Patents

Literature

44results about How to "High quality factor Qf" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microwave dielectric ceramic material for multi-layer ceramic capacitor and preparing method of microwave dielectric ceramic material

The invention discloses a microwave dielectric ceramic material for a multi-layer ceramic capacitor and a preparing method of the microwave dielectric ceramic material, and belongs to the technical field of electronic ceramic. The ceramic material is prepared from calcium-doped (MgZn)TiO3 system ceramic and a composite burning improver through ball milling mixing, granulating, forming, glue discharging and sintering, wherein the main crystal phase of the calcium-doped (MgZn)TiO3 system ceramic is MgTiO3, and the composite burning improver is prepared from BaCO3, B2O3, SiO2 and one or more of Li2CO3, Nb2O5 and Nd2O3. The prepared ceramic material has the advantages that a medium dielectric constant is achieved, sintering can be carried out at the medium temperature, a high Qf value is achieved, and the frequency temperature coefficient is stable. The preparing process is environmentally friendly and free of pollution, and the ceramic material can be used at the microwave frequency band of 300 M-300 GHz, can be widely applied to filters, oscillators and other microwave devices, and is especially suitable for the multi-layer ceramic capacitor.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

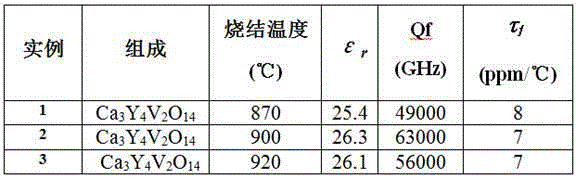

Low-temperature sinterable microwave dielectric ceramic Ca3Y4V2O14 having low dielectric constant

