Patents

Literature

47 results about "Cobalt(II) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

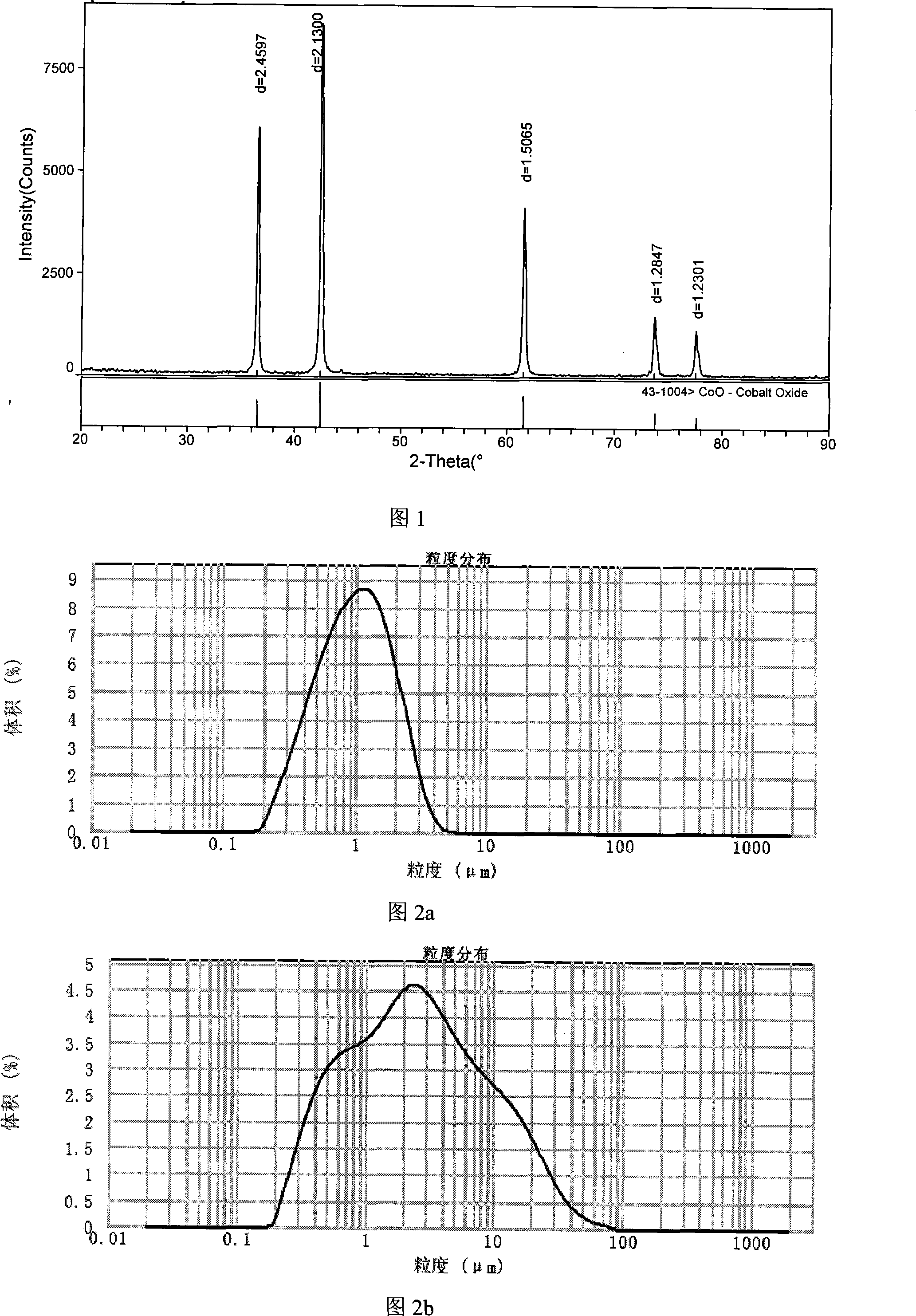

Cobalt(II) oxide or cobalt monoxide is an inorganic compound that appears as olive-green to red crystals, or as a greyish or black powder. It is used extensively in the ceramics industry as an additive to create blue colored glazes and enamels as well as in the chemical industry for producing cobalt(II) salts.

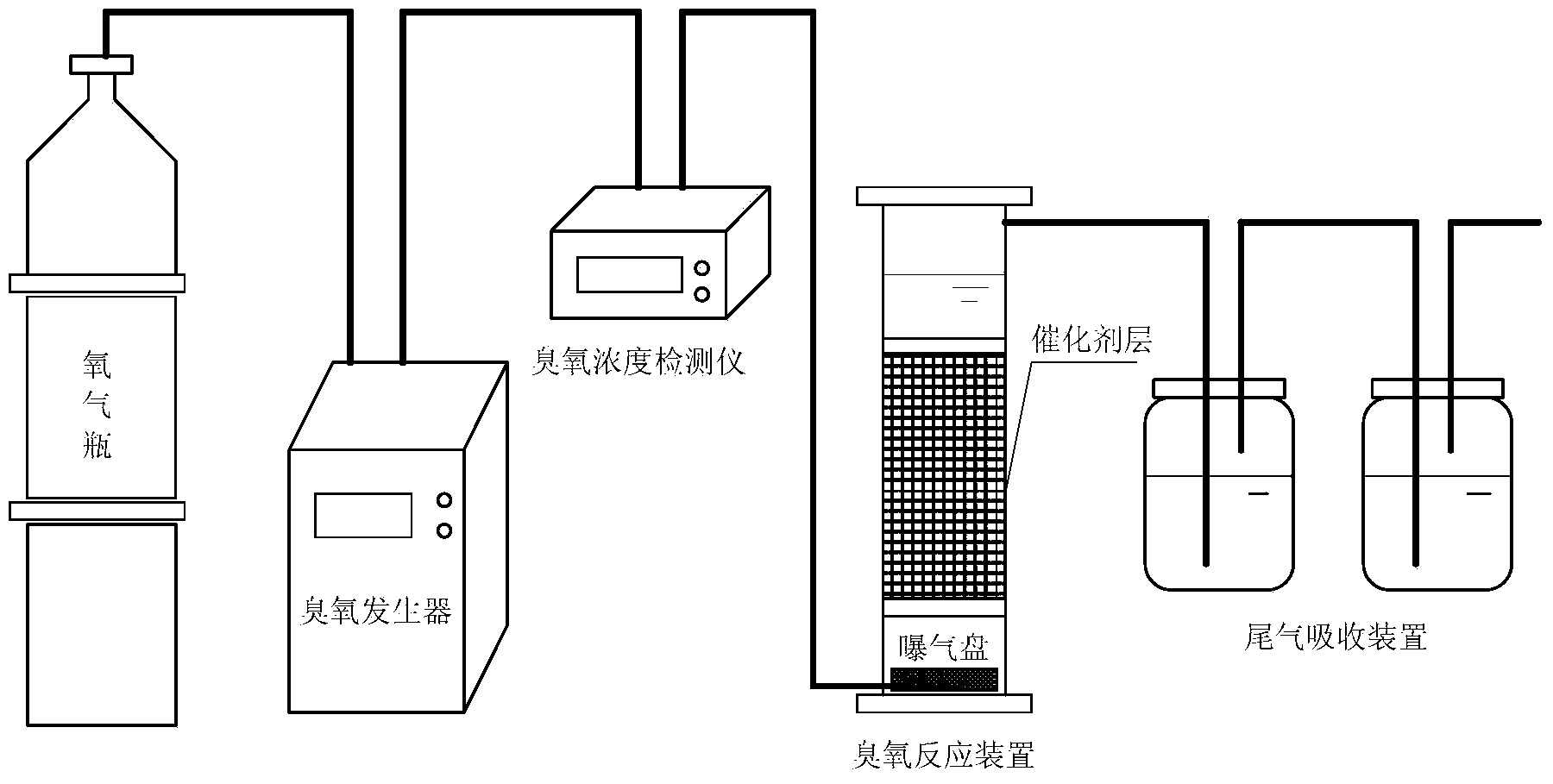

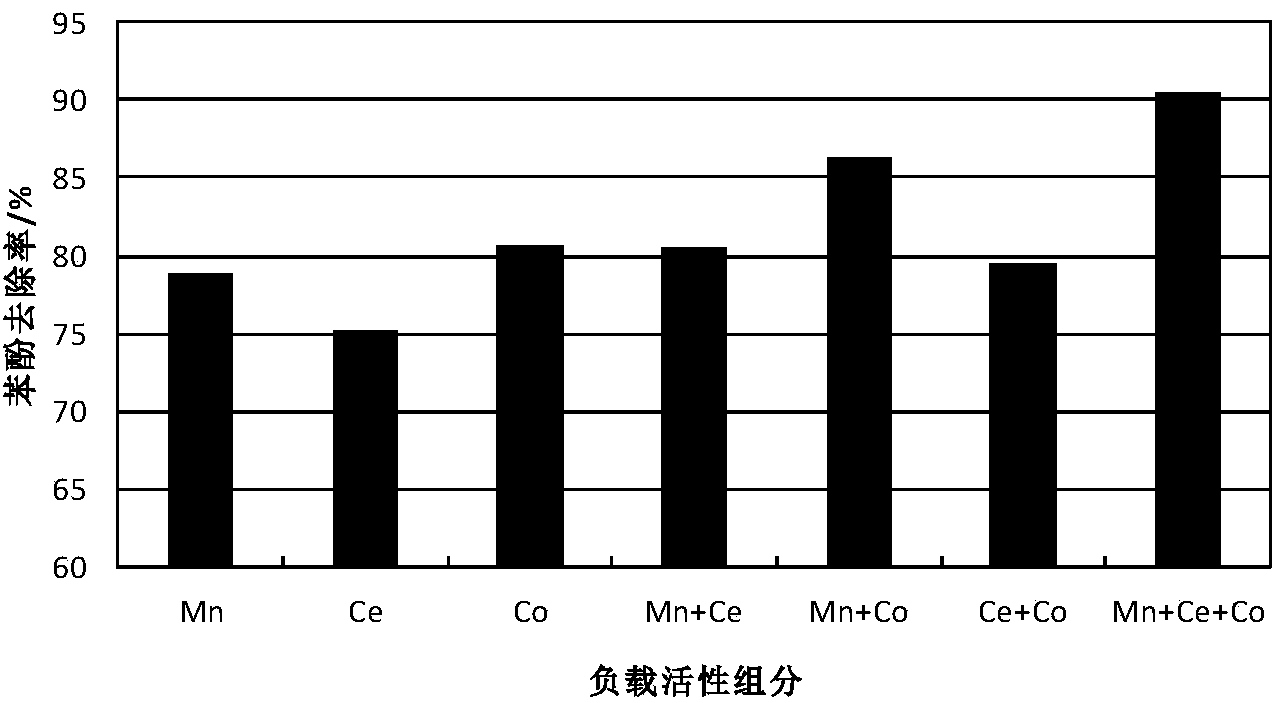

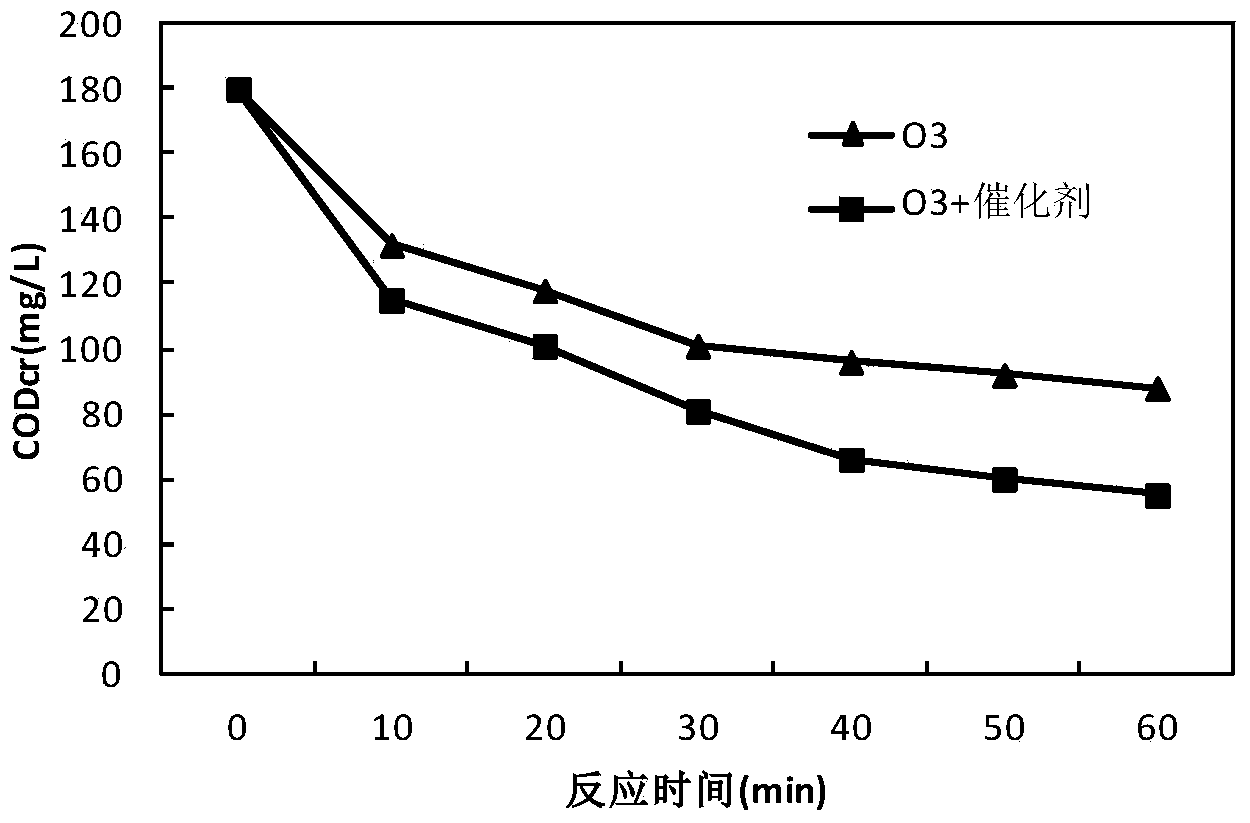

Preparation method for MnO2-CeO2-CoO/AC ternary supported catalyst for treatment of phenolic wastewater

ActiveCN104307534AEfficient catalytic degradationAccelerate the process of catalytic oxidationWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATECerium

The invention discloses a preparation method for an MnO2-CeO2-CoO / AC ternary supported catalyst for treatment of phenolic wastewater. The catalyst is prepared by that manganese dioxide, cerium oxide and cobalt oxide are loaded to a carrier activated carbon; the method comprises the following steps: preparing a mixed solution of manganese acetate, cerium acetate and cobaltous acetate with the concentration of 10%-30%, wherein the mass ratio of manganese to cerium to cobalt is (2-10):(1-3):1; adding a binder and the mixed solution into raw material coal dust, wherein the weight ratio of the raw material coal dust to the mixed solution to the binder is 100:(1-20):(20-30), mixing the components, and using an extruding die to extrude the mixture into carbon strips through a forming machine or pelletizing through a pelletizing machine, and sequentially performing air drying, carbonization, activation and aftertreatment on formed carbon strips or carbon balls, so that the ternary supported activated carbon catalyst with the grain size of 2-5 mm is finally obtained. In preparation, secondary pollution to the environment cannot be caused, and the prepared catalyst is good in catalytic effect, low in preparation cost and long in service life, and achieves higher application value.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

