A kind of dielectric ceramic material and preparation method thereof

A technology of dielectric ceramics and ceramic powders, applied in the direction of ceramics, inorganic insulators, etc., can solve problems such as difficult densification, low density, and loose ion arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

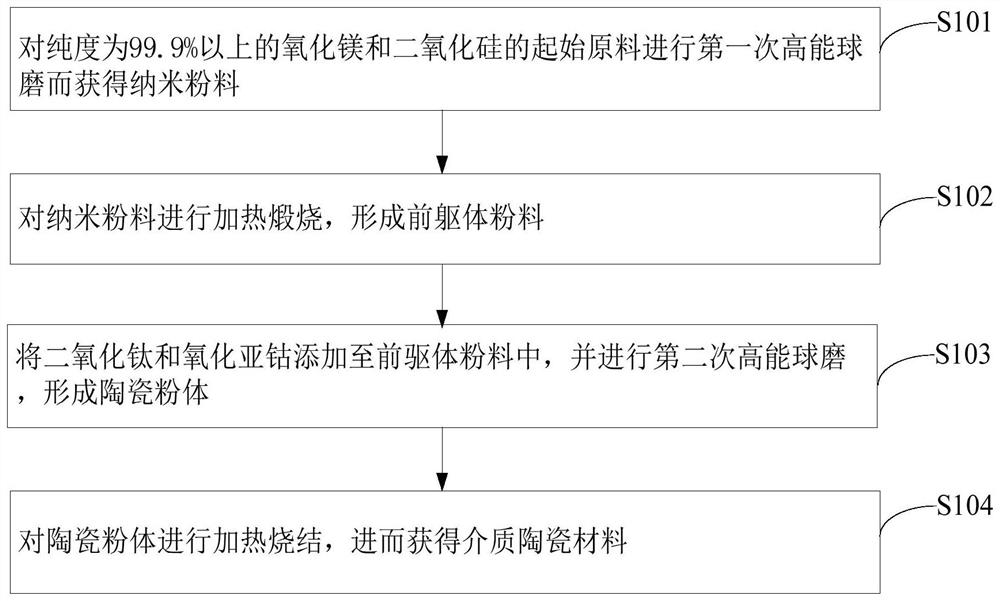

[0038] see image 3 , image 3 A schematic flow chart of an embodiment of the method for preparing a dielectric ceramic material of the present invention. The preparation method of the dielectric ceramic material in this embodiment includes:

[0039] Step S101, performing the first high-energy ball milling on the starting materials of magnesium oxide and silicon dioxide with a purity of more than 99.9% to obtain nanopowder;

[0040] Among them, [2MgO+(1+x)SiO 2 ] The mass percentage in the dielectric ceramic material is not less than 75%, further, [2MgO+(1+x)SiO 2 ] in the range of 75%-95% by mass, such as 75%, 85% or 95, etc., wherein the molar ratio of magnesium oxide to silicon dioxide is 2: (1+x), wherein, 0≤x≤0.2, For example, the value of x is 0.5, 1, 1.5, etc.

