Microwave dielectric ceramics with medium dielectric constant and ultra-low dielectric loss, preparation method and application thereof

A technology of microwave dielectric ceramics and ultra-low dielectric, applied in ceramics, inorganic insulators, etc., can solve the problems of large dielectric constant, blank microwave dielectric ceramic system, lack of ultra-low dielectric loss material system, etc., and achieve dielectric The effect of constant enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

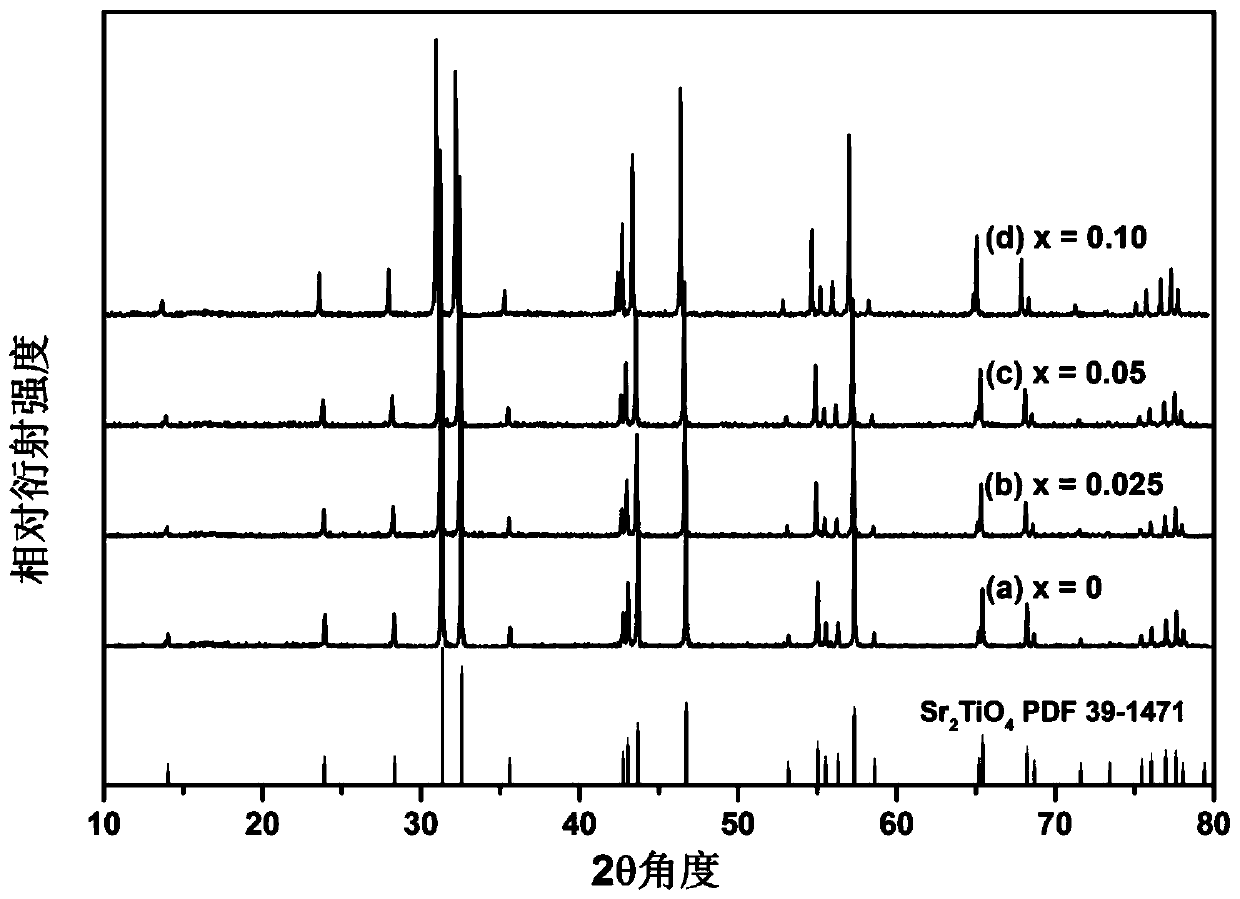

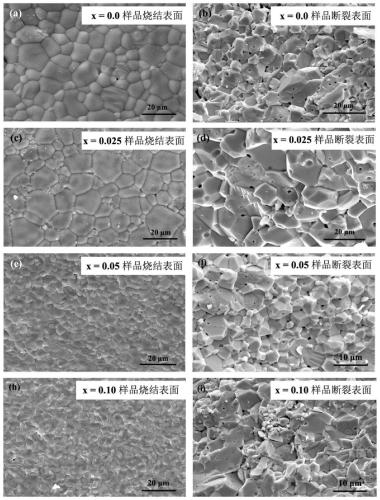

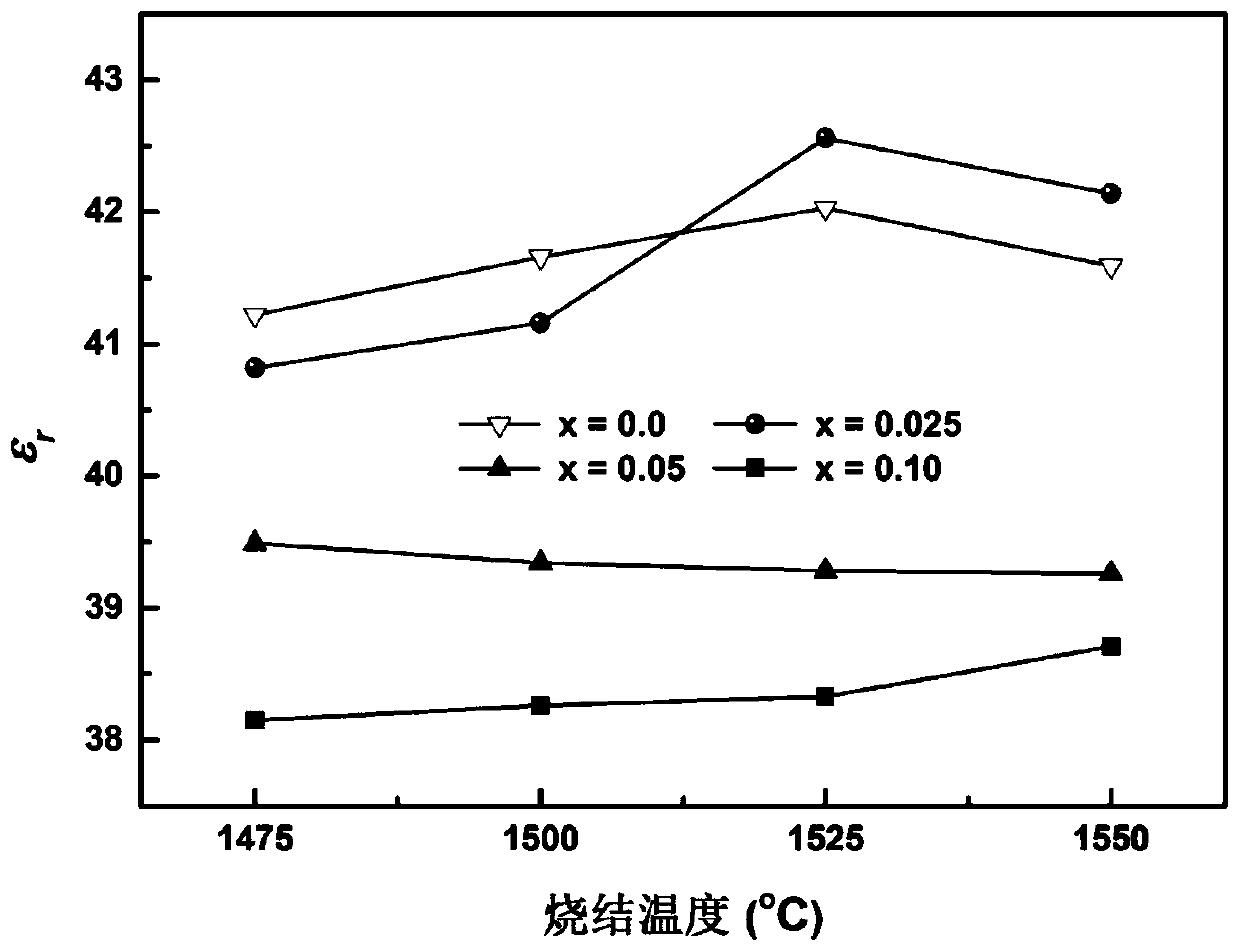

[0027] (1) SrCO 3 、TiO 2 and ZrO 2 Raw material powder (purity 99.99%) according to Sr 2 (Ti 0.975 Zr 0.025 )O 4 Stoichiometric weighing of ingredients;

[0028] (2) Put the chemical raw materials prepared in step (1) into a ball mill tank, add zirconia balls and absolute ethanol ball mill for 24 hours, and pass the 120-mesh sieve after the ball milled powder is dried in a drying oven;

[0029] (3) The powder prepared in step (2) is calcined at 1225° C. for 3 hours, then ball-milled twice, dried and passed through a 120-mesh sieve;

