Ceramic material, preparation method thereof, resonator, filter, and radio remote equipment

A cavity filter and ceramic powder technology, which is applied in the field of dielectric resonators, can solve the problems of poor dielectric properties and uneven density of microwave dielectric ceramics, and achieve the effects of good dielectric properties, stability and high dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

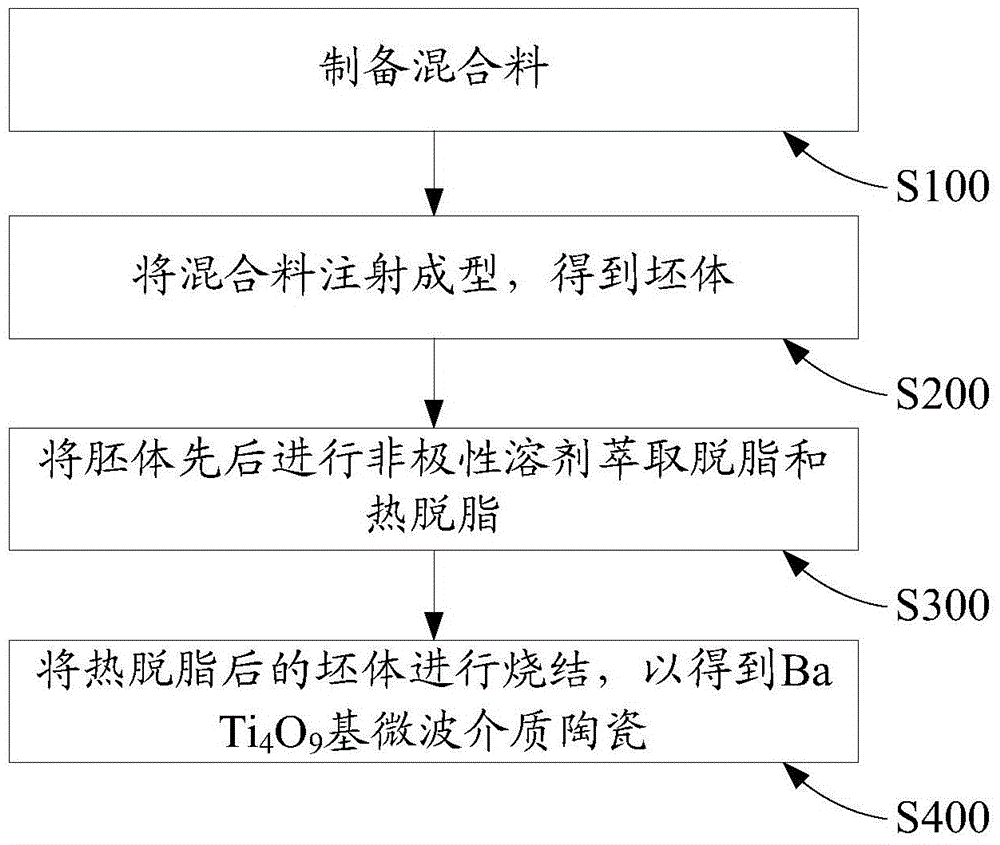

[0048] see figure 2 , figure 2 It is BaTi of the present invention 4 o 9 A schematic flow diagram of a preferred embodiment of a preparation method of a microwave-based dielectric ceramic material; the preparation method includes but is not limited to the following steps:

[0049] Step S100, preparing a mixture. The mixture contains at least BaTi 4 o 9 Base ceramic powder and organic binder.

[0050] In this example, the BaTi 4 o 9 The base ceramic powder and organic binder are mixed on a mixer until they are evenly mixed. The preferred mixing time is 4 to 8 hours to obtain an injection molding mixture. The content of different components in the mixture is related to the particle size, shape, and density of the powder. Relevant, so its mixture formula of different powders is different; For BaTi in the present invention 4 o 9 Base dielectric ceramics, in injection molding compounds, BaTi 4 o 9 The weight percentage of the base ceramic powder is preferably 76-85%, ...

Embodiment 1

[0066] The present embodiment main material formula adopts chemical formula: BaTi 4 o 9 +0.5mol%MoO 3 For the chemical composition, compare the properties of the dielectric resonators prepared by the dry pressing method and the injection molding method respectively. The dielectric properties of the main material itself in this embodiment are relative dielectric constant ε r is 37, the quality factor (Q×f) is 45000GHz, and the resonant frequency temperature coefficient τ f It is +5ppm / ℃. Preparation of BaTi by Injection Molding Process 4 o 9 The base dielectric resonator is realized through the following process steps:

[0067] (1) Mixing ceramic powder and organic binder: BaTi 4 o 9 The base ceramic powder and organic binder are evenly mixed to obtain an injection molding mixture. The content of different components in the mixture is related to the particle size, shape and density of the powder, so different powders have different mixture formulas; for BaTi 4 o 9 base...

Embodiment 2

[0078] The present embodiment main material formula adopts chemical formula: BaTi 4 o 9 +5mol%MoO 3 For the chemical composition, compare the properties of the dielectric resonators prepared by the dry pressing method and the injection molding method respectively. The dielectric properties of the main material itself in this embodiment are relative dielectric constant ε r is 36.4, the quality factor (Q×f) value is 53050GHz, and the resonant frequency temperature coefficient τ f It is +2ppm / ℃. Preparation of BaTi by Injection Molding Process 4 o 9 The base dielectric resonator is realized through the following process steps:

[0079] (1) Mixing ceramic powder and organic binder: in the injection molding mixture of this embodiment, BaTi 4 o 9 The weight percentage of the base ceramic powder is 76%, the weight percentage of the organic binder is 24%; the weight percentage of each component in the organic binder is 80% of the binder; 5% of the surfactant ; Low-melting poin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com