Low-temperature sintering tungstate microwave dielectric ceramic Li3R3W2O12 and preparation method thereof

A technology of microwave dielectric ceramics, li3r3w2o12, applied in the field of dielectric ceramic materials, can solve problems such as limited microwave dielectric ceramic systems, restrictions on low-temperature co-firing technology and development of microwave multilayer devices, and achieve great application value and resonant frequency temperature coefficient small effect

Active Publication Date: 2013-07-10

苏州弘吴科技中介服务有限公司

View PDF1 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] In the process of exploring and developing new low-firing microwave dielectric ceramic materials, material systems such as Li-based compounds, Bi-based compounds, tungstate compounds, and tellurate-based compounds with inherently low sintering temperatures have received extensive attention and research. A large number of exploratory studies have focused on Li-based binary or ternary compounds, and developed such as Li 2 TiO 3 , Li 3 NbO 4 , Li 2 MoO 4 and Li 2 MTi 3 o 8 (M=Mg or Zn) series of microwave dielectric ceramics with good performance, etc., but the microwave dielectric ceramic system that can be fired at low temperature is still relatively limited, which limits the development of low temperature co-firing technology and microwave multilayer devices to a large extent.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

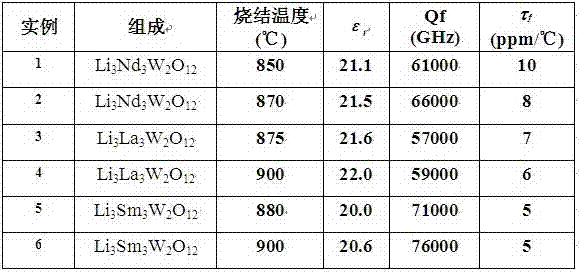

[0019] Table 1 shows six specific examples of different compositions and sintering temperatures constituting the present invention and their microwave dielectric properties. The preparation method is as above, and the microwave dielectric performance is evaluated by the cylindrical dielectric resonator method.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses low-temperature sintering tungstate microwave dielectric ceramic Li3R3W2O12 and a preparation method thereof. The low-temperature sintering tungstate microwave dielectric ceramic material comprises the components of Li3R3W2O12, wherein R is one of Nd, La and Sm. The method comprises the steps of (1) weighing and dosing the original powder of Li2CO3, R2O3 and WO3, of which the purity is more than 99.9% according to the chemical formula of Li3R3W2O12, wherein R is one of Nd, La and Sm; (2) mixing the materials for 12 hours in a wet ball grinding manner, wherein the solvent is distilled water, and pre-sintering for 6 hours after baking in the atmosphere of 800 DEG C; and (3) adding a binder to the prepared powder and pelletizing, then pressing and molding, and finally sintering for 4 hours in the atmosphere of 850-900 DEG C, wherein the binder adopts polyvinyl alcohol solution of which the mass concentration is 5%; and the dosage is 3% of the total weight of the powder. The ceramic prepared by the preparation method has good sintering property at 850-900 DEG C; the dielectric constant achieves 20-22; the quality factor Qf value can be up to 57000-76000GHz; and the resonant frequency temperature coefficient is small.

Description

technical field [0001] The invention relates to a dielectric ceramic material, in particular to a microwave dielectric ceramic material for microwave components used at microwave frequencies, such as a dielectric substrate, a resonator, and a filter, and a preparation method thereof. Background technique [0002] Microwave dielectric ceramics refer to ceramics that are used as dielectric materials in circuits in the microwave frequency band (mainly UHF and SHF bands) and perform one or more functions. They are widely used as resonators, filters, and dielectric substrates in modern communications. Components such as chips and dielectric waveguide circuits are the key basic materials of modern communication technology. They have been used in portable mobile phones, car phones, cordless phones, TV satellite receivers and military radars. They are used in modern communication tools. It is playing an increasingly important role in the process of miniaturization and integration. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B35/495C04B35/622

Inventor 方亮向飞唐莹

Owner 苏州弘吴科技中介服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com