A kind of low temperature sintered low dielectric glass ceramic material and preparation method thereof

A glass-ceramic and low-temperature sintering technology, which is applied in the field of low-temperature sintering glass-ceramic materials with low dielectric constant and low loss and its preparation field, can solve the problems of high slurry viscosity, high sintering temperature and high cost, and achieves improved transmission. Effects of speed and wiring density, stable temperature coefficient of resonance frequency, and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] As mentioned above, the preparation method of low-temperature sintering low dielectric glass-ceramic composite substrate material includes the following steps:

[0030] a. According to the composition ratio requirements of the KBS glass, K 2 CO 3 , SiO 2 and H 3 BO 3 powder mixing;

[0031] b. Mix the above-mentioned mixed powder with deionized water as a solvent, wet ball milling, and then dry;

[0032] c. Melting the dried powder above at a high temperature in an air atmosphere at 1500°C to form a KBS glass frit;

[0033] d. The above-mentioned KBS glass frit was wet ball milled with deionized water as a solvent, and then dried at 100°C to obtain KBS glass powder;

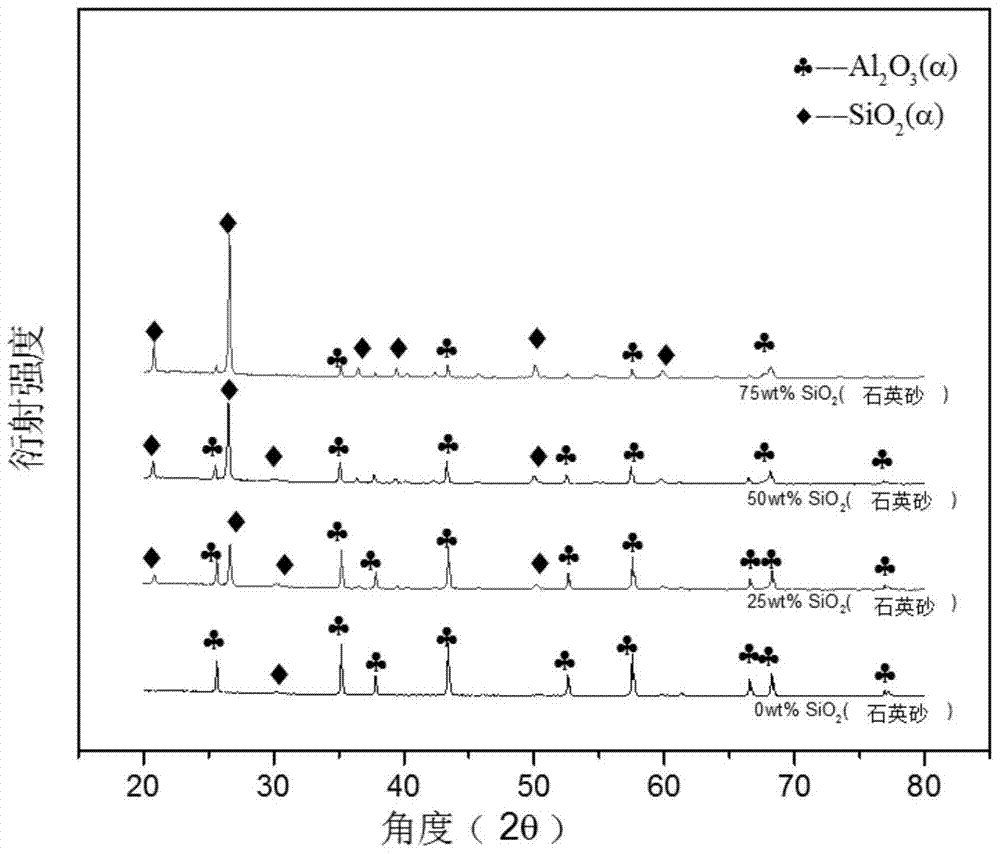

[0034] e, KBS glass powder and Al which account for 50-183% by weight respectively 2 o 3 and 8.3-133% quartz sand, mixed with deionized water solvent, wet ball milling, and dried acrylic acid solution with an additive amount of 2-5% of the total mass of raw materials as a binder for granulation;

...

