A low-temperature sintered composite microwave dielectric ceramic material and its preparation method

A microwave dielectric ceramic and low-temperature sintering technology, applied in ceramics, inorganic insulators, etc., can solve the problems of high viscosity, instability and limitation of slurry, and achieve the effect of high Qf value, lower sintering temperature, and stable temperature coefficient of resonant frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

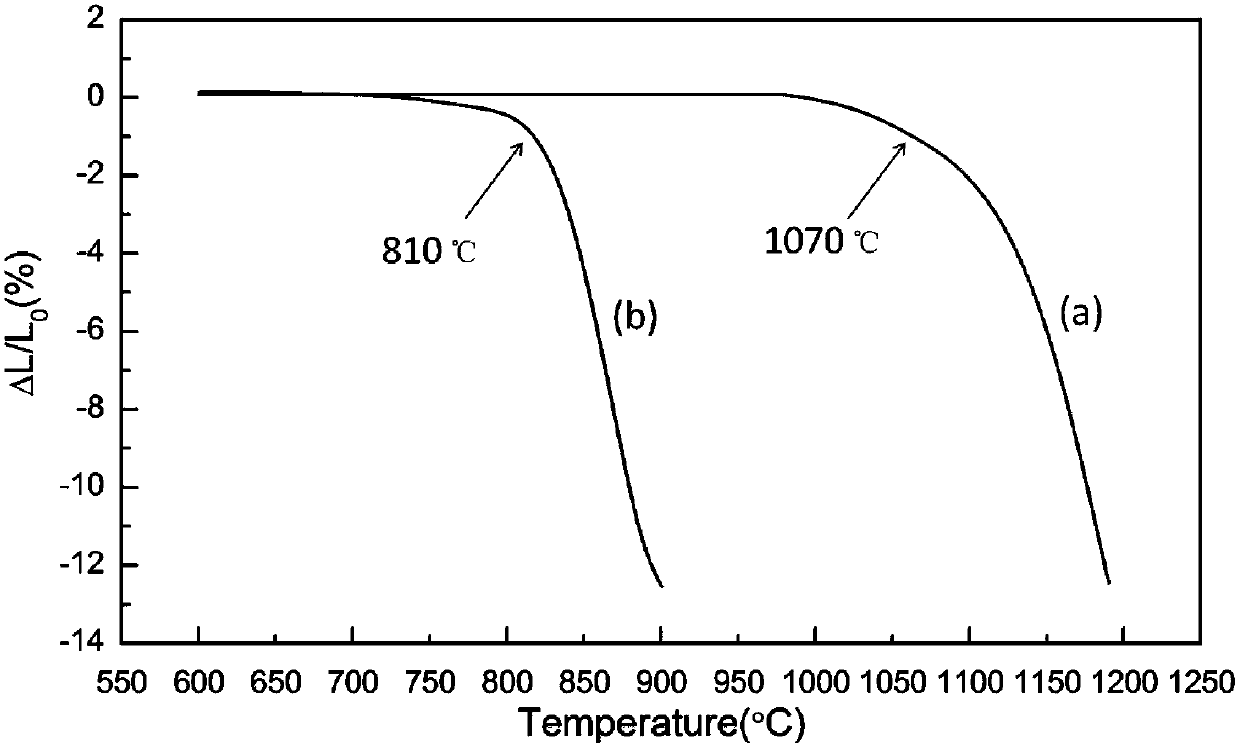

