High-heat-stability high-Q-value lithium-magnesium-niobium microwave dielectric ceramic

A technology of microwave dielectric ceramics and thermal stability, which is applied in the field of ceramic compositions, can solve the problems of large temperature coefficient of resonance frequency and low Q×f value, improve the temperature coefficient of resonance frequency, increase Q×f value, and simplify the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

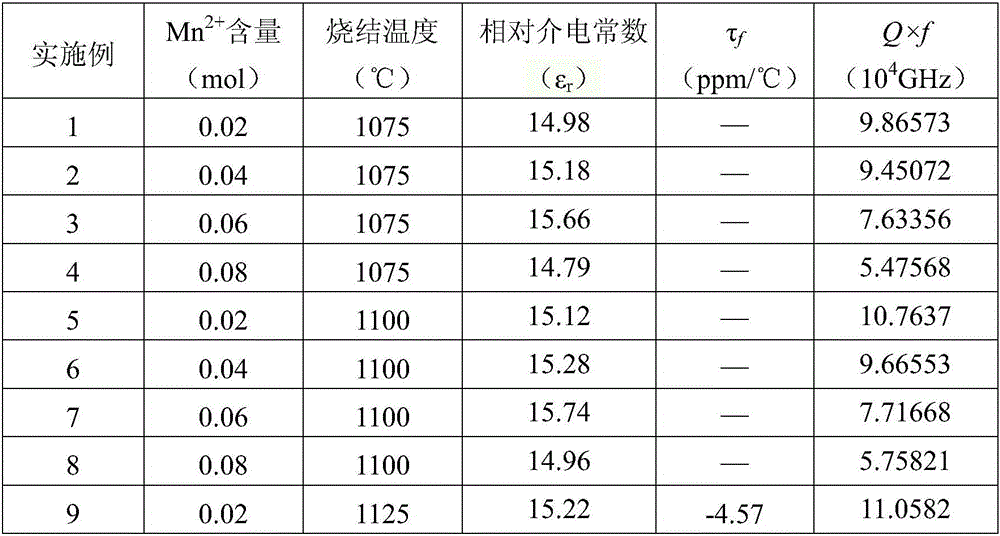

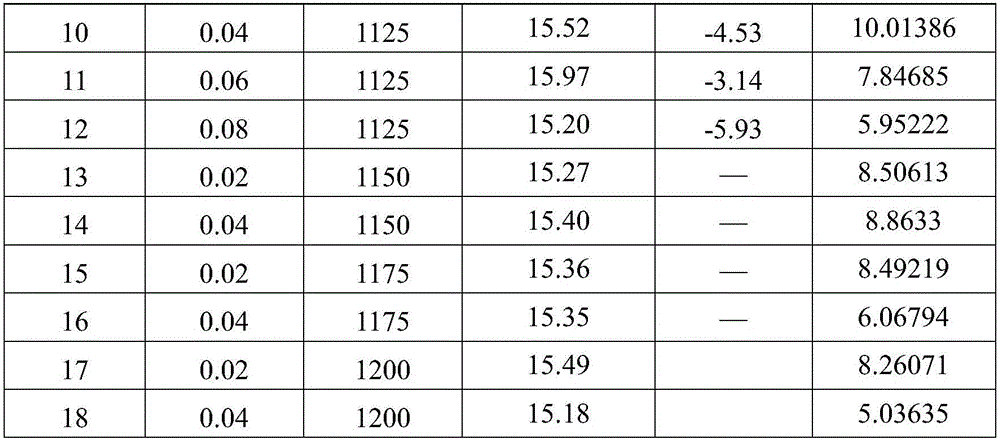

Examples

Embodiment 1

[0024] According to the microwave dielectric ceramic composition Li 3 (Mg 0.98 mn 0.02 ) 2 NbO 6 , called Li 2 CO 3 -10.1581g, MgO-7.2390g, Nb 2 o 5- -12.1806g, MnCO 3 -0.4214g of ingredients, 30g in total; the mixed powder was added to the polyester tank, after adding 160ml of deionized water and 150g of zirconium balls, ball milled on a planetary ball mill for 6 hours, and the speed of the ball mill was 1000 rpm;

[0025] 2. Put the ball-milled raw material in a drying oven, dry at 120°C and pass through a 40-mesh sieve to obtain a powder with uniform particles;

[0026] 3. Calcinate the powder at 925°C for 4 hours;

[0027] 4. Put the calcined powder into a polyester tank, ball mill it for 6 hours for the second time, dry it after discharge, and pass through a 40-mesh sieve; then add 8% paraffin wax as a binder for granulation, and Pass through an 80-mesh sieve; then use a powder tablet press to press into a green body with a diameter of 10mm and a thickness of 5m...

Embodiment 2

[0031] 1. According to the microwave dielectric ceramic composition Li 3 (Mg 0.96 mn 0.04 ) 2 NbO 6 , called Li 2 CO 3 -10.0663g, MgO-7.0281g, Nb 2 o 5 -12.0705g, MnCO 3 -0.8352g of ingredients, 30g in total; the mixed powder was added to the polyester tank, after adding 160ml of deionized water and 150g of zirconium balls, ball milled on a planetary ball mill for 6 hours, and the speed of the ball mill was 1000 rpm;

[0032] 2. Put the ball-milled raw material in a drying oven, dry at 120°C and pass through a 40-mesh sieve to obtain a powder with uniform particles;

[0033] 3. Calcinate the powder at 925°C for 4 hours;

[0034] 4. Put the calcined powder into a polyester tank, ball mill it for 6 hours for the second time, dry it after discharge, and pass through a 40-mesh sieve; then add 8% paraffin wax as a binder for granulation, and Pass through an 80-mesh sieve; then use a powder tablet press to press into a green body with a diameter of 10mm and a thickness of 5m...

Embodiment 3

[0038] 1. According to the microwave dielectric ceramic composition Li 3 (Mg 0.94 mn 0.06 ) 2 NbO 6 , called Li 2 CO 3 -9.9761g, MgO-6.8200g, Nb 2 o 5 -11.9624g, MnCO 3 -1.2415g of ingredients, 30g in total; the mixed powder is added to a polyester tank, after adding 160ml of deionized water and 150g of zirconium balls, ball milled on a planetary ball mill for 6 hours, and the speed of the ball mill is 1000 rpm;

[0039] 2. Put the ball-milled raw material in a drying oven, dry at 120°C and pass through a 40-mesh sieve to obtain a powder with uniform particles;

[0040] 3. Calcinate the powder at 925°C for 4 hours;

[0041] 4. Put the calcined powder into a polyester tank, ball mill it for 6 hours for the second time, dry it after discharge, and pass through a 40-mesh sieve; then add 8% paraffin wax as a binder for granulation, and Pass through an 80-mesh sieve; then use a powder tablet press to press into a green body with a diameter of 10mm and a thickness of 5mm w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com