Patents

Literature

148results about How to "Resonant frequency temperature coefficient is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature sintered microwave dielectric ceramic and sintering method thereof

The invention discloses low-temperature sintered microwave dielectric ceramic and a sintering method thereof. The low-temperature sintered microwave dielectric ceramic comprises Li2MTi3O8 and N, wherein an M element is Zn, Ni, Co or Mg, and N is B2O3, V2O5, CuO or Bi2O3. The performance of a product prepared by adopting a microwave sintering method disclosed by the invention is superior to that of a traditional solid-phase sintered product, the high-frequency dielectric constant (epsilonr) of the product reaches 20 to 30, a Q*f value reaches up to 6000 to 59000GHz, and the temperature coefficient (tauf) of a resonance frequency is small. Moreover, the presintering time and the sintering time can be shortened, and the sintering temperature is decreased, so that the requirements of LTCC (Low Temperature Co-fired Ceramic) production can be met, the performance of the product is improved, energy sources are saved, the production cost is lowered, the low-temperature sintered microwave dielectric ceramic can be used for the manufacture of microwave devices, such as an LTCC system, a multilayer dielectric resonator, a microwave antenna, a filter and the like, the volatilization of low-melting-point substances is inhibited, the environment is protected, and the low-temperature sintered microwave dielectric ceramic has an important industrial application value.

Owner:GUANGXI NEW FUTURE INFORMATION IND

Microwave dielectric ceramic Li3VO4 capable of being sintered at low temperature and preparation method thereof

ActiveCN103145419APromote sinteringResonant frequency temperature coefficient is smallDielectricCompression molding

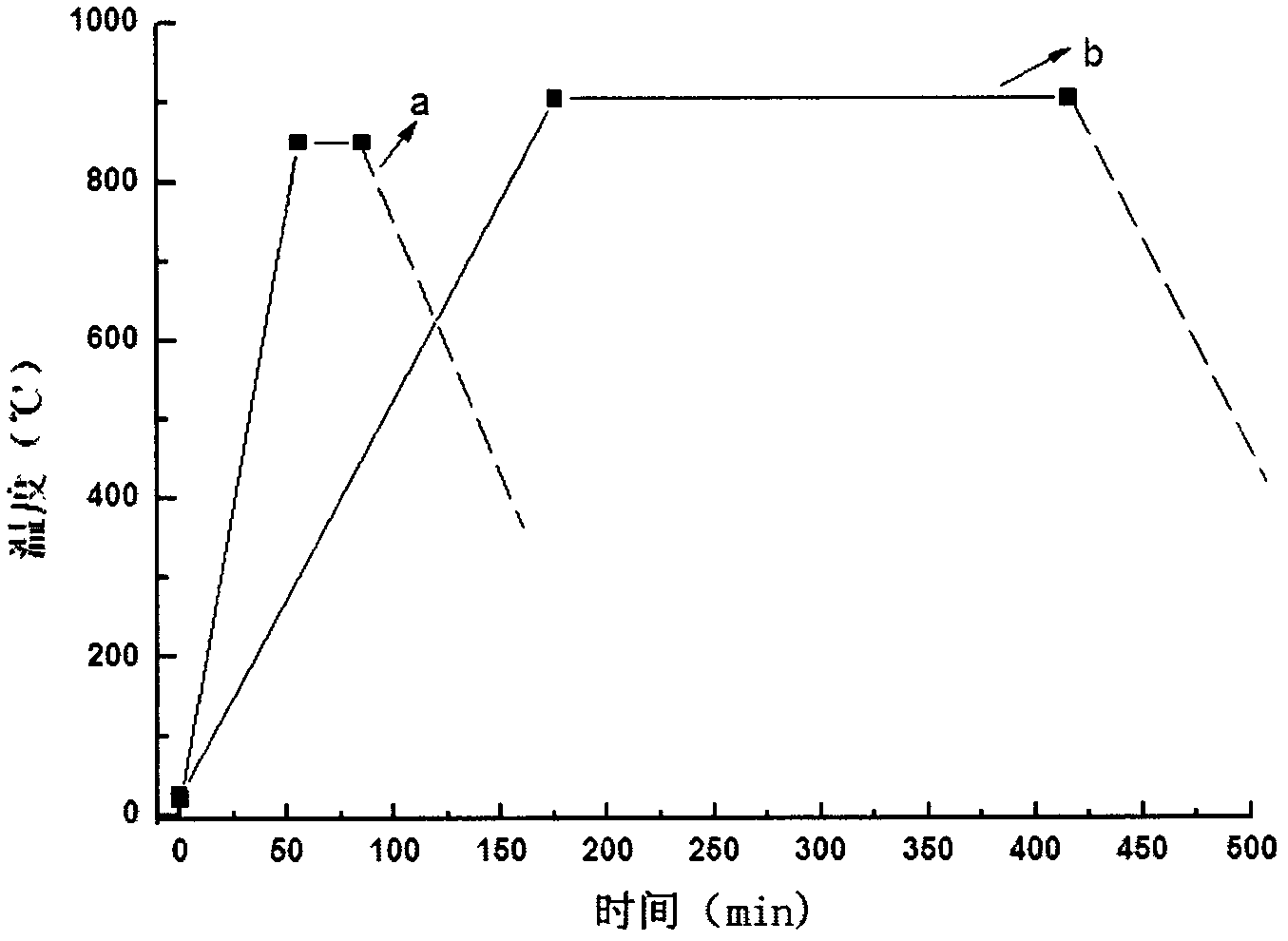

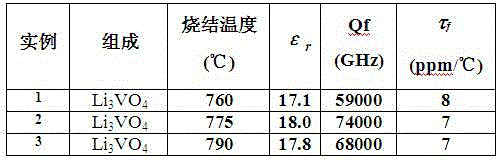

The invention discloses microwave dielectric ceramic Li3VO4 capable of being sintered at low temperature and a preparation method thereof. The dielectric ceramic material consists of Li3VO4. The preparation method comprises the following steps of: (1) weighing and dosing the raw powder of Li2CO3 and V2O5 with purity of over 99.9% according to the composition of Li3VO4; (2) performing wet-type ball milling mixing of the raw materials in step (1) for 12 hours, wherein the solvent is distilled water; and drying, and presintering for 6 hours in atmosphere at 700 DEG C; and (3) adding a binder into the powder prepared in step (2) and granulating, performing compression molding, and finally sintering for 4 hours in atmosphere at 760-790 DEG C, wherein the binder is a polyvinyl alcohol solution with mass concentration of 5%, and the dose accounts for 3% of the total amount of the powder. According to the invention, the prepared ceramic is sintered well at 760-790 DEG C, the dielectric constant reaches 17-18, the quality factor Qf is as high as 59,000-74,000GHz, the temperature coefficient of resonance frequency is small, and the ceramic has great value in industrial application.

Owner:苏州弘吴科技中介服务有限公司

Low-temperature sintering microwave dielectric ceramic Li2Ca2Si2O7 and preparation method thereof

InactiveCN103496959APromote sinteringResonant frequency temperature coefficient is smallDielectricAir atmosphere

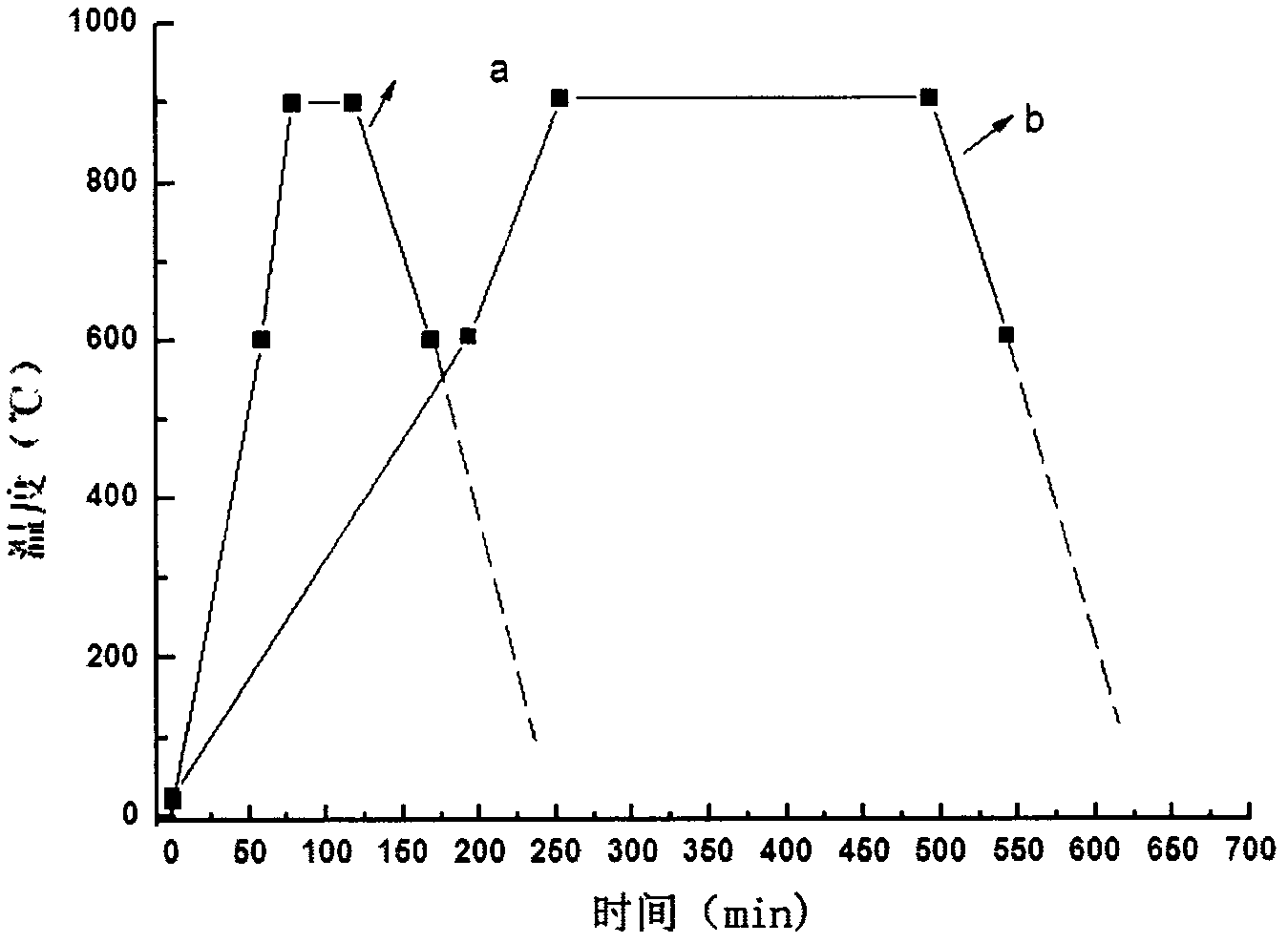

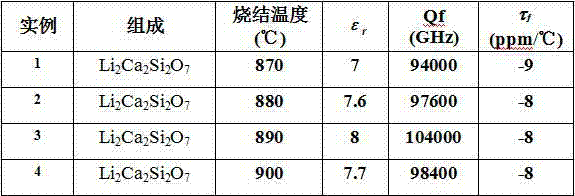

The invention discloses a low-temperature sintering microwave dielectric ceramic Li2Ca2Si2O7 and a preparation method thereof. The chemical composition formula of the low-temperature sintering microwave dielectric ceramic is Li2Ca2Si2O7. The preparation method comprises the steps of (1) weighing and batching original powder of Li2CO3, CaCO3 and SiO2 with the purity being over 99.9% according to the chemical formula Li2Ca2Si2O7; (2) carrying out mixing and wet ball-milling on raw materials obtained in the step (1) for 12 hours, taking distilled water as a solvent, drying, and then, pre-sintering in an air atmosphere for 6 hours at the temperature of 800 DEG C; (3) adding a binder into powder prepared in the step (2), granulating, then, carrying out compression molding, and finally, sintering in the air atmosphere for 4 hours at the temperature of 870-900 DEG C, wherein a polyvinyl alcohol solution with the mass concentration of 5% is adopted as the binder, and the dosage of the binder accounts for 3% of the total mass of the powder. According to the ceramic prepared by the preparation method, the sintering at the temperature of 870-900 DEG C is good, the dielectric constant reaches 7-8, the quality factor (Qf) reaches up to 94,000-104,000GHz, and the temperature coefficient of resonance frequency is small, so that the ceramic has a great application value in industries.

