Grid electrode enhanced surface plasmon laser and preparation method thereof

A surface plasmon, laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problem that the size cannot break through the optical diffraction limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 A grid electrode enhanced surface plasmon laser.

[0051] In this implementation case, silicon wafer 1 is selected as the substrate material, and the specific preparation method of a grid electrode-enhanced surface plasmon laser is as follows:

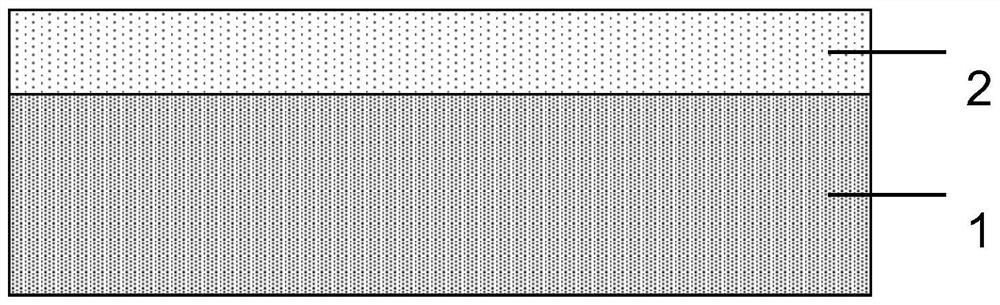

[0052] (1) if figure 1 As shown, a layer of SiO with a thickness of 200 nm was evaporated on a silicon wafer 1 by using plasma enhanced chemical vapor deposition (PECVD) technology. 2 Insulation layer 2, PECVD grown SiO 2 The way is to pass 5% SiH into the reaction chamber 4 / N 2 and N 2 The mixed gas of O, the flow rates are 100sccm and 450sccm respectively, under the condition of pressure 300mTorr, power 10W, temperature 350℃, through SiH x +O→SiO 2 (+H 2 ) reaction to deposit SiO on the epitaxial wafer surface 2 , the time is 9 minutes and 40 seconds;

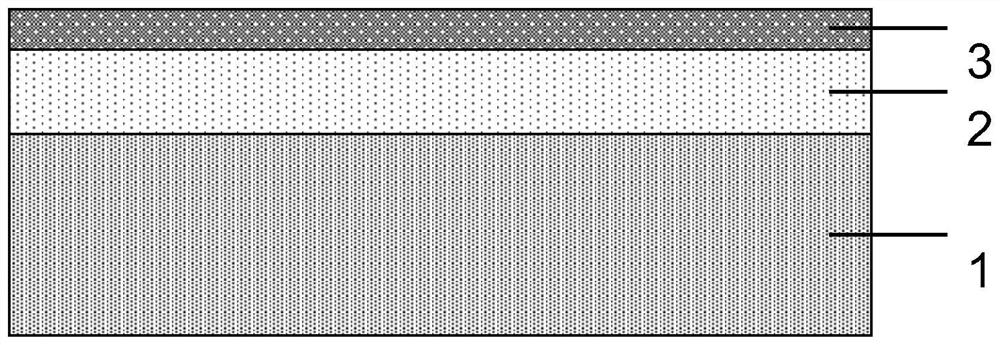

[0053] (2) if figure 2 As shown, in the first insulating layer SiO 2 A silver (Ag) metal layer 3 with a thickness of 80 nm is deposited on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com