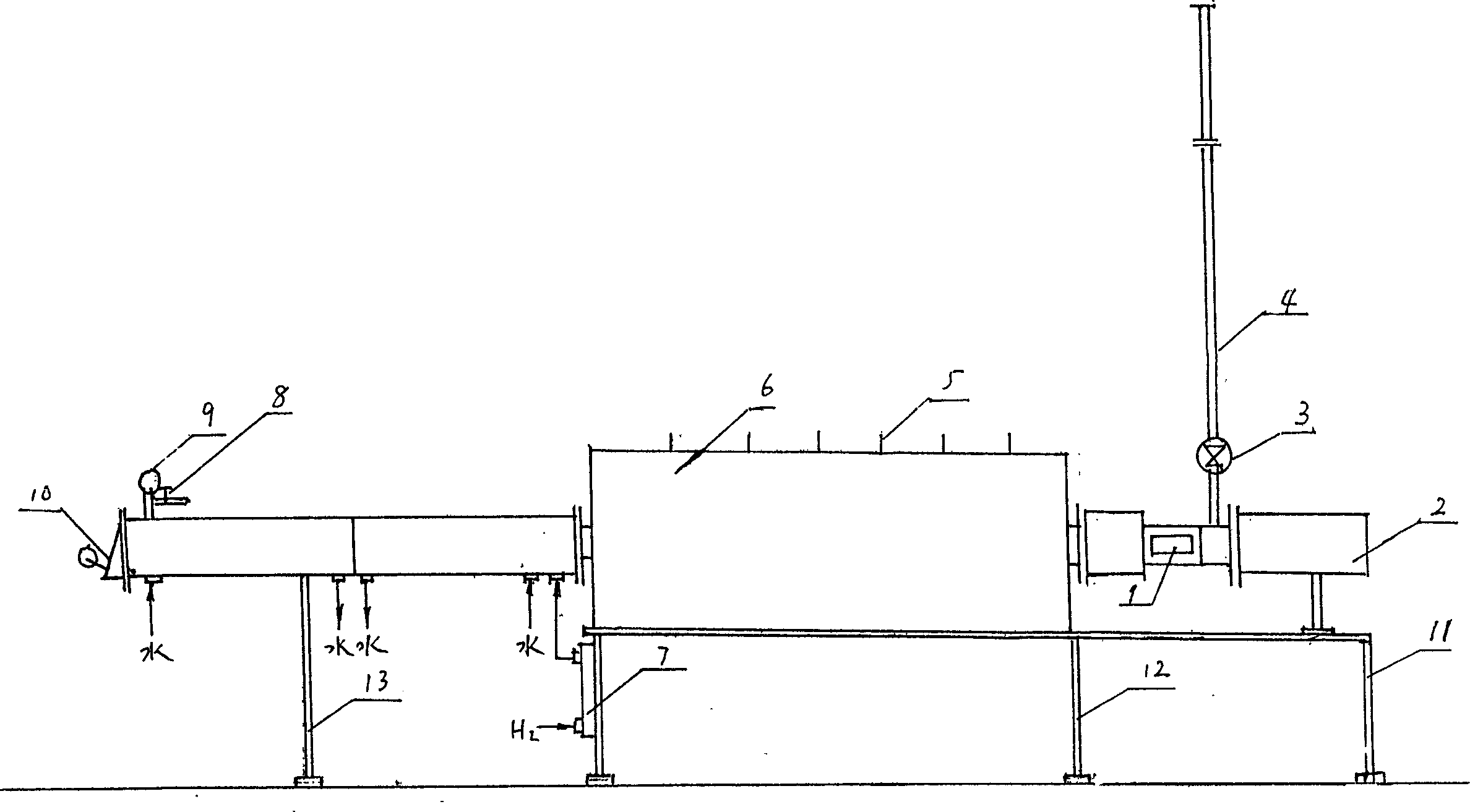

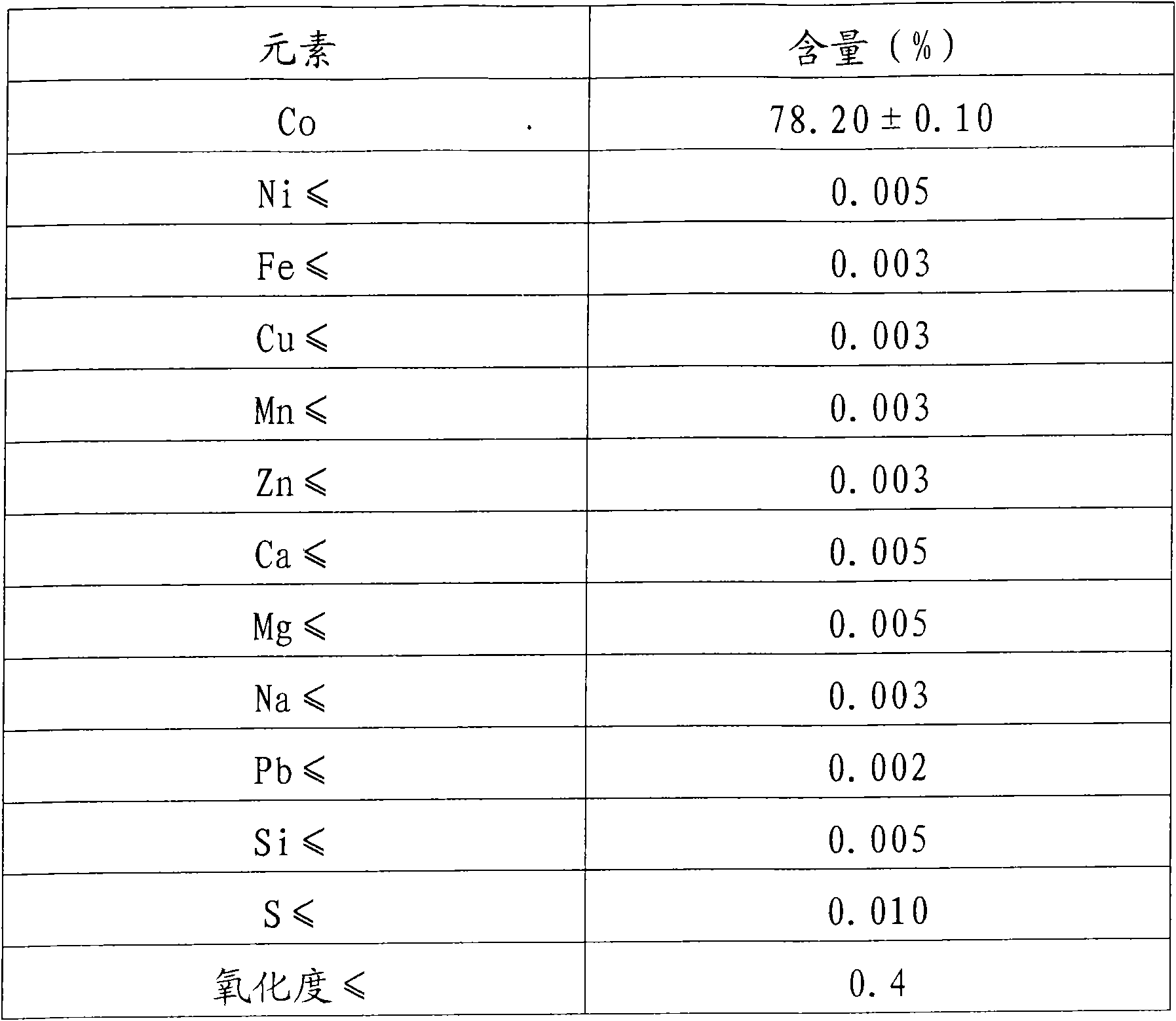

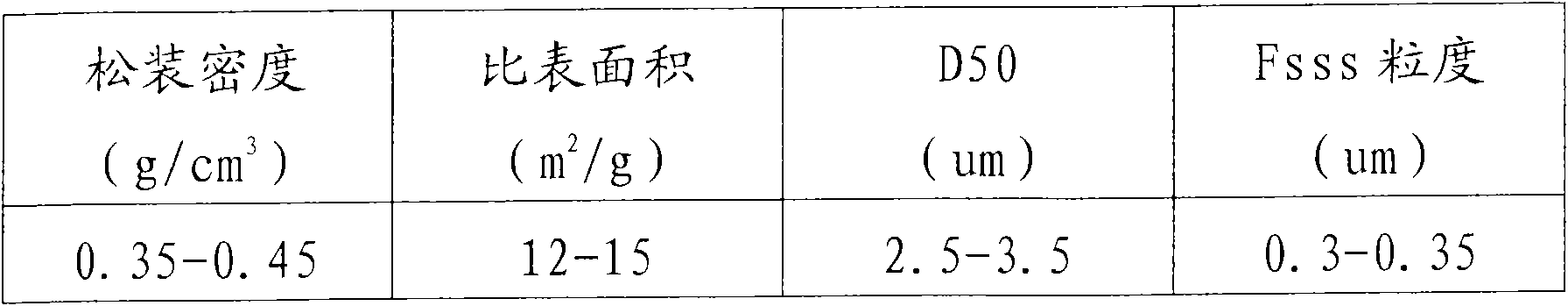

Preparation method and equipment for nano-grade superfine cobalt powder

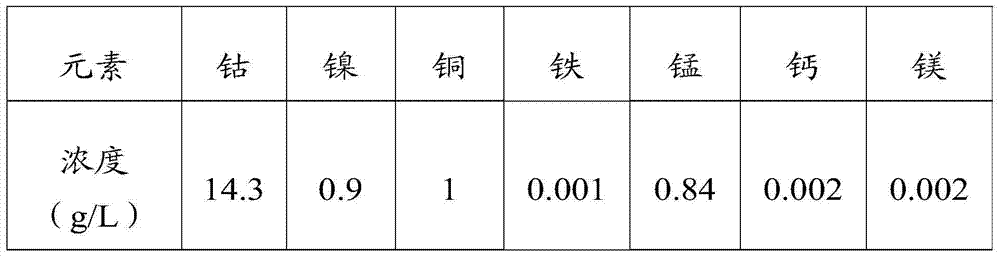

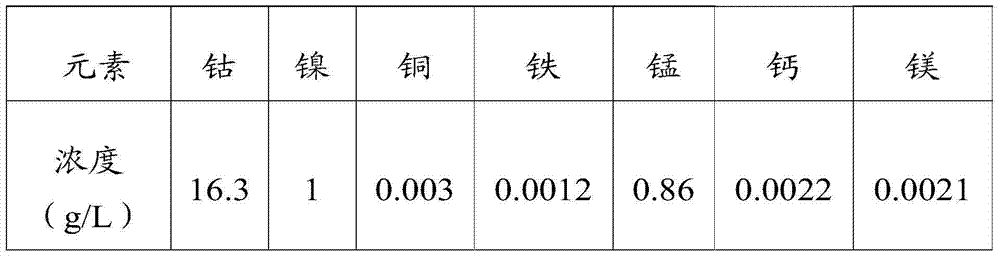

The invention discloses a nanometer super fine cobalt powder preparing method and device, which comprises the following steps: (1)solution strength of CoCl2 is 70-120g / l; NH4 HCO3 liquor is saturation density; the reaction temperature is at 25-50deg, c; pH=7.2-7.5; adding in reactor speed of CoCl2 is 20-100L / min; NH4 HCO3 fat solution is 60-400L / min; the ageing time is 0.5-2.0 hour;(2) the nanometer super fine cobalt powder thermal reduction can use hydrogen to deacidize or heat decomposition in high-temperature electric resistance furnace at 300-500deg C. The intermediate section and front end of feed head of high-temperature electric resistance furnace jamb installs exhaust stabilivolt guide and mechanical pulling-boat-machine; the furnace body heating device installs independently in 5 to 8 sections; the oven tail installs two to three sections of double layer hydrocooling device and checking-valve and micromanometer. The invention has short process, which reduces the cost.

Owner:湖南鼎伦新材料有限公司

Preparation method for violet pigment capable of reflecting infrared ray, and heat-isolating paint

InactiveCN103351649AGood infrared reflection performanceReduce investmentInorganic pigment treatmentPolyester coatingsInfraredBall mill

The invention discloses a preparation method for a violet pigment capable of reflecting infrared ray, and a heat-isolating paint. The preparation method comprises the following steps of: weighing aluminium oxide, cobaltous oxide, magnesium oxide, titanium dioxide and zinc oxide in a certain mass ratio, ball-milling and uniformly mixing; calcining the grinded mixture for 2-4 hours at 850-950 DEG C, cooling the mixture, and then mixing the mixture with a certain amount of ferric oxide, then ball-milling into a powder, and uniformly mixing the powder with a common alkyd varnish in a weight ratio of 1:9, wherein the obtained heat-isolating paint is capable of obviously reflecting the heat of infrared ray in the sunlight. In addition, the method disclosed by the invention is less in equipment investment, simple in preparation process and easy to operate, thus being suitable for large-scale industrialized production.

Owner:SHAANXI UNIV OF TECH

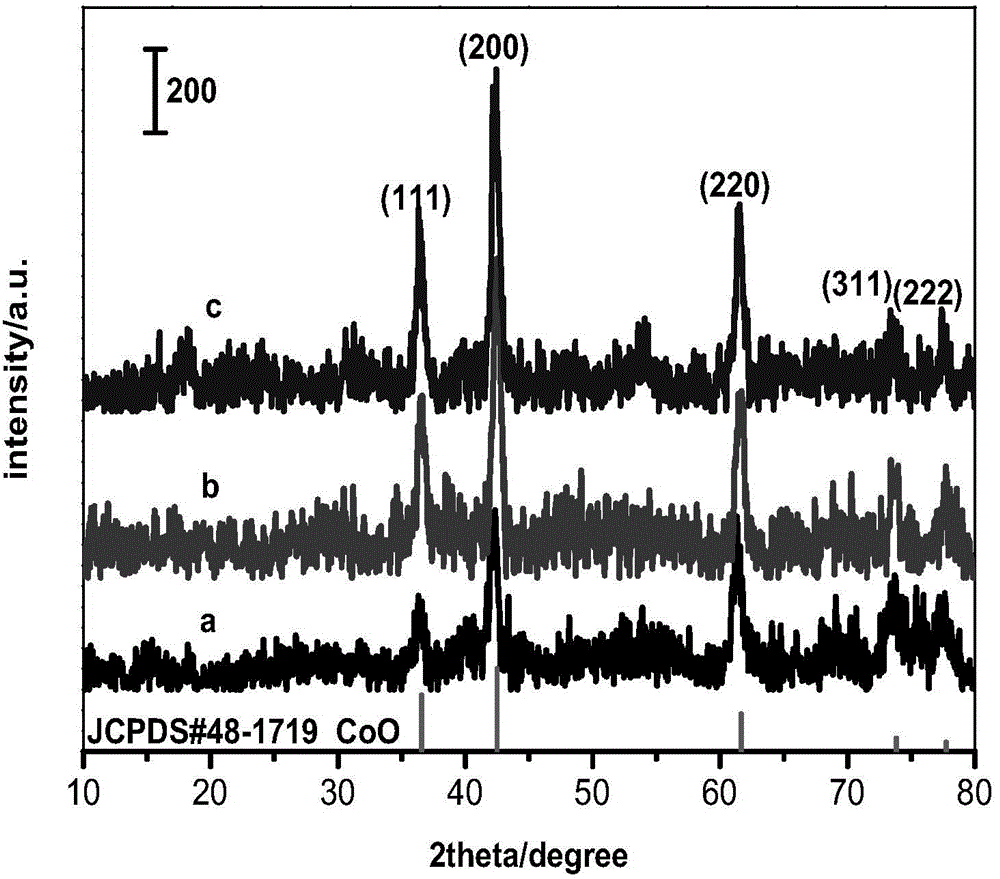

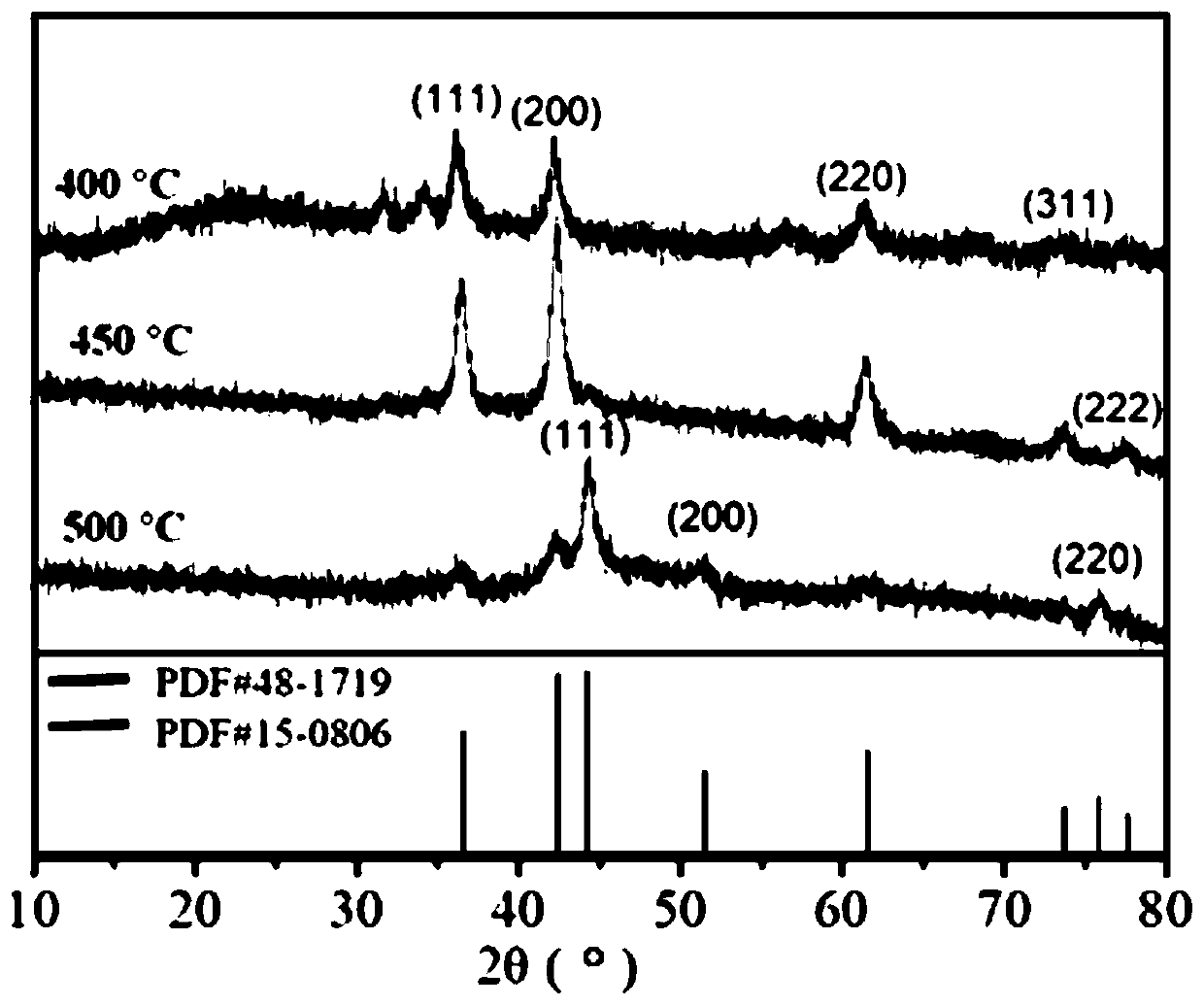

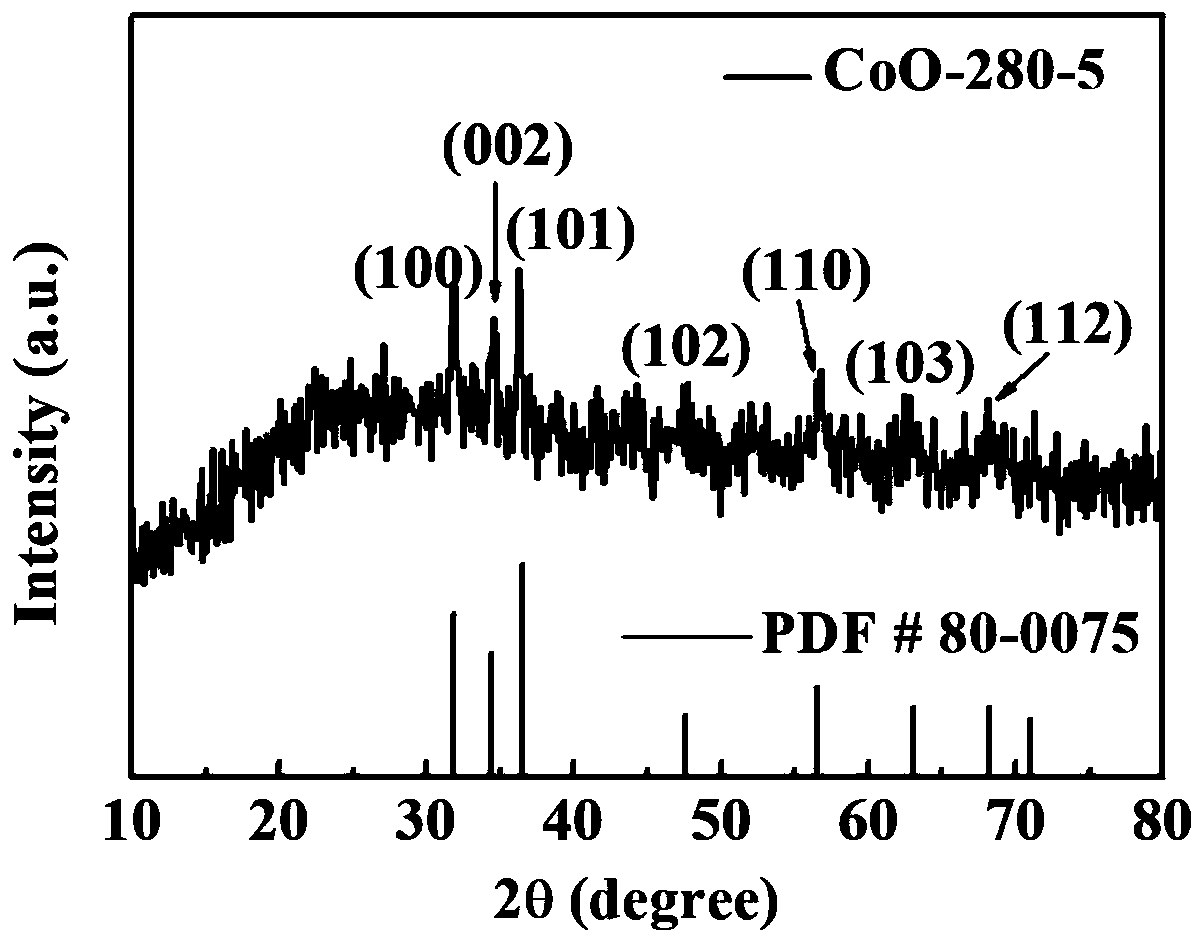

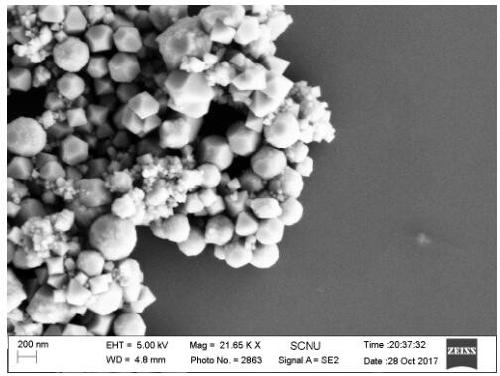

Synthetic method for monodispersed cobalt dioxide nanocrystalline

InactiveCN104925871ASimple processMild conditionsMaterial nanotechnologyCobalt oxides/hydroxidesCentrifugationInorganic compound

