Low-temperature sinterable microwave dielectric ceramic SrCuV2O7 and preparation method thereof

A technology of microwave dielectric ceramics and low-temperature sintering, applied in the field of dielectric ceramic materials, can solve the problems of increasing dielectric loss and high dielectric loss of materials, and achieve the effect of small temperature coefficient of resonance frequency and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

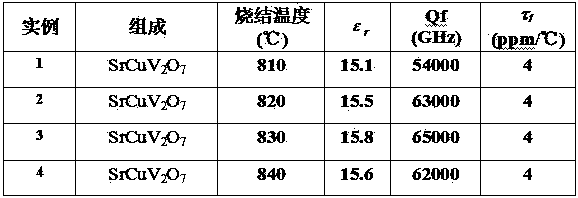

[0018] Table 1 shows four specific examples of different sintering temperatures constituting the present invention and their microwave dielectric properties. Its preparation method is as above-mentioned, carries out the evaluation of microwave dielectric property with cylinder dielectric resonator method; SrCuV 2 o 7 The powder was mixed with Ag powder accounting for 20% of the mass of the powder, pressed and molded, and then sintered at 840 °C for 4 hours; X-ray diffraction phase analysis and scanning electron microscope observation showed that SrCuV 2 o 7 There is no chemical reaction with Ag, that is, SrCuV 2 o 7 It can be co-fired with Ag electrodes at low temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com