A kind of cobaltous oxide for catalyst and its preparation method and application

A cobaltous oxide and catalyst technology, applied in chemical instruments and methods, cobalt oxide/cobalt hydroxide, physical/chemical process catalysts, etc., can solve the problems of difficult control of product microstructure, limited application, complicated preparation process, etc., to achieve Easy to achieve industrial production, high catalytic activity and stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Prepare cobaltous oxide in pure ionic liquid, its specific steps are as follows:

[0046]50mg cobalt acetylacetonate and 1g ionic liquid (1-butyl-3-methylimidazole bistrifluoromethanesulfonimide salt) are added in a 10ml glass bottle, then the glass bottle is placed in a tube furnace, After feeding nitrogen for 20 minutes, turn on the tube furnace for program-controlled temperature rise, so that the temperature in the tube furnace is raised from room temperature to 280 °C at a rate of 5 °C / min, and then keep the temperature at this temperature for 5 hours, and then let the tube furnace cool down naturally to room temperature. The black precipitate in the glass bottle was recovered by centrifugation, washed with ethanol and then dried in a vacuum oven to obtain the cobaltous oxide catalyst, which was designated as CoO-280-5.

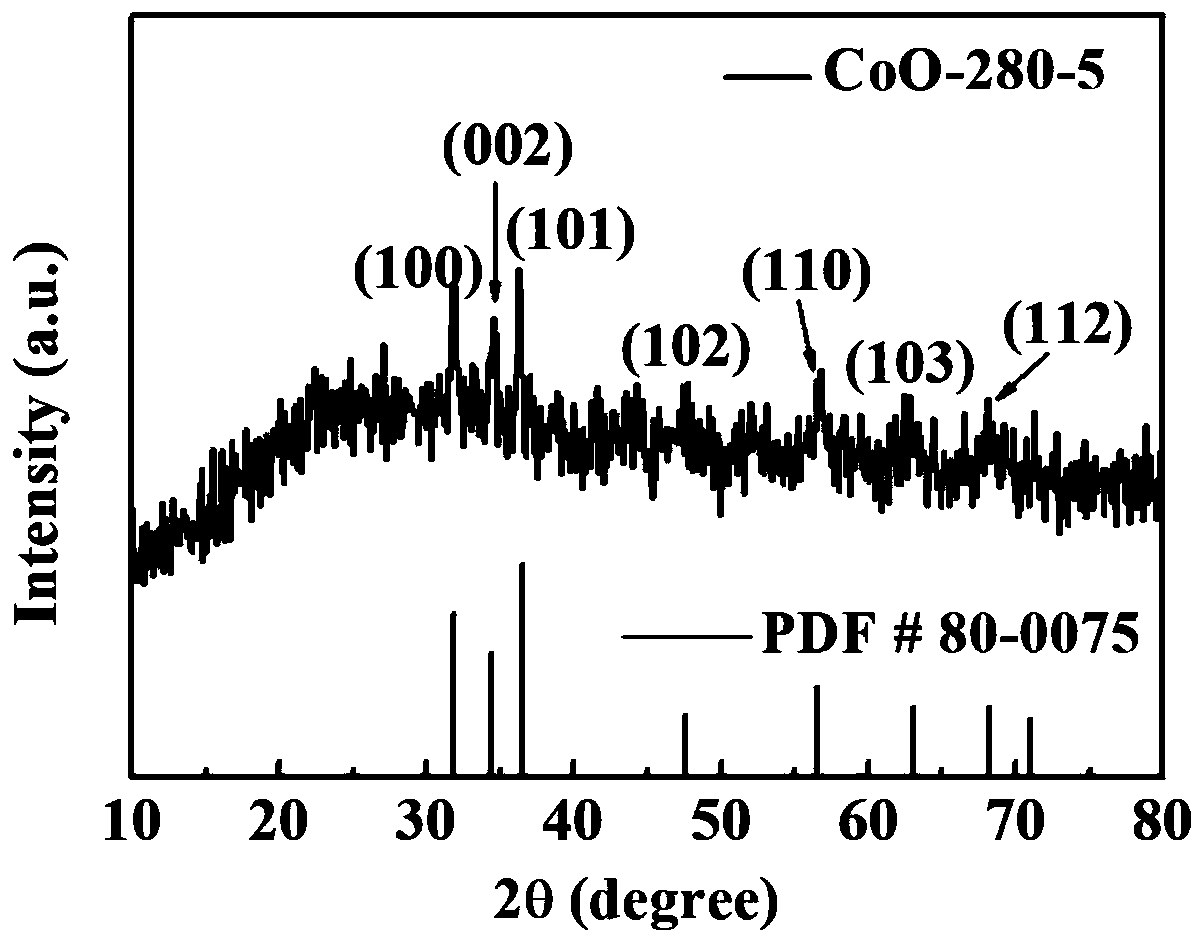

[0047] The XRD result of the cobaltous oxide prepared in this embodiment is as follows figure 1 As shown, it can be drawn from the diffraction p...