The invention relates to the technical field of synthetic method for inorganic compound, and in particular discloses a synthetic method for a monodispersed cobalt dioxide nanocrystalline. The method main overcomes the defects that the cost is high, the procedures are complex, and the capsule diameter is uneven in an existing method. According to the synthetic method for the monodispersed cobalt dioxide nanocrystalline, long-chain organic amine is used as a thermal solvent, organic cobalt salt is used as a cobalt source, the temperature is lifted to different temperatures to conduct thermal decomposition after uniform mixing is conducted under a certain temperature, and a product is obtained after centrifugation and washing are conducted for many times. By adjusting molar ratio of the solvent and a precursor, the molar ratio range of the thermal solvent and the cobalt source differs from 5:1 to 1600:1, the monodispersed cobalt dioxide nanocrystallines with different diameters are obtained, dispersing is good, the size distribution is narrow, the yield is comparatively high, and the monodispersed cobalt dioxide nanocrystallines can be used for industrial manufacture of nanoscale cobalt dioxide.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

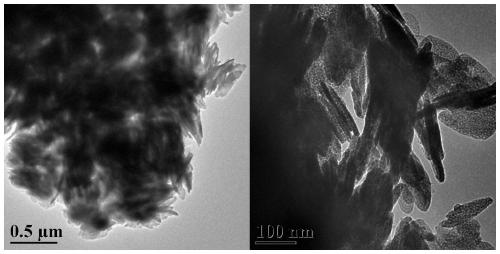

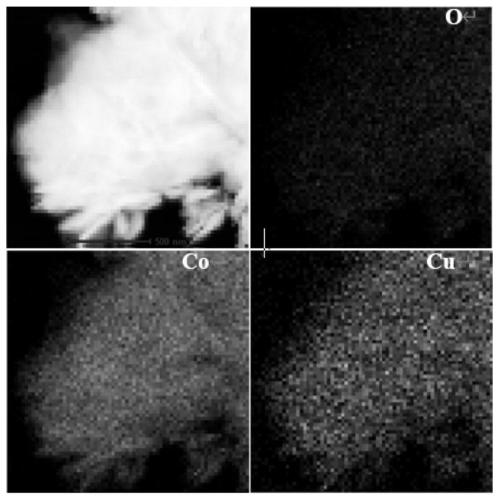

Preparation method of flaky cuprous oxide/cobaltous oxide nano composite material and application of flaky cuprous oxide/cobaltous oxide nano composite material in catalyzing hydrolysis of ammonia borane to produce hydrogen

ActiveCN111420664AEasy to prepareEvenly dispersedMaterial nanotechnologyEnergy inputActive agentCopper salt

The invention discloses a preparation method of a flaky cuprous oxide / cobaltous oxide nano composite material, which comprises the following steps: (1) dissolving soluble cobalt salt and copper salt in ultrapure water to prepare a mixed salt solution A; (2) dissolving a surfactant in ultrapure water, and adding tartrate to prepare a solution B; (3) slowly adding the solution B into the solution A,mixing to form a solution C, and stirring; (4) slowly dropwise adding an alkali solution into the solution C, and continuously stirring; (5) transferring to a reaction kettle, reacting at 120-180 DEGC for 2-24 hours, filtering, washing, collecting the product, and drying in a vacuum oven at 40-80 DEG C; and (6) calcining the dried powder at a low temperature of 200-300 DEG C for 0.1-5 hours. According to the invention, Tartrate is ingeniously selected as a complexing agent and a reducing agent, a simple hydrothermal synthesis method and low-temperature calcination treatment are adopted, andthe flaky cuprous oxide / cobaltous oxide nano composite material is successfully prepared.

Owner:HUIZHOU UNIV

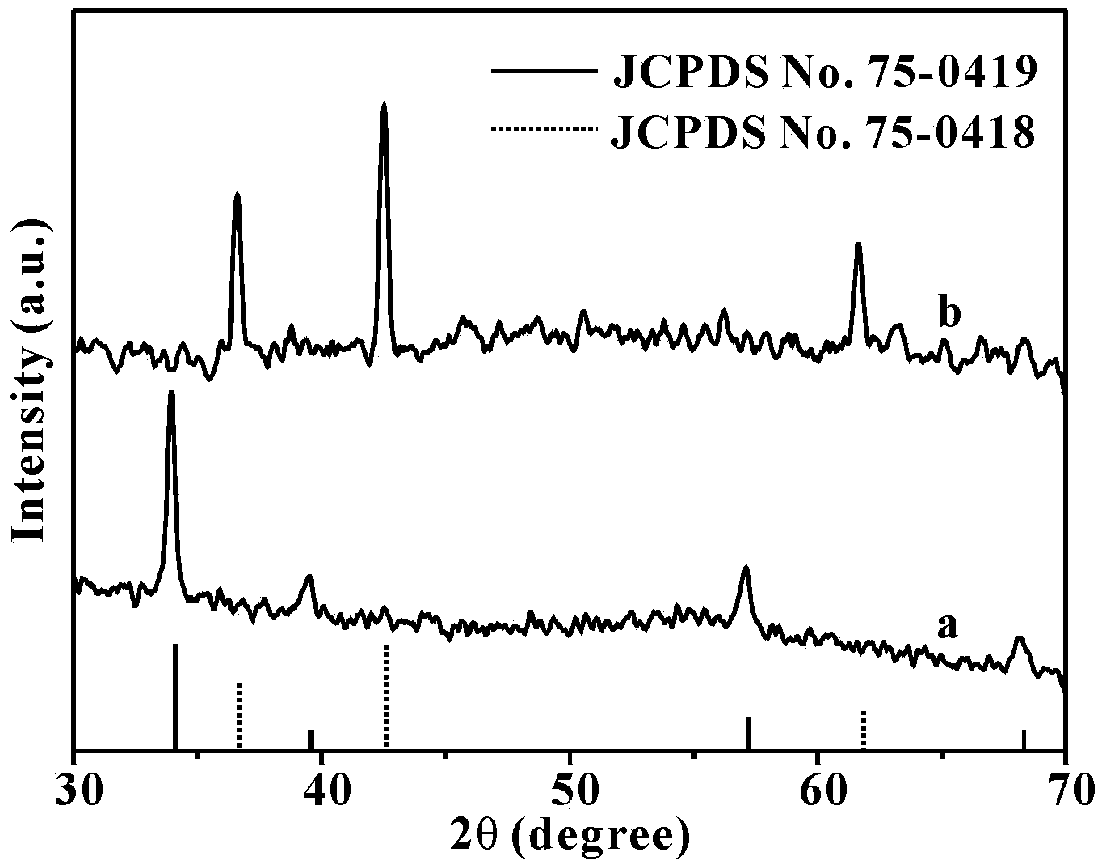

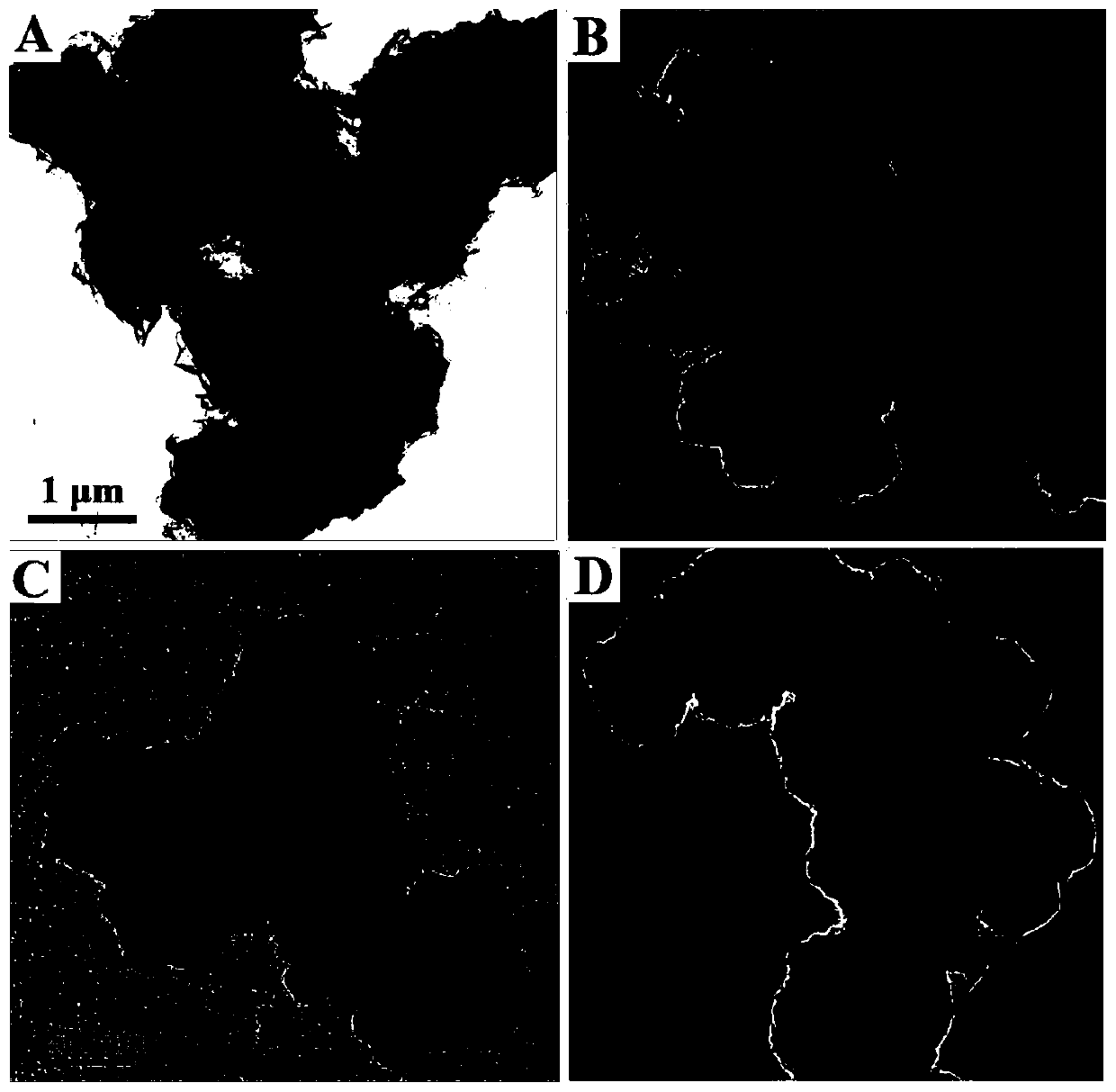

Cobaltous oxide slice, preparation method thereof and application of cobaltous oxide slice in visible-light photocatalysis total-decomposition of water

ActiveCN110386626AExcellent visible light total water splitting performanceHigh activityNanotechnologyHydrogen productionDecompositionFormation rate

The invention provides a cobaltous oxide slice. The cobaltous oxide slice is of a zinc blende structure, and has a nanosheet morphology. The invention discloses a method for preparing the zinc blende-type CoO ultrathin slice, which comprises the steps: dispersing sodium chloride and cobalt acetate in water for a reaction so as to obtain a precursor, and calcining the precursor at a specific temperature in an inert atmosphere so as to obtain the zinc blende-type CoO ultrathin slice. The invention also provides a method for achieving visible-light total decomposition of water by using the zinc blende-type CoO ultrathin slice. It is shown through experimental results that the zinc blende-type CoO ultrathin slice has higher performance in visible-light total-decomposition of water and higher stability than rock salt-mine-type CoO ultrathin sheets, and the formation rates of H2 and O2 under irradiation of visible light by means of the cobaltous oxide slice are 4.43 [mu]mol.g<-1>.h<-1> and 2.63 [mu]mol.g<-1>.h<-1> separately.

Owner:UNIV OF SCI & TECH OF CHINA

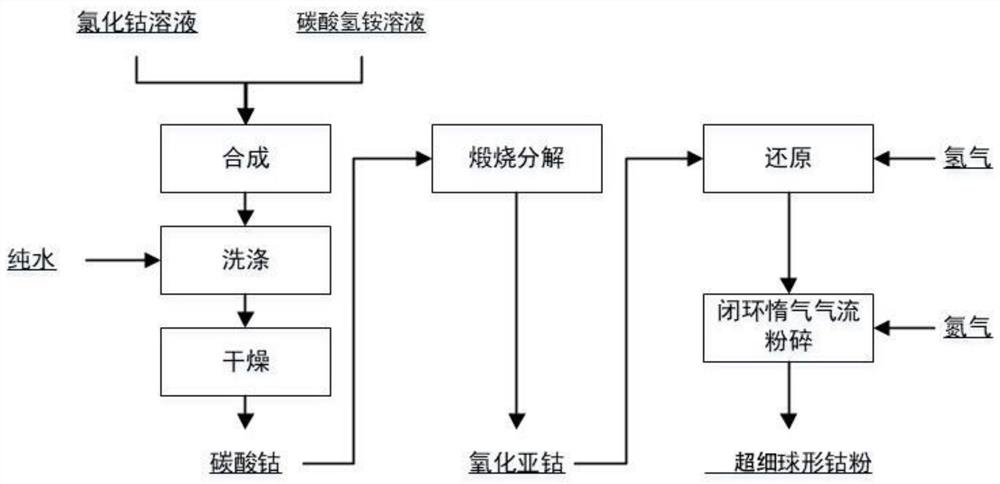

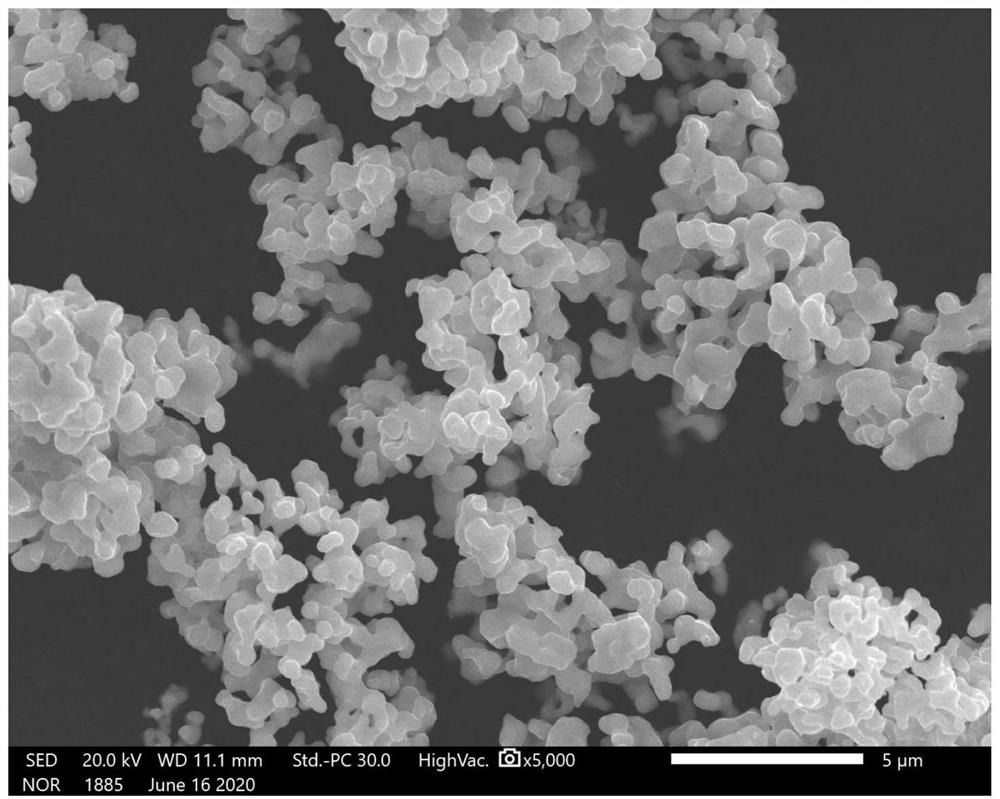

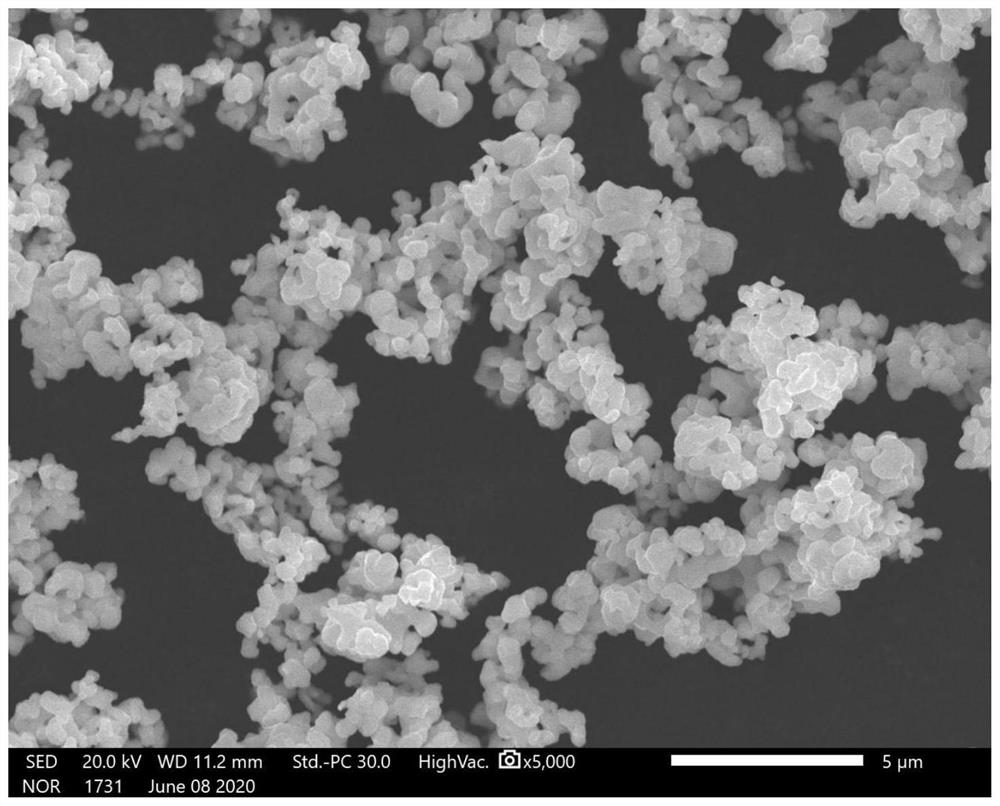

Preparation method of superfine spherical cobalt powder

PendingCN112355317AUniform particle sizeUniform and controllable particle sizeTransportation and packagingMetal-working apparatusCobalt saltEngineering

