Microwave dielectric material suitable for ultralow-temperature sintering and preparation method thereof

A microwave dielectric material and ultra-low temperature technology, applied in the field of microwave dielectric materials, can solve the problems of easy moisture absorption, toxicity of tellurium oxide, high price, etc., and achieve the effects of stable performance, widening the selection range, and reducing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

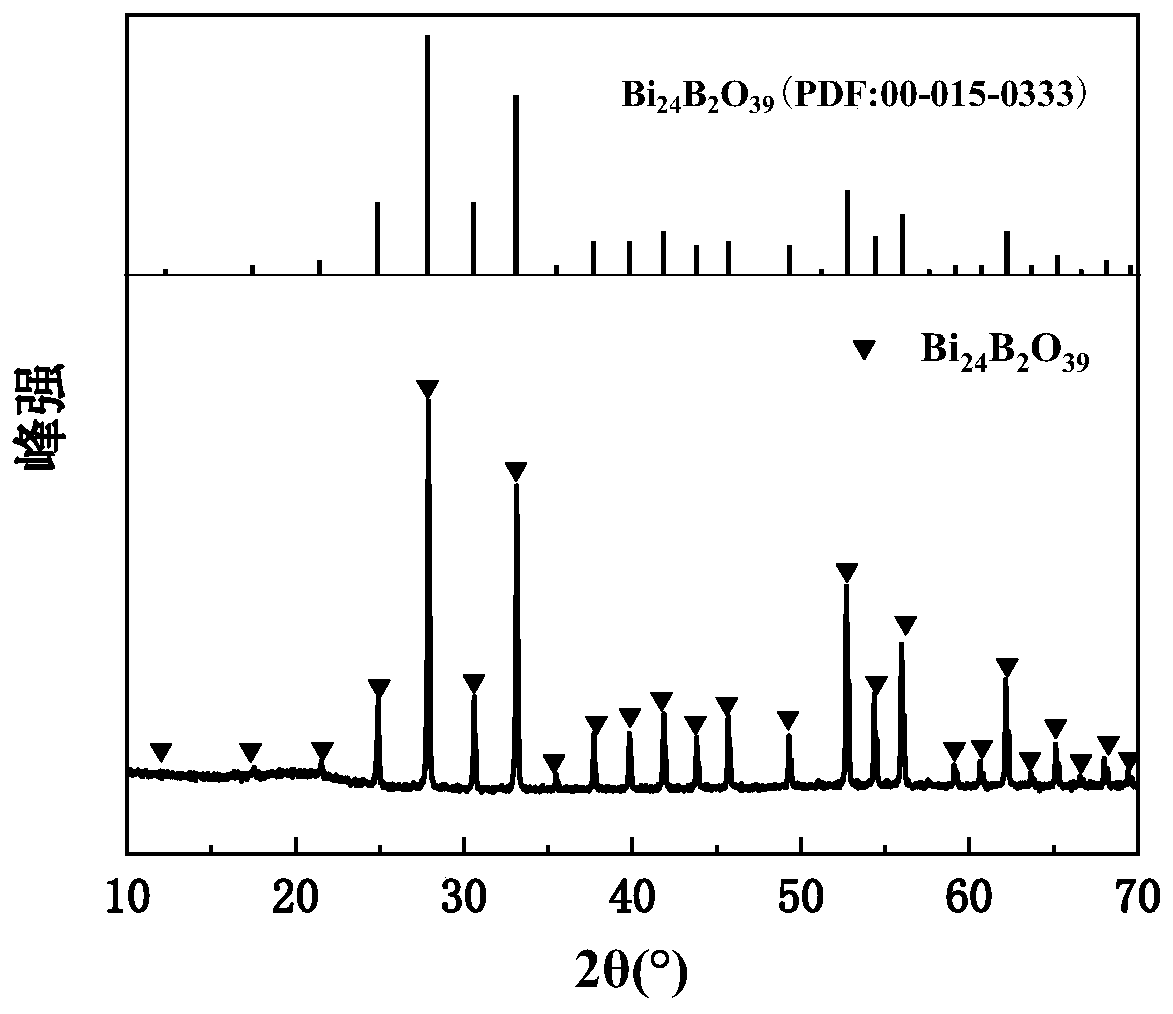

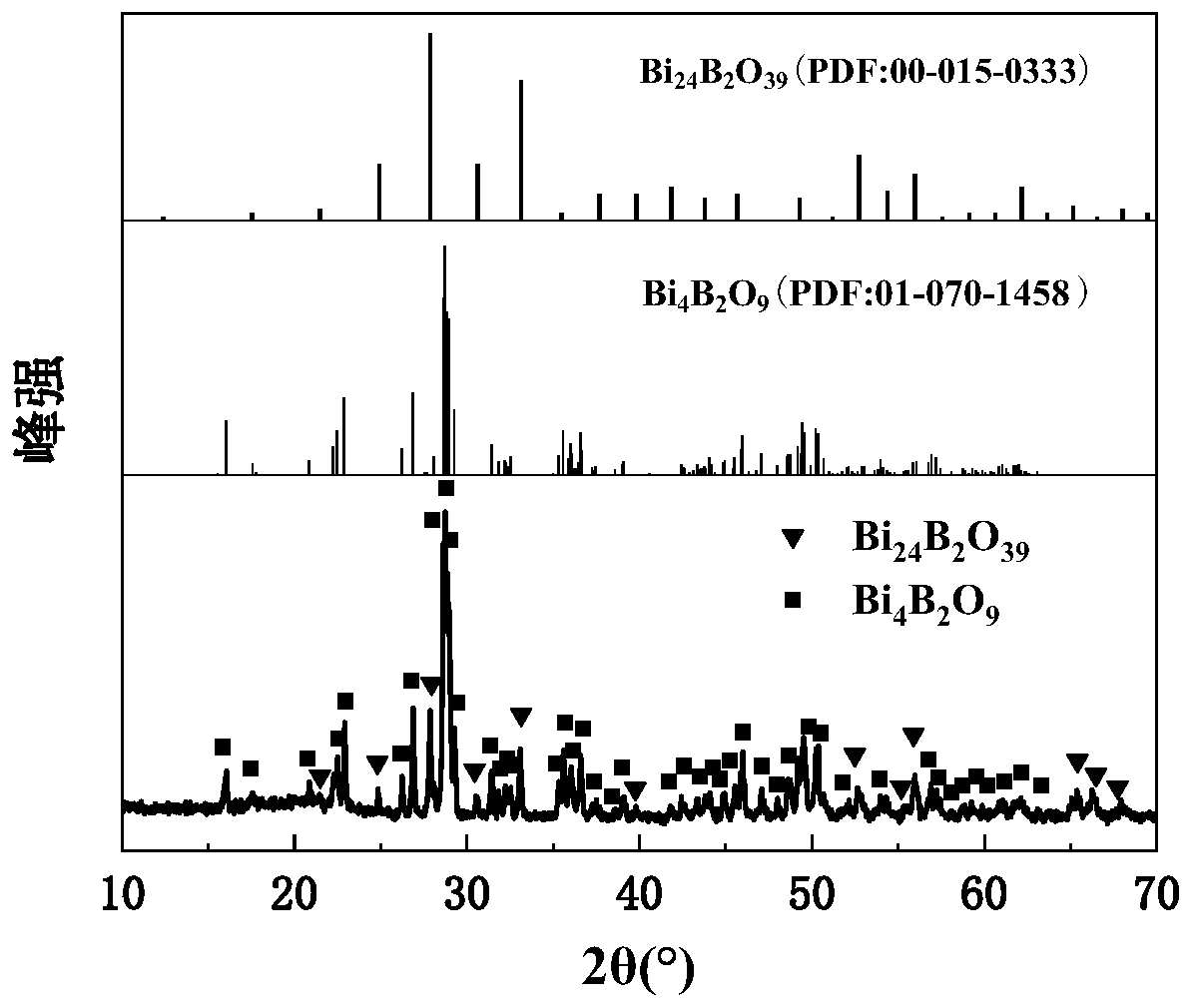

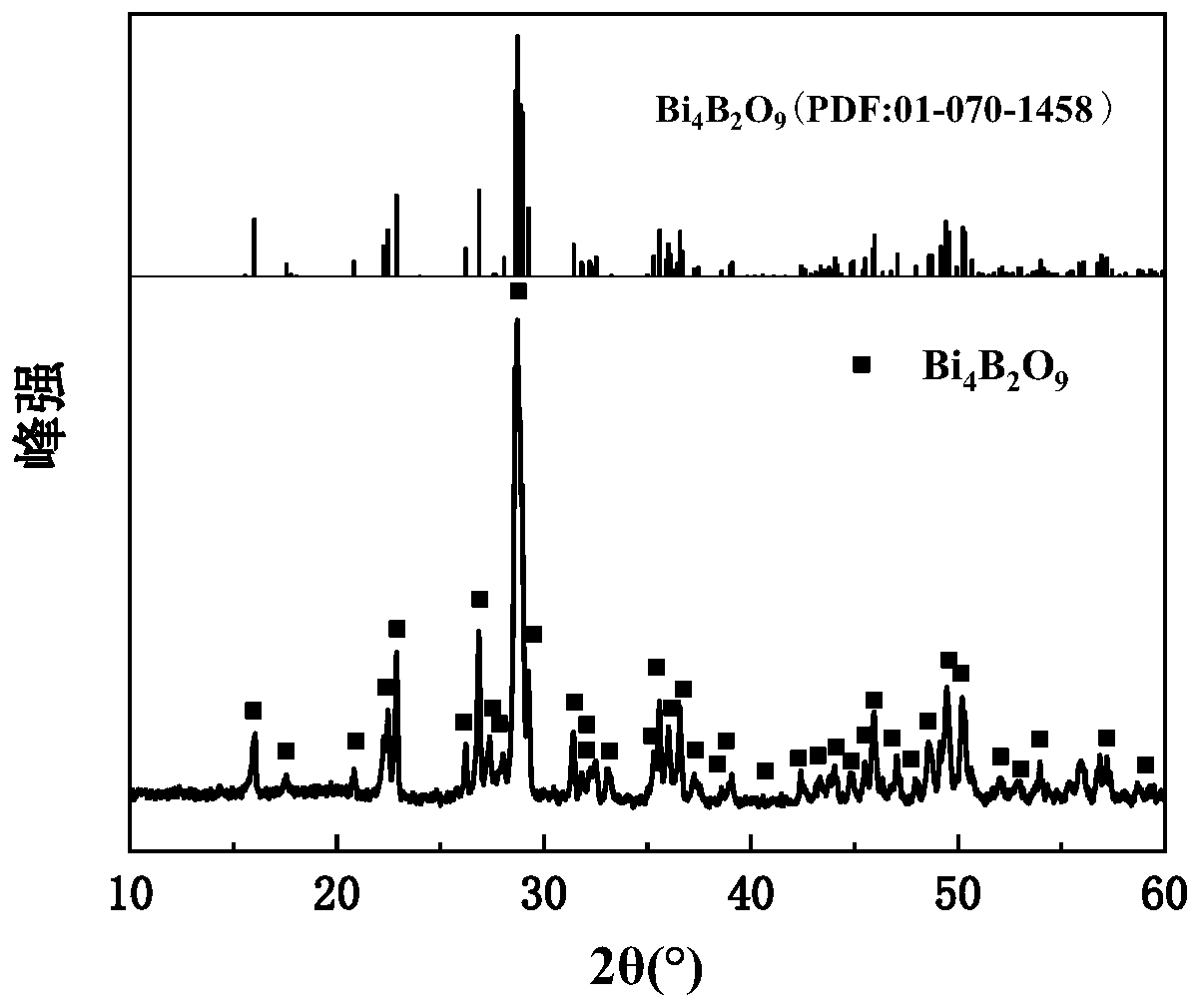

[0035] Bi 2 o 3 -B 2o 3 Microwave dielectric properties of several microwave dielectric materials in the system. The Bi of these microwave dielectric materials 2 o 3 and B 2 o 3 The molar ratio between is x:y, wherein: 1≤x≤12, 1≤y24 B 2 o 39 (Bi / B=12 / 1), Bi 24 B 2 o 39 +Bi 4 B 2 o 9 (Bi / B=4 / 1), Bi 4 B 2 o 9 (Bi / B=2 / 1), Bi 4 B 2 o 9 +Bi 6 B 10 o 24 (Bi / B=1 / 1, 2 / 3), Bi 6 B 10 o 24 (Bi / B=3 / 5), Bi 6 B 10 o 24 +Bi 2 B 8 o 15 (Bi / B=1 / 3). Prepare the microwave dielectric ceramic according to the following method:

[0036] (1) B with purity ≥ 98% 2 o 3 with Bi 2 o 3 as raw material, according to Bi 2 o 3 -B 2 o 3 In the system, Bi / B=12 / 1, 4 / 1, 2 / 1, 1 / 1, 2 / 3, 3 / 5, 1 / 3 (mol ratio) for batching, put the powder into the ball mill tank, and ball mill , and then pre-fired to obtain pre-fired ceramic powder;

[0037] (2) The pre-fired ceramic powder obtained in the step (1) is subjected to wet ball milling again, after drying, adding a binder to gra...

Embodiment 8~14

[0045] Its chemical formula is Bi 6 B 10 o 24 . Prepare the microwave dielectric ceramic according to the following method:

[0046] (1) B with purity ≥ 98% 2 o 3 with Bi 2 o 3 As raw material, according to the chemical formula Bi 6 B 10 o 24 The stoichiometric ratio is used for batching, the powder is put into a ball mill tank, ball milled, and then pre-fired to obtain a pre-fired ceramic powder;

[0047] (2) The pre-fired ceramic powder obtained in the step (1) is subjected to wet ball milling again, after drying, adding a binder to granulate, and then sintering after tableting to obtain the microwave dielectric ceramic.

[0048] The ball milling in step (1) is dry ball milling, using a planetary ball mill, and the ball milling time is 2 hours. Using dry ball milling and controlling the appropriate ball milling time not only ensures uniform mixing, but also solves the problem of B during drying after wet ball milling. 2 o 3 volatility problem.

[0049] The pre-...

Embodiment 15~17

[0055] Its chemical formula is Bi 6 B 10 o 24 . Prepare the microwave dielectric ceramic according to the following method:

[0056] (1) B with purity ≥ 98% 2 o 3 with Bi 2 o 3 As raw material, according to the chemical formula Bi 6 B 10 o 24 The stoichiometric ratio is used for batching, the powder is put into a ball mill tank, ball milled, and then pre-fired to obtain a pre-fired ceramic powder;

[0057] (2) The pre-fired ceramic powder obtained in the step (1) is subjected to wet ball milling again, after drying, adding a binder to granulate, and then sintering after tableting to obtain the microwave dielectric ceramic.

[0058] The ball milling in step (1) is dry ball milling, using a planetary ball mill, and the ball milling time is 2 hours. Using dry ball milling and controlling the appropriate ball milling time not only ensures uniform mixing, but also solves the problem of B during drying after wet ball milling. 2 o 3 volatility problem.

[0059] The pre-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com