Owner:浦北高迈新能源科技有限公司

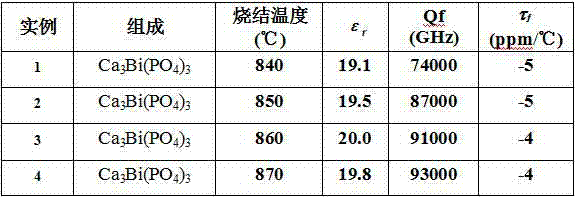

Low-temperature sintering microwave dielectric ceramic Ca3Bi(PO4)3 and preparation method thereof

InactiveCN103496964APromote sinteringResonant frequency temperature coefficient is smallDielectricAir atmosphere

The invention discloses a low-temperature sintering microwave dielectric ceramic Ca3Bi(PO4)3 and a preparation method thereof. The composition formula of the low-temperature sintering microwave dielectric ceramic is Ca3Bi(PO4)3. The preparation method comprises the steps of (1) weighing and batching original powder of CaCO3, Bi2O3 and P2O5 with the purity being over 99.9% according to the chemical formula Ca3Bi(PO4)3; (2) carrying out wet ball-milling and mixing on raw materials obtained in the step (1) for 12 hours, taking distilled water as a solvent, drying, and then, pre-sintering in an air atmosphere for 6 hours at the temperature of 750 DEG C; (3) adding a binder into powder prepared in the step (2), granulating, then, carrying out compression molding, and finally, sintering in the air atmosphere for 4 hours at the temperature of 840-870 DEG C, wherein a polyvinyl alcohol solution with the mass concentration of 5% is adopted as the binder, and the dosage of the binder accounts for 3% of the total mass of the powder. According to the ceramic prepared by the preparation method, the sintering at the temperature of 840-870 DEG C is good, the dielectric constant reaches 19-20, the quality factor (Qf) reaches up to 74,000-93,000GHz, and the temperature coefficient of resonance frequency is small, so that the ceramic has a great application value in industries.

Owner:浦北高迈新能源科技有限公司

Low dielectric constant microwave dielectric ceramic material

InactiveCN1765820ALow microwave dielectric lossResonant frequency temperature coefficient is smallCeramicsMicrowaveSolid solution

The invention provides a microwave medium ceramic material with low dielectric constant, low deterioration and good thermal stability. The material is a solid solution medium ceramic with a formula of uZnO-vSiO2-wTiO2, wherein 58.0 mol%<=u<=69.0 mol%, 28.0 mol%<=v<=35.0 mol%, 3.0 mol%<=w<=7 mol%, the principal crystalline phase is Zn2SiO4, the secondary crystalline is TiO2.

Owner:HUAZHONG UNIV OF SCI & TECH

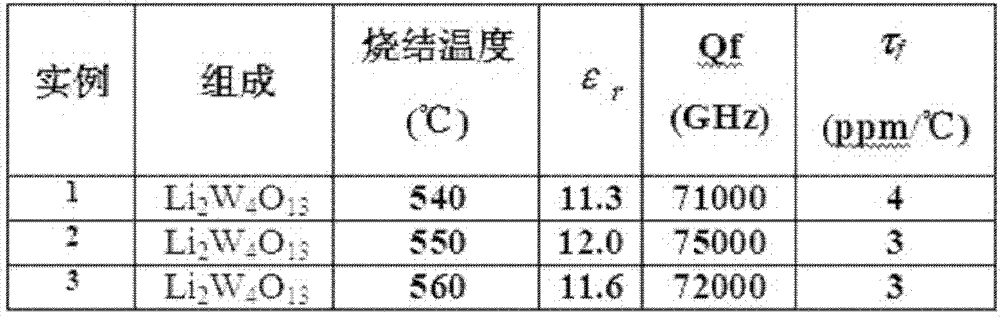

Low temperature sintered microwave dielectric ceramic Li2W4O13 and preparation method thereof

ActiveCN103113104APromote sinteringResonant frequency temperature coefficient is smallDielectricAdhesive

The invention discloses a low temperature sintered microwave dielectric ceramic Li2W4O13 and a preparation method thereof. The chemical formula of the dielectric ceramic material is Li2W4O13. The preparation method comprises the following steps of: (1) proportioning original powder of Li2CO3 and WO3 with purity over 99.9% according to the composition of Li2W4O13; (2) mixing the raw material in step (1) by a wet ball mill for 12 hours by taking distilled water as a solvent, and drying and pre-sintering for 6 hours in atmosphere at 500 DEG C; and (3) adding an adhesive to the prepared powder obtained in step (2) and prilling, then pressing and forming, and finally, sintering for 4 hours in atmosphere at 540-560 DEG C, wherein the adhesive is a polyvinyl alcohol liquor with mass concentration of 5%, and accounts for 3% of the total weight of the powder. Ceramic prepared by the invention is well sintered at 540-560 DEG C, and the dielectric constant reaches 11-12, and the quality factor Qf value reaches 71000-75000GHz. The ceramic is less in temperature coefficient of resonance frequency and has an extremely large application value in industry.

Owner:苏州弘吴科技中介服务有限公司

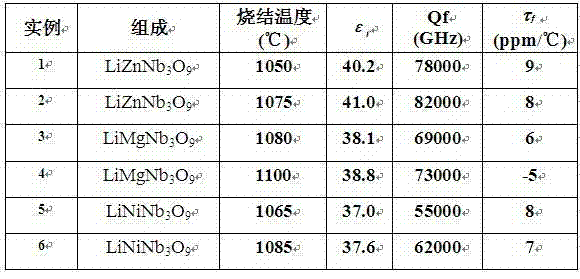

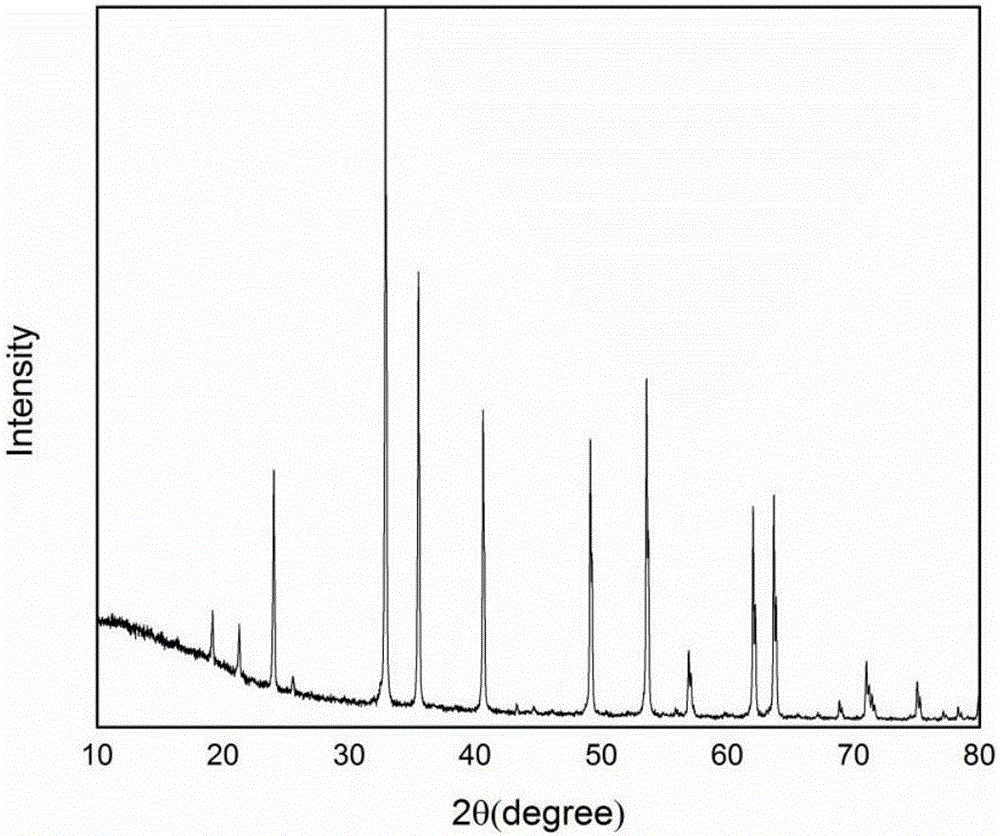

Niobate microwave dielectric ceramic LiMNb3O9 and preparation method thereof

ActiveCN103204680APromote sinteringResonant frequency temperature coefficient is smallCeramicsDielectricMicrowave

The invention discloses a niobate microwave dielectric ceramic LiMNb3O9 and a preparation method thereof. The niobate microwave dielectric ceramic material is constituted by LiMNb3O9, wherein M is one of Zn, Mg and Ni. The preparation method comprises the steps of: (1) weighing and mixing the raw powder of Li2CO3, MO and Nb2O5 with the purity over 99.9% according to the LiMNb3O9 chemical formula, wherein the M is one of Zn, Mg and Ni; (2) mixing the raw materials in the step (1) by wet-type ball milling for 12 hours with distilled water as the solvent, and an obtained mixture is dried and then pre-burned at 1000 DEG C for 6 hours; and (3) adding a binder into the powder prepared in the step (2) for pelleting, molding by pressing and finally sintering the molded product at 1050-1100 DEG C for 4 hours, wherein a polyvinyl alcohol solution with the mass concentration being 5% is employed as the binder and the the binder accounts for 3% of the total powder. The ceramic prepared according to the invention is well sintered at 1050-1100 DEG C, has a dielectric constant being 37-41, a quality factor Qf as high as 55000-82000GHz, a small temperature coefficient of resonance frequency and has great value in industry application.

Owner:苏州弘吴科技中介服务有限公司

Microwave dielectric ceramic material for multi-layer ceramic capacitor and preparing method of microwave dielectric ceramic material

The invention discloses a microwave dielectric ceramic material for a multi-layer ceramic capacitor and a preparing method of the microwave dielectric ceramic material, and belongs to the technical field of electronic ceramic. The ceramic material is prepared from calcium-doped (MgZn)TiO3 system ceramic and a composite burning improver through ball milling mixing, granulating, forming, glue discharging and sintering, wherein the main crystal phase of the calcium-doped (MgZn)TiO3 system ceramic is MgTiO3, and the composite burning improver is prepared from BaCO3, B2O3, SiO2 and one or more of Li2CO3, Nb2O5 and Nd2O3. The prepared ceramic material has the advantages that a medium dielectric constant is achieved, sintering can be carried out at the medium temperature, a high Qf value is achieved, and the frequency temperature coefficient is stable. The preparing process is environmentally friendly and free of pollution, and the ceramic material can be used at the microwave frequency band of 300 M-300 GHz, can be widely applied to filters, oscillators and other microwave devices, and is especially suitable for the multi-layer ceramic capacitor.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