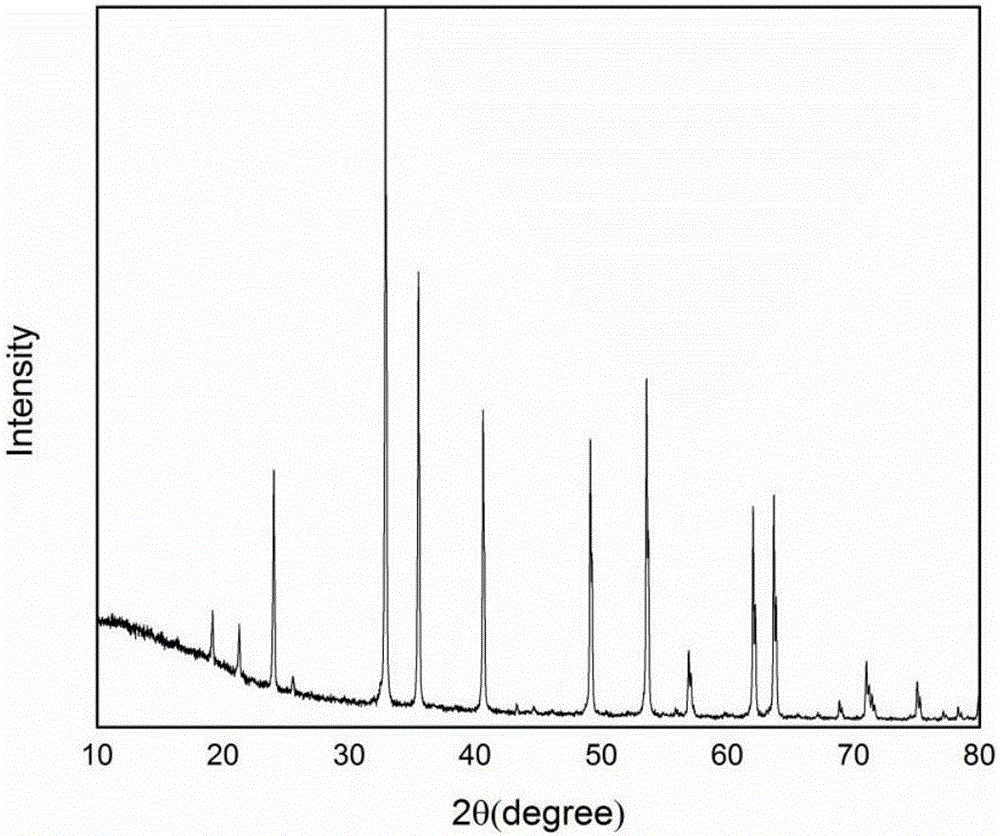

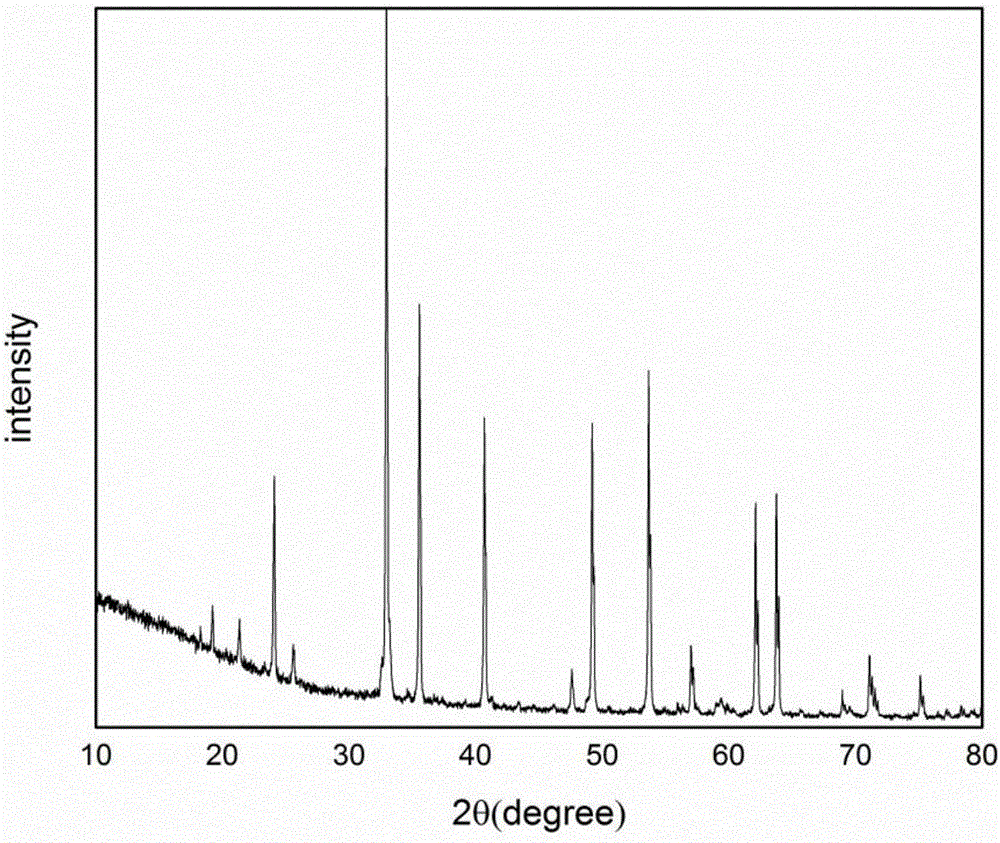

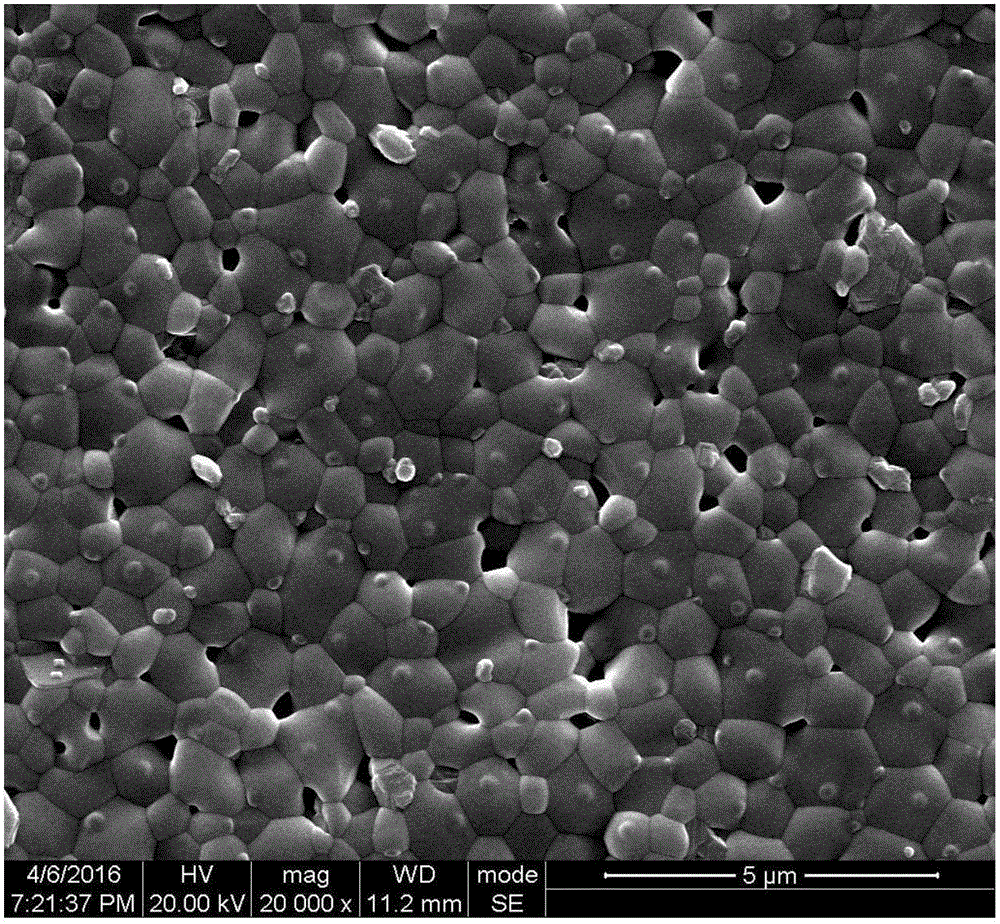

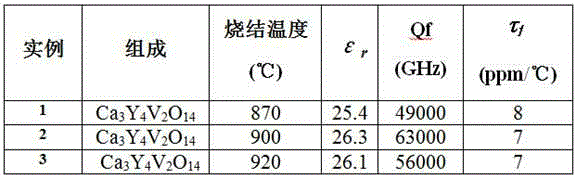

The invention discloses low-temperature sinterable temperature-stable type microwave dielectric ceramic Ca3Y4V2O14 having a low dielectric constant and a preparing method thereof. The method includes: (1) weighing original powder having purity higher than 99.9% (that is a weight percentage) of CaCO3, Y2O3 and V2O5 according to constitution of the Ca3Y4V2O14 and blending; (2) subjecting the raw materials in the step (1) to wet ball milling and mixing for 12 h, with a ball milling medium being distilled water, drying, and pre-sintering at 820 DEG C in an atmosphere of air for 6 h; and (3) adding an adhesive into the powder prepared in the step (2), granulating, performing compression moulding, and sintering at 870-920 DEG C in the atmosphere of air for 4 h, wherein the adhesive adopts a polyvinyl alcohol solution having a mass concentration of 5%, and the adding amount of the polyvinyl alcohol is 3% of the total mass of the powder. The ceramic prepared by the method is good in sintering performance at 870-920 DEG C, the dielectric constant of the ceramic is 25.4-26.3, the quality factor Qf of the ceramic is 49000-63000 GHz, and the temperature coefficient of resonance frequency of the ceramic is small. The ceramic has high application value in the industry.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

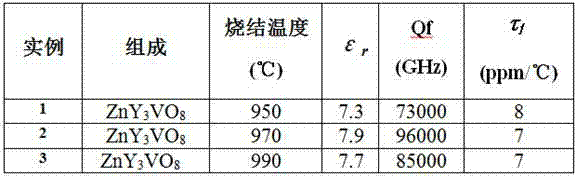

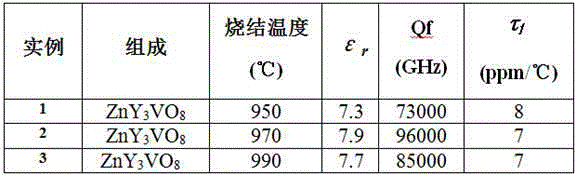

Microwave dielectric ceramic ZnY3VO8 with ultralow dielectric constant

The invention discloses a low-temperature sintering temperature-stable microwave dielectric ceramic ZnY3VO8 with an ultralow dielectric constant and a preparation method of the microwave dielectric ceramic ZnY3VO8. The preparation method comprises the following steps of (1) weighing initial powder of ZnO, Y2O3 and V2O5 according to the composition of ZnY3VO8, and proportioning, wherein the purities of ZnO, Y2O3 and V2O5 are larger than 99.9wt%; (2) carrying out wet-type ball milling on the raw materials in the step (1) by virtue of distilled water serving as a ball milling medium, mixing for 12 hours, and presintering in an atmospheric environment with the temperature of 900 DEG C for 6 hours after drying; and (3) adding an adhesive in the powder prepared in the step (2), granulating, then, carrying out compression molding, and finally, sintering in an atmospheric environment with the temperature of 950-990 DEG C for 4 hours, wherein the adhesive is a polyvinyl alcohol solution with the mass concentration of 5%, and the additive amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. The ceramic prepared by using the preparation method can be favorably sintered at the temperature of 950-990 DEG C, has the dielectric constant of 7.3-7.9 and is high in quality factor Qf value up to 73000-96000GHz and small in temperature coefficient of resonance frequency so as to have an extremely high application value in industry.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

