Low-temperature sintered microwave dielectric ceramic and sintering method thereof

A microwave dielectric ceramic and low-temperature sintering technology, which is applied in the field of low-temperature sintering microwave dielectric ceramics and its sintering, can solve the problems of low-temperature sintering aid volatilization, affecting the compactness of ceramics, affecting performance, etc., to reduce pollution, improve production efficiency, and save energy. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Li 2 ZnTi 3 o 8 Microwave Sintering Method of Low Temperature Microwave Dielectric Ceramics

[0028] Specifically follow the steps below:

[0029] 1. First weigh the analytically pure raw material Li with a purity of more than 99%. 2 CO 3 1308.72g, ZnO 1447.66g and TiO 2 4243.62g, mixed to prepare the main powder.

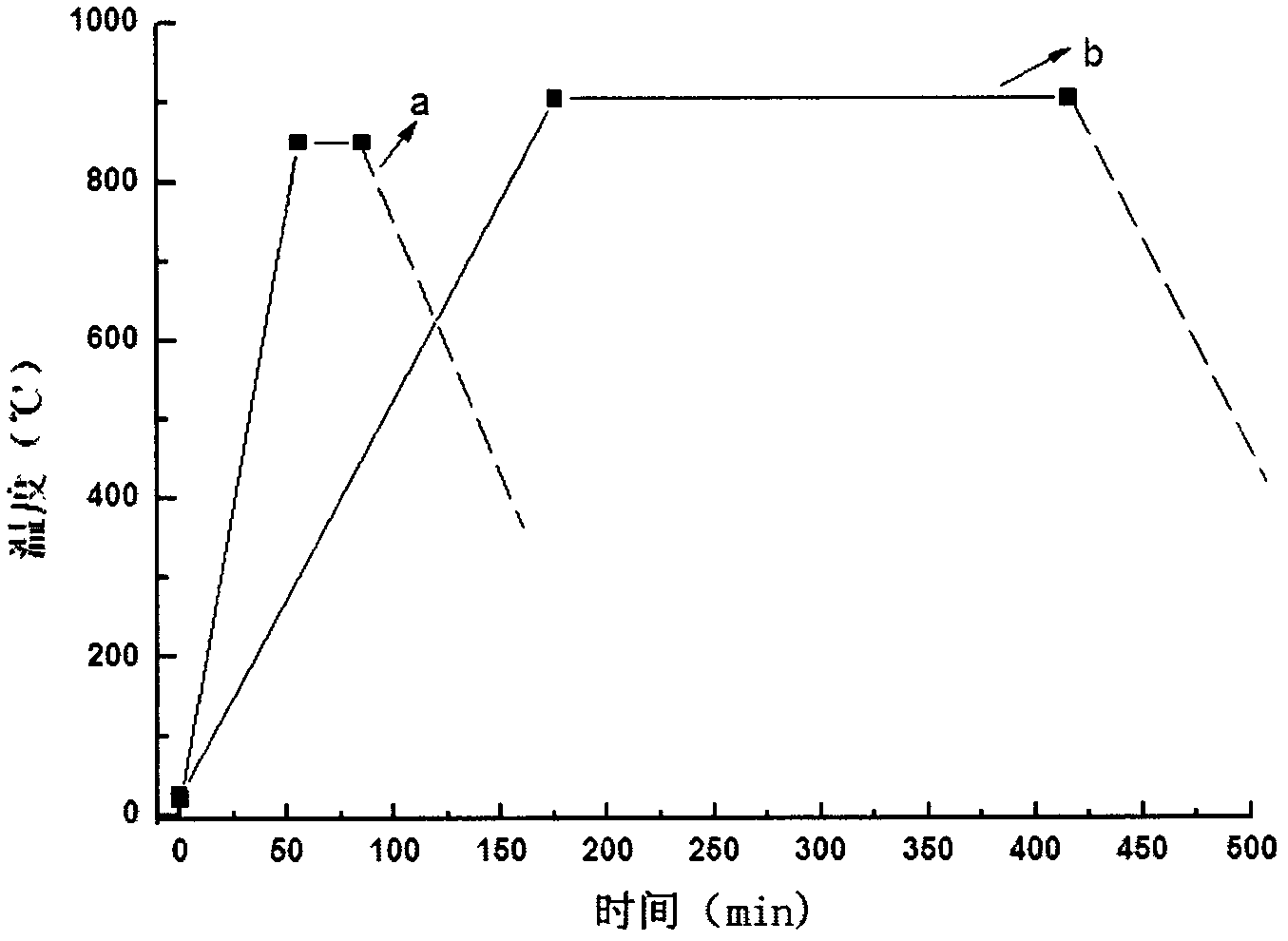

[0030] 2. Add 7kg of deionized water to the main powder in step 1 and mix it with a wet ball mill for 4 hours. After drying, put the powder into the sintering bowl, put the sintering bowl into the cavity of the microwave sintering furnace and pre-sinter for 79 minutes. The firing temperature is 825°C, the heating rate is 15°C / min, the holding time is 25 minutes, and natural cooling, as attached figure 1 Medium microwave sintering curve a is shown.

[0031] 3. After pulverizing the calcined powder in step 2, add 18.73g B 2 o 3 , add 6238.6g of deionized water, mix again by wet ball milling for 4 hours, add 623.86g of polyvinyl alcohol s...

