Composite multilayer ceramic electronic component

一种电子部件、陶瓷的技术,应用在复合层叠陶瓷电子部件领域,能够解决玻璃成分量稳定化、失去单独时特性等问题,达到Qf值高、绝缘可靠性高、提高绝缘可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0108] In Experimental Example 1, evaluation of a glass-ceramic single body for a high dielectric constant ceramic layer was performed.

[0109] First, as the first ceramic, mix MgCO at a prescribed ratio 3 and Al 2 o 3 And pre-calcined, wet pulverized, thus producing spinel compound: MgAl 2 o 4 , and to reconcile MgCO at a prescribed ratio 3 and SiO 2 Then pre-calcined and wet pulverized to produce forsterite compound: Mg 2 SiO 4 .

[0110] Next, mix the glass shown in Table 1, MgAl 2 o 4 , Mg 2 SiO 4 , BaO, TiO 2 , as RE 2 o 3 Nd 2 o 3 , MnO, and CuO so as to have the compositions shown in Table 2 and Table 3, and after mixing, an organic solvent and a binder were added to prepare a slurry.

[0111] [Table 2]

[0112]

[0113] [table 3]

[0114]

[0115] Next, the slurry was formed into a sheet by a doctor blade method and dried to obtain a ceramic green sheet. Samples were suitably produced using this ceramic green sheet, and as shown in Table 4 an...

experiment example 2

[0161] In Experimental Example 2, evaluation of a glass-ceramic single body for a low dielectric constant ceramic layer was performed.

[0162] As in the case of Experimental Example 1, a spinel compound: MgAl was prepared as the first ceramic 2 o 4 and forsterite compound: Mg 2 SiO 4 , forming the second ceramic BaO, TiO 2 , as RE 2 o 3 Nd 2 o 3 and Sm 2 o 3 , MnO, and CuO powders.

[0163] In addition, in this Experimental Example 2, as shown in Table 7 and Table 8, MgCO was blended at a predetermined ratio 3 、Al 2 o 3 and SiO 2 Then, calcining and wet pulverization were performed to produce the cordierite compound as the third ceramic: Mg 2 Al 4 Si 5 o 18 of powder. In addition, as shown in the same Table 7 and Table 8, BaCO was blended at a prescribed ratio 3 、Al 2 o 3 and SiO 2 And pre-fired, wet pulverized, thus produced barium feldspar compound as the third ceramic: BaAl 2 Si 2 o 8 of powder.

[0164] Next, the glasses shown in Table 1, MgAl 2...

