Varactor circuit with low phase noise

A low phase noise and phase noise technology, applied in the direction of reliability improvement and modification, can solve the problems of inability to reduce noise and VCO performance impact, and achieve the effect of improving Q value and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

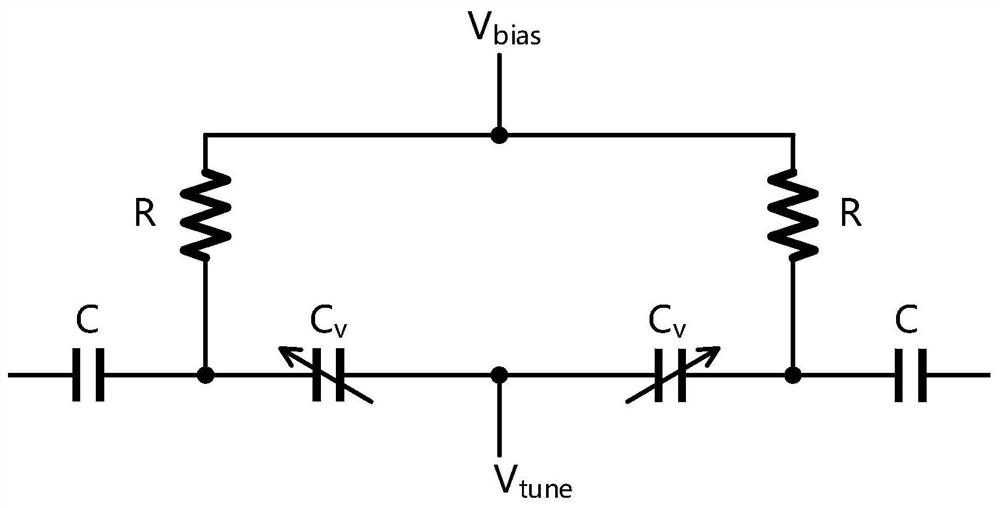

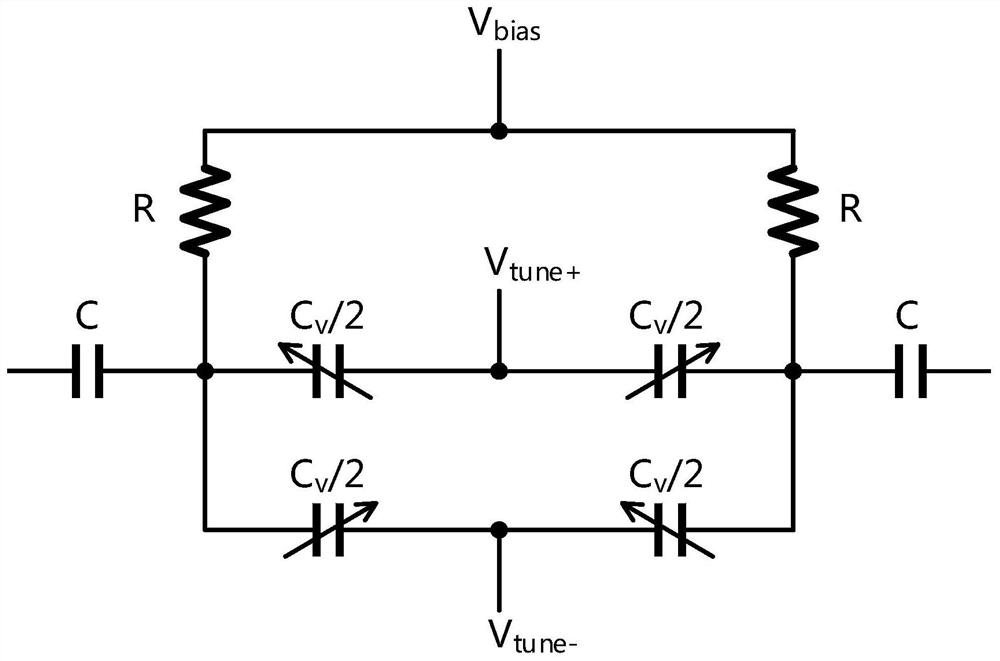

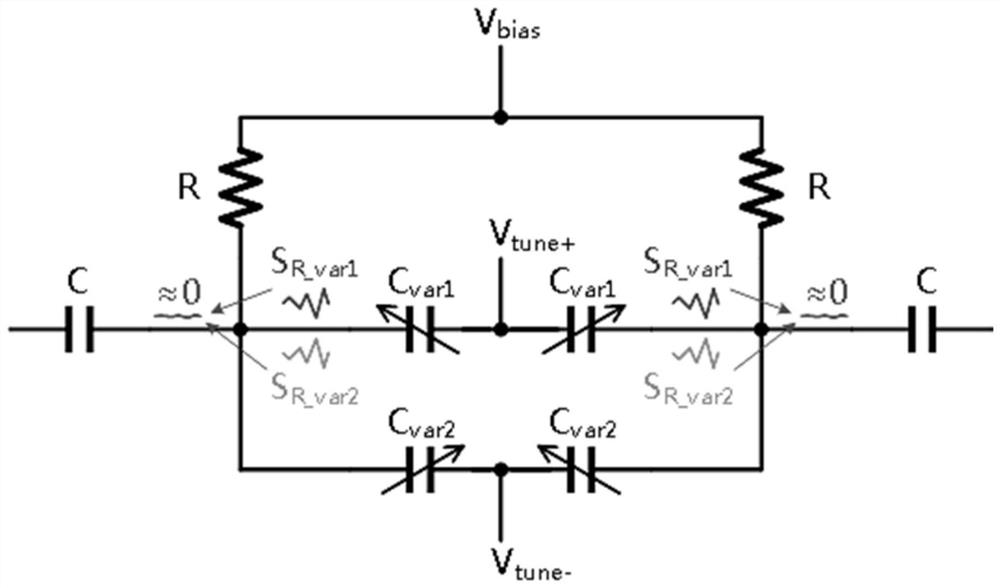

[0022] refer to Figure 1-Figure 3 , a varactor circuit with low phase noise, including two capacitors and two resistors, the two capacitors and the two resistors are connected in series, and the two resistors are located between the two capacitors, and there are multiple capacitors connected in parallel between the two resistors The first variable capacitor, and the two common terminal nodes are located between the capacitor and the resistor, a plurality of second variable capacitors are connected in parallel on the two common terminal nodes, and the first variable capacitor and the second variable capacitor have the same gain but The polarity is opposite, because the thermal noise of the resistor is common-mode noise, if the first variable capacitor and the second variable capacitor with the same gain but opposite polarity are selected and connected to the resistor in the same way, the thermal noise of the resistor is within a certain The phase noise generated by the first v...

Embodiment 2

[0026] refer to Figure 1-Figure 3 , a varactor circuit with low phase noise, including two capacitors and two resistors, the two capacitors and the two resistors are connected in series, and the two resistors are located between the two capacitors, and there are multiple capacitors connected in parallel between the two resistors The first variable capacitor, and the two common terminal nodes are located between the capacitor and the resistor, a plurality of second variable capacitors are connected in parallel on the two common terminal nodes, and the first variable capacitor and the second variable capacitor have the same gain but The polarity is opposite, because the thermal noise of the resistor is common-mode noise, if the first variable capacitor and the second variable capacitor with the same gain but opposite polarity are selected and connected to the resistor in the same way, the thermal noise of the resistor is within a certain The phase noise generated by the first v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com