[0030](4) Add 4wt% PVA solution to the powder obtained in step (3) and grind it evenly, pass through a 40 mesh sieve; subsequently, put the gained powder into a stainless steel mold with a diameter of 12mm, and keep the pressure under 98MPa pressure After 5 minutes, a ceramic green body with a thickness of 5 mm was obtained. The obtained ceramic green body was sintered at 1475° C.-1550° C. for 3 hours to finally obtain a ceramic sample. T...

Embodiment 2

[0032] (1) SrCO 3 、TiO 2 and ZrO 2 Raw material powder (purity 99.99%) according to Sr 2 (Ti 0.95 Zr 0.05 )O 4 Stoichiometric weighing of ingredients;

[0033] (2) Put the chemical raw materials prepared in step (1) into a ball mill tank, add zirconia balls and absolute ethanol ball mill for 24 hours, and pass the 120-mesh sieve after the ball milled powder is dried in a drying oven;

[0034] (3) The powder obtained in step (2) is calcined at 1250° C. for 3 hours, then ball-milled twice, and passed through a 120-mesh sieve after drying;

[0035] (4) Add 4wt% PVA solution to the powder obtained in step (3) and grind it evenly, pass through a 40 mesh sieve; subsequently, put the gained powder into a stainless steel mold with a diameter of 12mm, and keep the pressure under 98MPa pressure After 5 minutes, a ceramic green body with a thickness of 5 mm was obtained. The obtained ceramic green body was sintered at 1475° C.-1550° C. for 3 hours to finally obtain a ceramic samp...

Embodiment 3

[0037] (1) SrCO 3 、TiO 2 and ZrO 2 Raw material powder (purity 99.99%) according to Sr 2 (Ti 0.9 Zr 0.1 )O 4 Stoichiometric weighing of ingredients;

[0038] (2) Put the chemical raw materials prepared in step (1) into a ball mill tank, add zirconia balls and absolute ethanol ball mill for 24 hours, and pass the 120-mesh sieve after the ball milled powder is dried in a drying oven;

[0039] (3) The powder obtained in step (2) is calcined at 1250° C. for 3 hours, then ball-milled twice, and passed through a 120-mesh sieve after drying;

[0040] (4) Add 4wt% PVA solution to the powder obtained in step (3) and grind it evenly, pass through a 40 mesh sieve; subsequently, put the gained powder into a stainless steel mold with a diameter of 12mm, and keep the pressure under 98MPa pressure After 5 minutes, a ceramic green body with a thickness of 5 mm was obtained. The obtained ceramic green body was sintered at 1475° C.-1550° C. for 3 hours to finally obtain a ceramic sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com