experiment example 3

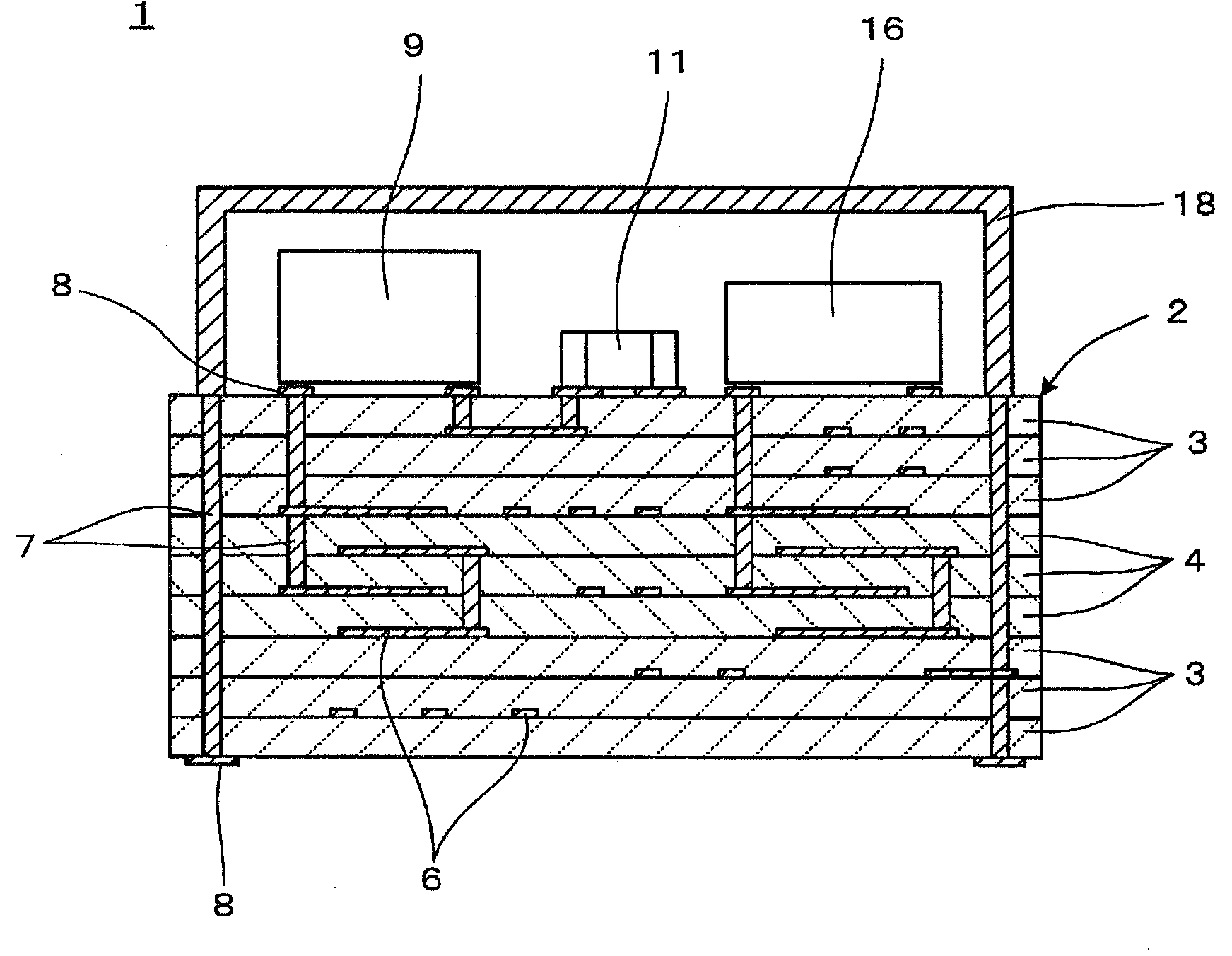

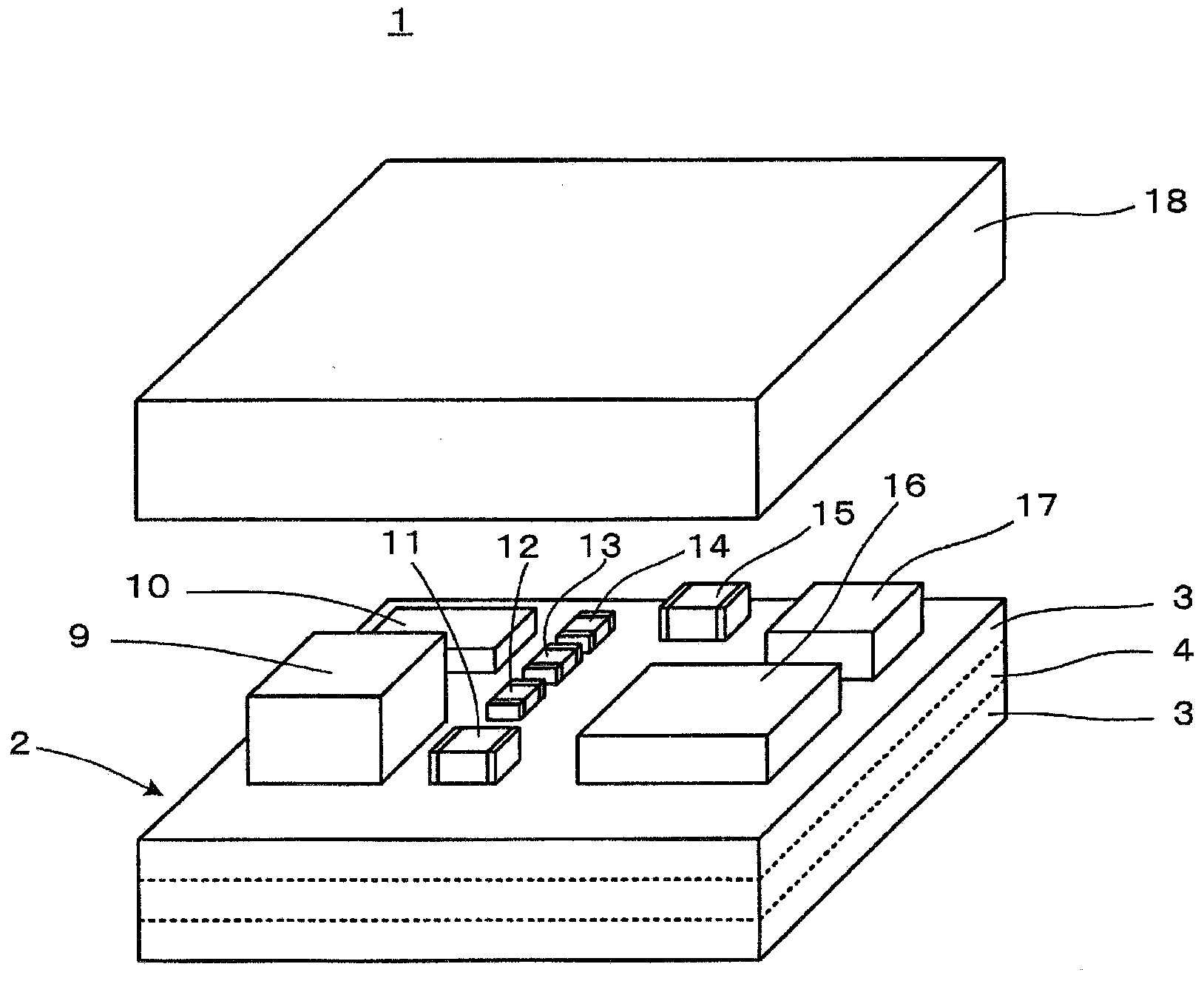

[0211] In Experimental Example 3, for each of the low-permittivity ceramic layer and the high-permittivity ceramic layer, the influence on the characteristics of each of the low-permittivity ceramic layer and the high-permittivity ceramic layer was investigated when they were made into a co-sintered body. r And the influence of the capacitance temperature coefficient β. exist Image 6 (A) and Image 6 In (B), two types of co-sintered bodies 71 and 72 produced in this experimental example are shown in cross-sectional views, respectively.

[0212] Image 6 The co-sintered body 71 shown in (A) has a structure in which a low dielectric constant ceramic layer 73 with a thickness of 10 μm is sandwiched between two high dielectric constant ceramic layers 74 and 75 with a thickness of 0.5 mm. Between the low dielectric constant ceramic layer 73 and each high dielectric constant ceramic layer 74, 75, internal electrodes 76 and 77 are formed to face each other in a part, and internal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com