Niobium zinc barium-based microwave medium ceramic and preparation method thereof

A microwave dielectric ceramic, barium-based technology, applied in ceramics, inorganic insulators, etc., achieves the effects of good reproducibility, small temperature coefficient of resonant frequency, and improved preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

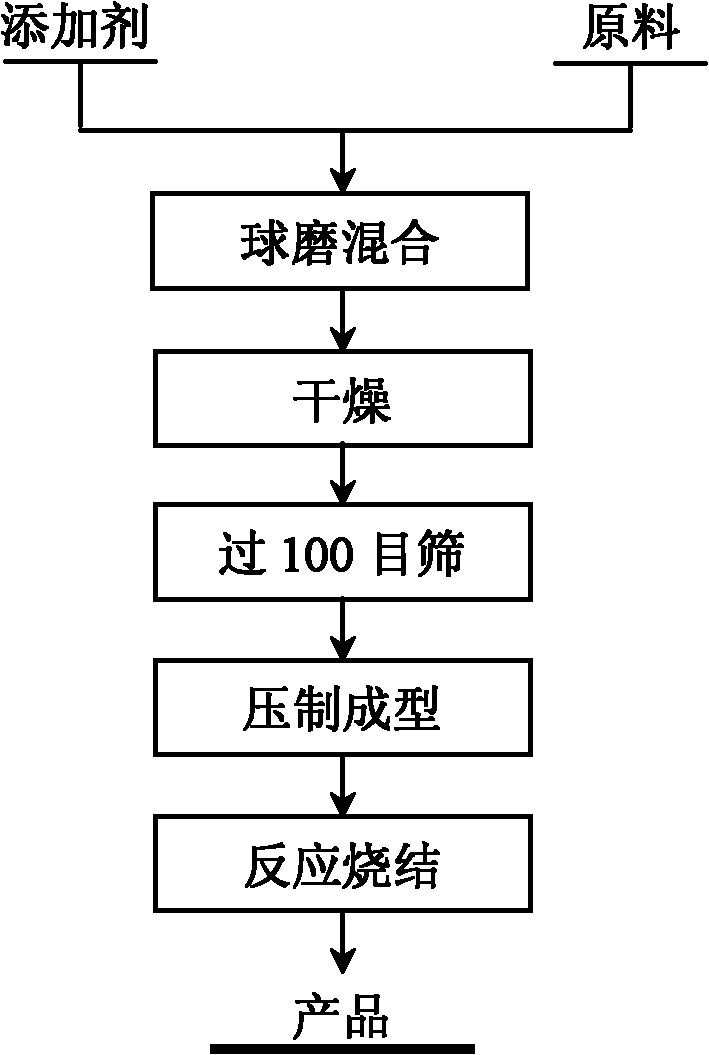

Method used

Image

Examples

Embodiment 1

[0031] Model test and analysis of the structure and performance of the prepared BZN ceramic material: use the Archimedes drainage method to measure the density of the ceramic material; use the Hakki-Colemen cylindrical dielectric resonance method to test the microwave dielectric properties (at room temperature), where the resonance The temperature coefficient of frequency is obtained in the range of 25-85°C.

[0032] The raw material is analytically pure BaCO 3 , ZnO and Nb 2 o 5 , according to the stoichiometric ratio of the target product Ba(Zn 1 / 3 Nb 2 / 3 )O 3 Weighing: Weigh BaCO 3 63.03g, ZnO8.67g and Nb 2 o 5 28.3g, and in 100g above-mentioned raw material, add following additive: 0.5gCuO, 0.5gLi 2 CO 3 , 0.5g V 2 o 5 and 1.5g ZnO-B 2 o 3 , where ZnO-B 2 o 3 The mass of the two is: 10gZnO, 90g B 2 o 3 . Put the above raw materials into a planetary ball mill, add absolute ethanol according to 1.5 times the total weight of the mixture, grind and mix for 1...

Embodiment 2

[0035] The raw material is analytically pure BaCO 3, ZnO and Nb 2 o 5 , according to the stoichiometric ratio of the target product Ba(Zn 1 / 3 Nb 2 / 3 )O 3 Weighing: Weigh BaCO 3 63.03g, ZnO8.67g and Nb 2 o 5 28.3g, and in 100g above-mentioned raw material, add following additive: 1.0gCuO, 1.0gLi 2 CO 3 , 1.0g V 2 o 5 and 2.5g ZnO-B 2 o 3 , where ZnO-B 2 o 3 The mass of the two is: 20gZnO, 80g B 2 o 3 . Put the above raw materials into a planetary ball mill, add absolute ethanol according to 1.5 times the total weight of the mixture, grind and mix for 20 hours to obtain a slurry; dry the mixed slurry at 100°C for 18 hours, pass through a 100-mesh sieve to obtain a uniform distribution Add polyvinyl alcohol for granulation, the amount of polyvinyl alcohol is 2% of the weight of the mixed powder, press it into small discs under the pressure of 100Mpa, carry out pressureless sintering in air atmosphere at 980°C for 5h, and heat up The speed is 2°C / min, and after n...

Embodiment 3

[0038] The raw material is analytically pure BaCO 3 , ZnO and Nb 2 o 5 , according to the stoichiometric ratio of the target product Ba(Zn 1 / 3 Nb 2 / 3 )O 3 Weighing: Weigh BaCO 3 63.03g, ZnO8.67g and Nb 2 o 5 28.3g, and in 100g above-mentioned raw material, add following additive: 0.5gCuO, 1.0g Li 2 CO 3 , 1.5g V 2 o 5 and 3.5g ZnO-B 2 o 3 , where ZnO-B 2 o 3 The mass of the two is: 20gZnO, 80g B 2 o 3 . Put the above raw materials into a planetary ball mill, add absolute ethanol according to 1.5 times the total weight of the mixture, grind and mix for 28 hours to obtain a slurry; dry the mixed slurry at 110°C for 20 hours, pass through a 100-mesh sieve to obtain a uniform distribution Add polyvinyl alcohol for granulation, the amount of polyvinyl alcohol is 3% of the weight of the mixed powder, press it into small discs under the pressure of 110Mpa, carry out pressureless sintering in air atmosphere at 1010°C for 3h, and heat up The speed is 2°C / min, and afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com