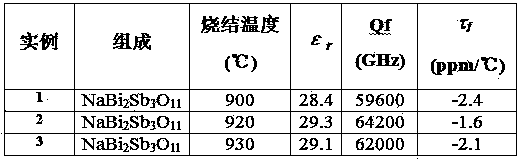

Low dielectric constant microwave dielectric ceramic NaBi2Sb3O11 capable of being sintered at low temperatures

The invention discloses a low dielectric constant microwave dielectric ceramic NaBi2Sb3O11 capable of being sintered at low temperatures and a preparation method of the ceramic. The preparation method comprises the following steps: (1) weighing and dosing original powder of Na2CO3, Bi2O3 and Sb2O5 with the purities which are over (99.9wt%) based on composition of NaBi2Sb3O11; (2) carrying out wet type ball-mill mixing on the raw material for 12 hours, wherein the ball-milling medium is distilled water, and pre-sintering for 6 hours in atmosphere at 850 DEG C after being dried; and (3) adding an adhesive into the power prepared by the step (2) and granulating, then compression-moulding, and finally sintering for 4 hours in atmosphere at 900-930 DEG C, wherein the adhesive is a 5% polyvinyl alcohol solution, the addition of polyvinyl alcohol accounts for 3% of total weight of the powder. The ceramic disclosed by the invention is well sintered at 900-930 DEG C, and the dielectric constant reaches 28.4-29.3, the quality factor Qf value reaches 59600-64200GHz, and the temperature coefficient of resonance frequency is small, so that the ceramic has extremely huge application value in industry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Low-temperature sintering available microwave dielectric ceramic Li4P2O7 and preparation method thereof

The invention discloses an application of a phosphor-containing compound Li4P2O7 serving as a low-temperature sintering available microwave dielectric ceramic. The microwave dielectric ceramic is prepared by the following steps: (1) preparing original powders of 99.9% Li2CO3 and 99.9% NH4H2PO4 according to the chemical formula of Li4P2O7; (2) mixing the raw material in the step (1) and carrying out wet ball milling for 12 hours, baking, and then pre-sintering for 6 hours in the atmosphere at 820 DEG C, wherein the ball milling medium is ethanol; and (3) adding adhesive into the powder prepared in the step (2), granulating, pressing to mold, and finally sintering for 4 hours in the atmosphere at 880-900 DEG C, wherein the adhesive is a 5% polyvinyl alcohol solution, and accounts for 3 percent of the total mass of the powder. The ceramic prepared by the method can be excellently sintered at 880-900 DEGC, the dielectric constant is 13-14, the quality factor Qf value is up to 67,000-79,000GHz; the temperature coefficient of resonance frequency is small, and the microwave dielectric ceramic has a great application value in industry.

Owner:苏州弘吴科技中介服务有限公司

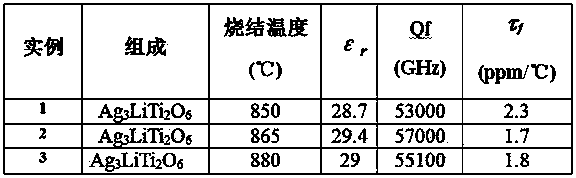

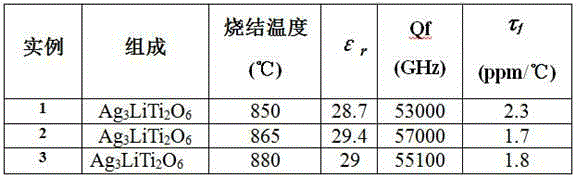

Low-dielectric-constant microwave dielectric ceramic Ag3LiTi2O6 with near-zero resonance frequency temperature coefficient

ActiveCN104291807AGood temperature stabilityHigh application valueTemperature coefficientLow-k dielectric

The invention discloses a low-dielectric-constant microwave dielectric ceramic Ag3LiTi2O6 which can be subjected to low temperature sintering and has a near-zero resonance frequency temperature coefficient and a preparation method thereof. The preparation method comprises the following steps: weighing and batching original powder of AgNO3, Li2CO3 and TiO2 of which the purity is more than 99.9% (in percentage by weight) according to the composition of Ag3LiTi2O6; (2) performing wet ball milling and mixing on raw materials in the step (1) for 12 hours by using distilled water as a ball milling medium, drying, and then pre-sintering for 6 hours in an atmosphere at 800 DEG C; and (3) adding a binding agent into powder prepared in the step (2) and pelletizing, then performing compression molding, and finally sintering for 4 hours in the atmosphere at 850-880 DEG C, wherein the binding agent adopts a polyvinyl alcohol solution with the mass concentration of 5%, and the addition amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. The ceramic prepared by using the method disclosed by the invention is good in sintering performance at 850-880 DEG C, ensures that the dielectric constant reaches 28.7-29.4, the quality factor (Qf) value reaches 53000-57000GHz, and the temperature coefficient of resonance frequency is close to zero, and has extremely large application values in industry.

Owner:阜阳申邦新材料技术有限公司

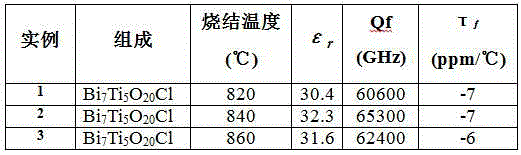

Temperature-stable type low-dielectric-constant microwave dielectric ceramic and preparation method thereof

ActiveCN104446448AImprove temperature stabilityHigh quality factor QfAir atmosphereCeramic sintering

The invention discloses a temperature-stable type low-dielectric-constant microwave dielectric ceramic Bi7Ti5O20C1and a preparation method thereof. The preparation method comprises the following steps: (1) weighing and preparing original powder of Bi2O3, TiO2 and BiOC1 with the purity of 99.9% (in percentage by weight) according to the proportioning of Bi7Ti5O20C1; (2) performing wet type ball-milling mixing on the raw materials in the step (1) for 12 hours, drying, and pre-sintering for 6 hours in the air atmosphere at 770 DEG C, wherein absolute ethyl alcohol is adopted as the ball-milling medium; (3) adding an adhesive into the powder prepared in the step (2), pelleting, pressing for forming, and finally sintering for 4 hours in the air atmosphere at 820-860 DEG C, wherein the adhesive is a polyvinyl alcohol solution with the mass concentration of 5%, and the polyvinyl alcohol accounts for 3% of the total mass of the powder. The ceramic disclosed by the invention is good in sintering property and has high application values in industry as the dielectric constant of the ceramic is up to 30.4-32.3, the quality factor Qf value of the ceramic is as high as 60,600-65,300 GHz, and the temperature coefficient of resonance frequency is small.