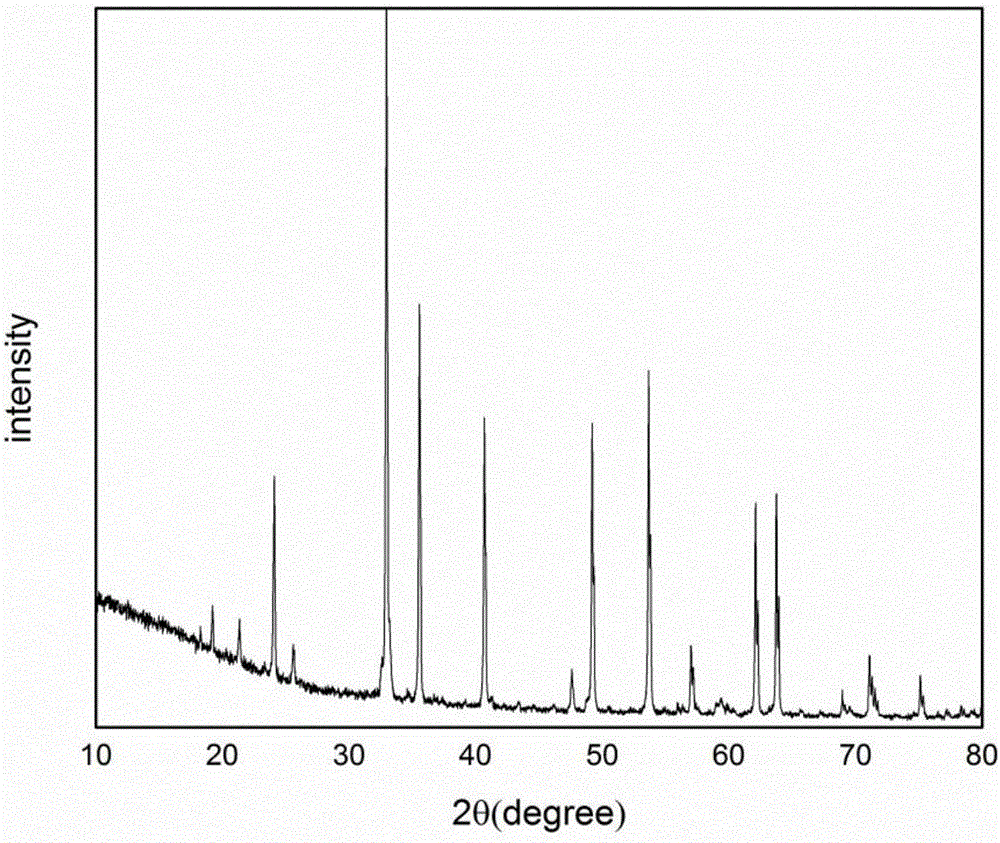

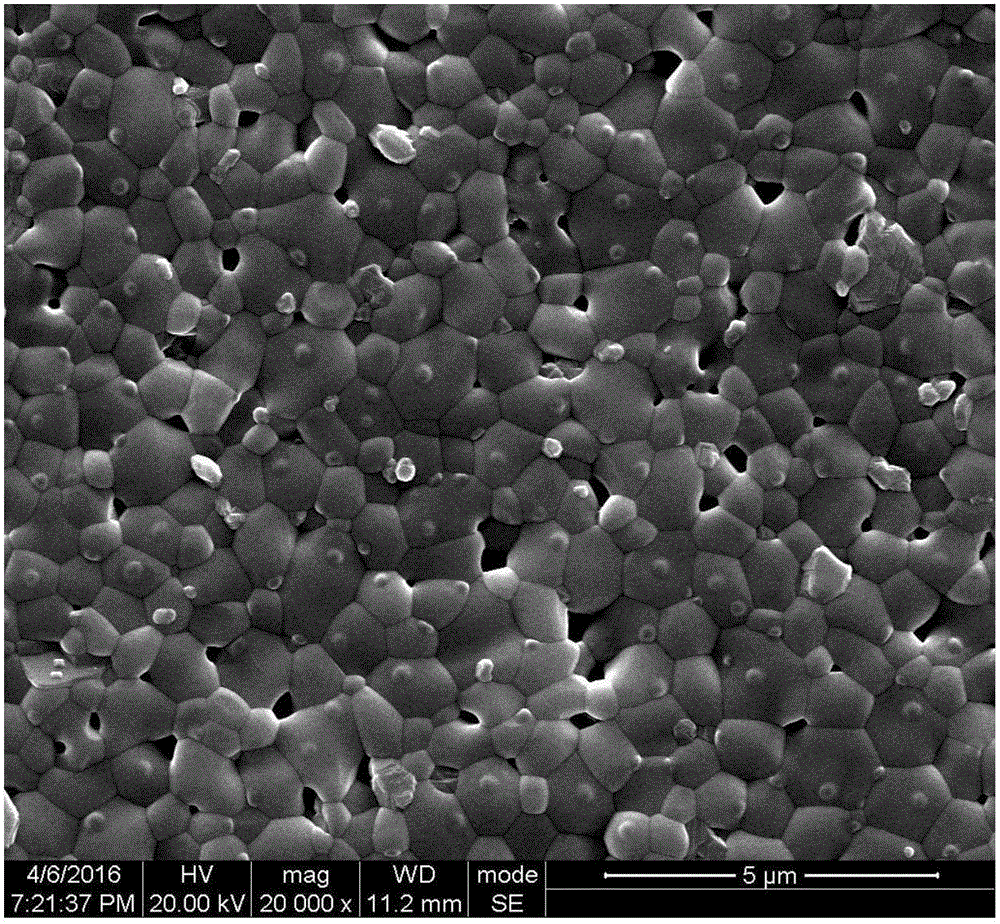

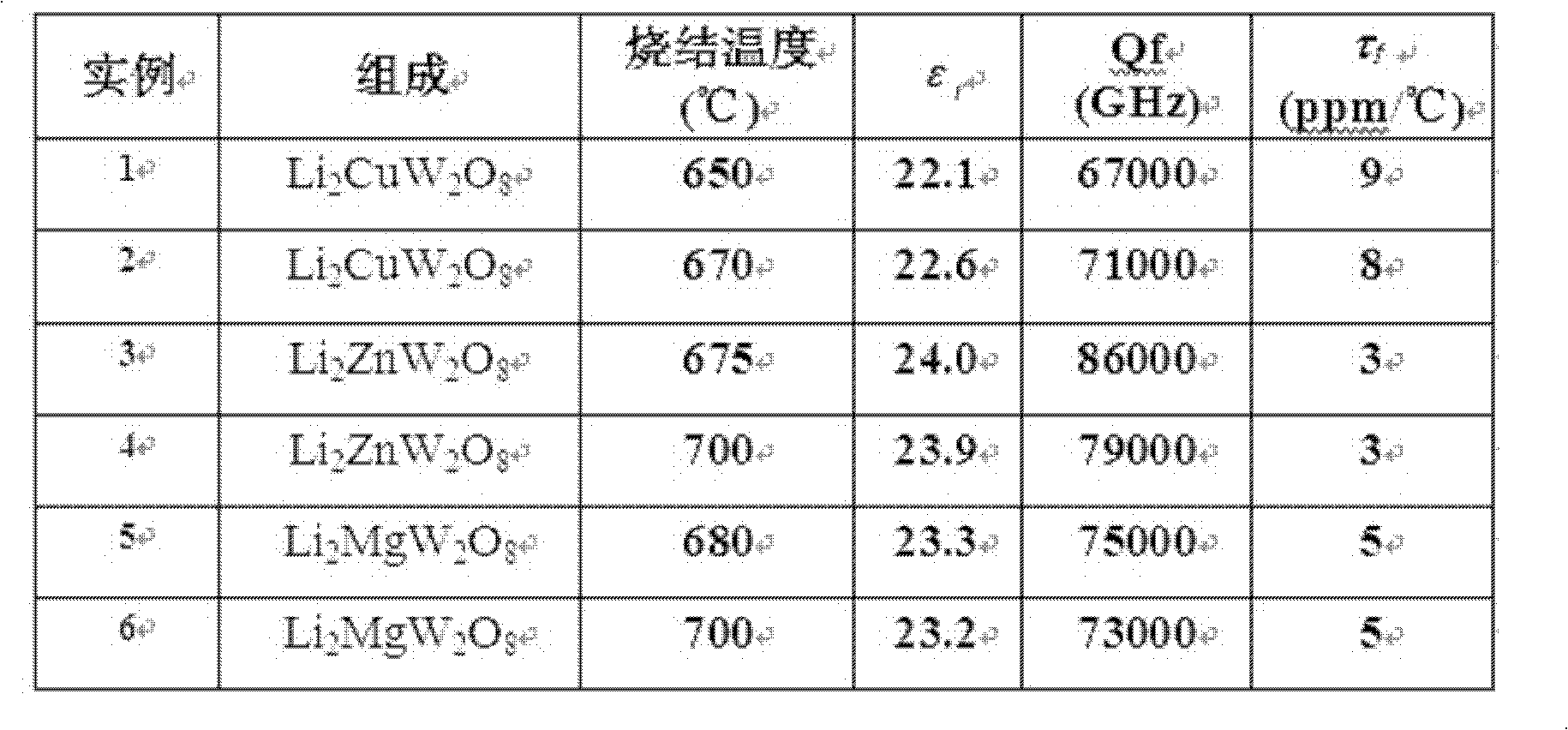

Low-temperature sintered tungstate microwave dielectric ceramic Li2MW2O8 and preparation method thereof

InactiveCN103159477AResonant frequency temperature coefficient is smallHigh application valueTemperature coefficientSolvent

The invention discloses a low-temperature sintered tungstate microwave dielectric ceramic Li2MW2O8 and a preparation method thereof. The low-temperature sintered tungstate microwave dielectric ceramic is made of a material with the component of Li2MW2O8, wherein M is selected from one of Zn, Mg and Cu. The preparation method of the low-temperature sintered tungstate microwave dielectric ceramic Li2MW2O8 comprises the following steps of: (1) weighting and proportioning initial Li2CO3, MO and WO3 powders with the purities of over 99.9% according to the chemical formula Li2MW2O8, wherein M is selected from one of Zn, Mg and Cu; (2) performing wet-type ball milling and mixing on the raw materials for 12 hours, drying the raw materials, and then, presintering the raw materials at 600-DEG C atmosphere for 6 hours, wherein distilled water is used as a solvent; and (3) adding a binder into the prepared powder, pelleting, then, carrying out compression moulding, and finally, sintering at 650-700 DEG C atmosphere for 4 hours, wherein the binder is a 5wt% polyvinyl alcohol solution and accounts for 3% of the total quantity of the powder. The ceramic prepared by the invention is good in sintering at the temperature of 650-700 DEG C, high dielectric constant up to 22-24, high quality factor (Qf) value up to 67000-86000GHz and small temperature coefficient of resonance frequency.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

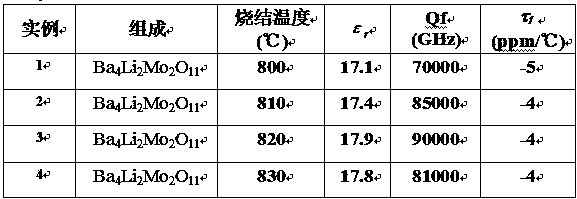

Low-temperature sinterable molybdenum-based microwave dielectric ceramic Ba4Li2Mo2O11

ActiveCN103396120APromote sinteringResonant frequency temperature coefficient is smallDielectricPolyvinyl alcohol

The invention discloses a low-temperature sinterable molybdenum-based microwave dielectric ceramic Ba4Li2Mo2O11 and a preparation method thereof. The chemical composition of the material of the low-temperature sinterable molybdenum-based microwave dielectric ceramic is Ba4Li2Mo2O11. The preparation method comprises: (1) weighing and proportioning original powders of BaCO3, Li2CO3 and MoO3 each with purity of 99.9% or more according the chemical formula of Ba4Li2Mo2O11; (2) performing wet-type ball milling and mixing on the raw materials of the step (1) for 12 h with a solvent of distilled water, drying, pre-burning for 6 h under atmosphere at 600 DEG C; and (3) adding a binder into the powder prepared in the step (2) and granulating, then performing compaction molding, and finally sintering under atmosphere at 800-830 DEG C for 4 h; wherein the binder employs a polyvinyl alcohol solution with a mass concentration of 5%, and accounts for 3% by mass of the whole powder. The prepared ceramic by the preparation method has good sintering at 800-830 DEG C, a dielectric constant of 17-18, a quality factor (Qf value) of up to 71000-90000 GHz, a small temperature coefficient of resonate frequency, and great application value in industry.