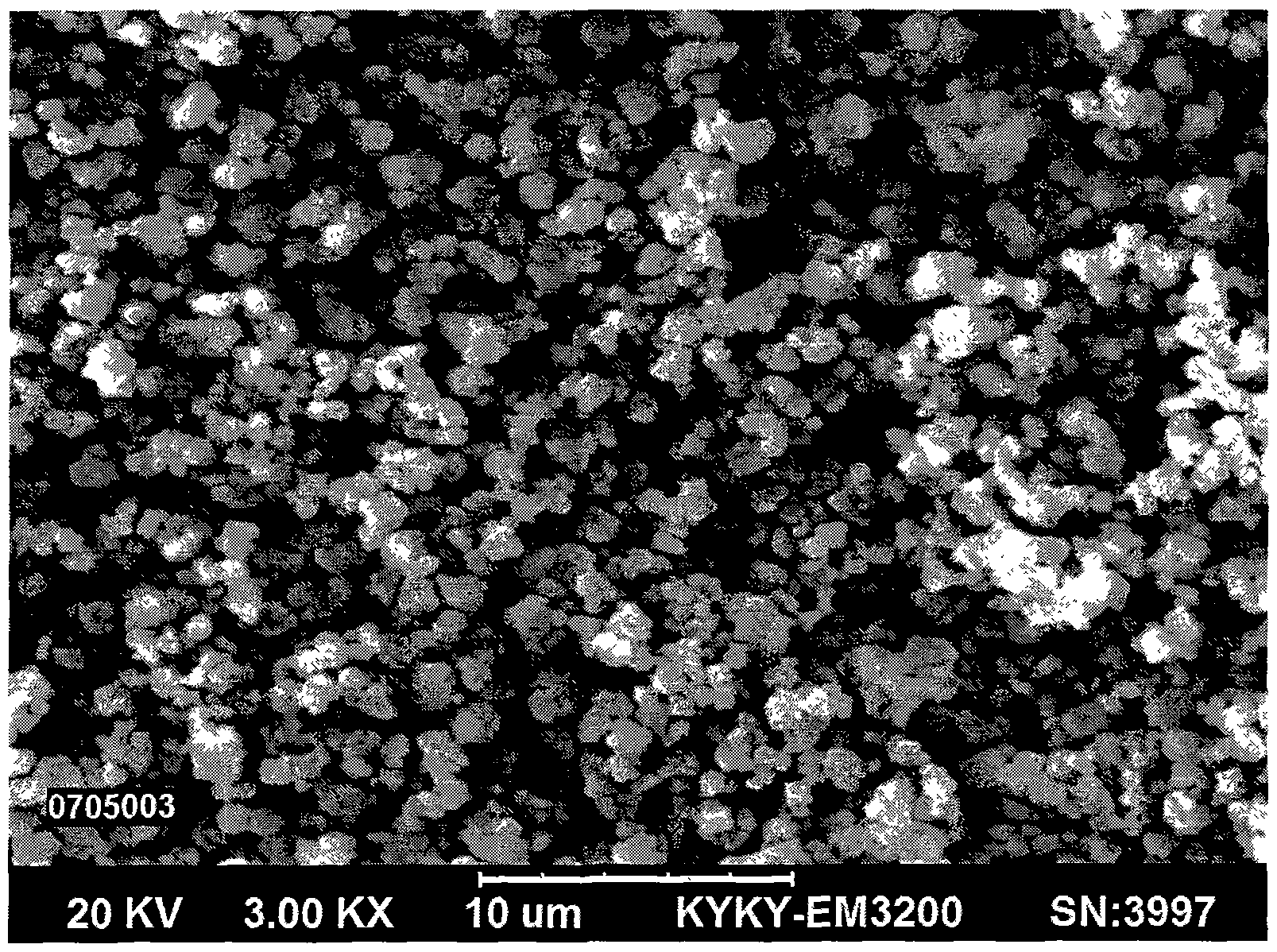

The invention relates to the technical field of cobalt-based powder material preparation, in particular to a preparation method of superfine spherical cobalt powder. The method comprises the followingsteps that (1), a cobalt salt solution reacts with an ammonium bicarbonate or sodium carbonate precipitant under a heating condition to obtain cobalt carbonate precipitate; (2), the cobalt carbonateprecipitate is filtered, washed with pure water, and dried to obtain cobalt carbonate powder; (3), the cobalt carbonate powder is placed into a calcining furnace, and heated and decomposed in an oxygen-free state to obtain cobaltous oxide; (4), the cobalt monoxide powder obtained by calcining and decomposing is placed into a reduction furnace, and hydrogen is introduced for reduction to obtain a loose spongy cobalt block; and (5), airflow milling is carried out on the spongy cobalt block in a closed cycle inert gas protective atmosphere to obtain the ultrafine spherical cobalt powder with theFisher particle size being 0.4-0.8 micrometer. The particle size of the prepared cobalt powder reaches the ultrafine grade, the cobalt powder is spherical, and the cobalt powder has the advantages ofbeing uniform and controllable in particle size, uniform in particle size distribution, good in flowing property and the like.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

Cobalt powder preparation method

The invention relates to the field of production of chemical raw materials, in particular to a cobalt powder preparation method. The cobalt powder preparation method includes the following steps that sulphuric acid is added into lithium cobalt paper for acidolysis of the lithium cobalt paper; after the pH value is regulated to 1 to 3, copper impurities are removed; hydrogen peroxide is added, then the pH value is regulated to 2 to 5, and filter pressing is performed to remove impurities; purification and reaction are carried out to obtain a cobalt nitrate solution; the cobalt nitrate solution reacts with ammonium carbonate to obtain cobalt carbonate; the cobalt carbonate is dried, calcined and cooled to obtain the cobalt powder. According to the preparation method, liquid caustic soda is not needed to treat the lithium cobalt paper, the reducing agent sulfur dioxide does not need to be added in the acidization either, and sodium carbonate is replaced with the ammonium carbonate in the cobalt precipitating process; the cobalt powder is produced and prepared through the lithium cobalt paper, so that production cost is greatly reduced, and environmental pollution is avoided; moreover, the prepared cobalt powder has very high hardness and compressive strength so that the cobalt powder not only can be used as the catalyst of secondary batteries but also can be applied to hard alloy additives and has a wider application range than cobalt oxide.

Owner:宁波雁门化工有限公司

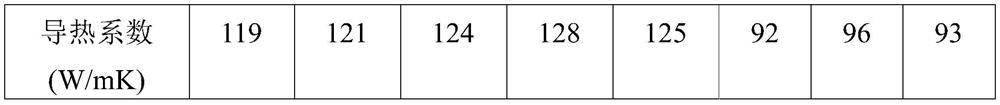

Stannic oxide-cobalt monooxide composite thin film material, lithium battery and preparation method

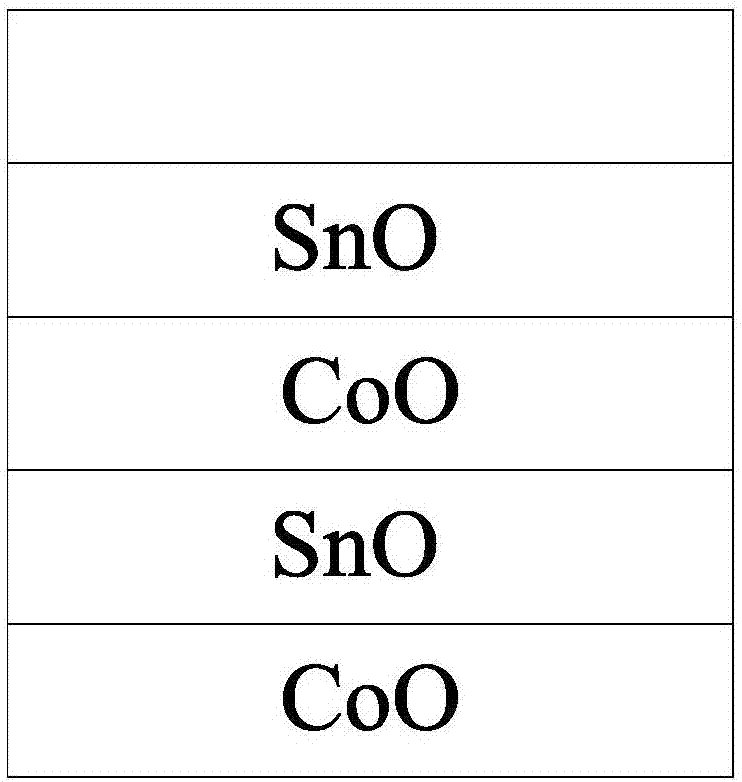

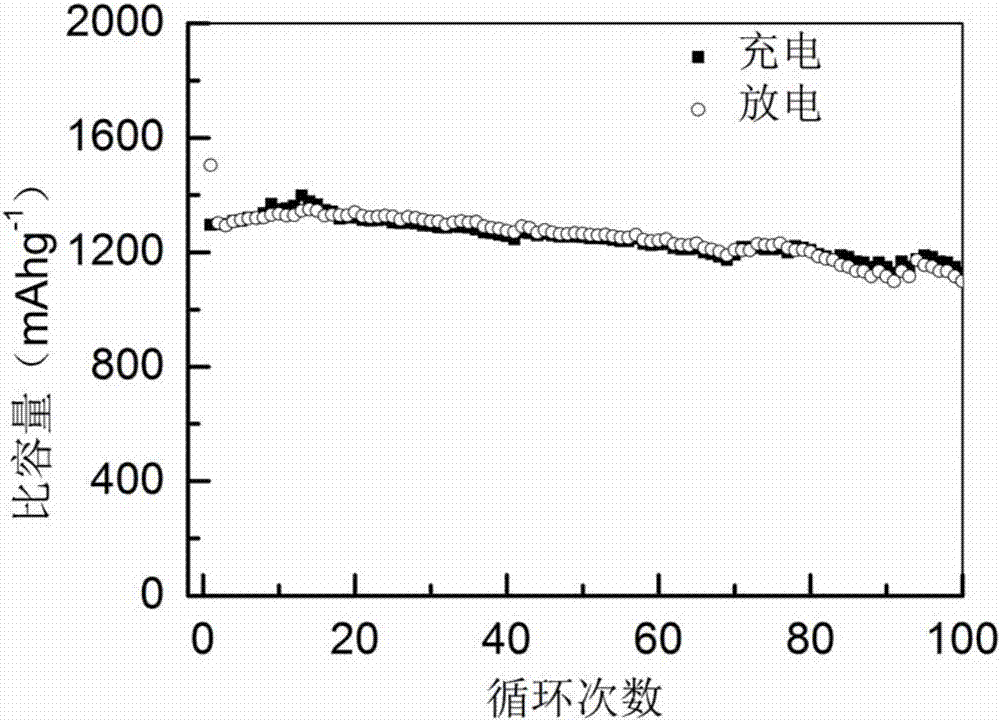

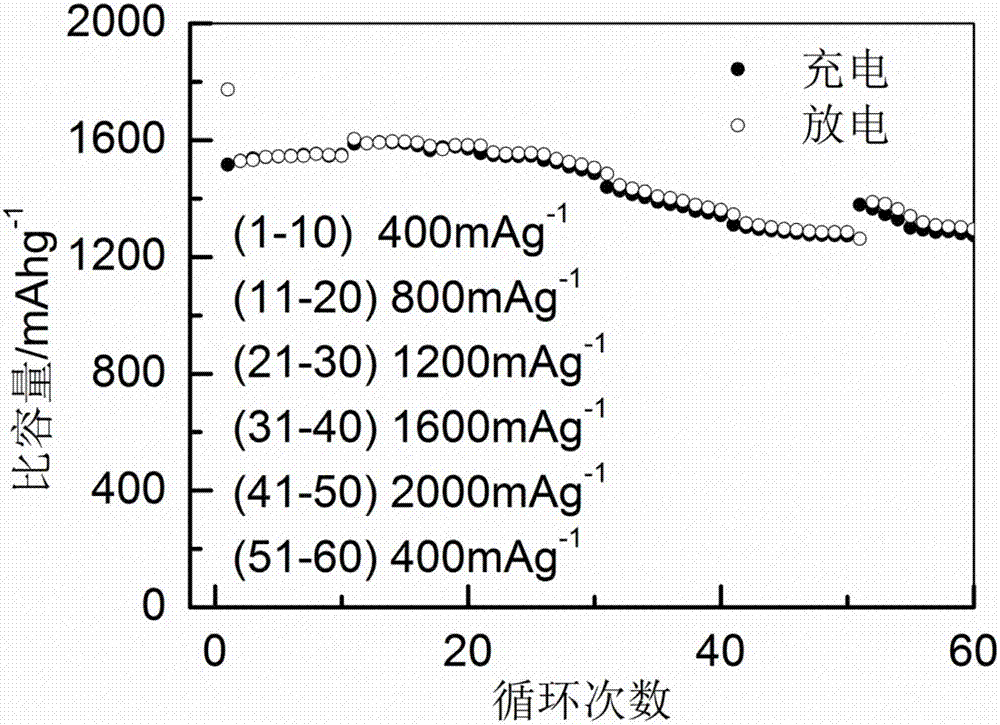

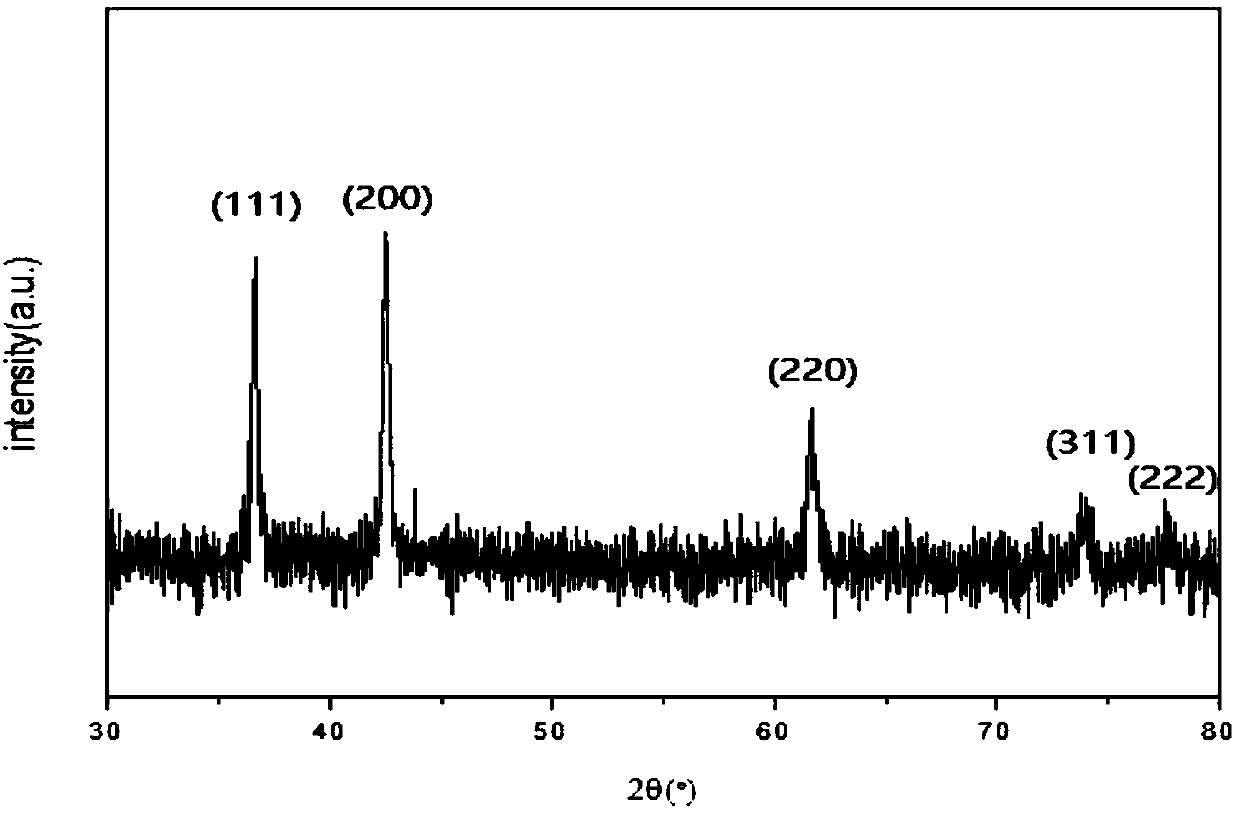

InactiveCN107275585AImproved magnification performanceIntegrity guaranteedMaterial nanotechnologyCell electrodesTin dioxideComposite film

The embodiment of the invention discloses a stannic oxide-cobalt monooxide composite thin film material, a lithium battery and a preparation method. The stannic oxide-cobalt monooxide composite thin film material comprises stannic oxide layers and cobalt monooxide layers, wherein the stannic oxide layers and the cobalt monooxide layers are arranged at intervals; the thickness of the stannic oxide layers or the cobalt monooxide layers is 2nm to 50nm; the total number of the stannic oxide layers or the cobalt monooxide layers is 20 to 100. The stannic oxide-cobalt monooxide composite thin film material prepared by an alternative deposition method has the advantages that when the stannic oxide-cobalt monooxide composite thin film material is used for preparing a cathode of a lithium ion battery, the good electromechanical property is realized; on one hand, the stannic oxide and the cobalt monooxide are alternatively distributed, so that the stress caused by volume change is effectively buffered, the structure integrity is further maintained, and the cycle stability is improved; on the other hand, the metal Co (cobalt) generated in the CoO (cobalt monooxide) energy storage reaction has the function of catalyzing the electrode charging and discharging reaction activity, and the rate performance of the battery is improved.