Owner:TONGXIANG BEITE TECH CO LTD

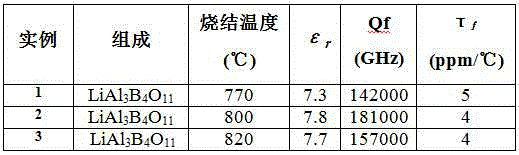

Temperature-stable microwave dielectric ceramics with ultralow dielectric constant and preparation method thereof

ActiveCN104446379AImprove temperature stabilityHigh quality factor QfAir atmosphereCeramic sintering

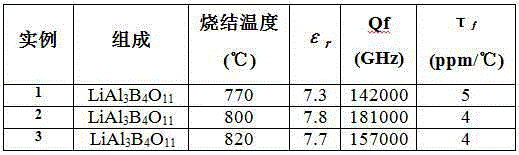

The invention discloses temperature-stable microwave dielectric ceramics LiAl3B4O11 with ultralow dielectric constant and a preparation method thereof. The preparation method comprises the steps: (1) weighing and dosing the raw material powder of Li2CO3, Al2O3 and H3BO3 with purity of more than 99.9% (weight percentage) according to the composition of the LiAl3B4O11; (2) ball-milling and mixing the raw materials in the step (1) for 12 hours in a wet method, utilizing absolute ethyl alcohol as the ball-milling medium, drying and then pre-burning for 6 hours in the air atmosphere of 700 degrees centigrade; (3) adding an adhesive to the powder prepared in the step (2), granulating, pressing and molding, and finally burning for 4 hours in the air atmosphere of 820 degrees centigrade, wherein the mass concentration of the adhesive is polyving akohol solution of 5% and the dosage of the polyving akohol accounts for 4% that of the total mass of the poweder. The prepared ceramics are sintered well and the dielectric constant is up to 7.3-7.8; the quality factor Qf value is up to 142,000-181,000GHz; the temperature coefficient of resonance frequency is small and the ceramics have great application value in industry.

Owner:江苏开创检测技术有限公司

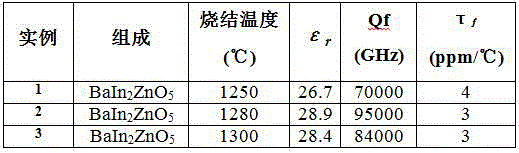

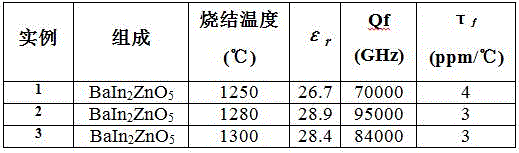

Low-dielectric-constant microwave dielectric ceramic BaIn2ZnO5 and preparation method thereof

The invention discloses temperature-stable type low-dielectric-constant microwave dielectric ceramic BaIn2ZnO5 and a preparation method thereof. The preparation method comprises the following steps: (1) weighing and blending original powder of BaCO3, In2O3 and ZnO of which the purity is 99.9% (percentage by weight) according to composition of BaIn2ZnO5; (2) performing wet ball-milling mixing on the raw materials obtained in the step (1) for 12 hours with distilled water as a ball milling medium, drying, and then pre-burning for 6 hours in a 1200 DEG C atmosphere; and (3) adding a bonding agent into the powder prepared in the step (2), pelleting, then performing press molding, and finally sintering for 4 hours in a 1250-1300 DEG C atmosphere, wherein the bonding agent is a polyvinyl alcohol solution with the mass concentration of 5%, and the added amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. The ceramic prepared by the method disclosed by the invention is good in sintering property, the dielectric constant reaches 26.7-28.9, the quality factor Qf reaches 70000-95000 GHz, and the temperature coefficient of resonance frequency is small, so that the ceramic has great application values in industry.

Owner:临泉县非凡装饰工程有限公司

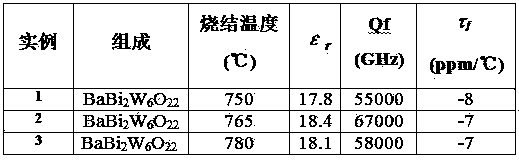

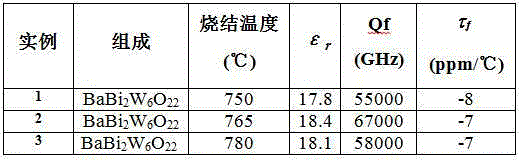

Temperature stable ultra-low dielectric constant microwave dielectric ceramic BaBi2W6O22

ActiveCN104261830ASmall temperature coefficientGood temperature stabilityTemperature coefficientLow-k dielectric

The invention discloses temperature stable ultra-low dielectric constant microwave dielectric ceramic BaBi2W6O22 which can be sintered at low temperature and a preparation method thereof. The method comprises the following steps: (1) weighing the following original powder with purity of over 99.9wt%: BaCO3, Bi2O3 and WO3 according to the composition of BaBi2W6O22; (2) mixing the raw materials in the step (1) by wet grinding for 12 hours by adopting distilled water as the grinding medium, baking, and pre-burning in the atmosphere at 700 DEG C for 6 hours; (3) adding a binder into the powder prepared in the step (2), granulating, pressing and forming, and sintering in the atmosphere at 750-780 DEG C for 4 hours, wherein the binder is prepared from polyvinyl alcohol solution with mass concentration of 5 percent, and the additive amount of polyvinyl alcohol is 3 percent of the total mass of the powder. The ceramic prepared by the method is well sintered at 750-780 DEG C, has the dielectric constant being 17.8-18.4 and the quality factor Qf value being up to 55000-67000GHz, has a small temperature coefficient of resonance frequency, and has a great application value in the industry.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

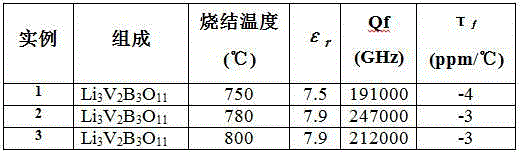

Ultralow-loss microwave dielectric ceramic Li3V2B3O11 and preparation method thereof

The invention discloses temperature-stable type ultralow-loss microwave dielectric ceramic Li3V2B3O11 and a preparation method thereof. The preparation method comprises steps as follows: (1), raw material powder of Li2CO3, V2O5 and H3BO3 with the purity of higher than 99.9% in percentage by weight is weighed and proportioned according to composition of Li3V2B3O11; (2), the raw material powder of the step (1) is subjected to wet type ball milling and mixing for 12 h, the ball milling medium adopts absolute ethyl alcohol, and the raw material powder is dried and pre-sintered in the air atmosphere at the temperature of 700 DEG C for 6 h; and (3), after a binding agent is added to the powder prepared in the step (2) and granulation is performed, the powder is subjected to compression forming and sintered in the air atmosphere at the temperature of 750-800 DEG C for 4 h finally, the binding agent adopts a polyvinyl alcohol solution with the mass concentration of 5%, and the adding amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. The prepared ceramic is sintered well, the dielectric constant reaches 7.5-7.9, the qualify factor (Qf) value is up to 191,000-247,000 GHz, the temperature coefficient of resonance frequency is small, and the prepared ceramic has great industrial application value.