Owner:苏州弘吴科技中介服务有限公司

Microwave dielectric ceramic Li3Nb3B2O12 sintered at ultralow temperature and preparation method thereof

ActiveCN103880422APromote sinteringResonant frequency temperature coefficient is smallDielectricElectricity

The invention discloses a microwave dielectric ceramic Li3Nb3B2O12 sintered at an ultralow temperature and a preparation method thereof. The chemical constitution of the microwave dielectric ceramic sintered at an ultralow temperature is Li3Nb3B2O12. The preparation method includes the following steps: (1) weighing and matching original powder of pure Li2CO3, Nb2O5 and B2O3 according to the chemical formula of Li3Nb3B2O12; (2) adding distilled water in the raw materials in the step (1), performing mixed wet ball milling for 12 hours, and pre-sintering for 6 hours in an atmosphere of 600 DEG C after drying; and (3) adding an adhesive in the powder prepared in the step (2) and pelleting, press forming, and finally sintering the powder for 4 hours in an atmosphere of 650-680 DEG C, wherein the adhesive is a polyvinyl alcohol solution with mass concentration of 5%, and the adhesive accounts for 3% of the total mass of the powder. The ceramic prepared by the preparation method provided by the invention has good sintering property at 650-680 DEG C, the dielectric constant of the ceramic reaches 9-10, the quality factor Qf value is up to 110000-138000GHz, the temperature coefficient of resonant frequency is small, the ceramic can be sintered together with Ag at a low temperature and has a large application value in industry.

Owner:苏州弘吴科技中介服务有限公司

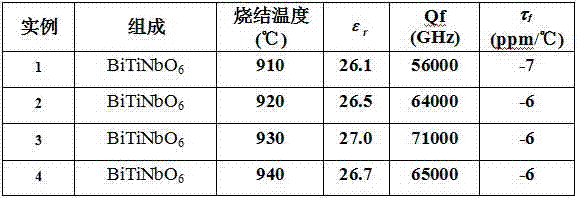

Low temperature sintered microwave dielectric ceramic BiTiNbO6 and preparation method thereof

ActiveCN103496973APromote sinteringResonant frequency temperature coefficient is smallTemperature coefficientSolvent

The invention discloses a low temperature sintered microwave dielectric ceramic BiTiNbO6 and a preparation method thereof. The chemical formula of the low temperature sintered microwave dielectric ceramic is BiTiNbO6. The preparation method comprises the following steps: (1) weighing and mixing original powder, with purity above 99.9%, of Bi2O3, TiO2 and Nb2O5 according to the chemical formula BiTiNbO6; (2) carrying out wet ball milling on the raw material mixture obtained in the step (1) for 12 hours and presintering the powder in an atmosphere at 850 DEG C for 6 hours after drying the powder, wherein the solvent is distilled water; (3) adding a binder to the powder prepared in the step (2) and then granulating the mixture, then carrying out compression forming and finally sintering the product in an atmosphere at 910-940 DEG C for 4 hours, wherein a polyvinyl alcohol solution with mass concentration of 5% is adopted as the binder and the dosage of the binder is 3% of the total mass of the powder. The prepared ceramic is well sintered at 910-940 DEG C, has dielectric constant of 26-27 and quality factor (Qf) as high as 56000-71000GHz, has low temperature coefficient of resonance frequency, can be co-sintered with Ag electrodes at low temperature and has great application value in industry.

Owner:苏州弘吴科技中介服务有限公司

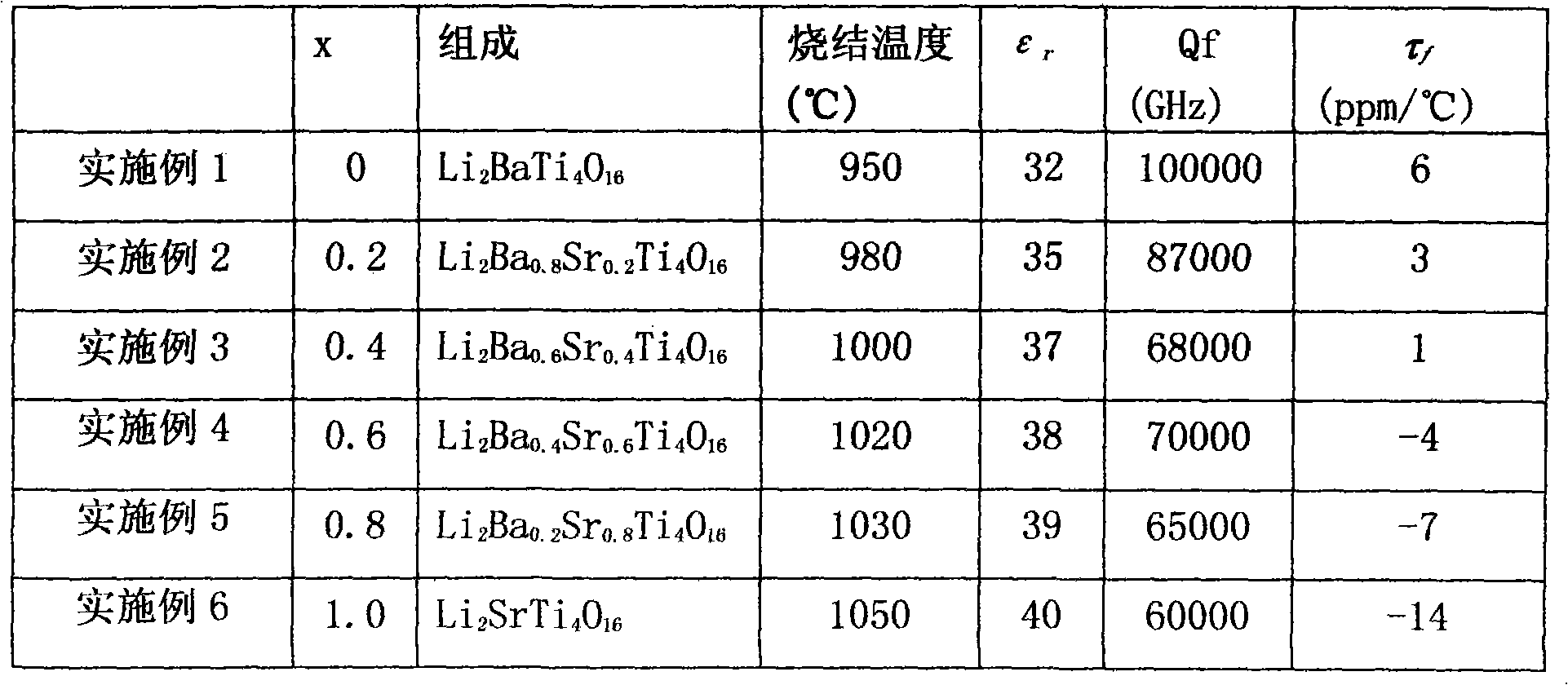

Low temperature sintered microwave dielectric ceramic Li2Ba1-xSrxTi4O16 and preparation method thereof

InactiveCN102249670AResonant frequency temperature coefficient is smallHigh application valueTemperature coefficientSolvent

The invention discloses a low temperature sintered microwave dielectric ceramic Li2Ba1-xSrxTi4O16 and a preparation method thereof. The components of the ceramic are shown in the formula of Li2Ba1-xSrxTi4O16, wherein x is more than or equal to 0 and less than or equal to 1. The preparation method comprises the following steps of: preparing raw materials of BaCO3, SrCO3, Li2CO3 and TiO2 original powder with the purity of over 99.9 percent according to the formula of Li2Ba1-xSrxTi4O16, wherein x is more than or equal to 0 and less than or equal to 1; mixing the prepared raw materials for 12 hours through wet ball-milling, wherein a solvent is distilled water; drying, and pre-sintering at 900DEG C in the air for 6 hours; adding an adhesive into the pre-sintered powder, granulating, and pressing for formation; and sintering at the temperature of between 950 and 1,050DEG C in the air for 4 hours, wherein the adhesive is a 5 mass percent polyvinyl alcohol solution and is 3 percent of the total weight of the pre-sintered powder. The ceramic is well sintered at the temperature of between 950 and 1,050DEG C, has the dielectric constant of 32-40, the quality factor Qf value of 60,000-100,000GHz, small temperature coefficient of resonance frequency, and great application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

