A low-temperature sintered low dielectric constant ceramic substrate material and its preparation method

A low dielectric constant, ceramic substrate technology, applied in the field of electronic information functional materials, can solve the problems of high slurry viscosity, high cost, high sintering temperature, etc., to achieve improved transmission speed and wiring density, high content of main crystal phase, mechanical high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing a low-dielectric-constant ceramic substrate material sintered at low temperature, comprising the following steps:

[0037] S1. According to the composition ratio requirements of the LBS glass, the Li 2 CO 3 , B 2 o 3 , SiO 2 , CaCO 3 、Na 2 CO 3 and Al 2 o 3 The powder is evenly mixed;

[0038] S2, ball milling and drying the mixed powder mixed in step S1, and then melting the dried powder at a high temperature in an air atmosphere at 1300° C. to 1400° C., cooling and extracting with deionized water to form an LBS glass block;

[0039] S3. The above-mentioned LBS glass block is wet ball-milled with deionized water as a solvent, and then dried to obtain LBS glass powder;

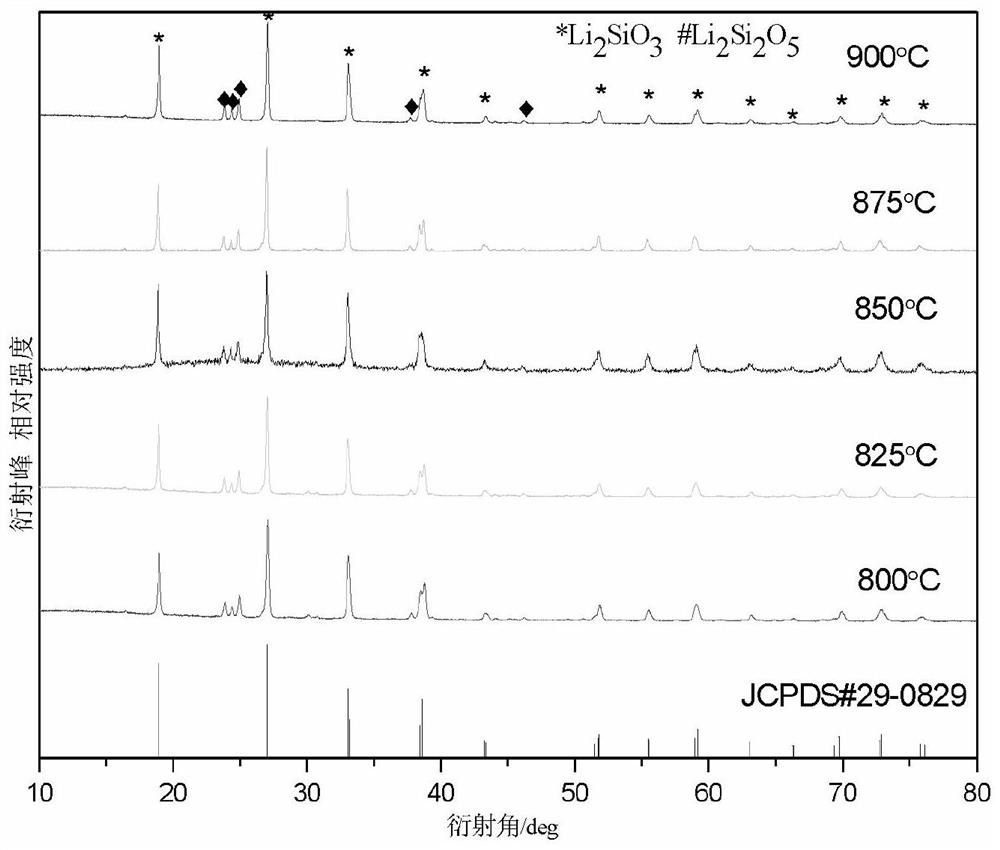

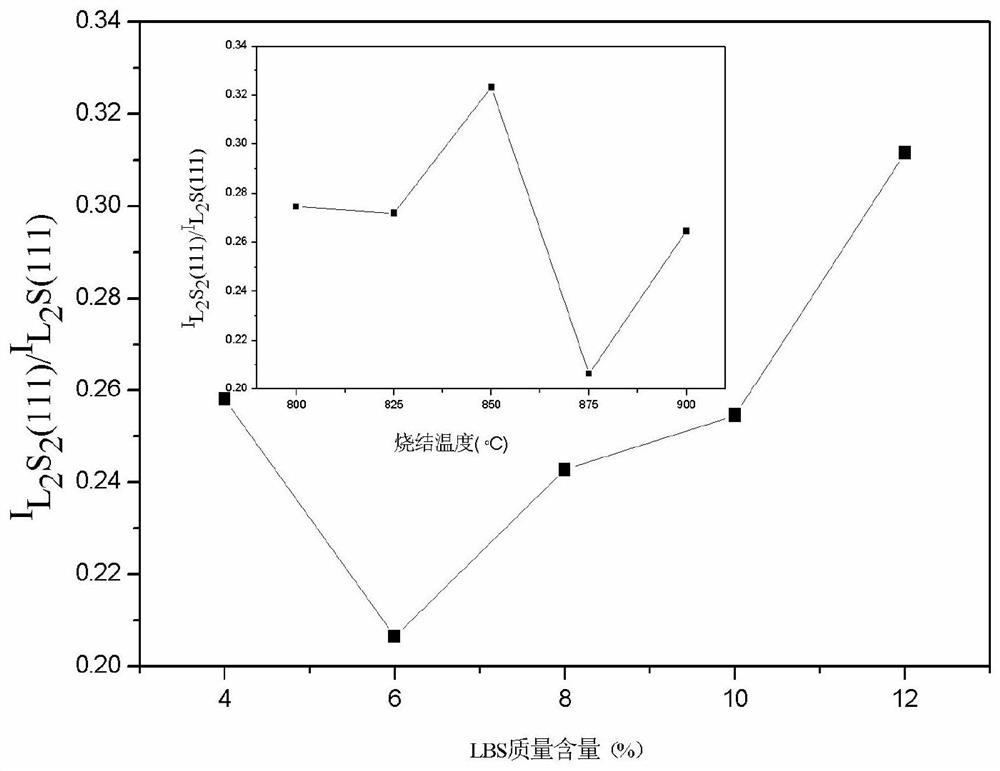

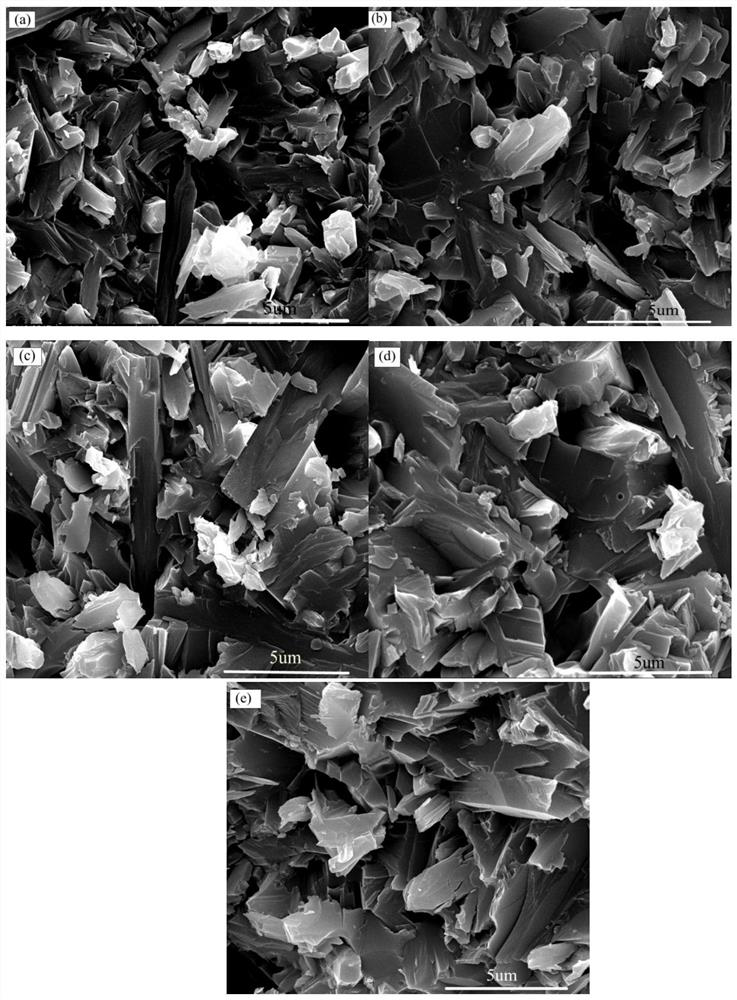