Owner:GUANGXI NEW FUTURE INFORMATION IND

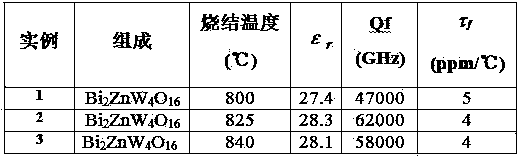

Microwave dielectric ceramic Bi2ZnW4O16 with low dielectric constant and capacity of low temperature sintering

The invention discloses a temperature stabilization type microwave dielectric ceramic Bi2ZnW4O16 with low dielectric constant and capacity of low temperature sintering as well as a preparation method thereof. The method comprises the steps as follows: (1), original powder of Bi2O3, ZnO and WO3 with the purity higher than 99.9% in percentage by weight is weighed and prepared according to composition of Bi2ZnW4O16; (2), raw materials in the step (1) are subjected to wet type ball milling and mixing for 12 hours, the ball milling medium is distilled water, and the mixture is pre-sintered for 6 hours in the air atmosphere at the temperature of 750 DEG C after dried; and (3), the powder prepared in the step (2) is added with a binding agent, pelletized, subjected to compression moulding and sintered for 4 hours in the air atmosphere at the temperature of 800 DEG C-840 DEG C finally, the binding agent adopts a polyvinyl alcohol solution with the mass concentration of 5%, and the adding amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. The prepared ceramic is well sintered at the temperature of 800 DEG C-840 DEG C, the dielectric constant reaches 27.4-28.3, the value of quality factor (Qf) is up to 47,000-62,000 GHz, the temperature coefficient of resonance frequency is small, and the ceramic has a great industrial application value.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

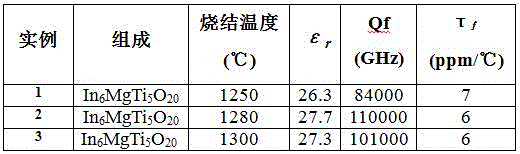

Low dielectric constant microwave dielectric ceramic in6mgti5o20 and preparation method thereof

InactiveCN104446439BReduce the temperatureImprove temperature stabilityAir atmosphereCeramic sintering

The invention discloses temperature stable type dielectric ceramic In6MgTi5O20 with a low dielectric constant and a preparation method of the temperature stable type microwave dielectric ceramic In6MgTi5O20 with the low dielectric constant. The preparation method comprises the following steps: (1) weighing and batching original powder of In2O3 with purity of 99.9wt%, MgO and TiO2 according to the composition of the In6MgTi5O20; (2) wet ball-milling and mixing the raw materials in the step (1) for 12 hours, and pre-sintering for 6 hours in an air atmosphere of 1200 DEG C after drying, wherein the ball-milling medium is distilled water; and (3) adding a binder into the powder prepared in the step (2) and pelletizing, then pressing and molding and finally sintering in the air atmosphere of 1250-1300 DEG C for 4 hours, wherein a 5wt% polyvinyl alcohol solution is adopted as the binder, the addition amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. The dielectric ceramic In6MgTi5O20 with the low dielectric constant prepared by the preparation method disclosed by the invention is good in sintering performance, has a dielectric constant of 26.3-27.7, a quality factor Qf value of 84000-110000GHz, a small resonant frequency coefficient, and a great application value in the industry.

Owner:临泉县非凡广告传媒有限责任公司

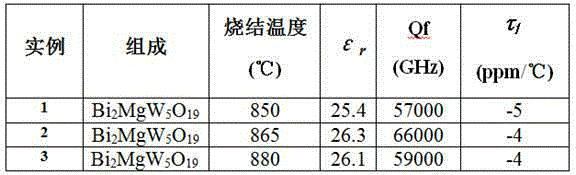

Low dielectric constant microwave dielectric ceramic bi2mgw5o19 that can be sintered at low temperature

The invention discloses low-temperature sinterable temperature-stable microwave dielectric ceramic Bi2MgW5O19 with a low dielectric constant, and a preparation method of the microwave dielectric ceramic Bi2MgW5O19. The method comprises the following steps: (1) weighing and burdening original powder of Bi2O3, MgO and WO3 with the purities being over 99.9% (mass percent) according to the components of Bi2MgW5O19; (2) carrying out wet ball-milling and mixing on the raw materials in the step (1) for 12 hours, wherein the ball-milling medium is distilled water, drying and then presintering in atmosphere at 800 DEG C for 6 hours; and (3) adding a binder to the powder prepared in the step (2), pelletizing, pressing and molding, and finally sintering in atmosphere at 850-880 DEG C for 4 hours, wherein the binder is a polyvinyl alcohol solution with the mass concentration being 5%, and the adding amount of polyvinyl alcohol accounts for 3% of total mass of the powder. The ceramic prepared by the method is good in sintering property at 850-880 DEG C, the dielectric constant reaches 25.4%-26.3%, the quality factor Qf value can reach 57,000-66,000GHz, the temperature coefficient of the resonance frequency is small, and the microwave dielectric ceramic Bi2MgW5O19 has great application value in industry.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

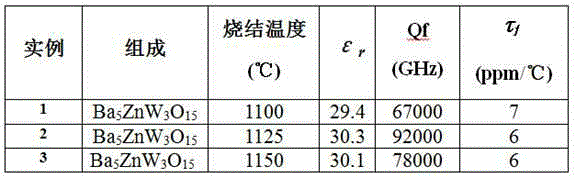

Low dielectric constant microwave dielectric ceramic ba5znw3o15 which can be sintered at low temperature

The invention discloses a temperature stabilization type microwave dielectric ceramic Ba5ZnW3O15 with low dielectric constant and a preparation method thereof. The method comprises the steps as follows: (1), original powder of BaCO3, ZnO and WO3 with the purity higher than 99.9% in percentage by weight is weighed and prepared according to composition of Ba5ZnW3O15; (2), raw materials in the step (1) are subjected to wet type ball milling and mixing for 12 hours, the ball milling medium is distilled water, and the mixture is pre-sintered for 6 hours in the air atmosphere at the temperature of 1,050 DEG C after dried; and (3), the powder prepared in the step (2) is added with a binding agent, pelletized, subjected to compression moulding and sintered for 4 hours in the air atmosphere at the temperature of 1,100 DEG C-1,150 DEG C finally, the binding agent adopts a polyvinyl alcohol solution with the mass concentration of 5%, and the adding amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. The prepared ceramic is well sintered at the temperature of 1,100 DEG C-1,150 DEG C, the dielectric constant reaches 29.4-30.3, the value of quality factor (Qf) is up to 67,000-92,000 GHz, the temperature coefficient of resonance frequency is small, and the ceramic has a great industrial application value.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