Owner:QINGDAO UNIV

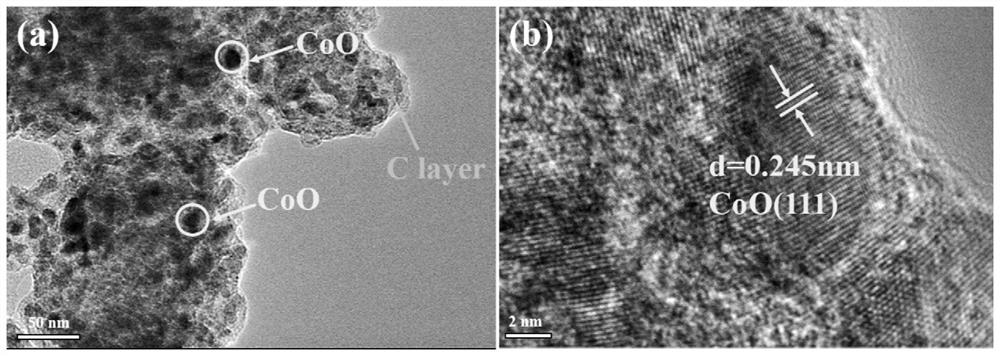

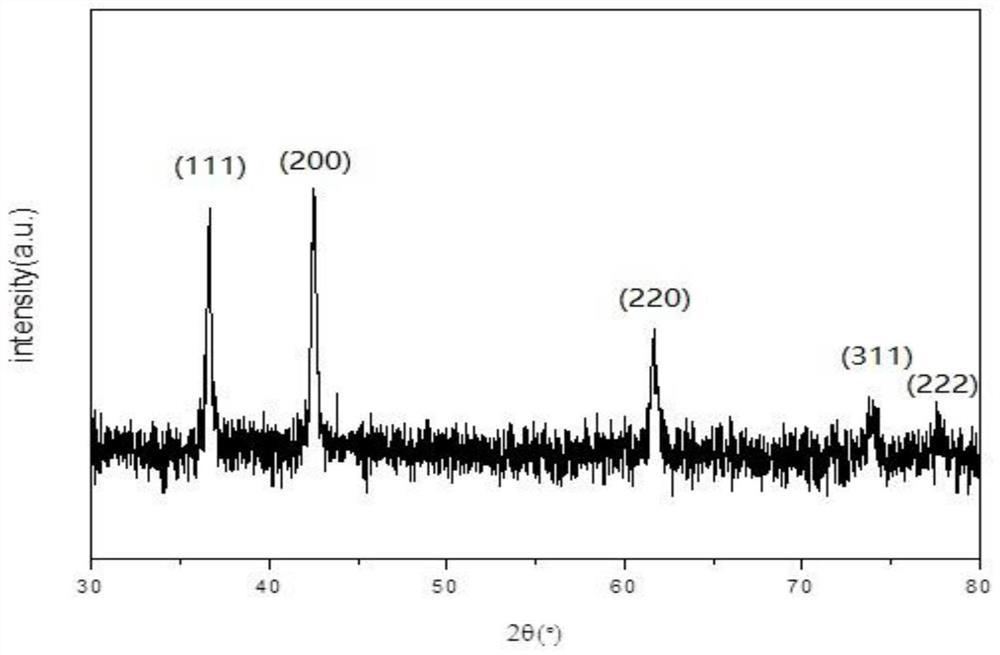

Nitrogen-doped graphene/cobaltous oxide composite material and preparation method thereof

The invention discloses a nitrogen-doped graphene / cobaltous oxide composite material. Graphite oxide, a cobaltous acetate solution and ammonium carbonate are taken as the main raw materials, and cobaltous oxide is loaded on nitrogen-doped graphene by adopting a water bath-hydrothermal-calcining method to obtain the nitrogen-doped graphene / cobaltous oxide composite material. Compounding of nitrogen-doped graphene and cobaltous oxide is proposed initially in the invention, the obtained composite material is high in cobaltous oxide purity, and a synergistic effect between cobaltous oxide and nitrogen-doped graphene can be achieved, so that an excellent catalytic ability on a fuel cell negative electrode oxygen reduction reaction can be achieved; meanwhile, the material cost of a catalyst is greatly lowered; and the involved preparation method is simple, high in repeatability and suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

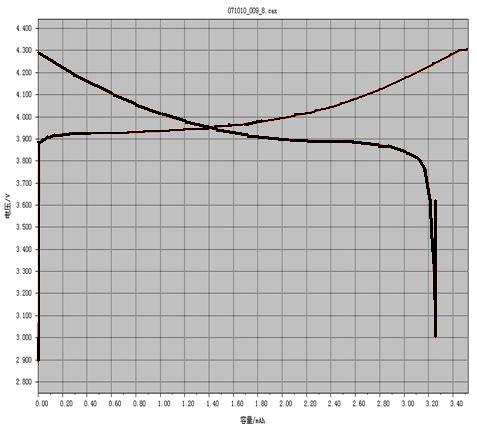

Method for preparing spherical cobaltous oxide

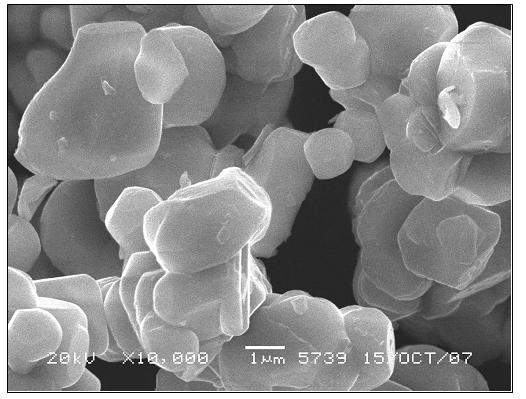

ActiveCN101182043BHigh activityHigh purityCell electrodesCobalt oxides/hydroxidesSpherical shapedHigh activity

The invention discloses a preparation method of spherical cobaltous oxide, and relates to cobalt solution which is obtained by the leaching and purification of cobalt ore that is used as cobalt raw material. The invention is characterized in that a precursor is prepared by a complexing-homogeneous precipitation method, that is the cobalt solution is made into complexing cobalt salt solution whichis then added with precipitator solution, thereby, the precipitate precursor is formed by controlling the synthesis of the precursor; the spherical cobaltous oxide is obtained by the thermal decomposition of the precursor at 300 to 550 degrees under inert or slight reducing gas atmosphere; and then spherical cobaltous oxide of the invention is formed through the associated passivation of the obtained spherical cobaltous oxide by using gas passivator and liquid passivator, and heat seal packing. The cobaltous oxide powder which is obtained by adopting the method of the invention has the advantages of high activity, high purity, uniform particle size, centralized distribution, smooth surface of particles and strong inoxidability, etc. The invention has easy technology flow, stable production quality, low cost, high automation, thereby being applicable to the large-scale industrialized production.

Owner:ZHEJIANG HUAYOU COBALT

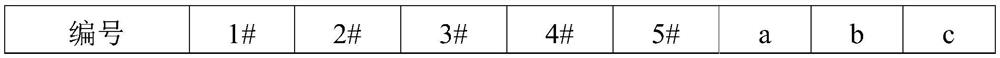

High-thermal-conductivity cobalt powder and preparation method thereof

ActiveCN112846212ARaw materials are cheap and easy to getEasy to operateMetal/alloy conductorsPhysical chemistryCobalt salt

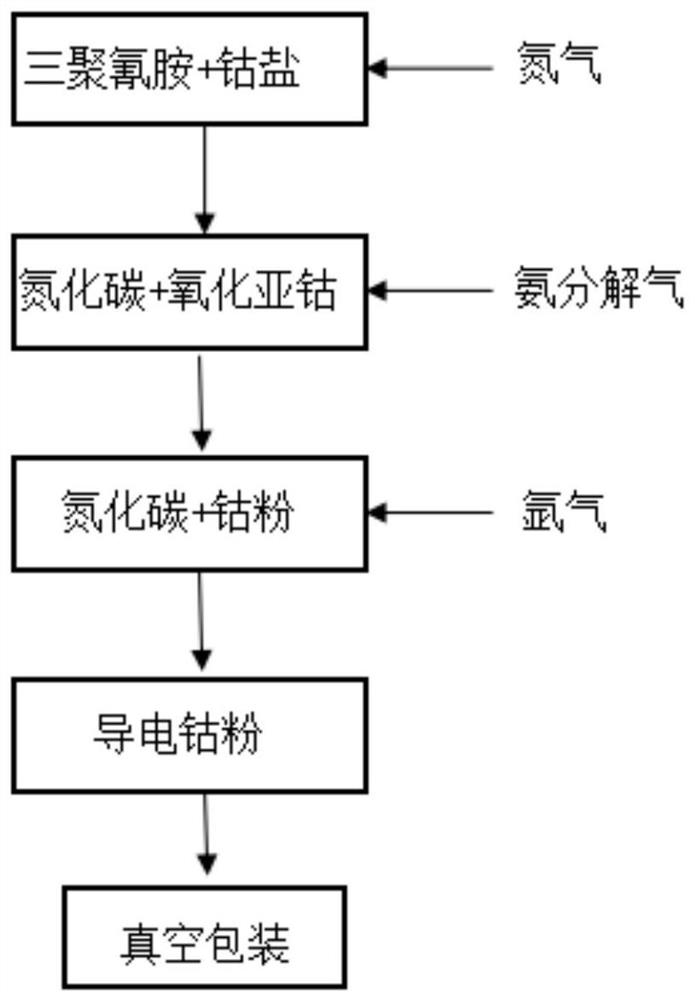

The invention provides high-conductivity cobalt powder and a preparation method thereof, and belongs to the technical field of metal powder preparation. The preparation method of the high-conductivity cobalt powder comprises the following steps of (1) grinding and uniformly mixing melamine and cobalt salt, and heating and reacting in an inert atmosphere in a stepped heating manner to obtain a compound of nitrogen carbide and cobaltous oxide; (2) roasting the compound of the nitrogen carbide and the cobaltous oxide in a decomposed ammonia atmosphere to obtain a compound of the nitrogen carbide and cobalt powder; and (3) carrying out a constant-temperature reaction on the compound of the nitrogen carbide and the cobalt powder in an inert atmosphere to obtain the high-conductivity cobalt powder compounded with graphene and / or carbon nanotubes. According to the preparation method, the raw materials are subjected to low-temperature heat treatment firstly, then the graphene and the carbon nanotubes are directly grown on the surface of the cobalt powder by adopting a high-temperature catalysis method, and the cobalt powder is chemically combined with the graphene and the carbon nanotubes, so that the heat conducting property of the cobalt powder is improved.

Owner:YUCHEN ADVANCED ENERGY MATERIALS & TECH WUXI

Thermal insulation coating and preparation method thereof

InactiveCN110903686ASimple manufacturing methodLow equipment requirementsReflecting/signal paintsFiberPolymer science

The invention discloses a thermal insulation coating which is characterized by being prepared from the following raw materials in parts by weight: 30 to 40 parts of a polymeric borate 2, 7-diaminofluorene / diglycidyl 1,2-cyclohexanedicarboxylate polycondensate, 3-6 parts of fluorobenzene modified diallyl isocyanurate, 1-3 parts of 3-trimethoxysilane propyl acrylate, 3-5 parts of cobaltous oxide hollow nanofibers, 3-6 parts of an aluminum-based metal organic framework, 10-20 parts of sepiolite powder, 1-3 parts of an initiator, 10-15 parts of a solvent and 3-5 parts of a functional additive. Theinvention also provides a preparation method of the thermal insulation coating. The thermal insulation coating disclosed by the invention has good comprehensive performance, remarkable thermal insulation effect, good weather resistance and storage stability, high adhesion strength, excellent mechanical property and chemical resistance stability and long service life.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

Preparation method of cobalt oxide powder

InactiveCN101993118AGranularity controllableUniform particle size distributionCobalt oxides/hydroxidesPtru catalystElectrical battery

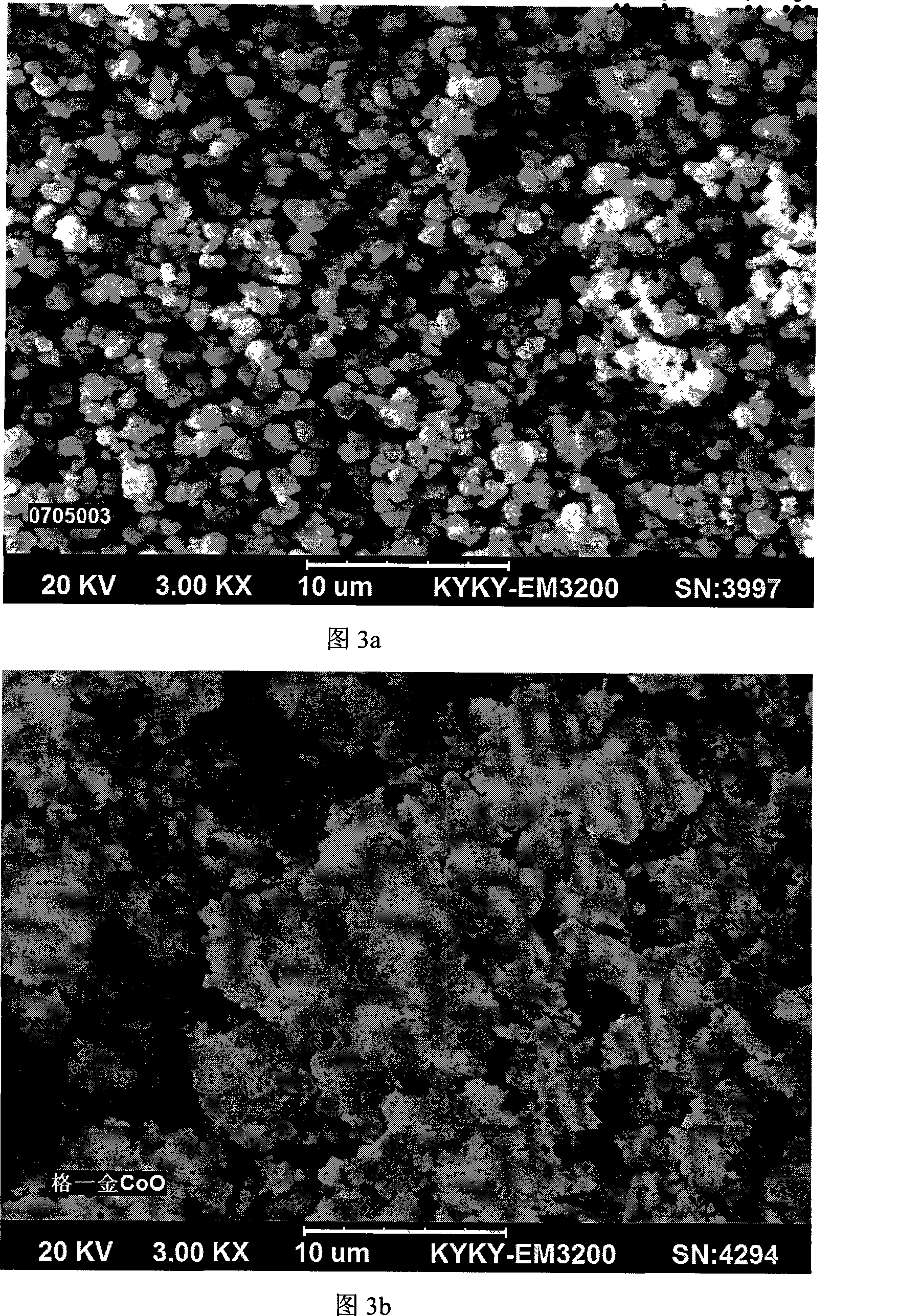

The invention discloses a preparation method of cobalt oxide powder and relates to a preparation method of the cobalt oxide powder in the fields of lithium ion battery cathode materials, fuel cells, catalysts, magnetic materials, electronic ceramics and the like. The method is characterized in that: solution of cobalt salt is atomized in the preparation process and thermally decomposed at a high temperature so as to obtain the cobalt oxide powder. In the method of the invention, the solution of cobalt salt serving as a raw material is atomized, the cobalt salt is thermally decomposed at a high temperature and under a controllable atmosphere so as to generate cobalt oxides (comprising cobalt monoxide CoO, cobaltosic oxide Co3O4 and cobalt sesquioxide Co2O3) and produced tail gas is absorbed to form regeneration acid. The method can further continuously realize a preparation process from solution to a cobalt oxide; and the particle size of the cobalt oxide powder prepared by the method is controllable in the range of between 0.2 and 20 microns and the cobalt oxide powder has uniform particle size distribution and high electrochemical performance. The preparation method saves energy, protects the environment and has low production cost and remarkable economic and social benefits.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

Superfine cobalt powder preparation method

PendingCN107649689APromote crystallizationHigh purityTransportation and packagingMetal-working apparatusProduct gasMetal powder

The invention relates to a metal powder preparation method, in particular to a superfine cobalt powder preparation method. The superfine cobalt powder preparation method comprises the steps of S1, taking dried and crushed spherical cobalt carbonate powder with the particle size less than or equal to 1 micron and conducting thermal decomposition on the spherical cobalt carbonate powder in an inertgas atmosphere at 300-600 DEG C for 4-8 h to obtain cobalt oxide powder; S2, conducting reduction on the cobalt oxide powder obtained in the step S1 at 350-500 DEG C in a reducing gas atmosphere for 6-10 h to obtain cobalt powder, wherein reducing gas comprises components including H2, N2 and H2O at the volume ratio 3:1:(0.01-0.02); and S3, conducting 200-mesh screening on the cobalt powder obtained in the step S2 to obtain superfine cobalt powder. By means of the method, the raw materials have a variety of sources, the production cost is low, operation is easy, and the superfine cobalt powderwith the average particle size less than or equal to 1.0 micron can be obtained.

Owner:YUCHEN ADVANCED ENERGY MATERIALS & TECH WUXI

Method for producing nanoscale cobalt (II) oxide

InactiveCN105084429ANarrow particle sizeNarrow particle size distributionMaterial nanotechnologyCobalt oxides/hydroxidesDecompositionPositive pressure

The invention discloses a method for producing nanoscale cobalt (II) oxide, particularly a production method of cobalt (II) oxide used as a cathode material of secondary batteries. The nanoscale cobalt (II) oxide is prepared from raw materials including cobalt nitrate crystals, 150 L of aqueous ammonia with the concentration of 180 g / L, 1800 L of sodium hydroxide with the concentration of 130 g / L, dilute aqueous ammonia with the concentration of 10%, and the like through the steps of dilution, dissolution, synthesis, deposition, filtration, slurrying, washing, drying, semi-reduction decomposition under the positive pressure atmosphere, passivation through inert gases, sieving and the like. The prepared nanoscale cobalt (II) oxide with the particle size being only 0.1-0.5 micron is relatively narrow in particle size distribution, uniform in particle size and good in dispersion effect. The secondary batteries produced through adopting the cobalt (II) oxide as the cathode material of secondary batteries is relatively short in charging time, and particularly, the charge and discharge capacity of the secondary batteries reaches up to 90% at the low temperature of minus 40 DEG C, so that the service life of the secondary batteries is relatively long.