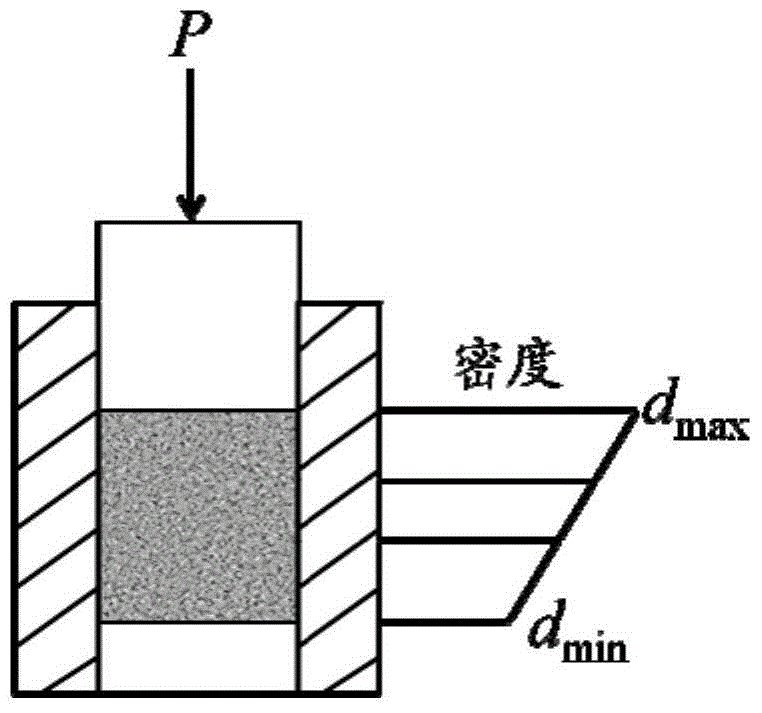

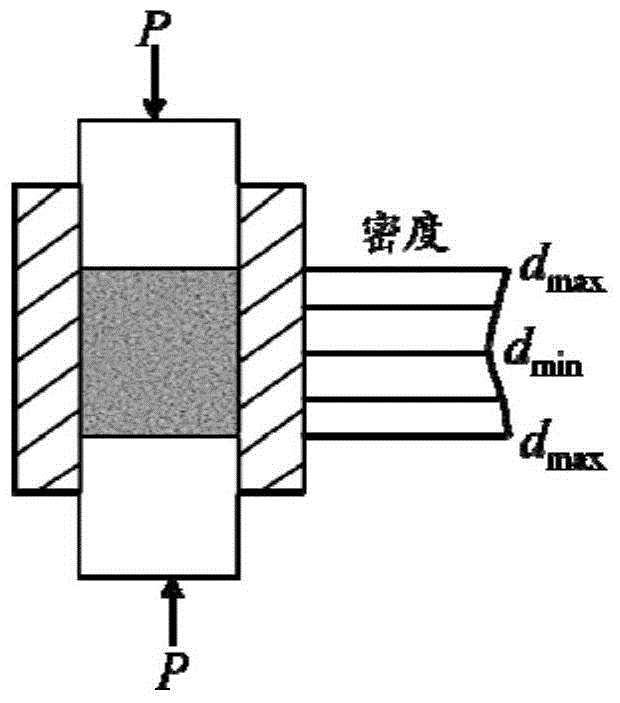

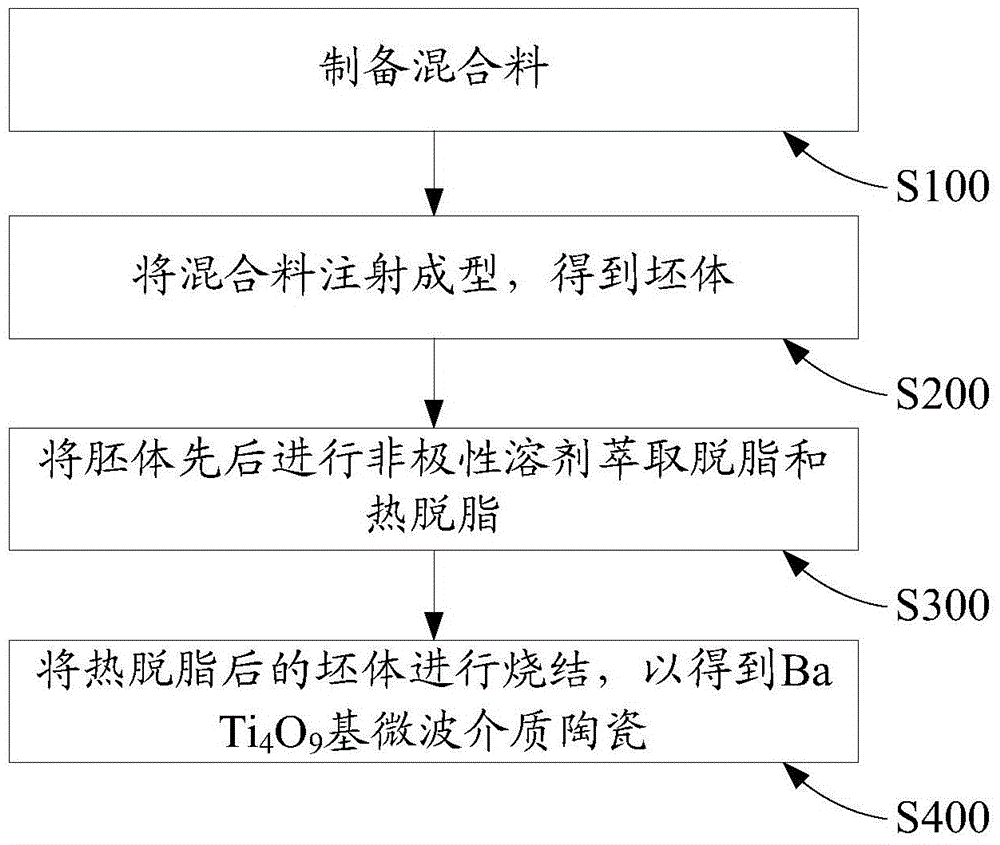

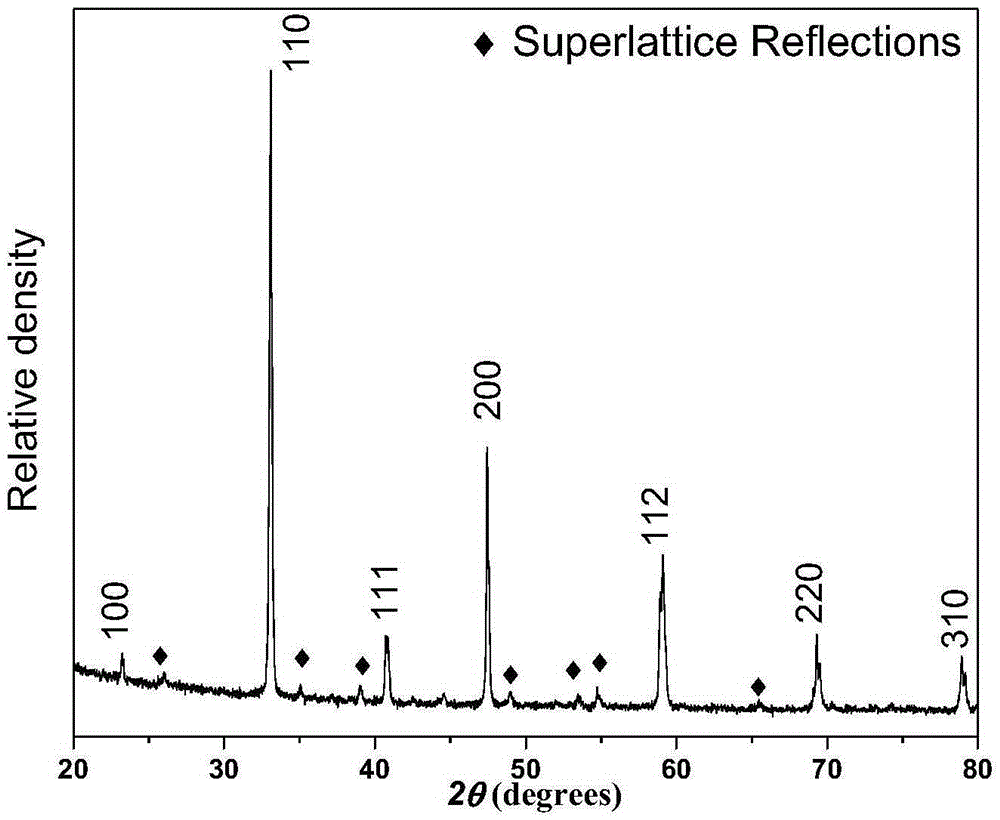

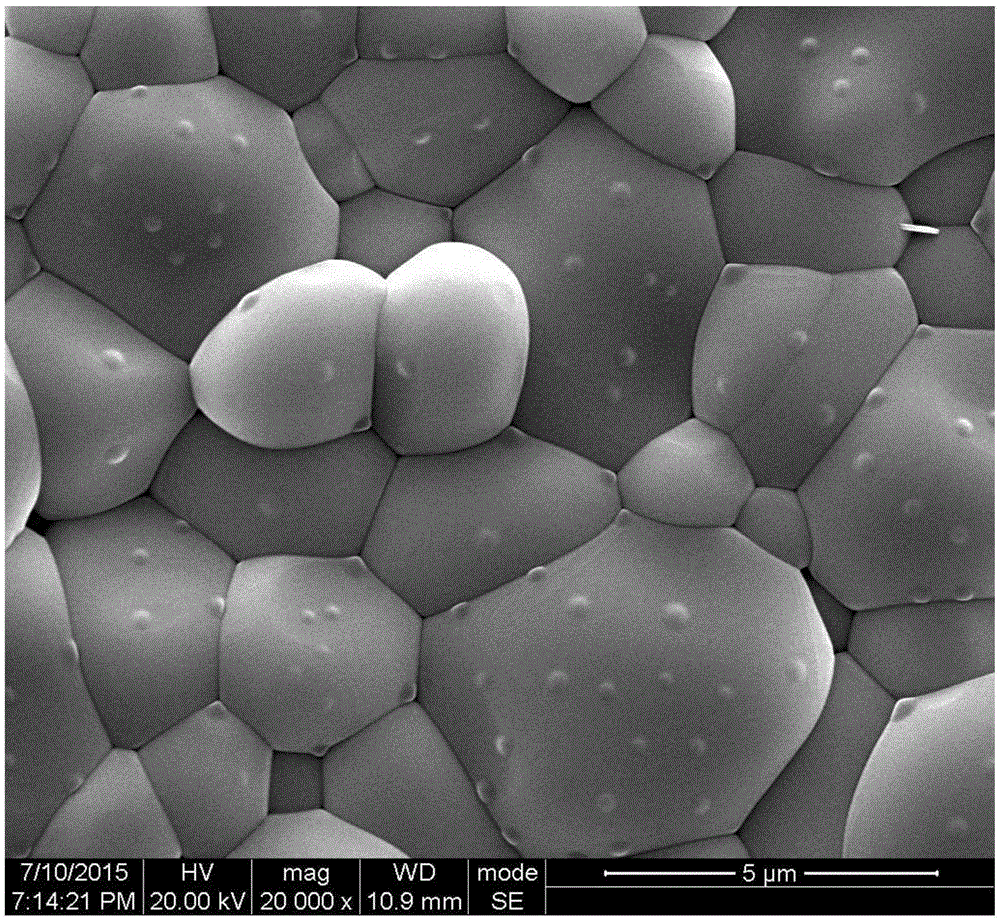

Ceramic material, preparation method thereof, resonator, filter, and radio remote equipment

The invention provides a BaTi4O9 base microwave medium ceramic material, a preparation method thereof, a resonator, a filter, and radio remote equipment. The preparation method of the medium ceramic material comprises the following steps: preparing a mixed material, which at least comprises BaTi4O9 base ceramic powder and an organic adhesive; subjecting the mixed material to an injection moulding treatment to obtain a blank; subjecting the blank to non-polar solvent extraction degreasing and thermal degreasing in sequence; and after thermal degreasing, sintering the blank to obtain the BaTi4O9 base microwave medium ceramic. According to the preparation method, an injection moulding technology is used to obtain the medium ceramic material, which has the advantages of uniform density and size distribution, and high size precision after sintering, moreover, the material cost is low, and the preparation technology is simple. Compared with the resonator prepared through a dry pressing technology, the provided resonator has a higher quality factor (Q*f) value and more stable property.

Owner:ANHUI TATFOOK TECH CO LTD

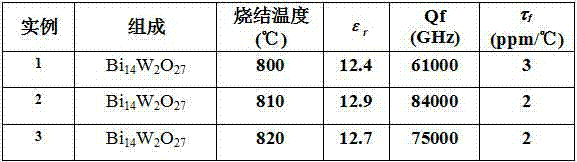

Low-temperature sintering temperature-stable microwave dielectric ceramic Bi14W2O27 and preparation method thereof

ActiveCN103496981APromote sinteringResonant frequency temperature coefficient is smallAir atmosphereDielectric

The invention discloses a low-temperature sintering temperature-stable microwave dielectric ceramic and a preparation method thereof. The composition formula of the low-temperature sintering temperature-stable microwave dielectric ceramic is Bi14W2O27. The preparation method comprises the steps of (1) weighing and batching original powder of Bi2O3 and WO3 with the purity being over 99.9% according to the chemical formula Bi14W2O27; (2) carrying out wet ball-milling and mixing on raw materials obtained in the step (1) for 12 hours, taking distilled water as a solvent, drying, and then, pre-sintering in an air atmosphere for 6 hours at the temperature of 700 DEG C; (3) adding a binder into powder prepared in the step (2), granulating, then, carrying out compression molding, and finally, sintering in the air atmosphere for 4 hours at the temperature of 800-820 DEG C, wherein a polyvinyl alcohol solution with the mass concentration of 5% is adopted as the binder, and the dosage of the binder accounts for 3% of the total mass of the powder. According to the ceramic prepared by the preparation method, the sintering at the temperature of 800-820 DEG C is good, the dielectric constant reaches 12-13, the quality factor (Qf) reaches up to 61,000-84,000GHz, the temperature coefficient of resonance frequency is small, and the ceramic can be subjected to low-temperature co-sintering together with a Ag electrode, so that the ceramic has a great application value in industries.

Owner:苏州弘吴科技中介服务有限公司

Ba-Zn-Nb microwave ceramic medium and its preparing process

InactiveCN101423394AHigh quality factorResonant frequency temperature coefficient is smallCeramicsIonCeramic

The invention relates to a barium-zinc-niobium series microwave dielectric ceramic and a method for preparing the same, which belong to the technical field of microwave dielectric material production. The ceramic comprises the chemical component of Ba(Zn1 / 3Nb2 / 3)O3-XMO(M represents Co, Cu and 2 / 3B), the mol ratio of Ba(Zn1 / 3Nb2 / 3)O3 to MO is 1 to X, and X is between 0.001 and 0.02. According to certain proportion, nitrate, oxalate and citric acid are dissolved into deionized water, and the pH value of the mixed solution is adjusted to between 5 and 8 by ammonia so as to form sol; the sol is dried to be dry gel which is subjected to calcining to form active powder; and the powder is shaped through wet milling and press, and is prepared into the microwave dielectric ceramic by sintering in a high-temperature furnace. The microwave dielectric ceramic can be sintered at different sintering temperatures of between 1,000 and 1,400 DEG C, has medium dielectric constant of between 20 and 40 and high quality factor with Q x f value of between 25,000 and 70,000GHz , and is expected to be widely used for manufacture of various microwave devices.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

High solid content lithium-niobium-titanium series microwave medium ceramic water-based casting green tape

InactiveCN102120703ASimple preparation processMeet environmental protection requirementsDielectric resonatorSlurry

The invention relates to a high solid content lithium-niobium-titanium series microwave medium ceramic water-based casting green tape, belonging to the preparation field of the microwave medium ceramic. In the preparation method of the green tape, lithium-niobium-titanium series low temperature sintered microwave medium ceramic is used as solid phase powder, water is used as solvent, styrene-acrylic emulsion is used as binder, and plasticizer, dispersant, defoaming agent, film-forming additive and the like are added to prepare ceramic slurry, and the casting and drying technology is performed to prepare the green tape. The prepared water-based microwave medium ceramic green tape has high solid content, smooth surface, good mechanical propertics, no pollution and low cost; electrode materials such as silver and copper can be printed on the surface of the green tape, binder is removed at 400-450 DEG C and the product is sintered at 860-950 DEG C to have excellent microwave dielectric properties. The green tape material is suitable to prepare multi-layer low temperature cofired ceramic (LTCC) electronic components such as chip dielectric resonators, filters, Baluns and antennas and has broad application prospect.