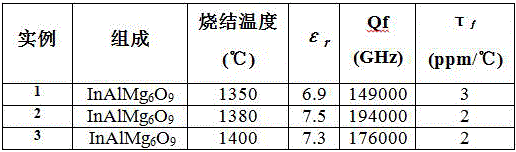

Ultra-low dielectric constant microwave dielectric ceramic inalmg 6 o 9 and its preparation method

ActiveCN104478412BImprove temperature stabilityHigh quality factor QfCeramic sinteringCompression molding

The invention discloses temperature-stable type ultralow-dielectric-constant dielectric ceramic InAlMg6O9 and a preparation method thereof. The preparation method comprises: (1) weighing original powders of In2O3, Al2O3 and MgO with the purity of 99.9 wt% or more according to the formula of InAlMg6O9 and proportioning; (2) performing wet-type ball milling mixing on the raw materials of the step (1) for 12 h by selecting distilled water as a ball milling medium, baking and pre-burning at 1300 DEG C in atmosphere for 6 h; and (3) adding a binder into the powder prepared in the step (2) and granulating, then performing compression molding, and finally sintering at 1350-1400 DEG C in atmosphere for 4 h, wherein the binder employs a polyvinyl alcohol solution with the mass concentration of 5% and the addition amount of polyvinyl alcohol is 3% by mass of the total powder. The prepared ceramic has good sintering, has the dielectric constant up to 6.9-7.5, has the quality factor Qf up to 149000-194000 GHz, has a small resonant-frequency temperature coefficient, and has extremely great application value in industry.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

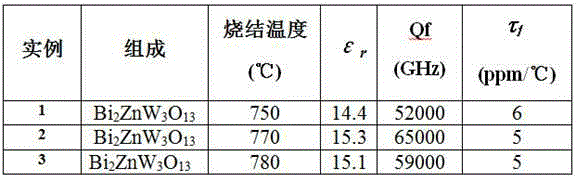

Low-temperature sinterable ultra-low dielectric constant microwave dielectric ceramic bi2znw3o13

The invention discloses a low-temperature-sintering stable-temperature ultralow-dielectric-constant microwave dielectric ceramic Bi2ZnW3O13 and a preparation method thereof. The preparation method comprises the following steps: (1) weighing and proportioning Bi2O3, ZnO and WO3 original powders with the purity of higher than 99.9 wt% according to the composition of the Bi2ZnW3O13; (2) carrying out wet ball milling mixing on the raw materials in the step (1) for 12 hours by using distilled water as a ball milling medium, drying, and presintering in a 700 DEG C atmospheric atmosphere for 6 hours; and (3) adding an adhesive into the powder prepared in the step (2), granulating, compacting, and finally, sintering in a 750-780 DEG C atmospheric atmosphere for 4 hours, wherein the adhesive adopts a 5 wt% polyvinyl alcohol solution, and the addition amount of the polyvinyl alcohol is 3% of the total mass of the powder. The ceramic has favorable sintering property at 750-780 DEG C, the dielectric constant reaches 14.4-15.3, the quality factor Qf value is up to 52000-65000 GHz, the temperature coefficient of resonance frequency is small, and the ceramic has great application value in industry.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

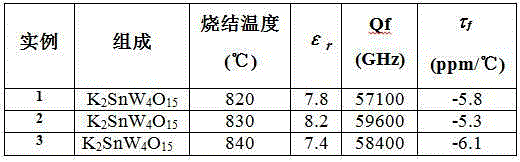

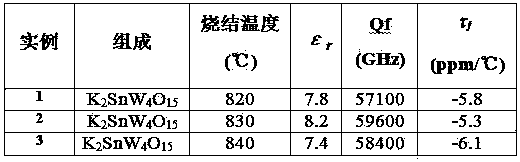

Ultra-low dielectric constant microwave dielectric ceramic k2snw4o15

The invention discloses a microwave dielectric ceramic K2SnW4O15 with an ultralow dielectric constant and a near-zero resonance frequency temperature coefficient and a preparation method of the microwave dielectric ceramic. The preparation method comprises the following steps: (1) weighing and burdening original powder of K2CO3, SnO2 and WO3 with the purity more than 99.9% (in percentage by weight) according to constituents of K2SnW4O15; (2) using a wet ball mill to mix the raw materials in the step (1) for 12 hours, adding distilled water as a ball milling medium in the ball mill, after drying, preburning the dried substance in the atmosphere at 750 DEG C for 6 hous; (3) adding a binding agent to the powder prepared in the step (2), pelletizing, carrying out compression molding on the pellets, and finally sintering the molded product for 4 hours in the atmosphere at 820-840 DEG C, wherein the binding agent is a polyvinyl alcohol solution with a mass concentration of 5%; the addition amount of the polyvinyl alcohol is 3% of the total mass of the powder. The ceramic prepared by the invention is well sintered at 820-840 DEG C; the dielectric constant of the ceramic is up to 7.4-8.2, the Qf (quality factor) is highly up to 57100-59600 GHz; the resonance frequency temperature coefficient is close to zero; the ceramic has the great application value in the industry.

Owner:阜阳申邦新材料技术有限公司

Low dielectric constant microwave dielectric ceramic ag3liti2o6 with near zero resonant frequency temperature coefficient

The invention discloses a low-dielectric-constant microwave dielectric ceramic Ag3LiTi2O6 which can be subjected to low temperature sintering and has a near-zero resonance frequency temperature coefficient and a preparation method thereof. The preparation method comprises the following steps: weighing and batching original powder of AgNO3, Li2CO3 and TiO2 of which the purity is more than 99.9% (in percentage by weight) according to the composition of Ag3LiTi2O6; (2) performing wet ball milling and mixing on raw materials in the step (1) for 12 hours by using distilled water as a ball milling medium, drying, and then pre-sintering for 6 hours in an atmosphere at 800 DEG C; and (3) adding a binding agent into powder prepared in the step (2) and pelletizing, then performing compression molding, and finally sintering for 4 hours in the atmosphere at 850-880 DEG C, wherein the binding agent adopts a polyvinyl alcohol solution with the mass concentration of 5%, and the addition amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. The ceramic prepared by using the method disclosed by the invention is good in sintering performance at 850-880 DEG C, ensures that the dielectric constant reaches 28.7-29.4, the quality factor (Qf) value reaches 53000-57000GHz, and the temperature coefficient of resonance frequency is close to zero, and has extremely large application values in industry.