[0040] S4. Will Li 2 CO 3 and SiO 2 The molar ratio of powder is Li 2 CO 3 : SiO 2 =0.9~1.1:1 for mixing ingredients, then ball milling according to the mass ratio of material:ball:water=1:5:1, then drying, and the dried powder i...

Embodiment 1

[0051] A low-temperature sintered low dielectric constant ceramic substrate material, which is composed of 100% Li 2 SiO 3 Composition; said Li 2 SiO 3 The molar ratio of each component is Li 2 O: SiO 2 =1:1.

Embodiment 2

[0053] A low-temperature sintered low dielectric constant ceramic substrate material, according to the mass ratio, its components include: 10% LBS glass, 90% Li 2 SiO 3 ;

[0054] According to the mass ratio, the composition of the LBS glass is: 25% Li 2 CO 3 , 42% B 2 o 3 , 16% SiO 2 , 8% CaCO 3 , 4% Na 2 CO 3 , and 5% Al 2 o 3 ,

[0055] The Li 2 SiO 3 The molar ratio of each component of ceramic powder is Li 2 O: SiO 2 =1:1.

[0056] The above low-temperature sintered low dielectric constant ceramic substrate material is prepared through the following steps:

[0057] S1. According to the composition ratio requirements of the LBS glass, the Li 2 CO 3 , B 2 o 3 , SiO 2 , CaCO 3 、Na 2 CO 3 and Al 2 o 3 The powder is evenly mixed;

[0058] S2. Wet ball mill the mixed powder mixed in step S1 for 5 hours, then dry and sieve, and melt the sieved powder at a high temperature in an air atmosphere at 1300°C to 1400°C for 1 hour, and then cool and extract wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com