Embodiment 2

[0032] Example 2: Li 2 ZnTi 3 o 8 Microwave Sintering Method of Low Temperature Microwave Dielectric Ceramics

[0033] Specifically follow the steps below:

[0034] 1. First weigh the analytically pure raw material Li with a purity of more than 99%. 2 CO 3 1308.72g, ZnO 1447.66g and TiO 2 4243.62g, mixed and prepared into the main powder;

[0035] 2. Add the main powder in step 1 to 7kg of deionized water and mix it with a wet ball mill for 4 hours. After drying, put the powder into the sintering bowl, put the sintering bowl into the cavity of the microwave sintering furnace and pre-sinter for 80 minutes. The firing temperature is 850°C, the heating rate is 15°C / min, the holding time is 25 minutes, and it is naturally cooled.

[0036] 3. After pulverizing the calcined powder in step 2, add 126.94gV 2 o 5 , add 6346.8g of deionized water, mix again by wet ball milling for 4 hours, add 634.68g of polyvinyl alcohol solution with a mass concentration of 5% after drying,...

Embodiment 3

[0037] Example 3: Li 2 ZnTi 3 o 8 Microwave Sintering Method of Low Temperature Microwave Dielectric Ceramics

[0038] Specifically follow the steps below:

[0039] 1. First weigh the analytically pure raw material Li with a purity of more than 99%. 2 CO 3 1308.72g, ZnO 1447.66g and TiO 2 4243.62g, mixed and prepared into the main powder;

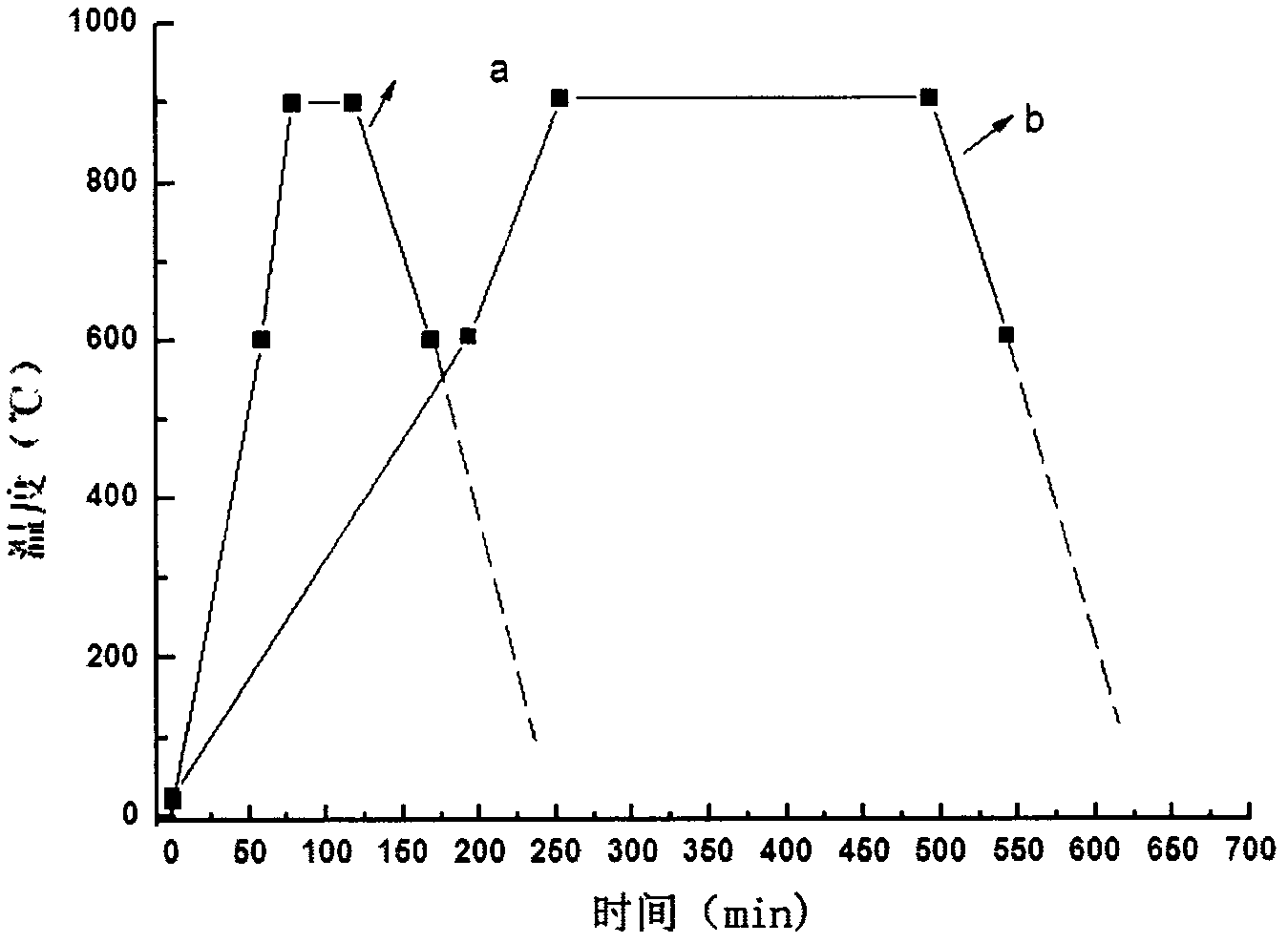

[0040] 2. Add 7kg of deionized water to the main powder in step 1, and mix it by wet ball milling for 6 hours. After drying, put the powder into the sintering bowl, put the sintering bowl into the cavity of the microwave sintering furnace and pre-sinter for 89 minutes. The pre-firing temperature is 900°C, the heating rate is 15°C / min, the holding time is 30 minutes, and it is naturally cooled.

[0041] 3. After pulverizing the calcined powder in step 2, add 62.83g of CuO, add 6282.7g of deionized water, mix again by wet ball milling for 6 hours, add 628.27g of polyvinyl alcohol solution with a mass concentration of 5% after drying,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com