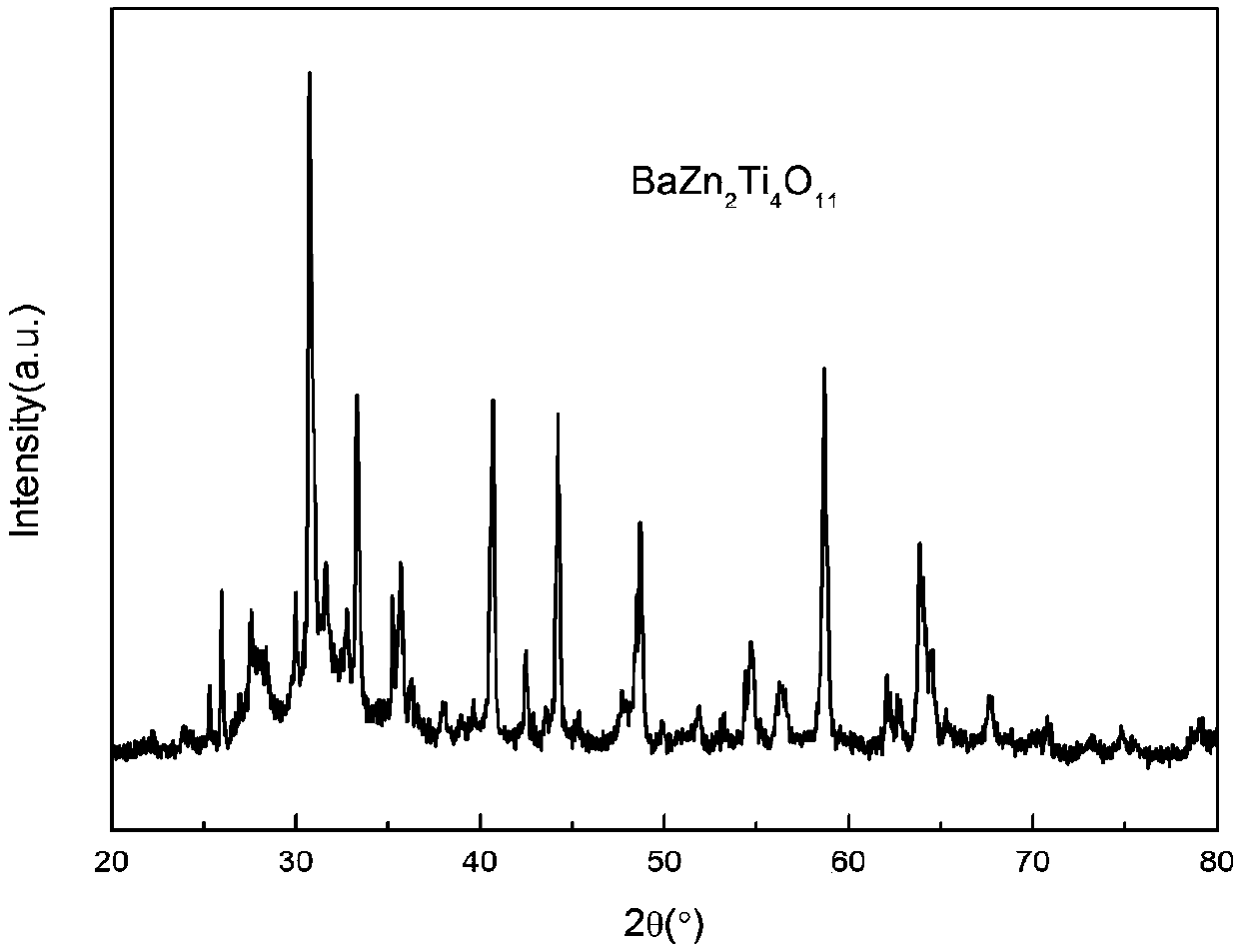

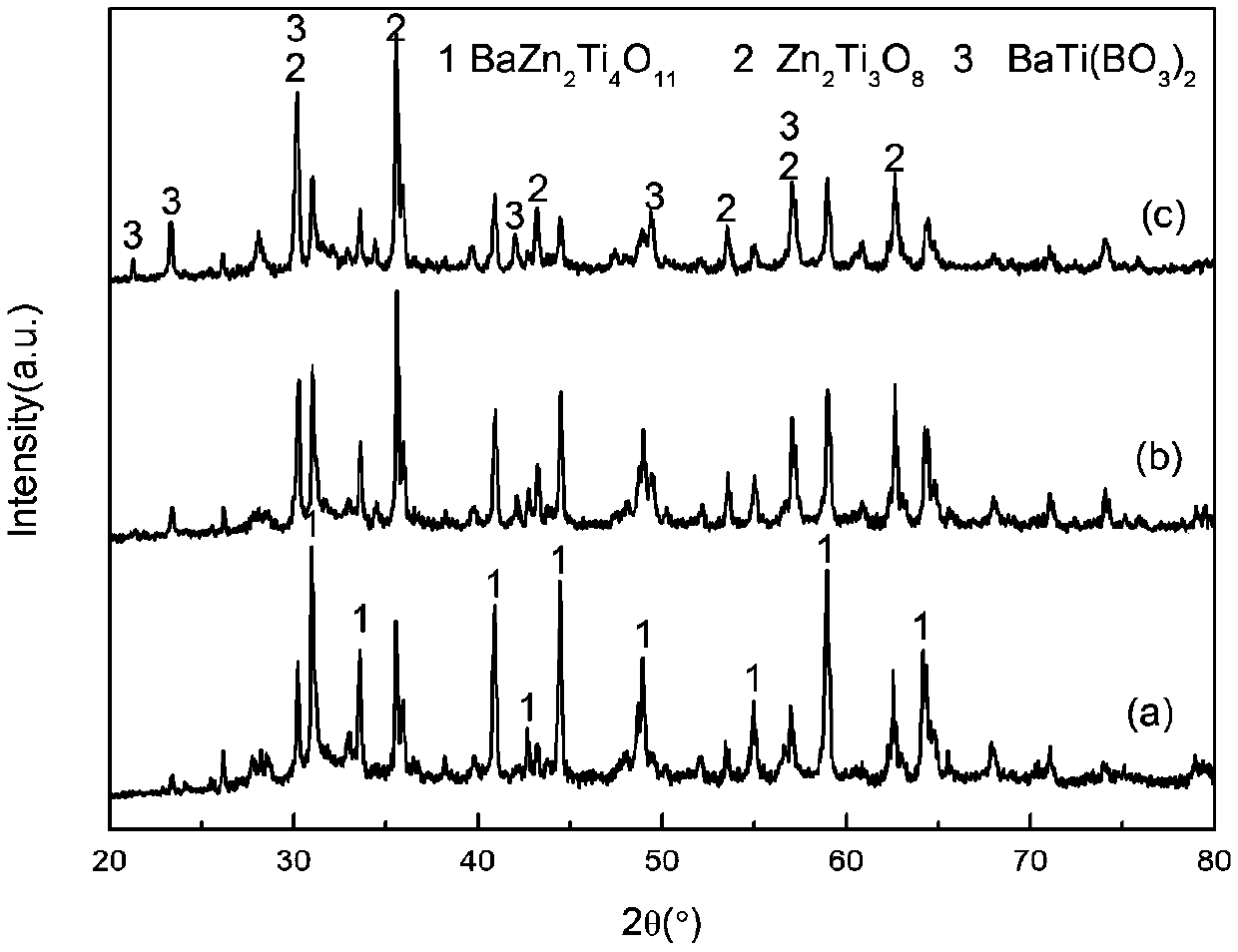

[0022] The material of the present invention is composed of BaO-ZnO-TiO with a mass percentage of 91% to 99%. 2 and a fever reducer with a mass percentage of 1% to 9%, BaO-ZnO-TiO 2 The composition of the material is BaZn 2 Ti 4 o 11 -xTiO 2 (x=1wt%-10wt%). The composition and weight percentage of the fever reducer are 46%≤Li 2 CO 3 ≤56.92%, 5.49%≤SiO 2 ≤9.76%, 30.59%≤B 2 o 3 ≤40.24%, 0%2 o 3 ≤20%, 0.24%≤MnCO 3 ≤1.84% and 0.99%≤BaCO 3 ≤7.34%, where MnCO 3 and BaCO 3 The weight ratio of the two is 1:4. The material can be synthesized by a solid phase method, and the specific steps are the same as the above steps.

[0023] The composition and microwave dielectric properties of embodiment are as follows

[0024]

[0025]

[0026]

[0027]

[0028] It can be seen from the above table that the addition of the heat reducer enables the system to be sintered densely at low temperature and obtain a medium dielectric constant of 24-26 and excellent microwave d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com