Embodiment 2

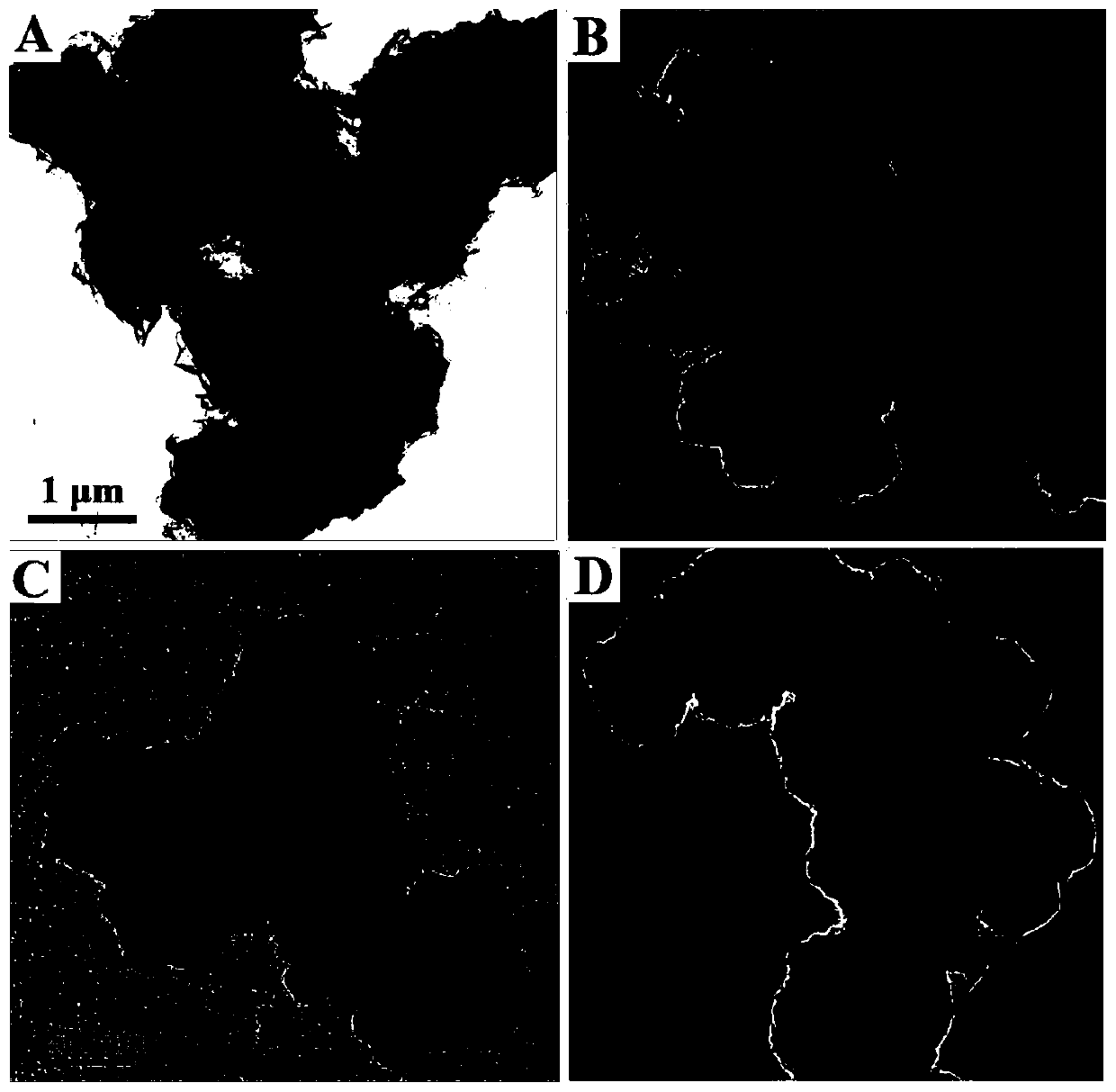

[0049] 50mg cobalt acetylacetonate and 1g ionic liquid (1-butyl-3-methylimidazole bistrifluoromethanesulfonimide salt) are added in a 10ml glass bottle, then the glass bottle is placed in a tube furnace, After feeding nitrogen for 20 minutes, turn on the tube furnace for program-controlled temperature rise, so that the temperature in the tube furnace is raised from room temperature to 280 °C at a rate of 5 °C / min, and then keep the temperature at this temperature for 1 hour, and then let the tube furnace cool down naturally to room temperature. Then reclaim the black precipitate in the glass bottle by centrifugation, wash it with ethanol and dry it in a vacuum oven. The transmission electron microscope image of its product is as follows: image 3 As shown in A.

Embodiment 3

[0051] 50mg cobalt acetylacetonate and 1g ionic liquid (1-butyl-3-methylimidazole bistrifluoromethanesulfonimide salt) are added in a 10ml glass bottle, then the glass bottle is placed in a tube furnace, After feeding nitrogen for 20 minutes, turn on the tube furnace for program-controlled temperature rise, so that the temperature in the tube furnace is raised from room temperature to 280 °C at a rate of 5 °C / min, and then keep the temperature at this temperature for 2 hours, and then let the tube furnace cool down naturally to room temperature, then reclaim the black precipitate in the glass bottle by centrifugation, wash with ethanol and then dry in a vacuum oven. The transmission electron microscope image of the product is as follows: image 3 Shown in B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com