Owner:阜阳申邦新材料技术有限公司

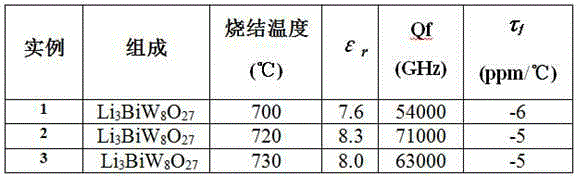

Low-temperature sinterable ultra-low dielectric constant microwave dielectric ceramic li3biw8o27

The invention discloses ultralow dielectric constant microwave dielectric ceramic Li3BiW8O27 capable of performing low-temperature sintering and a preparation method of the ultralow dielectric constant microwave dielectric ceramic Li3BiW8O27. The preparation method comprises the following steps: (1) weighing and dosing the original powder, having the purity more than 99.9wt%, of Li2CO3, Bi2O3 and WO3 according to the composition of Li3BiW8O27; (2) performing wet ball-milling on the raw material in the step (1), mixing for 12 hours, wherein the ball-milling medium is distilled water, and pre-sintering in the atmosphere at the temperature of 650 DEG C after drying; and (3) adding an adhesive into the powder prepared in the step (2), granulating, performing compression molding, and finally sintering in the atmosphere at the temperature of 700-730 DEG C, wherein the adhesive refers to 5% polyvinyl alcohol solution, and the addition amount of polyvinyl alcohol accounts for 3 percent of the total mass of the powder. The ceramic prepared by the invention has high sintering property at the temperature of 700-730 DEG C and has extremely high application values in the industry, the dielectric constant of the ceramic is 7.6-8.3, the quality factor Qf value reaches 54000-71000GHz, and the resonant frequency temperature coefficient is low.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

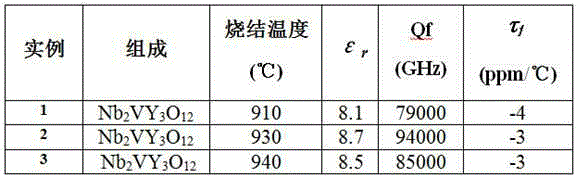

Temperature stable ultra-low dielectric constant microwave dielectric ceramic nb2vy3o12

The invention discloses a temperature stable type microwave dielectric ceramic Nb2VY3O12 with an ultralow dielectric constant as well as a preparation method thereof. The preparation method comprises the following steps: (1) weighing and blending original powder of Nb2O5, V2O5 and Y2O3 with the purity over 99.9% (weight percentage) according to composition of Nb2VY3O12; (2) mixing the raw material in the step (1) for 12 hours by a wet ball-mill, wherein the ball-milling medium is distilled water; and drying and pre-calcining for 6 hours in the atmosphere of 850 DEG C; and (3) adding an adhesive into the powder prepared in the step (2) and granulating, then compressing and moulding, and finally, sintering for 4 hours in the atmosphere of 910-940 DEG C; and the adhesive is a 5% polyvinyl alcohol solution, and the additive amount of polyvinyl alcohol accounts for 3% of total weight of the powder. The ceramic prepared by the invention is well sintered at 910-940 DEG C, the dielectric constant reaches 8.1-8.7, the quality factor Qf value reaches 79000-94000GHz, and the temperature coefficient of resonance frequency is small. The temperature stable type microwave dielectric ceramic Nb2VY3O12 has huge application value industrially.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

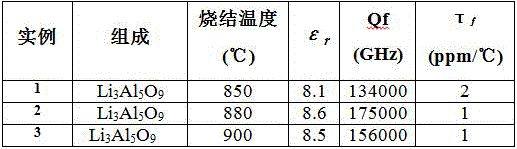

A kind of ultra-low dielectric constant microwave dielectric ceramic with nearly zero resonant frequency temperature coefficient and preparation method thereof

The invention discloses a low-temperature sintered ultralow dielectric constant microwave dielectric ceramic Li3Al5O9 with a near-zero temperature coefficient of resonance frequency and a preparation method of the microwave dielectric ceramic. The preparation method comprises the following steps: (1), weighing and dosing original powder of Li2CO3 and Al2O3 with the purity over 99.9% (percentage by weight); (2), wet ball-milling and mixing the raw material in the step (1), wherein the ball-milling medium is anhydrous ethanol, and pre-sintering for 6 hours in an atmosphere at 800 DEG C after drying; (3), adding a binder into the powder prepared in the step (2) and granulating, then pressing and molding, and finally sintering for 4 hours in an atmosphere at 850-900 DEG C, wherein the binder is a polyvinyl alcohol solution with mass concentration of 5% and the addition of polyvinyl alcohol is 3% of the total mass of the powder. The ceramic prepared by the invention is sintered well, the dielectric constant reaches 8.1-8.6, the quality factor value Qf reaches up to 134000-175000GHz, the temperature coefficient of resonance frequency is near-zero, and the microwave dielectric ceramic has an extremely huge application value industrially.

Owner:江苏开创检测技术有限公司

Temperature stable ultra-low dielectric constant microwave dielectric ceramic babi2w6o22

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Ultra-low dielectric constant microwave dielectric ceramic zny3vo8

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Microwave dielectric ceramic K2SnW4O15 with ultralow dielectric constant

The invention discloses a microwave dielectric ceramic K2SnW4O15 with an ultralow dielectric constant and a near-zero resonance frequency temperature coefficient and a preparation method of the microwave dielectric ceramic. The preparation method comprises the following steps: (1) weighing and burdening original powder of K2CO3, SnO2 and WO3 with the purity more than 99.9% (in percentage by weight) according to constituents of K2SnW4O15; (2) using a wet ball mill to mix the raw materials in the step (1) for 12 hours, adding distilled water as a ball milling medium in the ball mill, after drying, preburning the dried substance in the atmosphere at 750 DEG C for 6 hous; (3) adding a binding agent to the powder prepared in the step (2), pelletizing, carrying out compression molding on the pellets, and finally sintering the molded product for 4 hours in the atmosphere at 820-840 DEG C, wherein the binding agent is a polyvinyl alcohol solution with a mass concentration of 5%; the addition amount of the polyvinyl alcohol is 3% of the total mass of the powder. The ceramic prepared by the invention is well sintered at 820-840 DEG C; the dielectric constant of the ceramic is up to 7.4-8.2, the Qf (quality factor) is highly up to 57100-59600 GHz; the resonance frequency temperature coefficient is close to zero; the ceramic has the great application value in the industry.

Owner:阜阳申邦新材料技术有限公司

A kind of low dielectric constant microwave dielectric ceramic bain2zno5 and preparation method thereof

The invention discloses temperature-stable type low-dielectric-constant microwave dielectric ceramic BaIn2ZnO5 and a preparation method thereof. The preparation method comprises the following steps: (1) weighing and blending original powder of BaCO3, In2O3 and ZnO of which the purity is 99.9% (percentage by weight) according to composition of BaIn2ZnO5; (2) performing wet ball-milling mixing on the raw materials obtained in the step (1) for 12 hours with distilled water as a ball milling medium, drying, and then pre-burning for 6 hours in a 1200 DEG C atmosphere; and (3) adding a bonding agent into the powder prepared in the step (2), pelleting, then performing press molding, and finally sintering for 4 hours in a 1250-1300 DEG C atmosphere, wherein the bonding agent is a polyvinyl alcohol solution with the mass concentration of 5%, and the added amount of polyvinyl alcohol accounts for 3% of the total mass of the powder. The ceramic prepared by the method disclosed by the invention is good in sintering property, the dielectric constant reaches 26.7-28.9, the quality factor Qf reaches 70000-95000 GHz, and the temperature coefficient of resonance frequency is small, so that the ceramic has great application values in industry.