Owner:WUXI ZHONGJING METAL POWDER

Method for removing sulfate radicals in cobalt hydroxide

InactiveCN102390873AImprove the detachment effectSimple processCobalt oxides/hydroxidesChemical industrySulfate radicals

The invention discloses a method for removing sulfate radicals in cobalt hydroxide, relating to a preparation method of cobalt hydroxide and cobalt oxide for batteries in chemical industry. The method is characterized by comprising the following steps of: adding a sodium hydroxide solution to cobalt hydroxide for reacting, washing with deionized water, and finally filtering and drying to obtain the cobalt hydroxide. The method for removing sulfate radicals in the cobalt hydroxide adopts a method combining alkaline pretreatment and traditional wash washing and has the advantages of high efficiency, simple and feasible process, convenience for operation, low cost, good cobalt hydroxide radical removing effect and the like. By using the method disclosed by the invention, the cobalt hydroxide product with sulfate radical content lower than 0.2 percent can be prepared; and the cobalt oxide product with the sulfate radical content lower than 0.2 percent is obtained by calcining the cobalt hydroxide. The method disclosed by the invention has the advantages of simple and feasible process, convenience for operation, low cost, good sulfate radical removing effect and the like.

Owner:JINCHUAN GROUP LIMITED

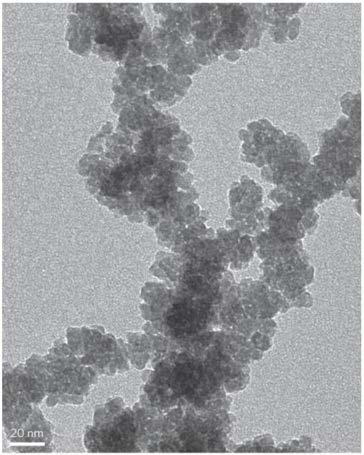

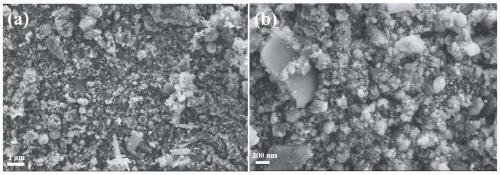

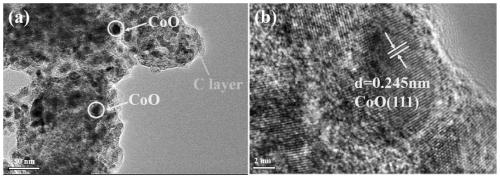

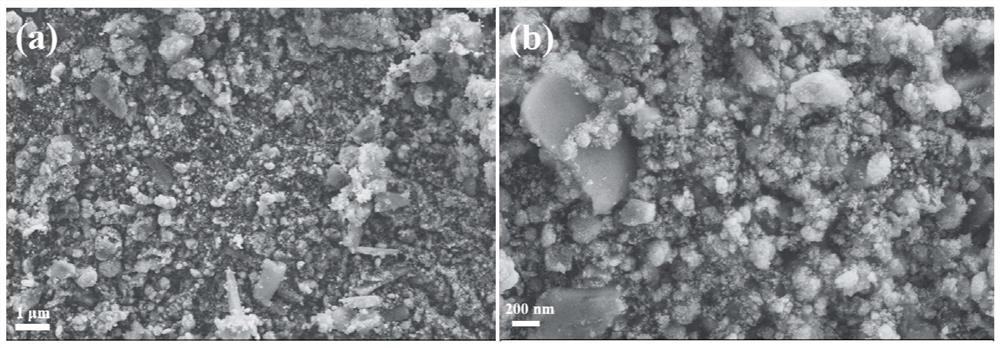

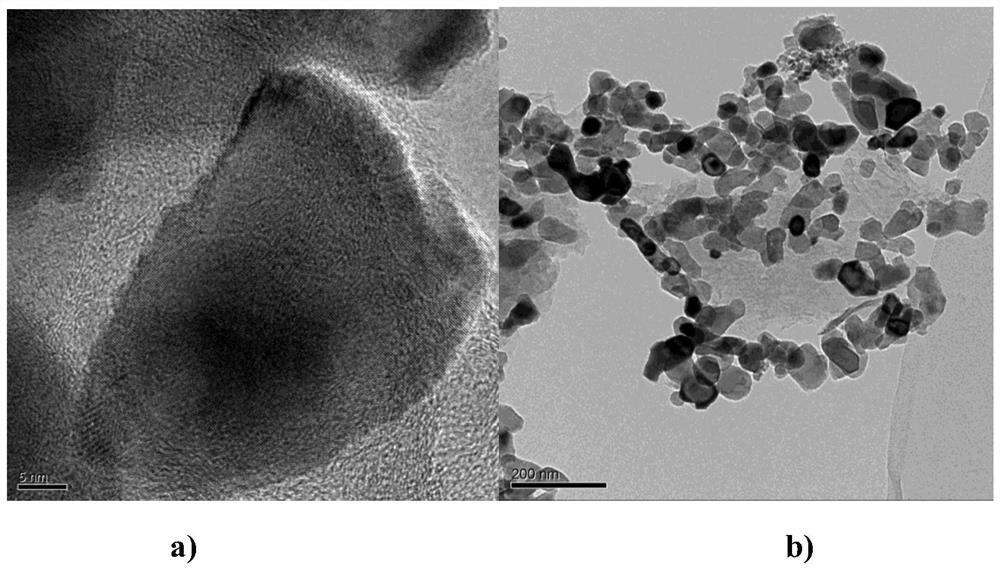

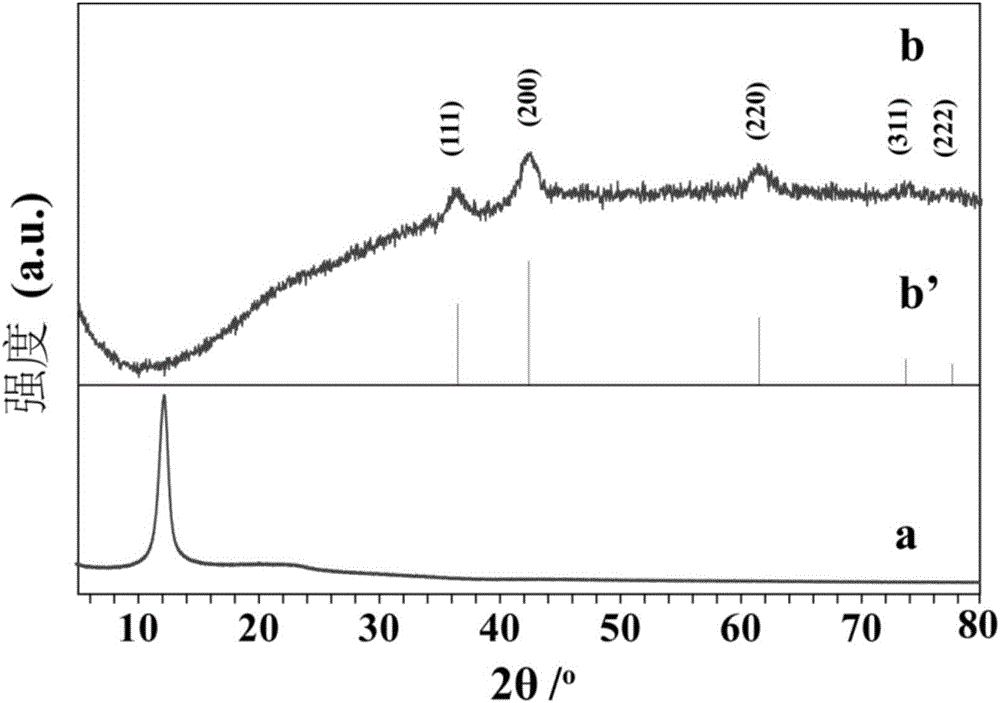

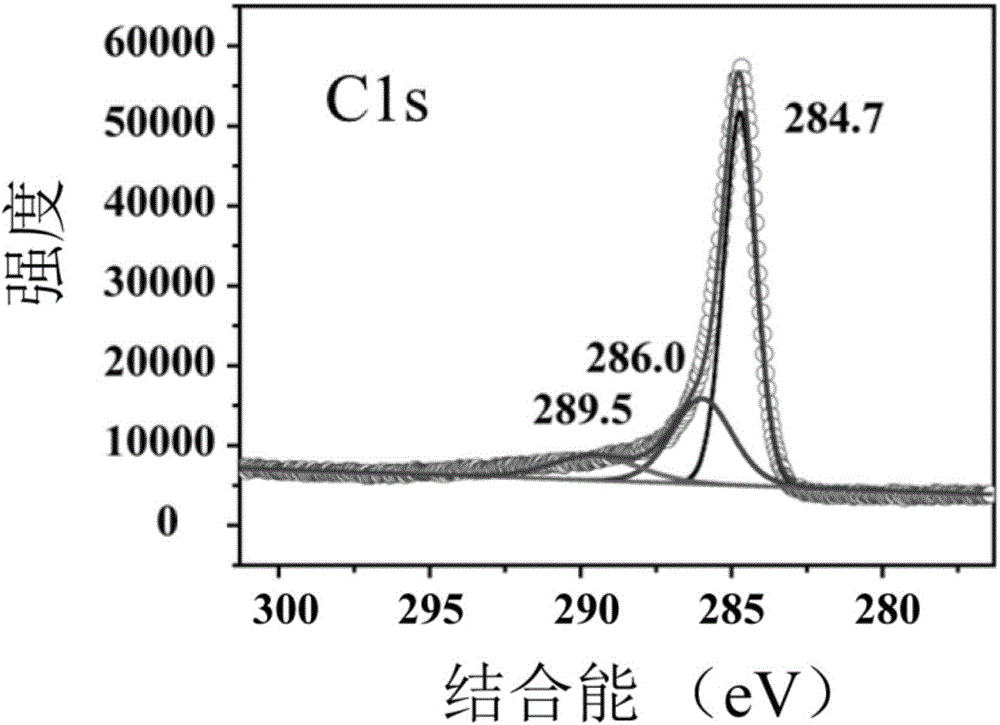

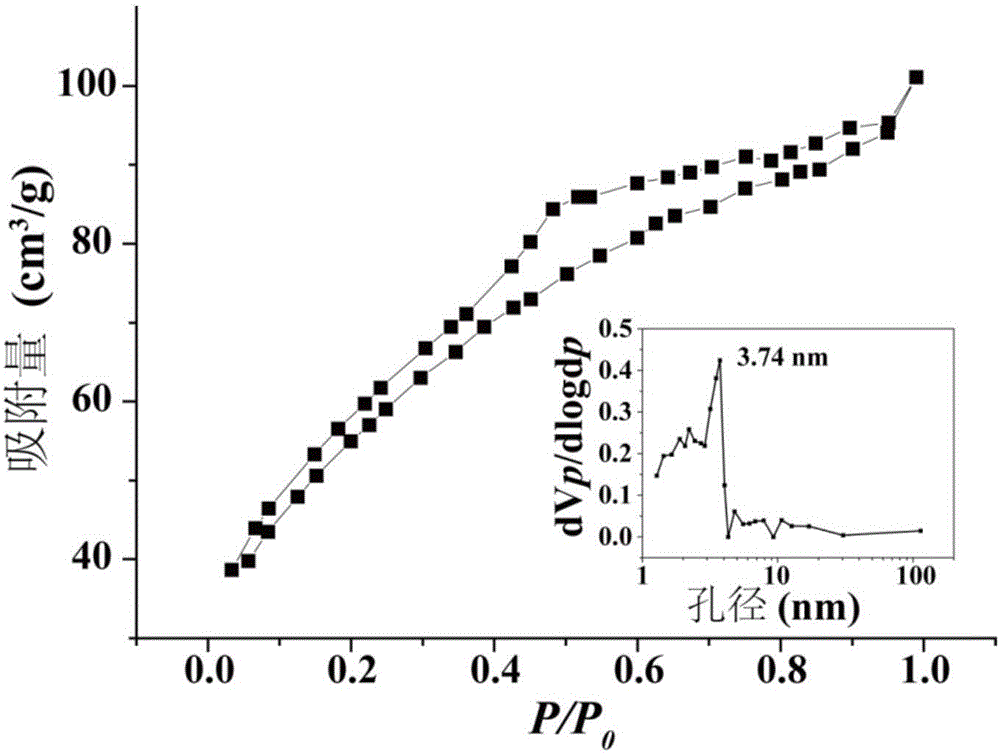

Nanometer carbon coated cobaltous oxide, and preparation method and applications thereof

ActiveCN110193347ADamage structureFerromagneticOther chemical processesWater contaminantsRoom temperatureColloid

The invention belongs to the field of metal inorganic oxide adsorption material, and discloses nanometer carbon coated cobaltous oxide, and a preparation method and applications thereof. The preparation method comprises following steps: citric acid and cobaltous acetate are dissolved in water through ultrasonic treatment, an obtained mixed solution is dried to be a colloid, the colloid is subjected to roasting treatment at Ar / H2 mixed atmosphere protection through heating to 400 to 500 DEG C, the temperature is reduced to room temperature through cooling, and an obtained product is subjected to grinding to obtain the nanometer carbon coated cobaltous oxide. The preparation process is simple; the raw materials are economical; the preparation method is suitable for large scale production; the obtained nanometer carbon coated cobaltous oxide is short in adsorption balance achievement time in removing of tetracycline, and high in adsorption capacity; and recycling can be realized, and is convenient.

Owner:SOUTH CHINA AGRI UNIV

Production method of cobaltous oxide for power battery

ActiveCN101786672AImprove energy storage utilizationExtended service lifeProductsElectrode manufacturing processesElectrical batteryPositive pressure

The invention relates to a production method of cobaltous oxide for a power battery, comprising the following steps of: firstly reacting a cobalt chloride solution with an ammonium acid carbonate precipitant through a third-order reaction tank to generate basic cobaltous carbonate slurries; then filtering the slurries, slurrying, washing, drying, and protecting and crashing by an inert gas to obtain basic cobaltous carbonate powder; then decomposing through a positive pressure atmosphere, wherein a decomposing furnace is internally provided with 10 computer temperature control areas, air inside the decomposing furnace is driven by the inert gas before feeding, then a CO2 gas is continuously charged, and a material boat loaded with the basic cobaltous carbonate powder passes through the 10 computer temperature control areas at the speed of 5 minutes per time so that basic cobaltous carbonate is decomposed to generate the cobaltous oxide for the power battery in the positive pressure atmosphere. The invention saves the energy and has low production cost; in addition, the cobaltous oxide has great high chemical purity and physical performance and can be used as powder materials of the power high-performance and high-power battery.

Owner:周红阳

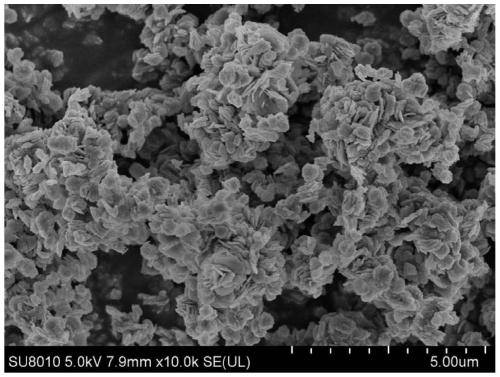

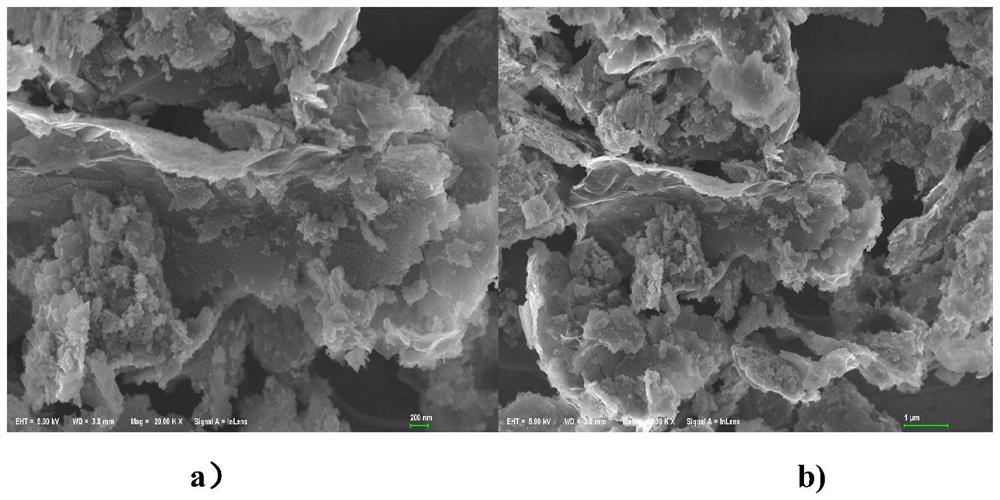

A kind of cobaltous oxide for catalyst and its preparation method and application

InactiveCN108579748BCatalytically activeImprove catalytic performanceElectrolysis componentsMetal/metal-oxides/metal-hydroxide catalystsSolventOxygen evolution

The invention discloses cobalt oxide for catalysts and its preparation method and application. Its preparation method is: using cobalt acetylacetonate as the cobalt source, using ionic liquid as the solvent, the ionic liquid is 1-butyl-3-methylimidazole bistrifluoromethanesulfonimide salt, in an inert gas atmosphere The precipitate prepared by reaction using ionothermal method is cobaltous oxide for catalyst. The cobaltous oxide prepared by the present invention has an ultra-thin sheet structure, which can expose more catalytically active sites, and therefore has high electrocatalytic activity for oxygen evolution reaction. The preparation process is simple and is suitable for industrial production. The field of reaction electrocatalysts has potential practical application value.