Embodiment 1

[0042] a. K 2 CO 3 , SiO 2 and H 3 BO 3 The powders are mixed, and their masses are 0.35g, 28g and 19.15g respectively;

[0043] b. Use deionized water as the solvent for the powder prepared in step a, wet ball mill and mix for 6 hours, dry and melt at 1500°C in the atmosphere for 1 hour at high temperature to form a KBS glass frit;

[0044] c. The KBS glass frit was wet-milled for 6 hours with deionized water as a solvent, and then dried at 100°C to obtain KBS glass powder;

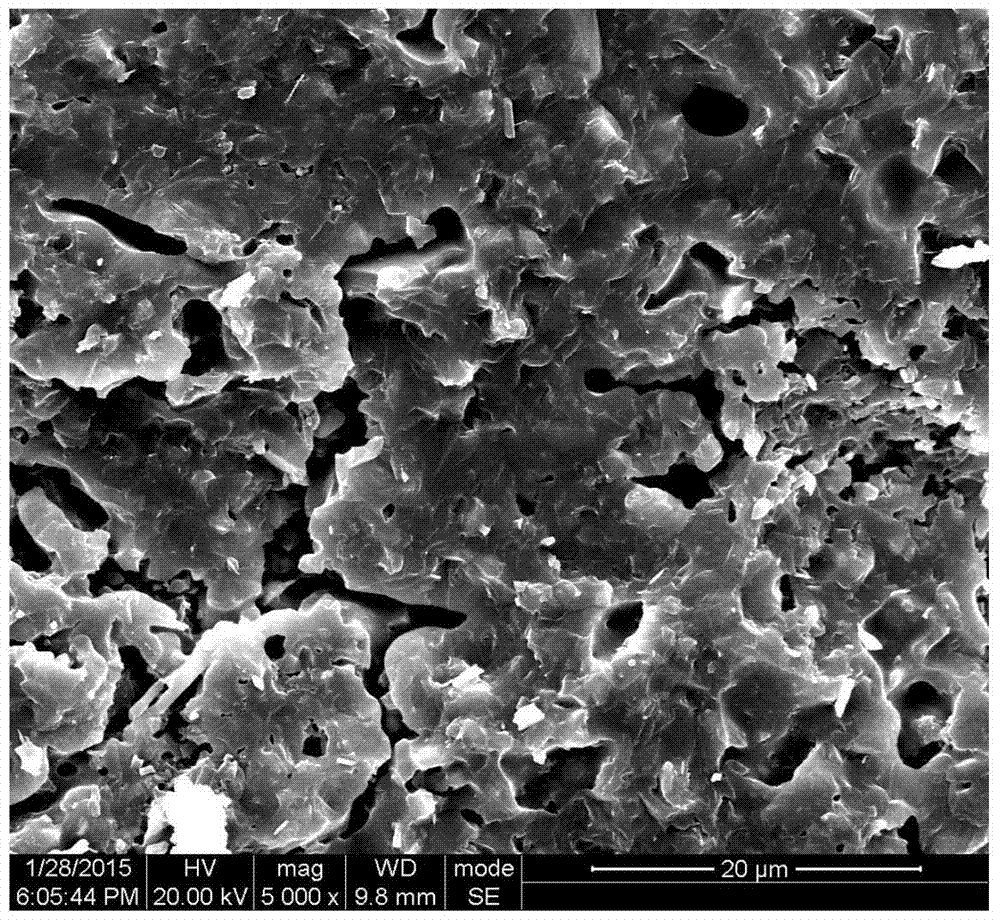

[0045] d, the above KBS glass powder and 52.5g Al 2 o 3 Mixing, using deionized water solvent, mixing by wet ball milling for 8 hours, drying and granulating with an acrylic acid solution whose additive amount accounts for 2-5% of the total mass of raw materials as a binder;

[0046] e, the granules obtained by the above-mentioned granulation are dry-pressed and formed, and the forming pressure is 20Mpa;

[0047] f. Sintering the dry-pressed material in step e for 1 hour in an air atmosphere at 8...