Owner:临泉县非凡装饰工程有限公司

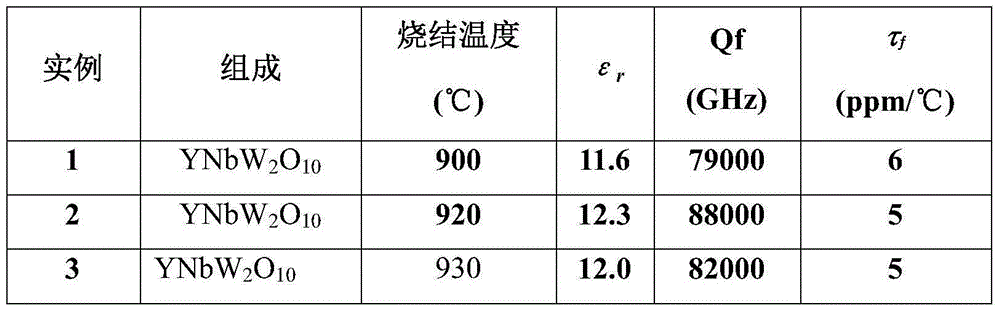

Temperature stable ultra-low dielectric constant microwave dielectric ceramic and preparation method thereof

The invention discloses a temperature stable ultralow dielectric constant microwave dielectric ceramic YNbW2O10 and a preparation method thereof. The preparation method comprises the following steps: (1) weighing and proportioning original powder of Y2O3, Nb2O5 and WO3 with the purity being over 99.9% (in percentage by weight) according to composition of YNbW2O10; (2) mixing the raw materials for 12h by wet ball-milling, wherein the ball-milling medium is distilled water, and drying and pre-sintering for 6 hours in an atmosphere of 850 DEG C; and (3) adding an adhesive into the powder prepared in the step (2) and granulating, then, carrying out pressure moulding, and finally, sintering in the atmosphere at of 900-930 DEG C for 4 hours, wherein the adhesive is a 5% polyvinyl alcohol solution in mass concentration, and the addition of polyvinyl alcohol accounts for 3% of total weight of powder. The ceramic prepared by the method is well sintered at 900-930 DEG C, and the dielectric constant reaches 11.6-12.3, the quality factor Qf value reaches up to 79000-88000GHz, and the temperature coefficient of resonance frequency is small. The ceramic has an extremely huge application value in industry.

Owner:宜都市博通电子有限责任公司

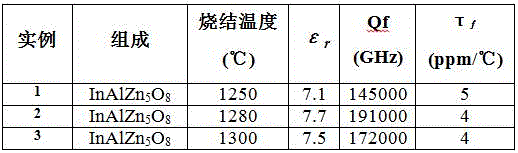

Ultra-low dielectric constant microwave dielectric ceramic inalzn 5 o 8 and its preparation method

The invention discloses a temperature stabilized microwave dielectric ceramic InAlZn5O8 with an ultralow dielectric constant and a preparation method thereof. The preparation method includes the following steps: (1) weighing and batching original powder of In2O3, Al2O3 and ZnO with the purity of 99.9% (weight percentage) above according to the composition of InAlZn5O8; (2) wet type balling-milling and mixing the raw materials in step (1) for 12 hours, taking distilled water as the ball-milling medium, drying the mixture and pre-burning the mixture for 6 hours at the atmosphere of 1200 DEG C; (3), adding a binder in the powder prepared in the step (2) and pelleting, pressing and forming, and finally sintering the product for 4 hours at the atmosphere of 1250-1300 DEG C, wherein the binder is polyvinyl alcohol solution with the mass concentration of 5%, the additive amount of the polyvinyl alcohol is 3% of the total mass of the powder. The prepared ceramic is well sintered, has the dielectric constant reaching 7.1-7.7, the Qf (quality factor) value reaching 145000-191000 GHz, is low in temperature coefficient of resonance frequency, and has great application value in the industry.

Owner:临泉县非凡广告传媒有限责任公司

A temperature-stable ultra-low dielectric constant microwave dielectric ceramic and its preparation method

ActiveCN104446379BImprove temperature stabilityHigh quality factor QfAir atmosphereCeramic sintering

The invention discloses temperature-stable microwave dielectric ceramics LiAl3B4O11 with ultralow dielectric constant and a preparation method thereof. The preparation method comprises the steps: (1) weighing and dosing the raw material powder of Li2CO3, Al2O3 and H3BO3 with purity of more than 99.9% (weight percentage) according to the composition of the LiAl3B4O11; (2) ball-milling and mixing the raw materials in the step (1) for 12 hours in a wet method, utilizing absolute ethyl alcohol as the ball-milling medium, drying and then pre-burning for 6 hours in the air atmosphere of 700 degrees centigrade; (3) adding an adhesive to the powder prepared in the step (2), granulating, pressing and molding, and finally burning for 4 hours in the air atmosphere of 820 degrees centigrade, wherein the mass concentration of the adhesive is polyving akohol solution of 5% and the dosage of the polyving akohol accounts for 4% that of the total mass of the poweder. The prepared ceramics are sintered well and the dielectric constant is up to 7.3-7.8; the quality factor Qf value is up to 142,000-181,000GHz; the temperature coefficient of resonance frequency is small and the ceramics have great application value in industry.

Owner:江苏开创检测技术有限公司

Low-dielectric constant microwave dielectric ceramic ca3y4v2o14 that can be sintered at low temperature

The invention discloses low-temperature sinterable temperature-stable type microwave dielectric ceramic Ca3Y4V2O14 having a low dielectric constant and a preparing method thereof. The method includes: (1) weighing original powder having purity higher than 99.9% (that is a weight percentage) of CaCO3, Y2O3 and V2O5 according to constitution of the Ca3Y4V2O14 and blending; (2) subjecting the raw materials in the step (1) to wet ball milling and mixing for 12 h, with a ball milling medium being distilled water, drying, and pre-sintering at 820 DEG C in an atmosphere of air for 6 h; and (3) adding an adhesive into the powder prepared in the step (2), granulating, performing compression moulding, and sintering at 870-920 DEG C in the atmosphere of air for 4 h, wherein the adhesive adopts a polyvinyl alcohol solution having a mass concentration of 5%, and the adding amount of the polyvinyl alcohol is 3% of the total mass of the powder. The ceramic prepared by the method is good in sintering performance at 870-920 DEG C, the dielectric constant of the ceramic is 25.4-26.3, the quality factor Qf of the ceramic is 49000-63000 GHz, and the temperature coefficient of resonance frequency of the ceramic is small. The ceramic has high application value in the industry.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com