Owner:SHANDONG UNIV

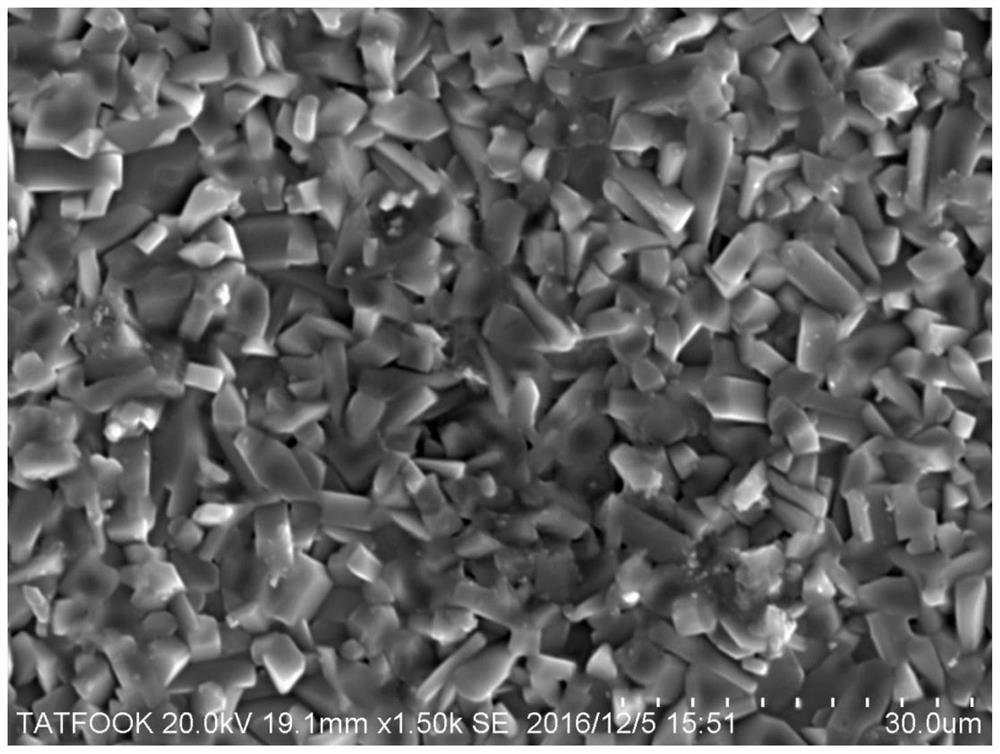

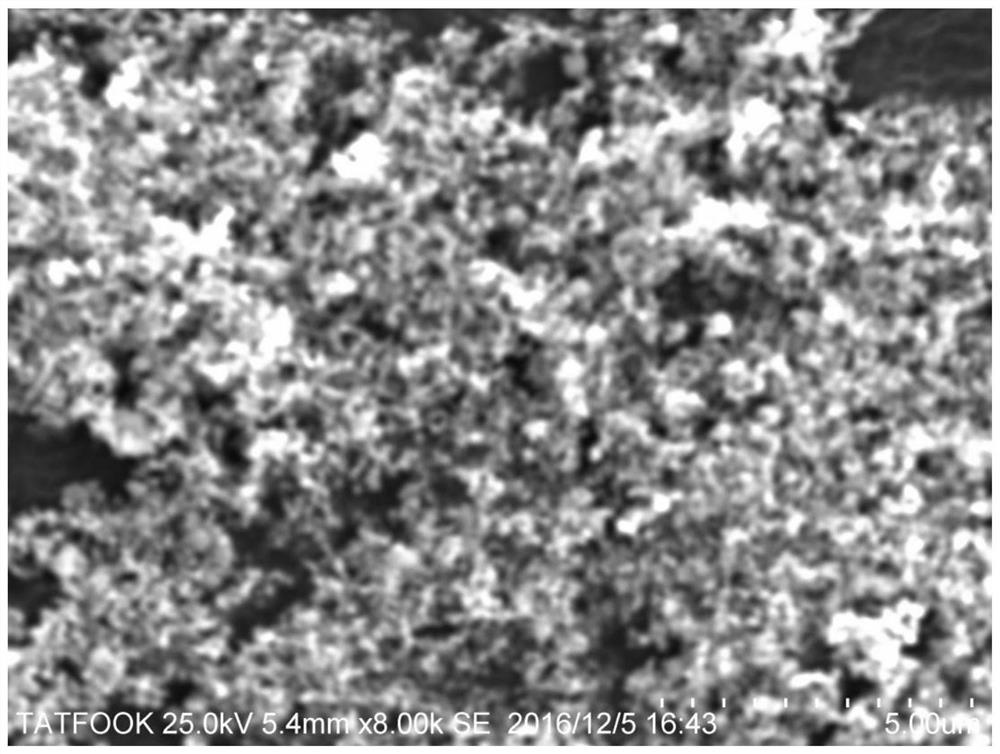

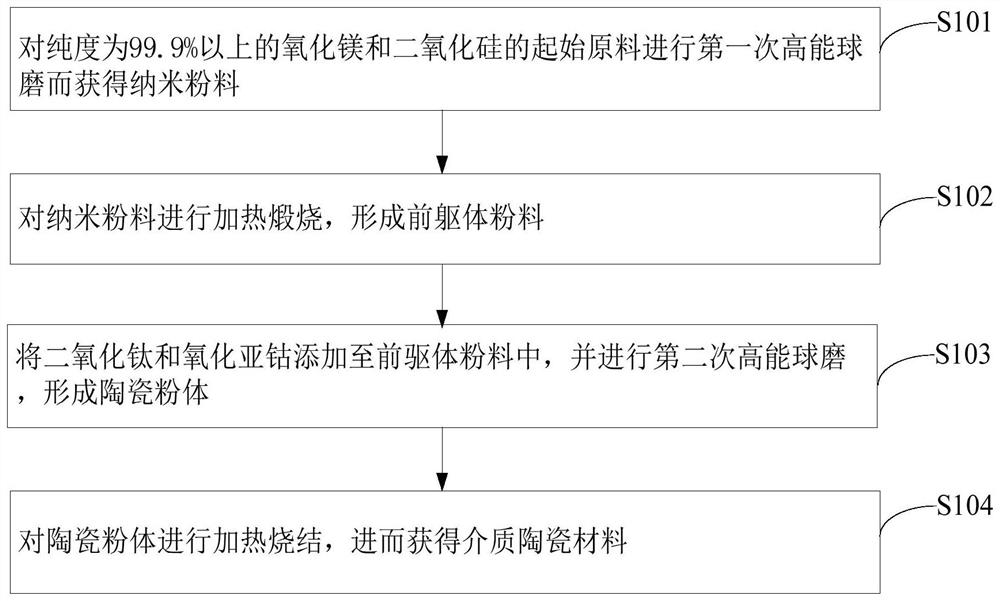

A kind of dielectric ceramic material and preparation method thereof

A dielectric ceramic material and a preparation method thereof. The dielectric ceramic material contains titanium dioxide and cobaltous oxide. The quality factor Q value of the dielectric ceramic material is high, and the compactness is high. At the same time, the temperature during heating and sintering is also reduced; because it contains titanium dioxide and cobaltous oxide, the temperature coefficient of the resonant frequency of the material can be effectively improved.

Owner:ANHUI TATFOOK TECH CO LTD

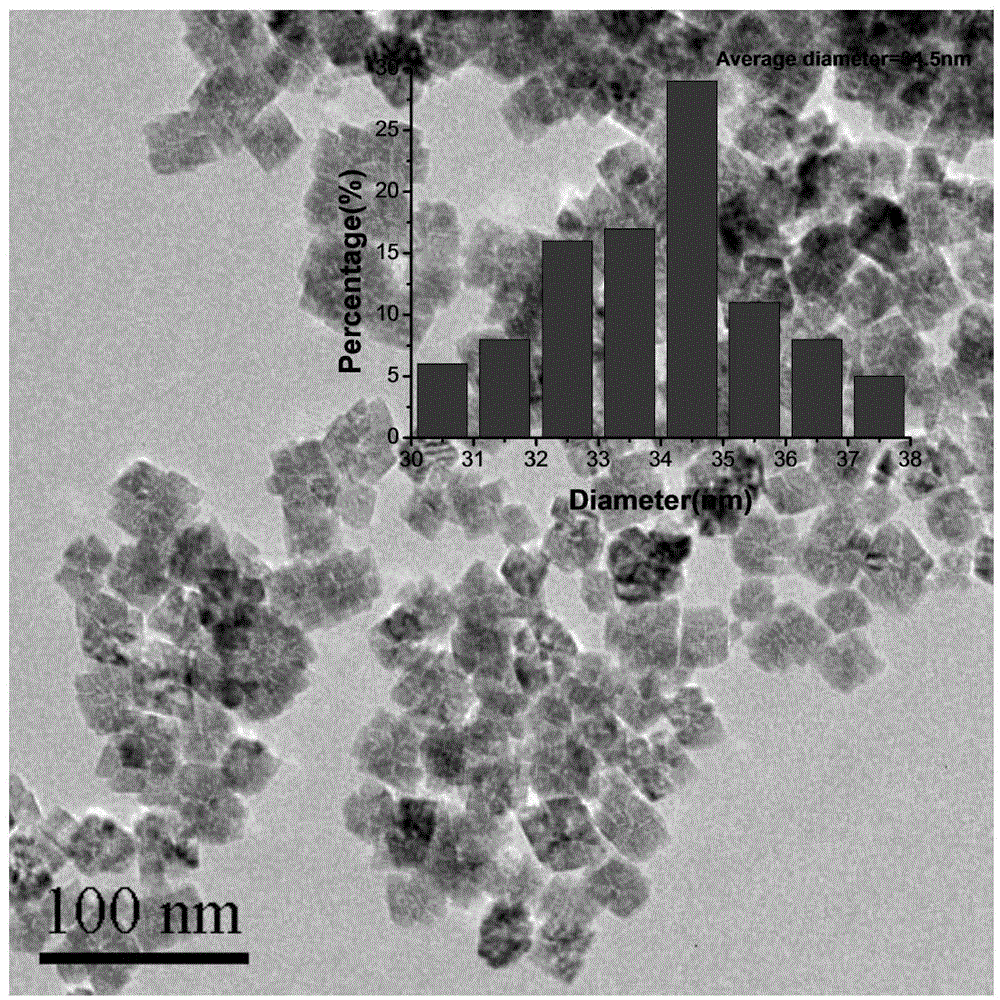

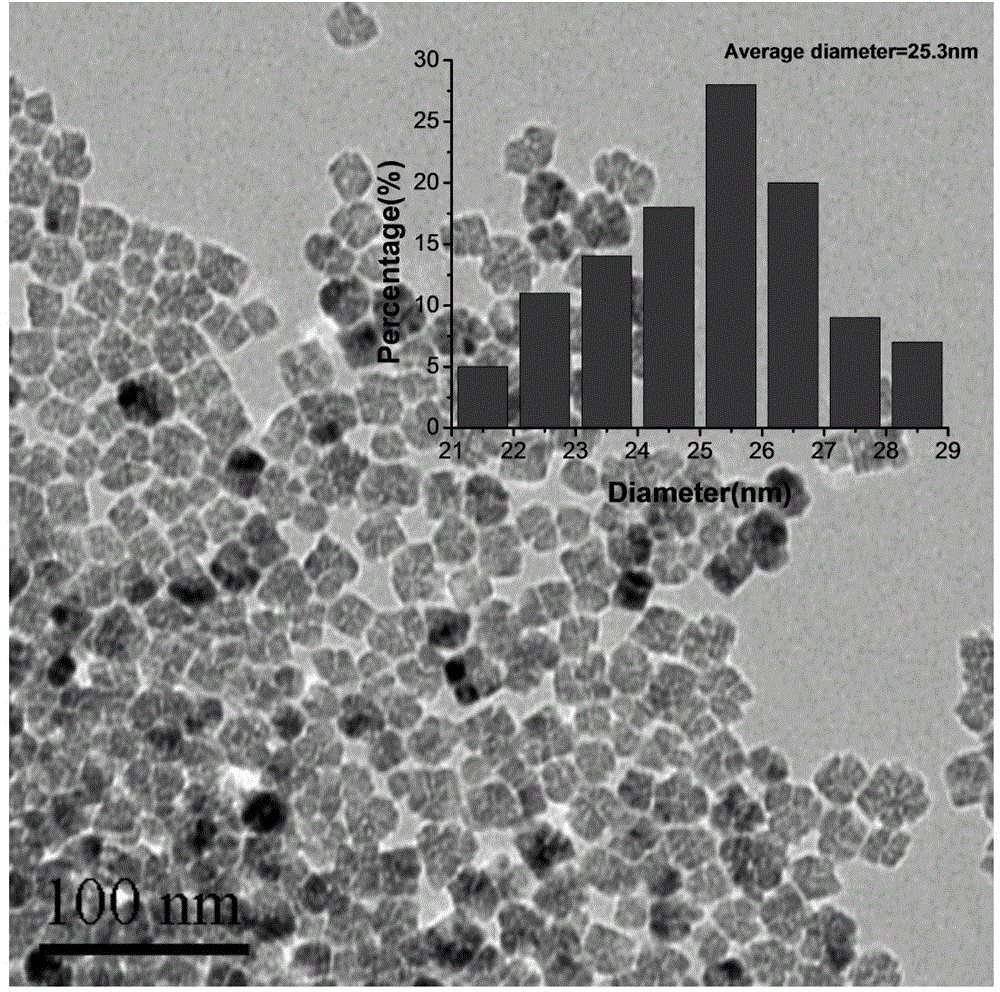

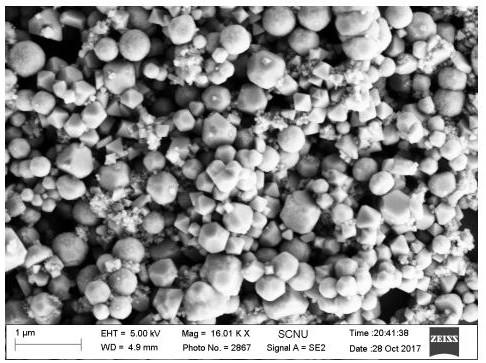

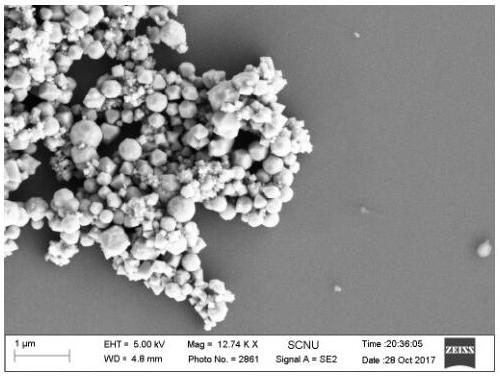

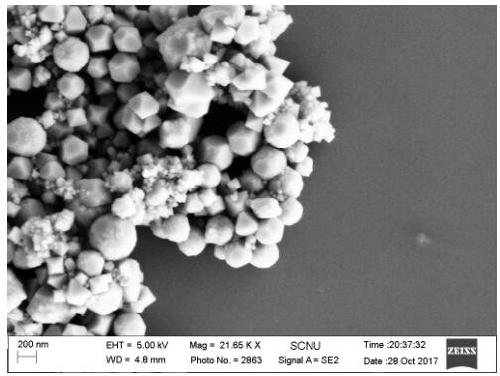

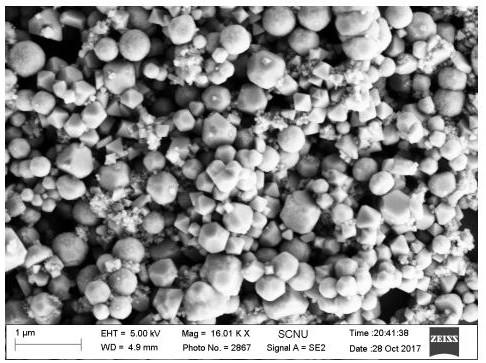

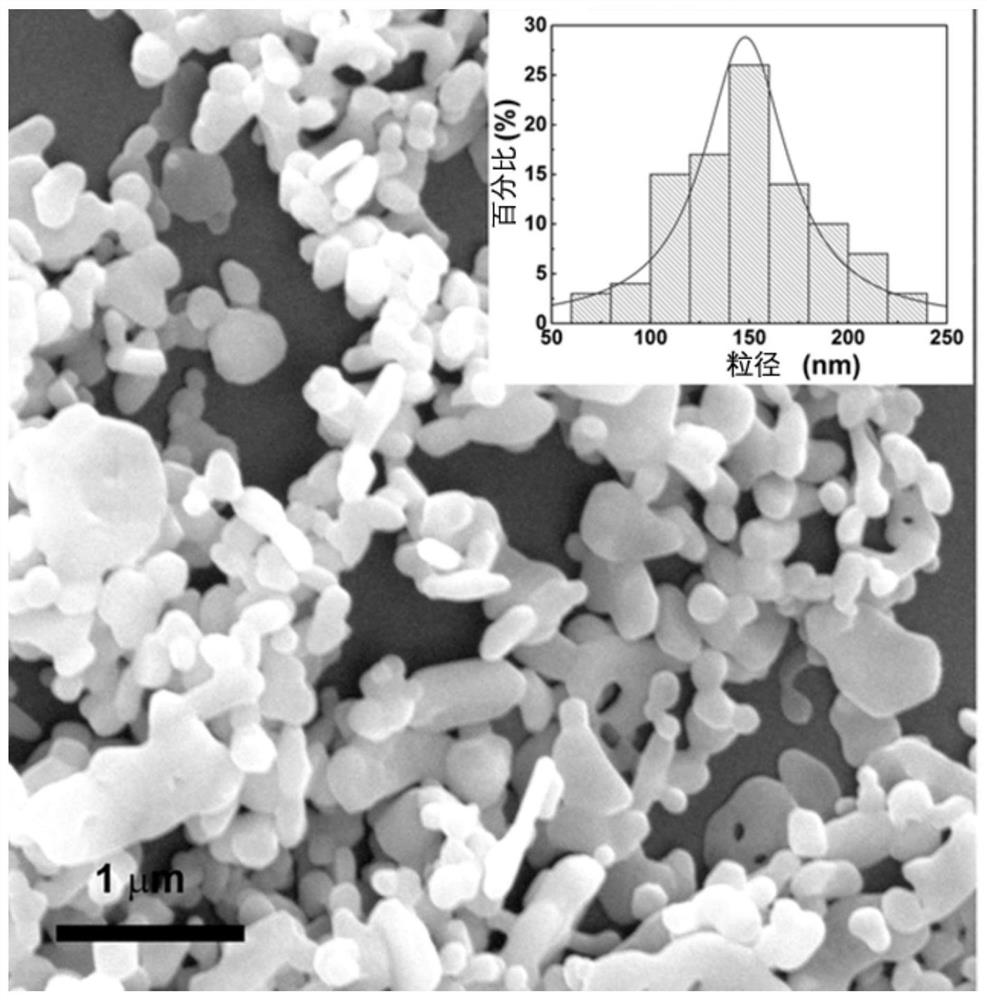

A preparation method of cobaltous oxide nanocrystals and cobaltous oxide nanocrystals prepared therefrom

ActiveCN108975415BFully developedUniform particle size distributionMaterial nanotechnologyCobalt oxides/hydroxidesReaction temperaturePhysical chemistry

The invention provides a method for preparing cobaltous oxide nanocrystals and the prepared cobaltous oxide nanocrystals. The preparation method comprises the following steps: using cobalt salt and triphenylphosphine as precursors, completely dissolving the precursors in oleylamine, reacting in a closed environment for 10-20 hours, washing and drying to obtain cobaltous oxide nanocrystals, The reaction temperature is 120-180°C, the purity of the cobalt salt is ≥99.5%, and the mass ratio of the cobalt salt to triphenylphosphine is ≥1:10. In the preparation method of cobaltous oxide nanocrystals of the present invention, cobaltous oxide nanocrystals are prepared by hydrothermal reaction of specific purity cobalt salt and triphenylphosphine under certain temperature conditions, with complete grain development, uniform particle size distribution, and There is less agglomeration, and the reaction raw materials of the preparation method of the present invention are easy to obtain, the production cost is low, the uneven particle size distribution and the mixing of impurities caused by the sintering process are avoided, and the industrial production is easy.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Preparation method of cobalt oxide nanocrystal and prepared cobalt oxide nanocrystal

