Microwave ceramic dielectric material and preparation method thereof

A technology of dielectric materials and microwave ceramics, which is applied in the field of dielectric ceramics, can solve problems such as limited applications, and achieve the effects of uniform particles, cost savings, and uniform growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

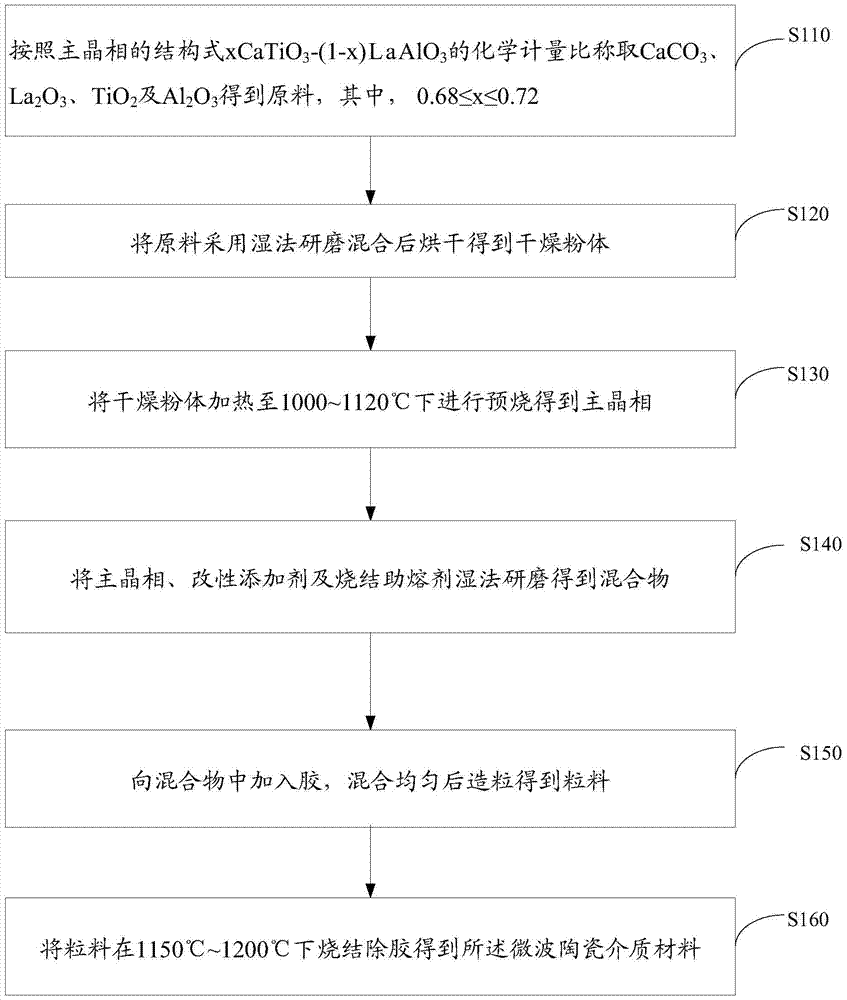

[0029] see figure 1 , the preparation method of the microwave ceramic dielectric material of an embodiment, comprises the following steps:

[0030] S110, according to the structural formula xCaTiO of the main crystal phase 3 -(1-x)LaAlO 3 The stoichiometric ratio of CaCO 3 , La 2 o 3 、TiO 2 and Al 2 o 3 The starting material is obtained, wherein, 0.68≤x≤0.72.

[0031] S120. The raw materials are wet ground and mixed, and then dried to obtain a dry powder.

[0032] Preferably, deionized water is added to the raw material, and the mass ratio of deionized water to raw material is 1:1-1:1.5, ground for 5-15 hours, and dried to obtain a dry powder. Further, grind until the particle size is 0.5-1.0 μm.

[0033] In this embodiment, zirconia balls are used as grinding media for grinding. Zirconia balls have a smooth working spherical surface, and are especially suitable for vertical stirring mills, horizontal stirring mills, vibration mills and various high-speed pin-type s...

