High electric strength lead-free energy storage medium ceramic material and preparation method thereof

A technology of energy storage medium and ceramic material, which is applied in the field of medium ceramic material with high electrical strength and high energy storage efficiency and its preparation, can solve problems such as limited application, and achieve energy cost saving, wide application prospect and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

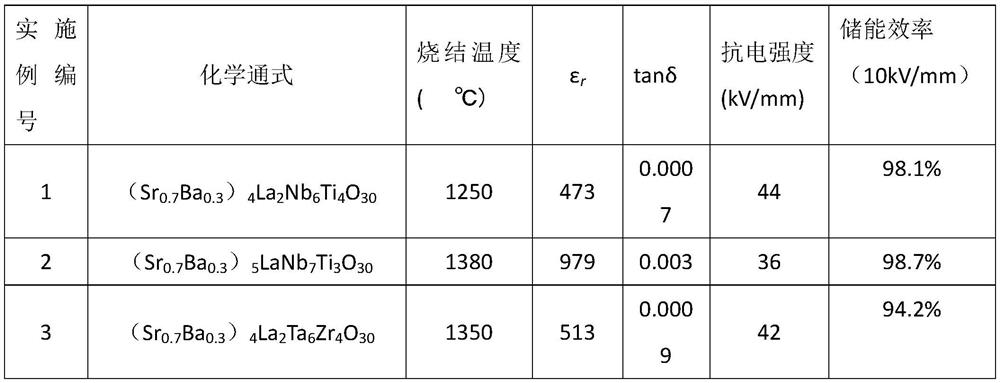

Examples

preparation example Construction

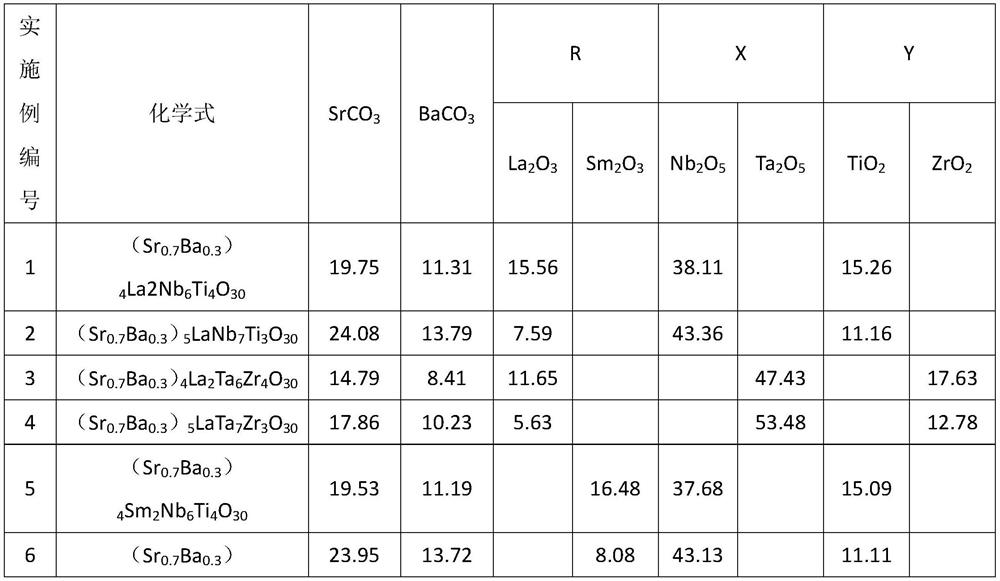

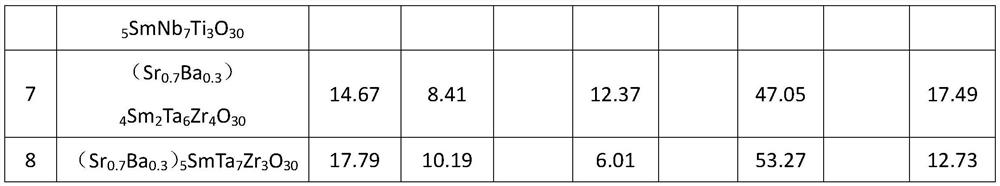

[0032] Its preparation method comprises the following steps:

[0033] Step 1: SrCO 3 , BaCO 3 , rare earth oxides of Nb or Ta, oxides of titanium or zirconium, trivalent rare earth oxides, according to (Sr 0.7 Ba 0.3 ) a R 6-a x 2+a Y 8-a o 30 , where X is Nb 5+ or Ta 5+ , Y is Ti 4+ or Zr 4+ , R is a trivalent rare earth, and the molar ratio of a=4 or 5 is used for preparing materials, and the resulting mixture is milled with zirconia balls, and absolute ethanol is used as a solvent, according to the weight ratio of mixture: grinding balls: ethanol Grinding for 1:(5-7):(2-4) for 5-8 hours, finally obtaining a homogeneous mixture;

[0034] Step 2: Dry the ball-milled mixture at 120°C and pass through a 60-mesh sieve to obtain a dry powder, then pre-fire and keep it warm at 1050-1250°C for 3-5 hours to obtain a sample briquette;

[0035] Step 3: Pulverize the sample burnt block, use zirconia balls as the ball milling medium, and use absolute ethanol as the solvent,...

Embodiment 1

[0042] Step 1: according to the embodiment 1 batching of table 1, SrCO 3 、BaCO 3 , La 2 o 3 , Nb 2 o 5 and TiO 2 , 19.75%, 11.31%, 15.56%, 38.11% and 15.26% mass ratios are prepared respectively, the mixture obtained is a ball milling medium with zirconia balls, and absolute ethanol is a solvent, according to the mixture: grinding balls: The weight ratio of ethanol was 1:5:2 to grind for 6 hours, and finally a homogeneous mixture was obtained;

[0043] Step 2: The mixture after ball milling was dried at 120°C and passed through a 60-mesh sieve to obtain a dry powder, and then pre-fired at 1050°C for 3 hours to obtain a sample briquette;

[0044] Step 3: Pulverize the sample burnt block, use zirconia balls as the ball milling medium, use absolute ethanol as the solvent, grind for 2 hours according to the weight ratio of mixture: balls: ethanol is 1:5:2, dry and make Granulation treatment, the granulation size is controlled at 120 mesh, and the granules are put into the f...

Embodiment 2

[0047] Step 1: according to the embodiment 2 batching of table 1, SrCO 3 、BaCO 3 , La 2 o 3 , Nb 2 o 5 and TiO 2 According to the mass ratio of 24.08%, 13.79%, 7.59%, 43.36% and 11.16% respectively, the mass ratio of the stock is prepared, and the obtained mixture is used as the ball milling medium with zirconia balls, and with absolute ethanol as the solvent, according to the mixing method Material: Grinding ball: The weight ratio of ethanol is 1:6:3 and grinds for 7 hours, finally obtains the mixture that mixes evenly;

[0048] Step 2: The mixture after ball milling was dried at 120°C and passed through a 60-mesh sieve to obtain a dry powder, and then pre-fired at 1100°C for 4 hours to obtain a sample briquette;

[0049] Step 3: Pulverize the sample burnt block, use zirconia balls as the ball milling medium, use absolute ethanol as the solvent, grind for 3 hours according to the weight ratio of mixture: balls: ethanol is 1:6:3, dry and make Granulation treatment, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com