A kind of zmat series microwave ceramic material and its preparation method and application

A technology of microwave ceramics and ceramic materials, which is applied in the field of information functional materials, can solve problems such as low dielectric constant, and achieve the effect of low dielectric constant and high Qf value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the ZMAT series microwave ceramic material of the present invention comprises the following steps:

[0031] ①Solid-phase synthesis of the main material Mg 2 Sn x Si 5+2x Al 4-4x O 18 : According to the proportion of each metal element and silicon element in the main material, weigh the high-purity magnesium hydroxide, tin oxide, silicon dioxide and alumina of the corresponding mass, and place them in a ball mill. The mass ratio is solid material: water = 1: ( 1.0~2.0) was added with water for wet ball milling. The ball is ground into uniform powder, and the particle size D50 can be 0.9-2.0um; then it is dried by spray drying tower or other methods; then it is calcined in the temperature range of 1220℃~1320℃ in an air furnace for 2~4 hours; finally the main material is obtained Mg 2 Sn x Si 5+2x Al 4-4x O 18 powder.

[0032] ②Solid-phase synthesis of auxiliary material Zr 1-3y La 4y TiO 4 : According to the molar ratio of each meta...

Embodiment

[0045] This embodiment provides a ZMAT-based microwave ceramic material and a preparation method thereof, and the solution of the present invention is not limited to this embodiment. The ceramic material includes a main crystalline phase and modifying additives. The chemical formula of the main crystal phase is Mg 2 Sn x Si 5+2x Al 4-4x O 18 ·aZr 1-3y La 4y TiO 4 , where 0.05<x<0.1, 0.1<y<0.3, 0.01<a<0.05. The mass fraction of the main crystal phase in the ceramic material is 98-99.5 wt %. The mass fraction of the modified additive in the ceramic material is 0.5-2 wt %.

[0046] (1) According to the main material Mg 2 Sn x Si 5+2x Al 4-4x O 18 The composition of , where 0.052 Sn x Si 5+2x Al 4-4x O 18 powder.

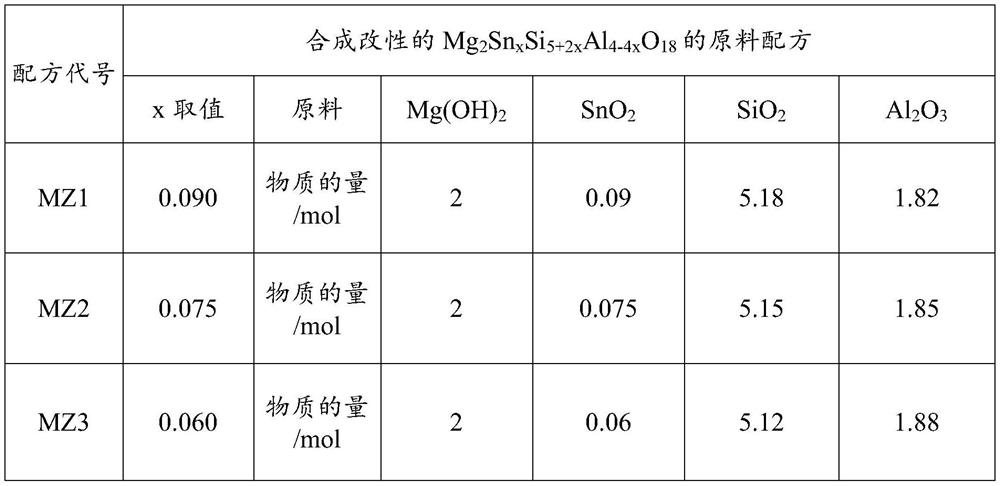

[0047] Table 1 Main material Mg 2 Sn x Si 5+2x Al 4-4x O 18 Example formula

[0048]

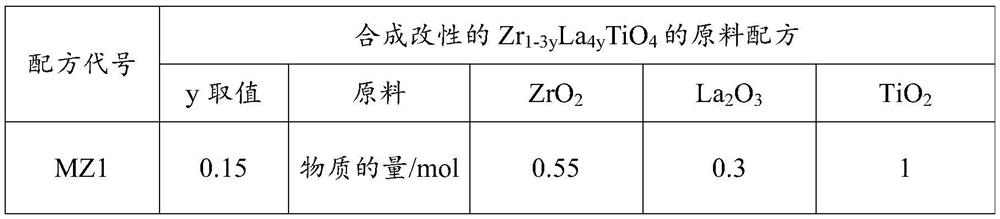

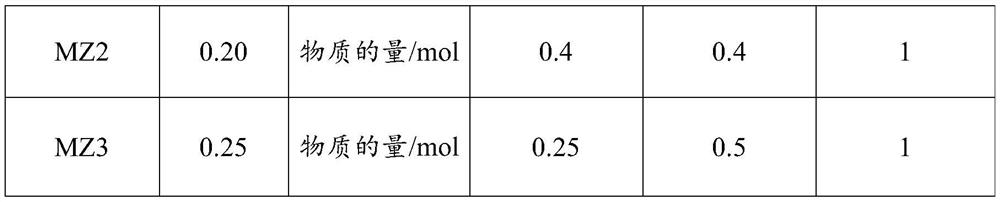

[0049] (2) According to the auxiliary material Zr 1-3y La 4y TiO 4 The composition of 0.1<y<0.3: zirconium dioxide, lanthanum oxide and titanium dioxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com