Cordierite microwave dielectric material with ultralow dielectric constant and near-zero temperature coefficient of resonance frequency and preparation method of cordierite microwave dielectric material

An ultra-low dielectric constant and resonant frequency technology, applied in the field of cordierite microwave materials and their preparation, can solve the problems of limiting the application of cordierite microwave dielectric ceramics, and achieve the elimination of adverse effects, improvement of resonance temperature coefficient, and low The effect of dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A cordierite-based microwave dielectric material with ultra-low dielectric constant and near-zero resonant frequency temperature coefficient, the preparation method thereof comprises the following steps:

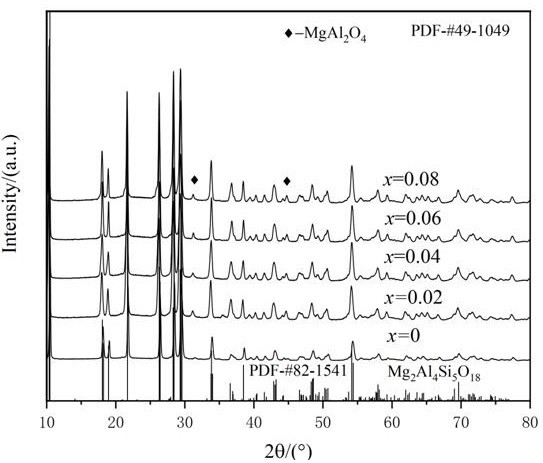

[0028] Step 1: According to the molar ratio of SiO 2 :Al 2 O 3 :Li 2 CO 3 :MgO=5:2: x :(2- x ) weigh the raw materials ( x= 0~0.08), take the electronic balance of 1 / 10,000 as the raw material to ensure that the error between the weighing value and the theoretical calculation value is not greater than 0.0005g; place the weighed raw material in a ball mill, use zirconium balls as grinding balls, and Deionized water was used as the ball milling medium, and the ball was milled at a speed of 250 rpm for 4 h. After the ball milling, the slurry was placed in a constant temperature drying box and dried to constant weight for use.

[0029] Step 2: Mash the agglomerated mixed powder obtained in step 1 in a mortar, put it into a crucible for compaction, raise the tempera...

Embodiment 2

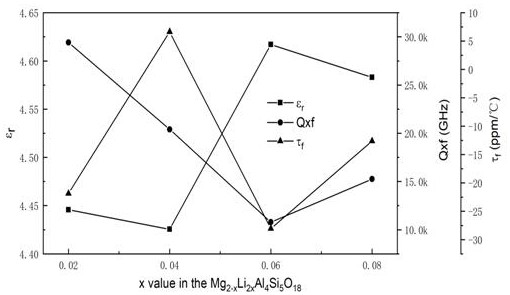

[0036] Compared with Example 1 in this example, only the sintering temperature in step 5 was changed from 1380°C to 1400°C, and the rest were the same as those in Example 1. ɛ r value and τ f value, x = 0.02~0.08, ɛ r = 4.44~4.60, τ f = -43~- 7ppm / ℃.

Embodiment 3

[0038] Compared with Embodiment 1, this embodiment is fixed x =0.04, change the value of sintering temperature to 1380~1400℃. The rest are the same as in Example 1, and the obtained samples are ɛ r value and τ f value, ɛ r = 4.42~4.55, τ f = -36~+7ppm / ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com