Zinc barium titanate system ceramic low temperature sintering material and preparation method thereof

A zinc-barium titanate, low-temperature sintering technology, applied in the field of electronic ceramics and its manufacturing, can solve the problems of increasing material dielectric loss, unstable glass performance, high slurry viscosity, etc., and achieves lower sintering temperature, high application value, raw materials low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

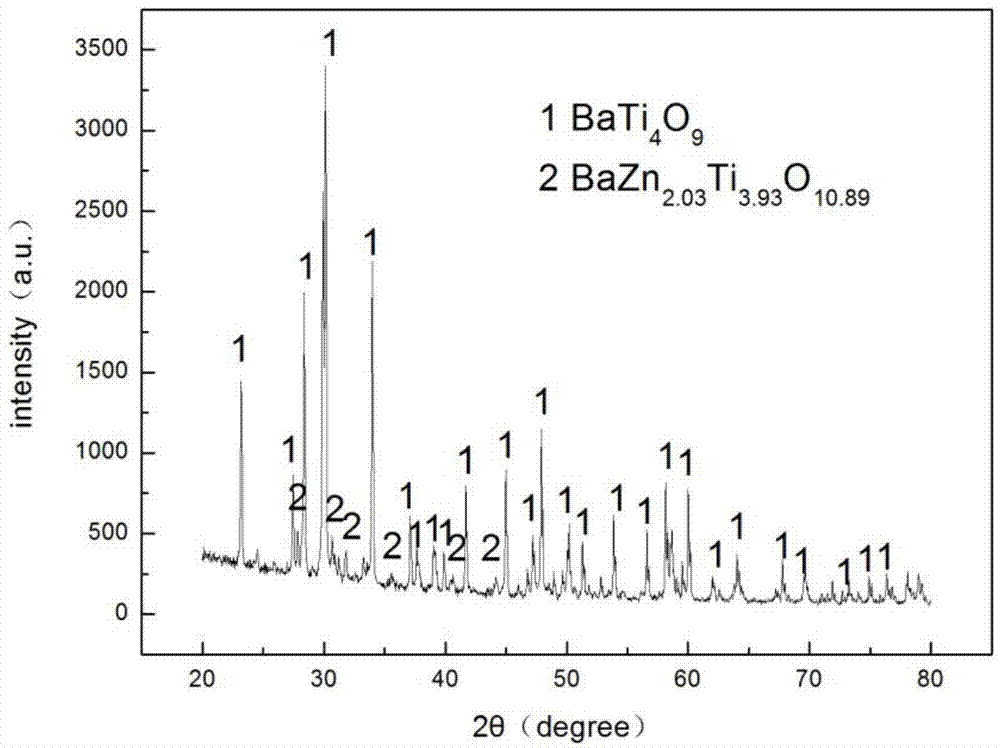

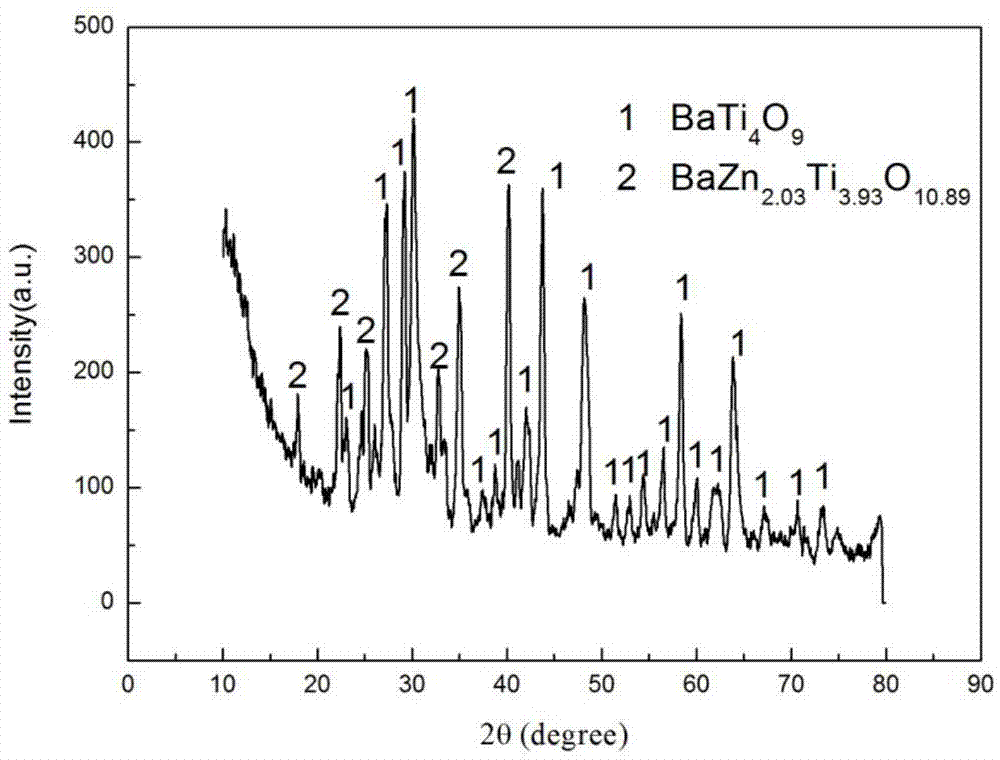

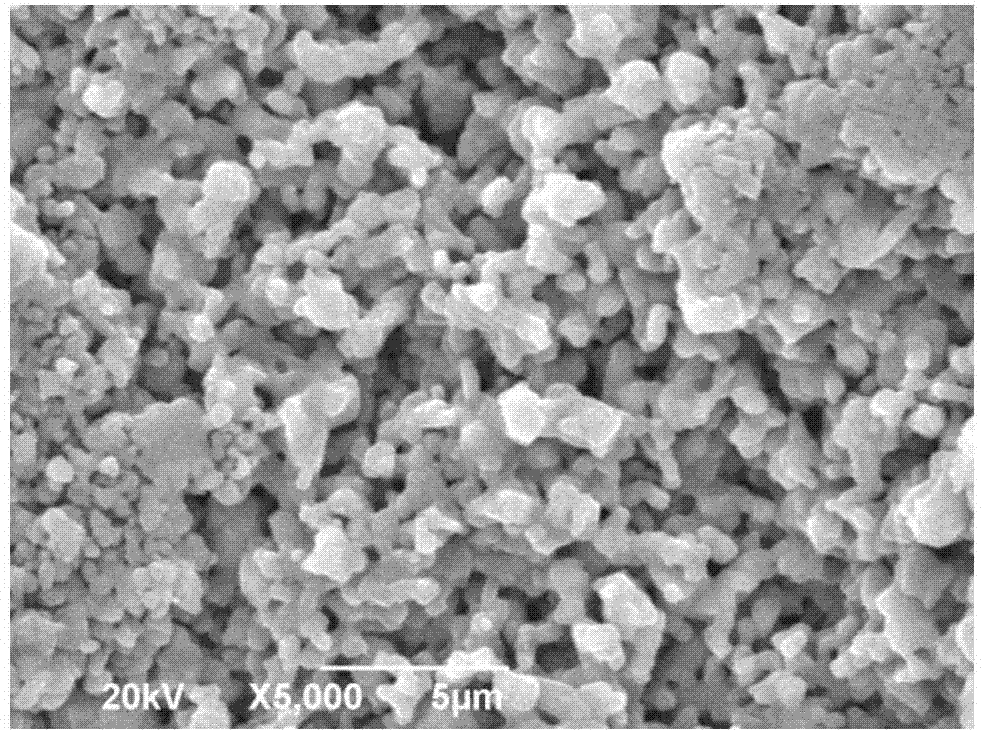

[0037] The material of the present invention is composed of BaO-ZnO-TiO with a mass percentage of 89.95% to 94.69%. 2 and a fever reducer with a mass percentage of 5.31% to 10.05%, BaO-ZnO-TiO 2 The composition of the material system is (1-x)BaTi 4 o 9 -xBaZn 2 Ti 4 o 11 (0.15≤x≤0.25), the raw material of the fever reducer contains: Li 2 CO 3 , SiO 2 , B 2 o 3 , ZnO, Al 2 o 3 , MnCO 3 , CuO. Table 1 shows the data of several specific examples of the composition content of the present invention, and Table 2 shows the microwave dielectric properties of each example. Its preparation method is:

[0038] Step 1: Barium oxide (BaO), zinc oxide (ZnO), titanium dioxide (TiO 2 ) of the original powder by 0.85BaTi 4 o 9 -0.15BaZn 2 Ti 4 o 11 composition ingredients;

[0039] Step 2: Mix the ingredients prepared in step 1 with deionized water as a solvent, and mix them with a planetary ball mill for 3 to 5 hours, take them out and dry them at 80-120°C, sieve them thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com