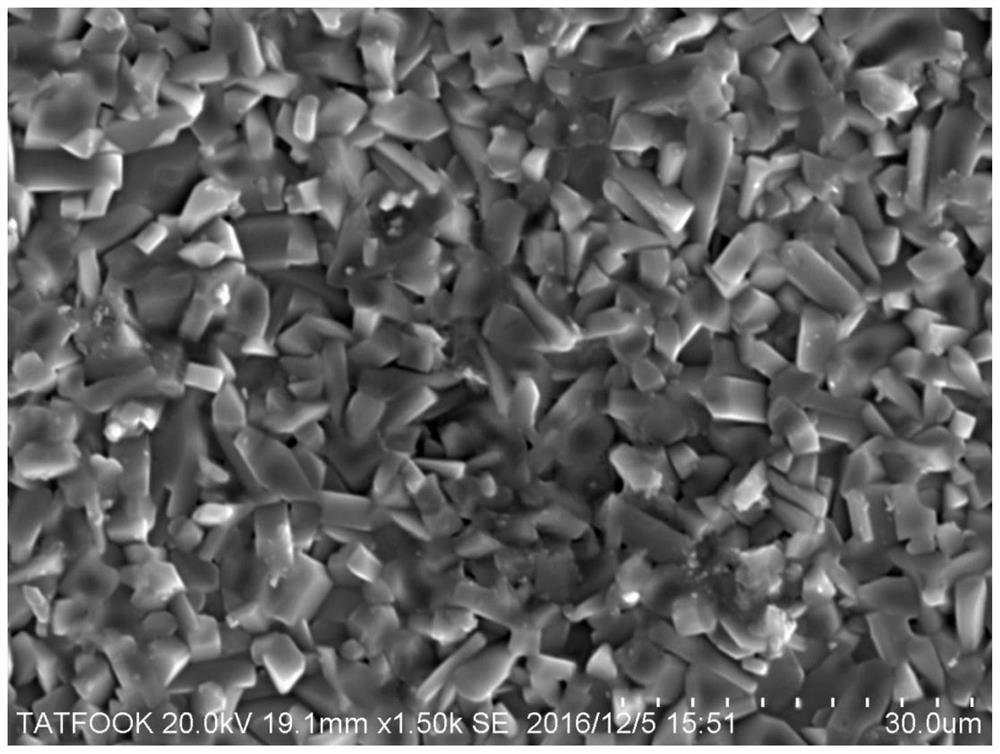

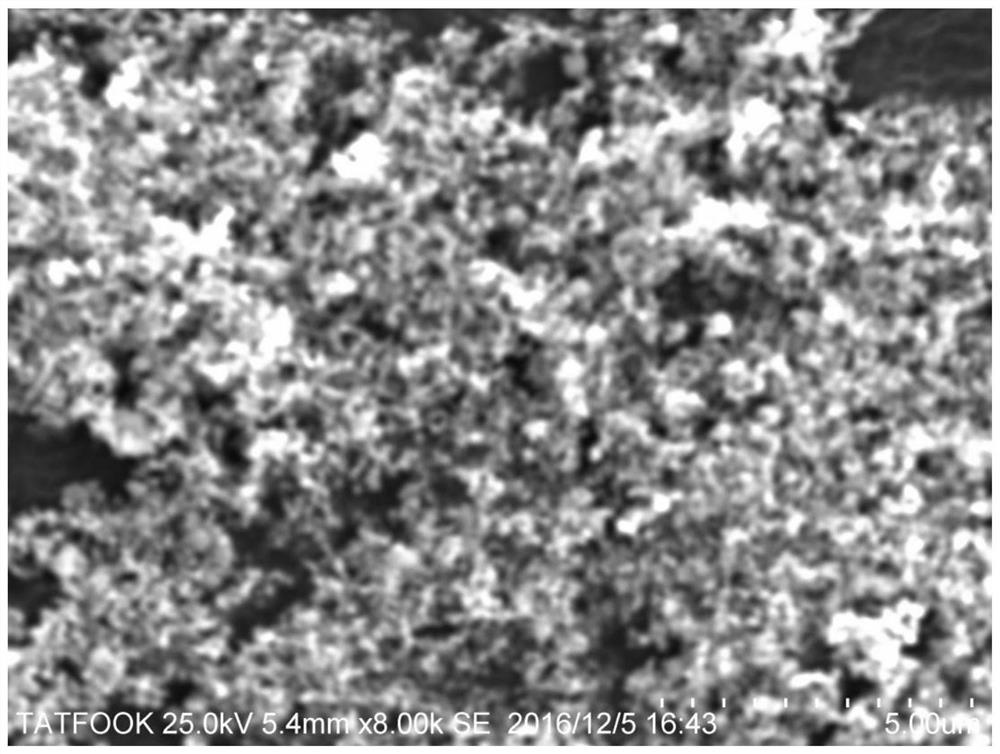

[0041] The particle size d50 of the nano-powder after the first high-energy ball milling is distributed within the range of 50-400nm. Further, the d50 of the nano-powder is distributed within the range of 5...

Embodiment 1

[0070] The raw material ratio expression of the present embodiment is: [2MgO+(1+0.05)SiO 2 ]+5wt%TiO 2 +0.25wt% CoO, using magnesium oxide, silicon dioxide, titanium dioxide, and cobaltous oxide with a purity of more than 99% as the main raw materials, through the following steps.

[0071] 1. Using magnesium oxide and silicon dioxide with a purity of more than 99% as the starting powder, according to the expression 2MgO+(1+0.05)SiO 2 After the required mole percentage is weighed, zirconia balls and deionized water are added into the ball milling medium, and mixed mechanically, and dried after mixing to obtain a dry powder. Wherein, the weight ratio of starting powder, ball milling medium and deionized water is 1:1.5:2, and the mixing time is 4 hours.

[0072]2. The dry powder obtained in step 1 is subjected to high-energy ball milling for the first time to obtain nanometer powder. Among them, the ball-to-material ratio is 5:1, the rotating speed is 550 rpm, the ball milling...

Embodiment 2

[0078] The raw material ratio expression of the present embodiment is: [2MgO+(1+0.1)SiO 2 ]+8wt%TiO 2 +0.4wt% CoO, using magnesium oxide, silicon dioxide, titanium dioxide, and cobaltous oxide with a purity of more than 99% as the main raw materials, through the following steps.

[0079] 1. Using magnesium oxide and silicon dioxide with a purity of more than 99% as the starting powder, according to the expression 2MgO+(1+0.1)SiO 2 After the required mole percentage is weighed, zirconia balls and deionized water are added into the ball milling medium, and mixed mechanically, and dried after mixing to obtain a dry powder. Wherein, the weight ratio of starting powder, ball milling medium and deionized water is 1:1.5:2, and the mixing time is 4 hours.

[0080] 2. The dry powder obtained in step 1 is subjected to high-energy ball milling for the first time to obtain nanometer powder. Among them, the ball-to-material ratio is 6:1, the rotating speed is 600 rpm, the ball milling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com