-0.85]: [1-0.85] ratio respectively Weigh CaCO with a purity above 99.5% 3 , MgO, ZnO, SiO 2 , SrCO 3 、TiO 2 The powder is ball-milled in a high-speed ball mill and fully mixed, then taken out, dried, ground, and pre-calcined at a high temperature to obtain (CaMg 0.95 Zn 0.05 Si 2 o 6 ) 0.85 -(SrTiO 3 ) 0.15 For the composite powder, the calcining temperature is 950° C., and the calcining time is 3.5 hours.

[0031] (2) Prepare ceramic powder: add 0.1% by weight (ie 0.1wt%) metal oxide Al to the composite powder 2 o 3 , secondary ball milling in a high-speed ball mill, adding 25% binder of composite powder weight and then granulating to obtain ceramic powder. The composition of the ceramic powder is (CaMg 0.95 Zn 0.05 Si 2 o 6 ) 0.85 -(SrTiO 3 ) 0.15 +0.1wt.%Al 2 o 3 . The bonding agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com