ActiveCN108975415AFully developedUniform particle size distributionMaterial nanotechnologyCobalt oxides/hydroxidesReaction temperatureImpurity

The invention provides a preparation method of cobalt oxide nanocrystal and the prepared cobalt oxide nanocrystal. The preparation method comprises the following steps of using cobalt salt and triphenylphosphine as precursors, completely dissolving the precursors into oil amine, reacting for 10 to 20h under the closed environment, washing and drying, so as to obtain the cobalt oxide nanocrystal, wherein the reaction temperature is 120 to 180 DEG C, the purity of the cobalt salt is greater than or equal to 99.5%, and the mass ratio of the cobalt salt to the triphenylphosphine is greater than orequal to 1:10. The preparation method of the cobalt oxide nanocrystal has the advantages that the cobalt salt and triphenylphosphine with certain purity are performed with hydrothermal reaction undercertain temperature condition, so as to obtain the cobalt oxide nanocrystal; the development of the crystal grain is complete, the granularity distribution is uniform, and the degree of agglomerationbetween the particles is low; the reaction raw materials are easy to obtain, the production cost is low, the problems of nonuniformity of particle size distribution and mixing of impurities due to sintering process are solved, and the industrialized production is easy.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

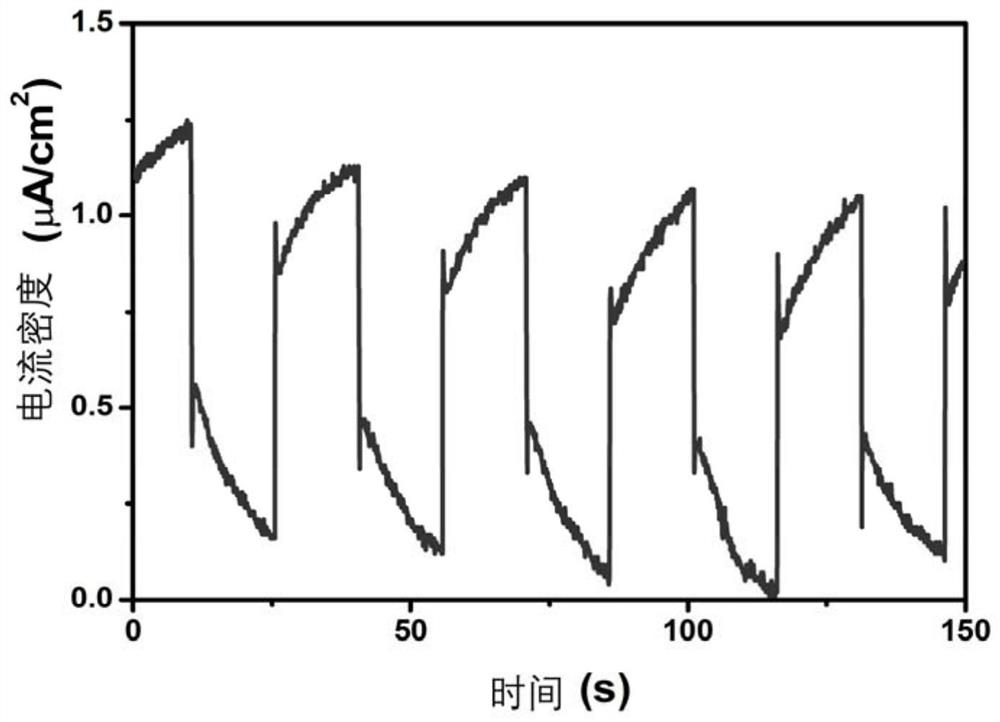

Cobaltous oxide photocatalytic material with high photoelectrocatalytic activity and preparation method thereof

ActiveCN113663672ALow costImprove photocatalytic reactivityHydrogen productionHydrogen/synthetic gas productionPhotocatalytic reactionAqueous sodium hydroxide

The invention relates to a cobaltous oxide photocatalytic material with high photoelectrocatalytic activity and a preparation method thereof. According to the method, a precursor is prepared from a cobalt oxalate aqueous solution and a sodium hydroxide aqueous solution, and the cobaltous oxide is prepared through microwave hydrothermal treatment, drying and high-temperature treatment. The invention provides a novel synthesis method of cobaltous oxide powder with a controllable grain size. The method can significantly improve the photocatalytic reaction activity of the material. The cobaltous oxide powder produced by the method is expected to be further applied in the field of photocatalysis. The production method is low in cost and simple and convenient in synthesis process, can be applied to mass production, and effectively saves the production cost. The cobaltous oxide powder prepared by the method has excellent photoelectrocatalytic activity and has a relatively large commercialization prospect.

Owner:香港城市大学深圳研究院

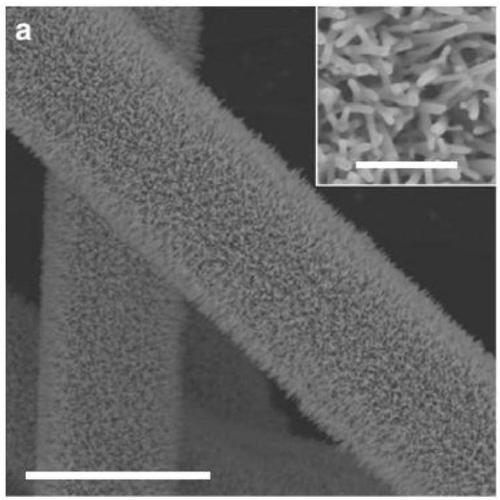

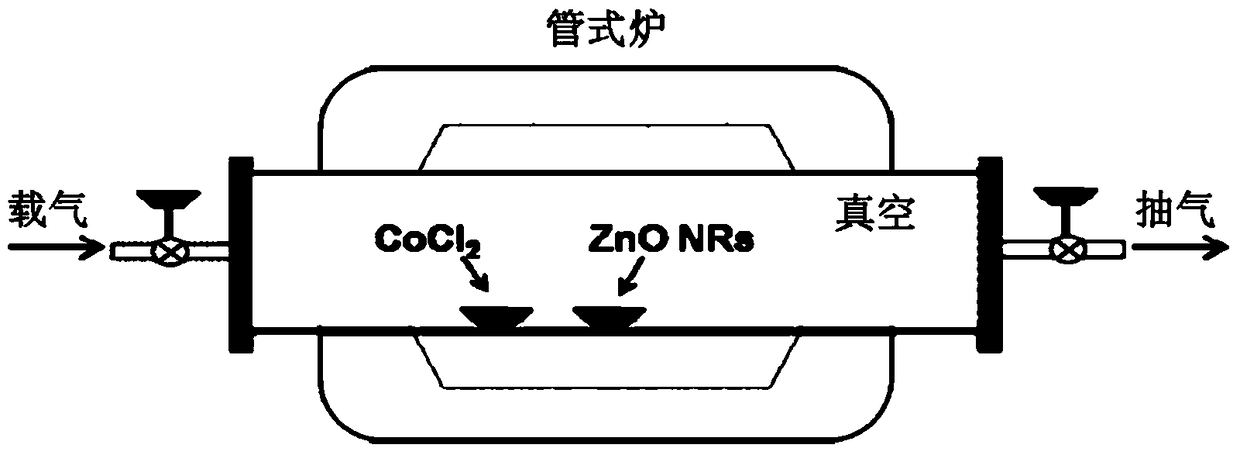

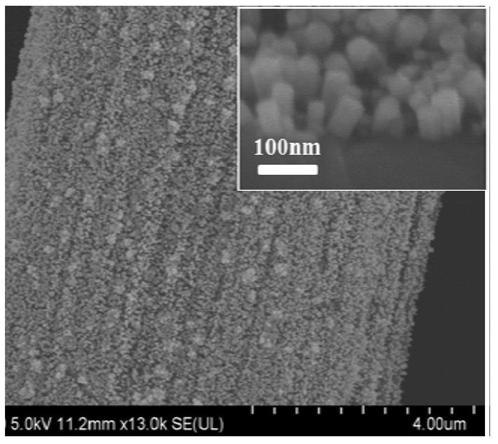

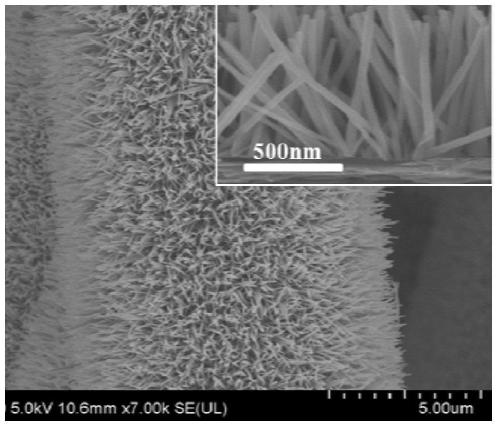

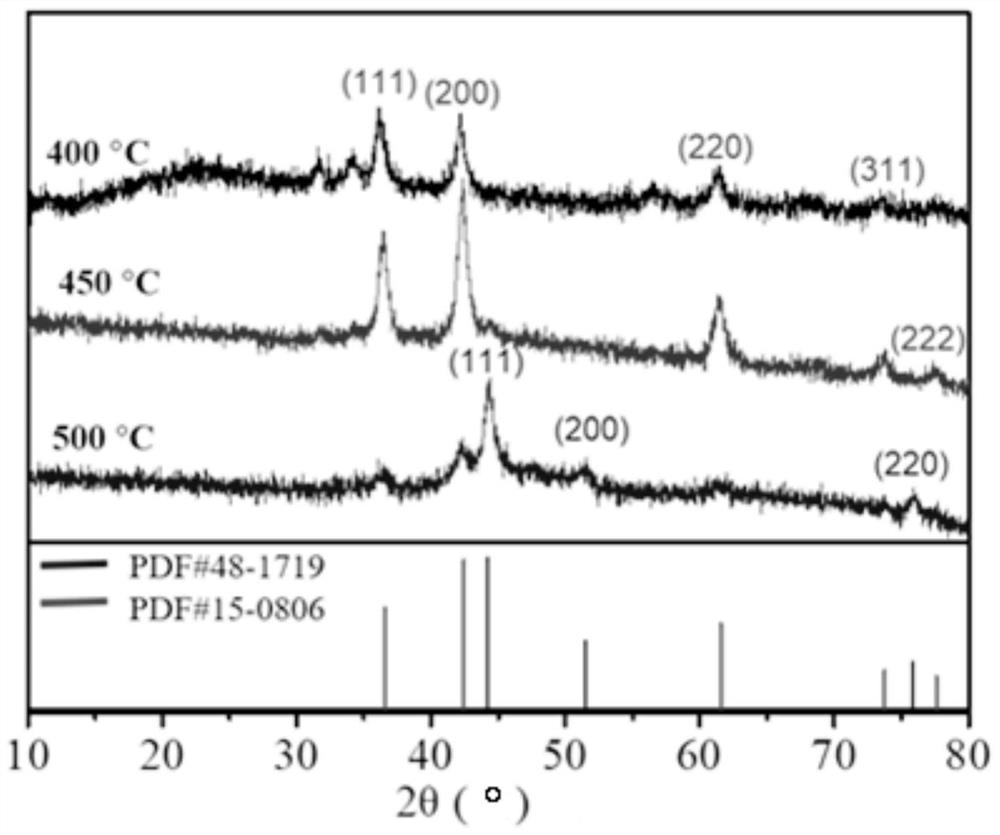

Preparation method of a single crystal porous cobaltous oxide nanorod array

InactiveCN105543960BProcess stabilityImprove universalityPolycrystalline material growthNanotechnologyFuel cellsTube furnace

A method for preparing a monocrystalline porous cobalt(II) oxide (CoO) nanorod array is as follows: a growth substrate with a prepared Zn seed layer is placed at 400-500 DEG C for annealing for 0.15-1h; a 0.1-0.5M ZnO hydrothermal growth liquid is prepared; the annealed growth substrate is placed in a reactor, the growth substrate of the annealed growth substrate is tilted down, the ZnO hydrothermal growth liquid is added, the reactor is placed in a cylinder and sealed, the cylinder is placed in a 100 DEG C constant temperature drying oven for preparation of ZnO nanorod arrays; the growth substrate is then placed at 500 DEG C for annealing for 1h; the annealed growth substrate is placed at the center of a tube furnace, CoCl2 powder is used as a Co evaporation source, the tube furnace is vacuumized to 0.1-0 .5Torr, then a carrier gas is introduced into the tube furnace, and the tube furnace is heated to 400-700 DEG C, and thermally insulated for 0.1-1h to obtain the monocrystalline porous cobalt(II) oxide (CoO) nanorod array very conducive to gas adsorption. The monocrystalline porous cobalt(II) oxide (CoO) nanorod array is stable in process, well universal, and suitable for the majority of flexible substrates and conductive substrates, makes industrially practical application possible, and has good application prospects in the fields of fuel cells, catalysis, and the like.

Owner:TIANJIN UNIV

A kind of nano-carbon-coated cobaltous oxide and its preparation method and application

ActiveCN110193347BEasy to makeRaw material economyOther chemical processesWater contaminantsAdsorption equilibriumEthylic acid

The invention belongs to the field of metal inorganic oxide adsorption materials, and discloses a nanometer carbon-coated cobaltous oxide, a preparation method and an application thereof. The citric acid and cobalt acetate were ultrasonically dissolved in water, and the resulting mixed solution was dried to a colloidal state, and then heated in Ar / H 2 Under the protection of a mixed atmosphere, the temperature is raised to 400-500° C. for roasting treatment, cooled to room temperature, and the obtained product is ground to obtain a nanometer carbon-coated cobaltous oxide material. The preparation process of the present invention is simple, the raw material is economical, and is applicable to large-scale production. The obtained nano-carbon-coated cobaltous oxide for removing tetracycline has the characteristics of short adsorption equilibrium time and high adsorption capacity, and has the characteristics of convenient recovery and recycling use.

Owner:SOUTH CHINA AGRI UNIV

A kind of nitrogen-doped graphene/cobaltous oxide composite material and preparation method thereof

ActiveCN108054396BHigh purityImprove catalytic performanceCell electrodesDoped graphenePtru catalyst

The invention discloses a nitrogen-doped graphene / cobaltous oxide composite material. Graphite oxide, a cobaltous acetate solution and ammonium carbonate are taken as the main raw materials, and cobaltous oxide is loaded on nitrogen-doped graphene by adopting a water bath-hydrothermal-calcining method to obtain the nitrogen-doped graphene / cobaltous oxide composite material. Compounding of nitrogen-doped graphene and cobaltous oxide is proposed initially in the invention, the obtained composite material is high in cobaltous oxide purity, and a synergistic effect between cobaltous oxide and nitrogen-doped graphene can be achieved, so that an excellent catalytic ability on a fuel cell negative electrode oxygen reduction reaction can be achieved; meanwhile, the material cost of a catalyst is greatly lowered; and the involved preparation method is simple, high in repeatability and suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

Preparation method of superfine cobalt powder

The invention discloses a preparation method of superfine cobalt powder and belongs to the technical field of hard alloys. According to the method, at first, sodium dodecyl benzene sulfonate and OP-10 serve as emulsifying agents, potassium persulfate serves as an initiator, styrene and acrylic acid serve as monomers, polystyrene acrylic emulsion is prepared after the reaction, citric acid serves as a complexing agent in cooperation, in the reaction process, yeast consumes the citric acid, cobalt ions are released slowly and hydrolyzed in an alkalescence environment to generate cobaltous hydroxide, after the cobaltous hydroxide is heated and dehydrated, cobalt monoxide crystal nuclei are generated and uniformly adsorbed to the surface of polystyrene acrylic acid and reduced into cobalt elementary substances through L-ascorbic acid, finally, dopamine is utilized for coating the cobalt elementary substances, the cobalt elementary substances are prevented from being oxidized in the drying process, and after high-temperature anaerobic calcinations is carried out to remove polystyrene acrylic acid kernels and the dopamine, the superfine cobalt powder is prepared. According to the method, in the preparation process, the cobalt elementary substances can be effectively prevented from agglomerating, growing up and being oxidized, the particle size of the obtained product is small, and the distribution range of the particle size is narrow.

Owner:常州瑞坦商贸有限公司

Cobaltous oxide nanocrystal-graphene composite material and preparation method and application thereof

InactiveCN106602011AImprove catalytic performanceGood dispersionCell electrodesLi-accumulatorsDispersityOrganic solvent

The embodiment of the invention provides a cobaltous oxide nanocrystal-graphene composite material. The embodiment of the invention further provides a preparation method of the composite material. The method comprises the following steps of (1) adding graphite oxide to a first organic solvent and dispersing the graphite oxide; (2) adding cobalt acetylacetonate and octadecylamine, heating a mixture to 120-140 DEG C, maintaining the temperature for 20-50 minutes, carrying out heating until the solution boils and reflows and maintaining the temperature for 1-5 hours; (3) adding the mixture to a second organic solvent to suddenly stop the reaction, separating solids and washing and drying the solids; and (4) carrying out thermal treatment on the dried solids in an inert gas for 1-3 hours. The embodiment of the invention further provides an application of the composite material in an organic system Li-O2 battery as an anode catalyst. According to the composite material provided by the embodiment of the invention, cobaltous oxide nanocrystal uniformly grows on a graphene substrate, the dispersity is good and the agglomeration phenomenon is avoided, so that the catalytic performance of the composite material is relatively good.

Owner:BEIJING NORMAL UNIVERSITY +1

Cobalt oxide for coating positive electrode material of lithium battery and preparation method thereof

ActiveCN113896249AParticles are bigLarge specific surface areaMaterial nanotechnologyPositive electrodesNitrogen gasSodium hydroxide

The invention discloses a cobalt oxide with a large specific surface area and a preparation method thereof. The method comprises the following steps: (1) preparing a cobalt salt solution and a sodium hydroxide solution; (2) under a stirring condition, adding a cobalt salt solution and a sodium hydroxide solution into a reaction kettle in a parallel flow manner, controlling the pH value to be 8-12, generating cobaltous hydroxide and reacting for 60-120 minutes, and introducing nitrogen as a protective gas; (3) stopping feeding, introducing nitrogen, introducing air serving as a first oxidant, adding a second oxidant with the oxidizing capacity higher than that of the air into the reaction kettle, oxidizing the cobalt hydroxide, controlling the molar ratio of the second oxidant to the cobalt element to be (0.2-0.8): 1, and adjusting the flow of the air to generate cobalt oxide mCoOOH.(1-m)Co3O4, wherein m is 0.36-1; and (4) filtering, washing and drying the oxidized slurry, and crushing by adopting mechanical crushing equipment to obtain a cobalt oxide finished product with the specific surface area of more than 30m < 2 > / g.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com