Owner:佛山市华南精细陶瓷技术研究开发中心 +1

High-dielectric low-loss microwave dielectric ceramic material and preparation method thereof

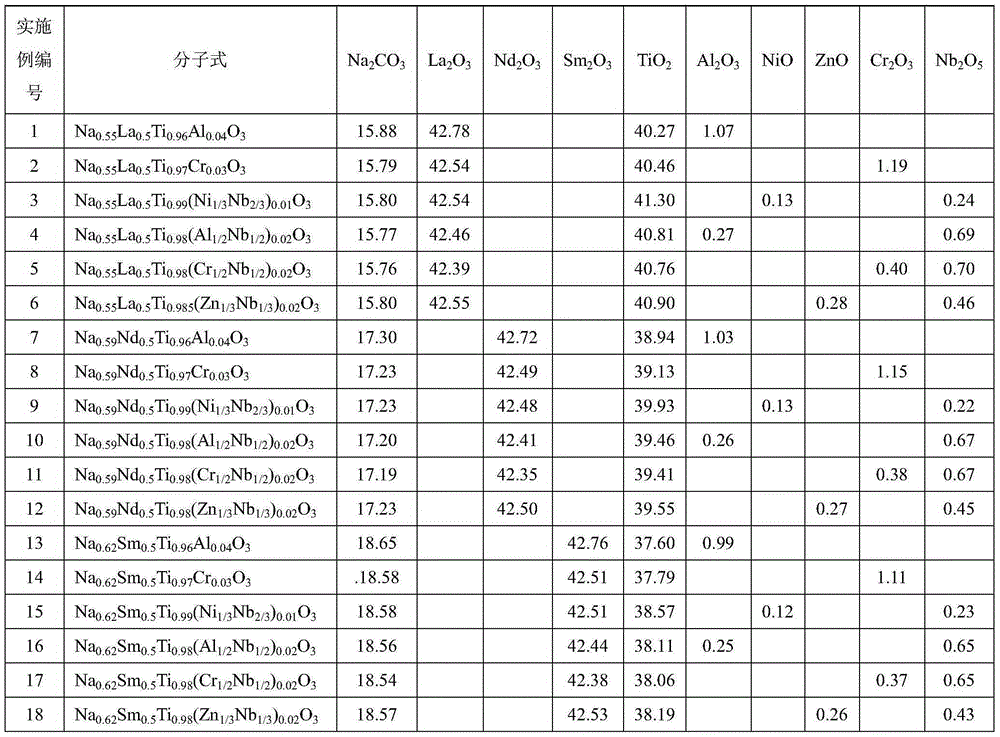

The invention provides a high-dielectric low-loss microwave dielectric ceramic material. The general chemical formula of the material is (Na0.5+yLn0.5)(Ti1-xCx)O3, Ln=La or Nd or Sm, wherein x is larger than or equal to 0.01 and is smaller than or equal to 0.04, y is larger than or equal to 0.05 or is smaller than or equal to 0.12, the composition of C is VW, V represents Nb with the valence state higher than four, W represents a single ion or compound ions with the valence state lower than or equal to four and the average ion radius approximating to Ti4+, and V and M achieve simultaneous replacement or independent replacement. The invention further provides a preparation method of the high-dielectric low-loss microwave dielectric ceramic material. The preparation method comprises the steps of burdening, ball grinding, drying and sieving, presintering, pelleting, compression molding and sintering. The prepared material has the high dielectric constant and high Q*f value, contains no Pb or Cd or other volatile toxic metals in the formula, and is stable in performance and capable of meeting application requirements of modern microwave devices, raw materials are sufficiently supplied in China, the cost is relatively low, and the high-performance microwave ceramic can be low in cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

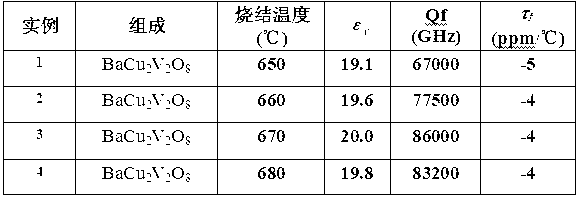

Microwave dielectric ceramic BaCu2V2O8 with low temperature sintering function and preparation method thereof

ActiveCN103319176APromote sinteringResonant frequency temperature coefficient is smallDielectricPolyvinyl alcohol

The invention discloses microwave dielectric ceramic BaCu2V2O8 with a low temperature sintering function and a preparation method thereof. The microwave dielectric ceramic BaCu2V2O8 with the low temperature sintering function comprises BaCu2V2O8. The preparation method comprises the following steps of: (1) weighing and burdening raw powder containing BaCO3, CuO and V2O5 and having the purity of 99.9 percent according to a BaCu2V2O8 chemical formula; (2) carrying wet ball-grinding and mixing for 12 hours, drying and then presintering for 6 hours in an atmosphere of 600 DEG C, wherein the solvent is distilled water; (3), adding a binder, granulating, then carrying out compression molding and finally sintering for 4 hours in an atmosphere of 650-680 DEG C, wherein the binder is a polyvinyl alcohol solution with the mass concentration of 5 percent and accounts for 3 percent by total mass of the powder. The ceramic prepared by using the preparation method has a favorable sintering property at 650-680 DEG C, the dielectric constant reaching 19-20, the quality factor Qf up to 67000-86000GHz and small temperature coefficient of resonance frequency, can be co-sintered with an Ag electrode at low temperature and has a great application value in the industry.

Owner:苏州弘吴科技中介服务有限公司

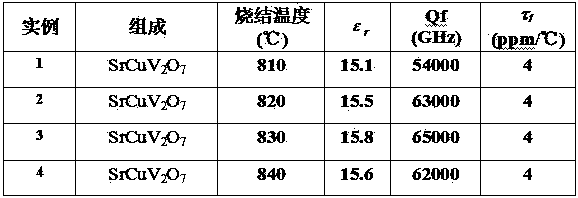

Low-temperature sinterable microwave dielectric ceramic SrCuV2O7 and preparation method thereof

ActiveCN103467095AResonant frequency temperature coefficient is smallHigh application valueSolventTemperature coefficient

The invention discloses a low-temperature sinterable microwave dielectric ceramic SrCuV2O7 and a preparation method thereof. The chemical composition of the low-temperature sinterable microwave dielectric ceramic is SrCuV2O7. The preparation method comprises the following steps: (1) weighing and proportioning SrCO3, CuO and V2O5 original powder with the purity of higher than 99.9% according to the chemical formula SrCuV2O7; (2) carrying out wet-type ball milling mixing on the raw materials in the step (1) for 12 hours by using distilled water as a solvent, drying, and presintering at 600 DEG C in air for 6 hours; and (3) adding an adhesive into the powder prepared in the step (2), granulating, carrying out compression molding, and finally, sintering at 810-840 DEG C in air for 4 hours, wherein the adhesive is a 5 wt% polyvinyl alcohol solution, and accounts for 3 wt% of the powder. The ceramic disclosed by the invention can be well sintered at 810-840 DEG C; the dielectric constant is up to 15-16, the quality factor Qf is up to 54000-65000 GHz, and the temperature coefficient of resonance frequency is small; and thus, the ceramic has great application value in industry.

Owner:苏州弘吴科技中介服务有限公司

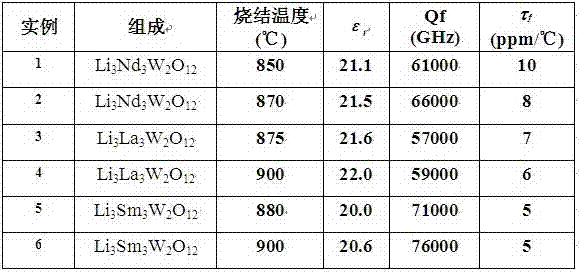

Low-temperature sintering tungstate microwave dielectric ceramic Li3R3W2O12 and preparation method thereof

ActiveCN103193483AResonant frequency temperature coefficient is smallHigh application valueSolventTemperature coefficient

The invention discloses low-temperature sintering tungstate microwave dielectric ceramic Li3R3W2O12 and a preparation method thereof. The low-temperature sintering tungstate microwave dielectric ceramic material comprises the components of Li3R3W2O12, wherein R is one of Nd, La and Sm. The method comprises the steps of (1) weighing and dosing the original powder of Li2CO3, R2O3 and WO3, of which the purity is more than 99.9% according to the chemical formula of Li3R3W2O12, wherein R is one of Nd, La and Sm; (2) mixing the materials for 12 hours in a wet ball grinding manner, wherein the solvent is distilled water, and pre-sintering for 6 hours after baking in the atmosphere of 800 DEG C; and (3) adding a binder to the prepared powder and pelletizing, then pressing and molding, and finally sintering for 4 hours in the atmosphere of 850-900 DEG C, wherein the binder adopts polyvinyl alcohol solution of which the mass concentration is 5%; and the dosage is 3% of the total weight of the powder. The ceramic prepared by the preparation method has good sintering property at 850-900 DEG C; the dielectric constant achieves 20-22; the quality factor Qf value can be up to 57000-76000GHz; and the resonant frequency temperature coefficient is small.

Owner:苏州弘吴科技中介服务有限公司

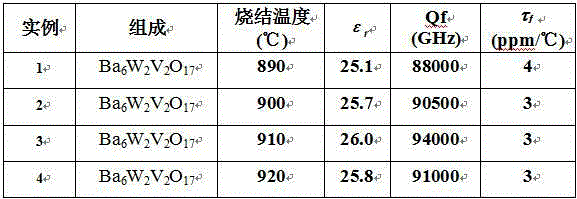

Microwave dielectric ceramic Ba6W2V2O17 capable of being sintered at low temperature and preparation method thereof

ActiveCN103553612APromote sinteringResonant frequency temperature coefficient is smallTemperature coefficientAir atmosphere

The invention discloses microwave dielectric ceramic Ba6W2V2O17 capable of being sintered at a low temperature and a preparation method thereof. The microwave dielectric ceramic capable of being sintered at the low temperature has the composition of Ba6W2V2O17. The preparation method comprises the following steps: (1) weighing and batching original powder of BaCO3, WO3 and V2O5 with the purity of over 99.9 percent according to the chemical formula of the Ba6W2V2O17; (2) mixing the raw materials of the step (1) and performing wet milling for 12 hours, wherein the solvent is distilled water; pre-sintering for 6 hours in air atmosphere at 830 DEG C after the mixture is dried; (3) adding an adhesive into the prepared powder, granulating, pressing, forming, and sintering for 4 hours in the air atmosphere at 920 DEG C, wherein the adhesive adopts a polyvinyl alcohol solution with the mass concentration of 5 percent, and the dosage of the polyvinyl alcohol solution accounts for 3 percent of the total mass of the powder. The ceramic prepared by the invention is sintered well between 890 and 920 DEG C, has the dielectric constant between 25 and 26, the Qf (quality factor) value between 88,000 and 94,000 GHz, and low temperature coefficient of resonance frequency, can be co-fired with an Ag electrode, and has a great application value in industry.

Owner:苏州弘吴科技中介服务有限公司

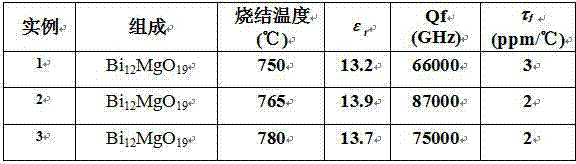

Niobium zinc barium-based microwave medium ceramic and preparation method thereof

InactiveCN101830708AReduce pollutionImprove production efficiencyCeramicsCompression moldingMicrowave

The invention relates to the field of microwave medium ceramic of material science, in particular to Ba(Zn1 / 3Nb2 / 3)O3(BZN)-based microwave medium ceramic sintered by low-temperature reaction and a preparation method thereof. The method comprises the following steps of: adding the following additives in percentage by mass into a Ba(Zn1 / 3Nb2 / 3)O3(BZN) base material: 0.5 to 1.5 percent of CuO, 0.5 to 1.5 percent of Li2CO3, 0.5 to 1.5 percent of V2O5 and 1.5 to 4.5 percent of ZnO-B2O3; and performing common ball-milling and mixing, drying, screening and compression molding on the mixture, and then obtaining a dense ceramic product by reacting and sintering the mixture, wherein the sintering temperature can be reduced to 950 DEG C. The microwave medium ceramic has good microwave performance, and reduces the energy consumption and the cost.