Embodiment 2

[0055] a. K 2 CO 3 , SiO 2 and H 3 BO 3 The powders are mixed, and their masses are 0.35g, 28g and 19.15g respectively;

[0056] b. Use deionized water as the solvent for the powder prepared in step a, wet ball mill and mix for 6 hours, dry and melt at 1500°C in the atmosphere for 1 hour at high temperature to form a KBS glass frit;

[0057] c. The KBS glass frit was wet-milled for 6 hours with deionized water as a solvent, and then dried at 100°C to obtain KBS glass powder;

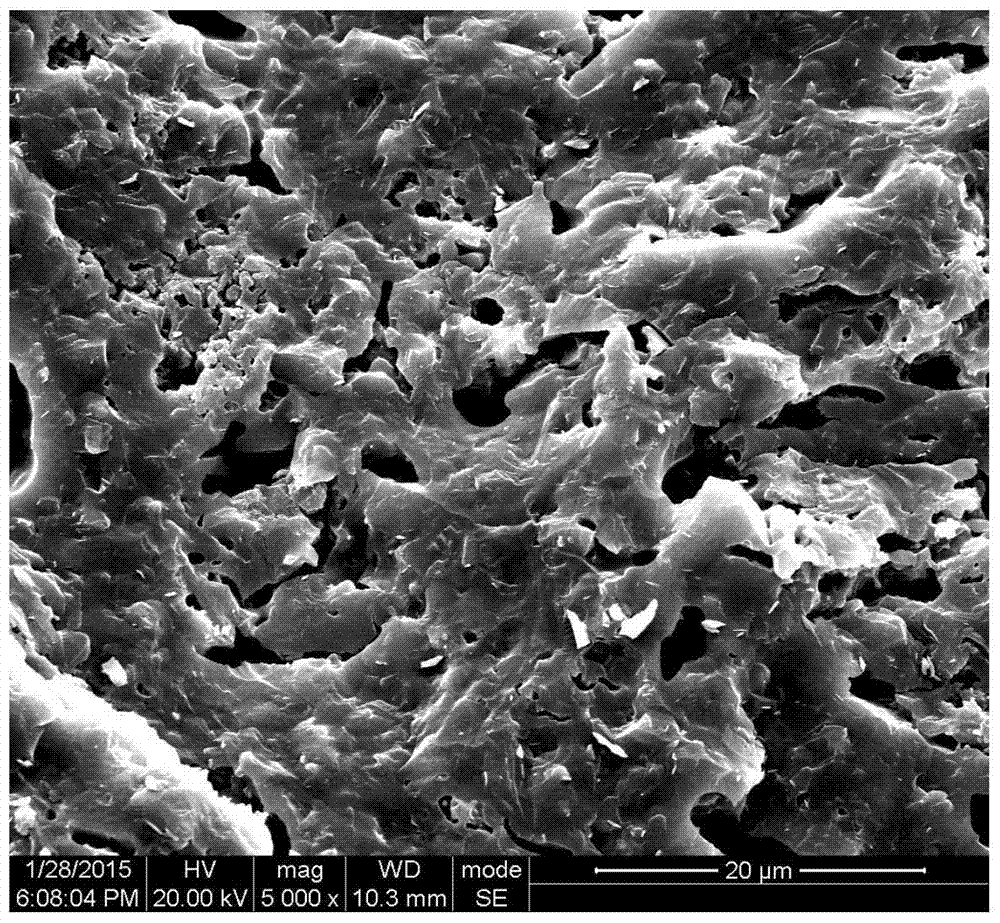

[0058] d, the above KBS glass powder and 26.25g Al 2 o 3 and 26.25g of quartz sand, mixed with deionized water solvent and wet ball mill for 8 hours, and after drying, the acrylic acid solution whose additive amount accounts for 2 to 5% of the total mass of raw materials is used as a binder for granulation;

[0059] e, the granules obtained by the above-mentioned granulation are dry-pressed and formed, and the forming pressure is 20Mpa;

[0060] f. Sintering the dry-pressed material in step e for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com