Embodiment 1~ Embodiment 10

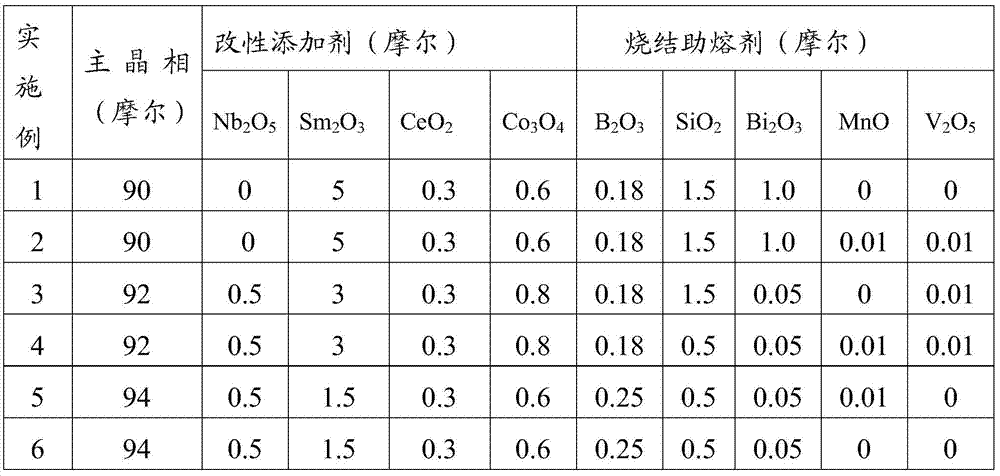

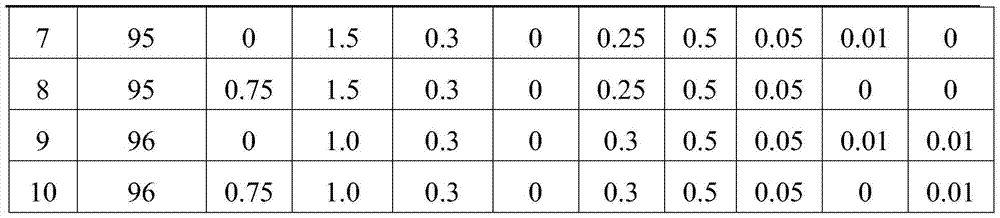

[0059] The composition of the main crystal phase of the microwave dielectric ceramics of Examples 1-10 is 0.68CaTiO 3 -0.32LaAlO 3 , the content of the main crystal phase, the composition and content of the modifying additive, and the composition and content of the sintering flux are shown in Table 1.

[0060] Table 1

[0061]

[0062]

[0063] The microwave dielectric ceramics of Examples 1 to 10 are made into test samples, with an Agilent network analyzer, the plate method is used to test the dielectric constant of the microwave dielectric ceramic materials whose material numbers are 1 to 10, and the Qf value and τ are tested by the closed cavity method f , and the results are shown in Table 2.

[0064] Table 2

[0065] invention material

Embodiment 11

[0067] 0.68mol of CaCO 3 , 0.16mol of La 2 o 3 , 0.68mol of TiO 2 and 0.16mol of Al 2 o 3 After mixing, add 200 mL of deionized water, use zirconium balls as the grinding medium, grind for 5 hours, and dry at 200°C to obtain a dry powder. The dry powder is raised from room temperature to 1000°C for 3 hours in a microwave sintering kiln, kept at 1230°C for 3 hours, and then lowered to room temperature to obtain the main crystal phase, whose structural formula is CaTiO 3 -(1-x)LaAlO 3 , where x=0.68.

[0068] In terms of mole percentage, 90% of the main crystal phase, 1.0% of Nb 2 o 5 , 3.7% Sm 2 o 3 , 0.3% CeO 2 , 0% Co 3 o 4 , 2.0% B 2 o 3 , 1.0% SiO 2 , 1.0% Bi 2 o 3 , 0.5% MnO and 0.5% V 2 o 5 After mixing, add 300mL deionized water, use zirconium balls as the grinding medium, grind for 5 hours to obtain the mixture, add 15g of PVA to the mixture, and spray granulate to obtain pellets; the pellets are pressed under a pressure of 10MPa to a size of 15mm× ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com