Owner:江苏兴云新能源有限公司

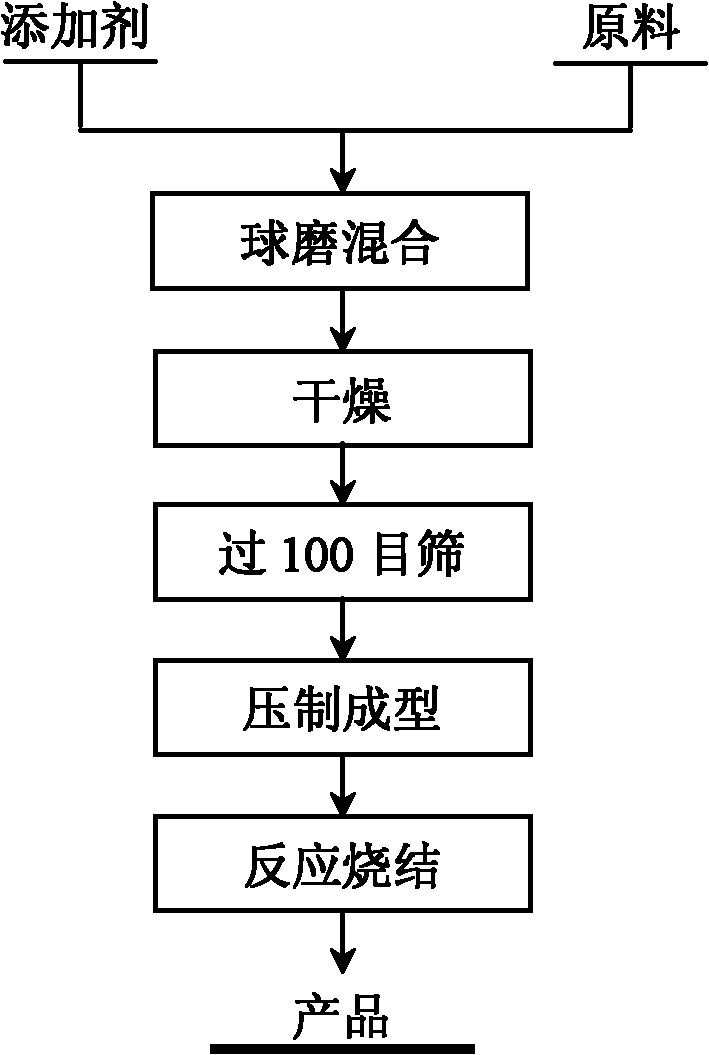

Low-temperature sintering microwave dielectric ceramic Bi12MgO19 and preparation method thereof

InactiveCN103570345APromote sinteringResonant frequency temperature coefficient is smallDielectricPolyvinyl alcohol

The invention discloses low-temperature sintering microwave dielectric ceramic and a preparation method thereof. The composition of the low-temperature sintering microwave dielectric ceramic is Bi12MgO19. The preparation method comprises the following steps: (1) weighing original powder of Bi2O3 and MgO with the purities of above 99.9% according to the chemical formula Bi12MgO19; (2) carrying out wet-type ball milling on the raw materials in the step (1) and mixing for 12 hours, wherein a solvent is distilled water, drying, and then presintering for 6 hours at the 700 DEG C atmosphere; and (3) adding a binding agent to the powder prepared in the step (2), pelleting, carrying out compression molding, and finally sintering for 4 hours at the 750-780 DEG C atmosphere, wherein the binding agent is a polyvinyl alcohol solution with the mass concentration of 5%, and the dosage of the binding agent accounts for 3% of the total mass of the powder. The low-temperature sintering microwave dielectric ceramic prepared by the method has good sintering property at 750-780 DEG C, the dielectric constant of the ceramic reaches 13-14, the quality factor Qf of the ceramic reaches up to 66000-87000 GHz, the temperature coefficient of the resonance frequency of the ceramic is small, and therefore, the ceramic has enormous application value in industries.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

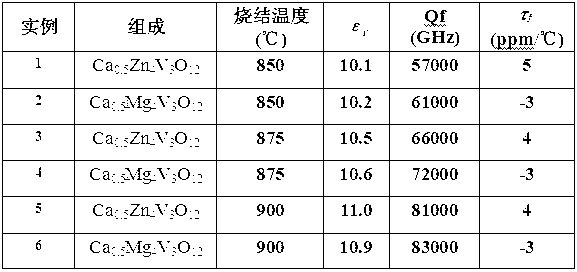

Low temperature sinterable vanadate microwave dielectric ceramic Ca0.5M4V3O12 and preparation method thereof

InactiveCN103232244APromote sinteringResonant frequency temperature coefficient is smallPolyvinyl alcoholResonance

The invention discloses a low temperature sinterable vanadate microwave dielectric ceramic Ca0.5M4V3O12 and a preparation method thereof. The material composition of the low temperature sinterable vanadate microwave dielectric ceramic is Ca0.5M4V3O12, wherein the M is one of Zn and Mg. The preparation method comprises the following steps of (1) weighing original powders of CaCO3, MO and VO3 with the purity above 99.9% according to the chemical formula of the Ca0.5M4V3O12, wherein the M is one of Zn and Mg; (2) carrying out wet ball-milling mixing for 12 hours, taking distilled water as a solvent, drying and pre-burning for 6 hours at the temperature of 750 DEG C; and (3) adding an adhesion agent, granulating, carrying out compression moulding and finally sintering for 4 hours at the temperature of 800-900 DEG C, wherein a polyvinyl alcohol solution with the mass concentration of 5% is adopted as the adhesion agent and the dose of the adhesion agent accounts for 3% of the total dose of the powder. The ceramic disclosed by the invention has the advantages that the sintering is good at the temperature of 850-900 DEG C, the dielectric constant is up to 10-11, the quality factor is up to 57000-83000GHz and the temperature coefficient of resonance frequency is small, and therefore, the ceramic has great application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

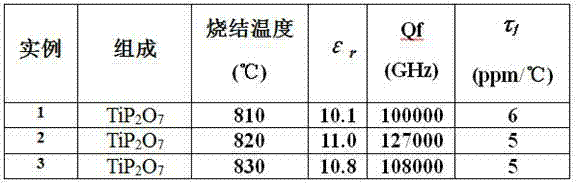

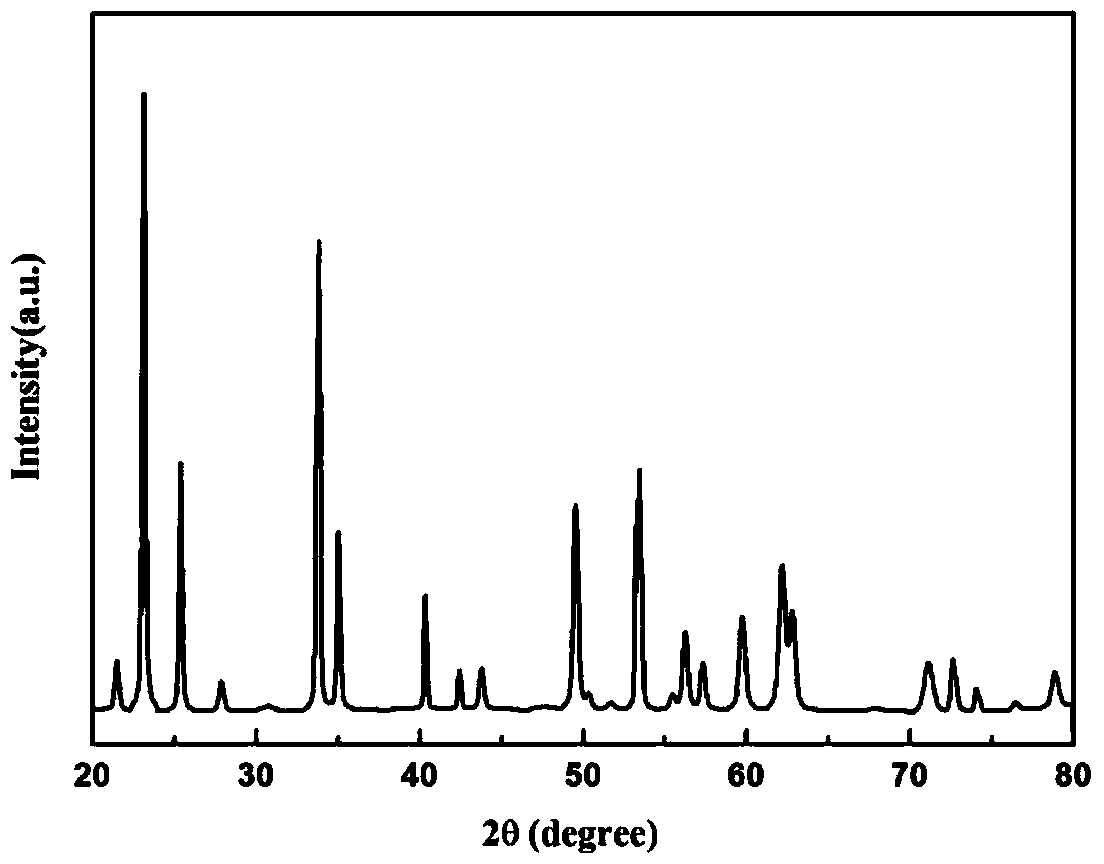

Low-temperature sintering available microwave dielectric ceramic TiP2O7 with ultralow dielectric constant and preparation method thereof

ActiveCN103922719APromote sinteringResonant frequency temperature coefficient is smallPolyvinyl alcoholAdhesive

The invention discloses an application of a composite oxide TiP2O7 in serving as low-temperature sintering available microwave dielectric ceramic with ultralow dielectric constant. The method comprises the following steps: (1) weighing and blending original powder, having the purity of over 99.9 percent, of TiO2 and NH4H2PO4 according to a chemical formula of TiP2O7; (2) carrying out wet ball-milling and mixing on the raw materials in the step (1) for 12 hours with ethanol serving as a ball-milling medium, baking, and pre-sintering for 6 hours in the atmosphere at 750 DEG C; and (3) adding adhesive into the powder prepared in the step (2), granulating, pressing to mold, and finally sintering for 4 hours in the atmosphere at 810-830 DEG C, wherein the adhesive is a 5% polyvinyl alcohol solution, and accounts for 3 percent of the total mass of the powder. According the ceramic prepared by the method, the sintering at 810-830 DEGC is excellent, the quality factor Qf value is up to 100,000-127,000GHz when the dielectric constant is 10-11, the temperature coefficient of resonance frequency is small, and the microwave dielectric ceramic has a great application value in industry.

Owner:苏州弘吴科技中介服务有限公司

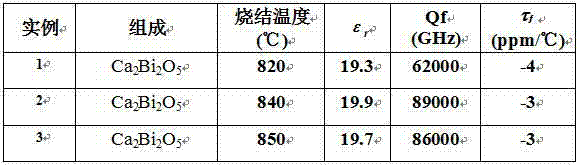

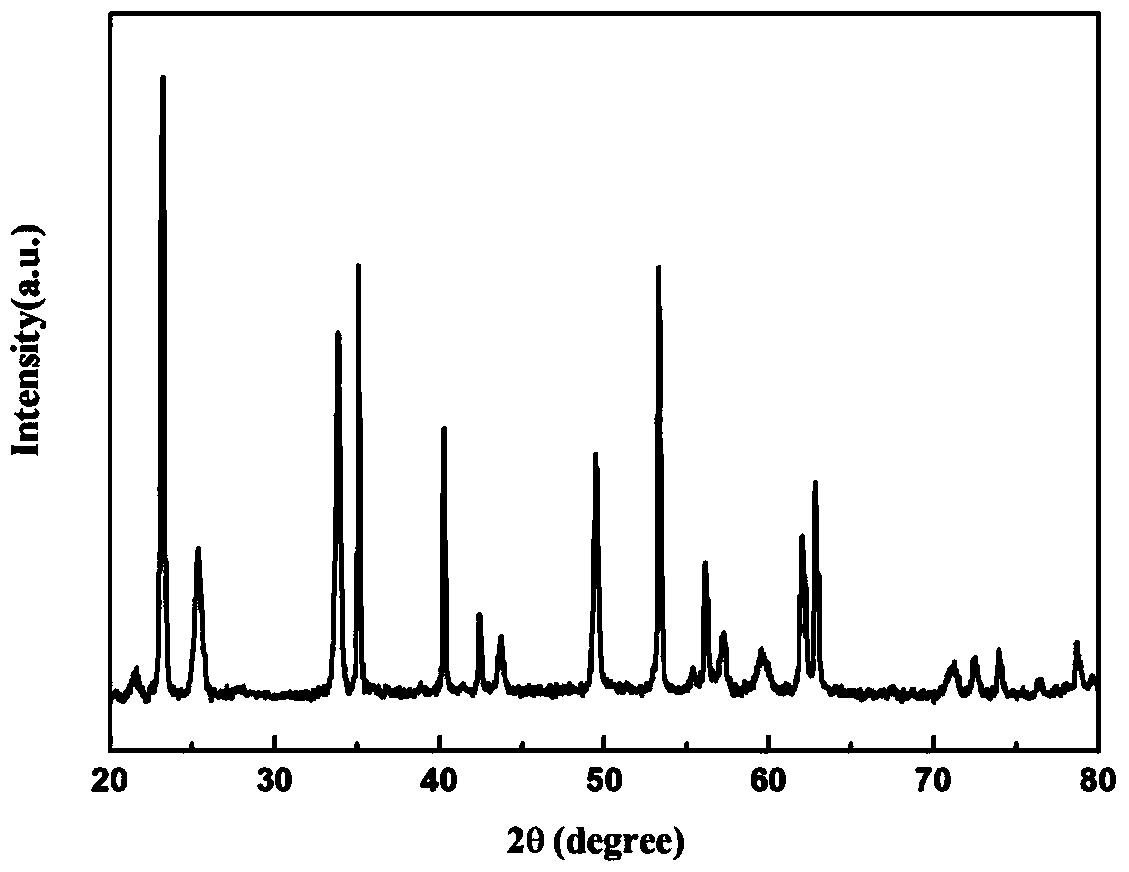

Low temperature sintering microwave dielectric ceramic Ca2Bi2O5 and preparation method thereof

ActiveCN103539444APromote sinteringResonant frequency temperature coefficient is smallDielectricMicrowave

The invention discloses low temperature sintering microwave dielectric ceramic Ca2Bi2O5 and a preparation method thereof. Composition of the low temperature sintering microwave dielectric ceramic is Ca2Bi2O5. The preparation method comprises the following steps: (1) weighing and dosing original powder of CaCO3 and Bi2O3 with the purity over 99.9% according to the chemical formula Ca2Bi2O5; (2) wet-type ball-milling and mixing the raw material in step (1) for 12 hours, wherein the solvent is distilled water, and drying and pre-sintering for 6 hours in atmosphere at 750 DEG C; and (3) adding a binder into the powder prepared in step (2) and prilling, then, pressing to mould, and finally, sintering for 4 hours in atmosphere at 820-850 DEG C, wherein the binder is polyvinyl alcohol liquor with mass concentration of 5%, and the dose accounts for 3% of total weight of the powder. The ceramic disclosed by the invention is well sintered at 820-850 DEG C, and the dielectric constant reaches 1-20, the quality factor Qf value reaches 62000-89000GHz and the temperature coefficient of resonance frequency is small. The ceramic has an extremely huge application value in industry.

Owner:苏州弘吴科技中介服务有限公司

High-dielectric-constant lithium-niobium-titanium-based low-temperature-fired ceramics and preparation method thereof

The invention discloses a high-dielectric-constant lithium-niobium-titanium-based low-temperature-fired microwave dielectric ceramic material and a preparation method thereof. The material disclosed by the invention can be prepared through the solid-phase reaction of a lithium-rich lithium-niobium-titanium-based material and a lithium borosilicate glass burning improver of an amount accounting for 1-10% by weight of a main crystal phase. The composition of the lithium-rich lithium-niobium-titanium-based material is Li1.0+xNb0.6Ti0.5O3-yLBS, wherein the LBS is the lithium borosilicate glass burning improver, x is not smaller than 0 but not greater than 0.2 (mole ratio), and y is not smaller than 0 but not greater than 0.1 (weight ratio). The LBS is prepared from the following raw materials: lithium carbonate (Li2CO3), silicon dioxide (SiO2) and boron oxide (B2O3). The low-temperature-fired microwave dielectric ceramics LTCC (Low-Temperature Co-fired Ceramics) prepared by the method have the advantages that the firing at the temperature of 850-900 DEG C is good, the high dielectric constant [epsilon]r is 65-70, the quality factor Qf is moderate, and the temperature coefficient of resonance frequency is small; the ceramics can be applied to the production of microwave devices, such as LTCC systems, multilayer dielectric resonators, microwave antennae, wave filters and the like, and have great application values in industry.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

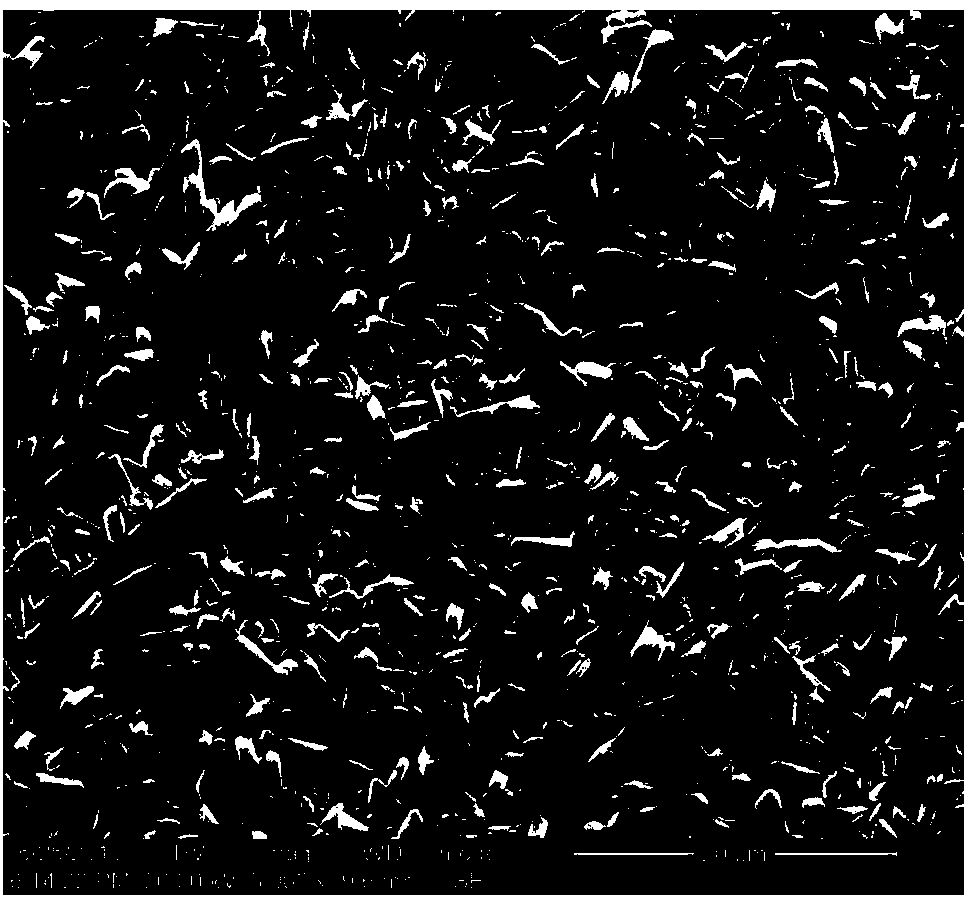

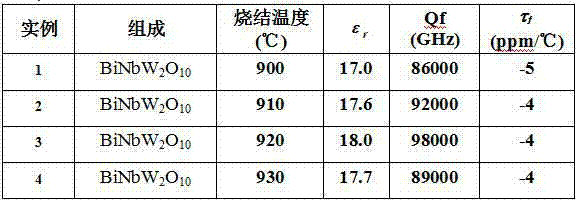

Microwave dielectric ceramic BiNbW2O10 capable of being sintered at low temperature and preparation method thereof

ActiveCN103539449APromote sinteringResonant frequency temperature coefficient is smallDielectricPolyvinyl alcohol

The invention discloses microwave dielectric ceramic BiNbW2O10 capable of being sintered at low temperature and a preparation method thereof. The composition of the microwave dielectric ceramic capable of being sintered at low temperature is BiNbW2O10. The preparation method comprises the following steps of: (1) weighing the original powder of Bi2O3, Nb2O5 and WO3 having the purity of more than 99.9% according to the chemical formula BiNbW2O10, and mixing all the original powder together; (2) performing mixing and wet ball milling on the raw materials of the step (1) for 12 hours while taking distilled water as a solvent, and pre-sintering for 6 hours in atmosphere at 850 DEG C; (3) adding a binder to the powder obtained in the step (2) and pelleting, then carrying out compression molding, and finally sintering for 4 hours in atmosphere at the temperature ranging from 900 to 930 DEG C, wherein the binder is a polyvinyl alcohol solution having the mass concentration of 5%, and the dosage of the binder is 3% of the total weight of the powder. The ceramic prepared by the preparation method disclosed by the invention is well sintered at the temperature ranging from 900 to 930 DEG C; the dielectric constant of the ceramic is in the range from 17 to 18, the value of the quality factor Qf of the ceramic is within the range from 86000 to 98000 GHz and the temperature coefficient of resonant frequency of the ceramic is low; the ceramic can be co-sintered at the low temperature with an Ag electrode and has an enormous application value in industry.

Owner:苏州弘吴科技中介服务有限公司

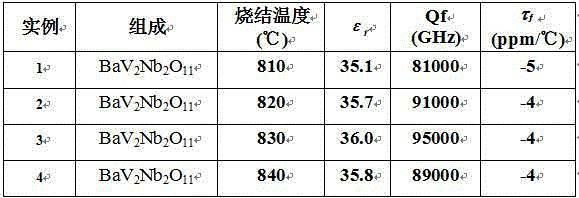

Microwave dielectric ceramic BaV2Nb2O11 capable of sintering at low temperature and preparation method thereof

InactiveCN103553613AResonant frequency temperature coefficient is smallHigh application valueSolventTemperature coefficient

The invention discloses microwave dielectric ceramic BaV2Nb2O11 capable of sintering at a low temperature and a preparation method thereof. The microwave dielectric ceramic capable of being sintered at the low temperature has the composition of BaV2Nb2O11. The preparation method comprises the following steps: (1) weighing and batching original powder of BaCO3, V2O5 and Nb2O5 with the purity over 99.9 percent according to the chemical formula of the BaV2Nb2O11; (2) mixing the raw materials of the step (1) and performing wet milling for 12 hours, wherein the solvent is distilled water; pre-sintering for 6 hours in air atmosphere at 750 DEG C after the mixture is dried; (3) adding an adhesive into the prepared powder, granulating, pressing, forming, and sintering for 4 hours in the air atmosphere at the temperature between 810 and 840 DEG C, wherein the adhesive adopts a polyvinyl alcohol solution with the mass concentration of 5 percent, and the dosage of the polyvinyl alcohol solution accounts for 3 percent of the total mass of the powder. The ceramic prepared by the invention is sintered well between 810 and 840 DEG C, has the dielectric constant between 35 and 36, the Qf (quality factor) value of between 81,000 and 95,000 GHz, and low temperature coefficient of resonance frequency, can be co-fired with an Ag electrode, and has a great application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com