Industrial wastewater treatment microbial inoculum and preparation method thereof

A technology of industrial wastewater and bacterial agents, applied in the field of water treatment, can solve the problems of secondary pollution, high operating costs, slow speed, etc., and achieve the effect of strong adsorption capacity, large specific surface area, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

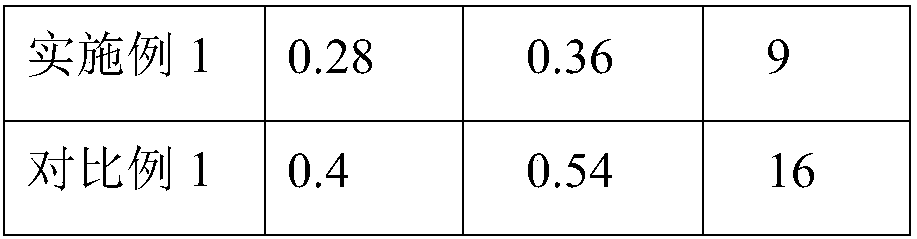

Examples

Embodiment 1

[0029] A bacterial agent for industrial wastewater treatment, comprising the following components in parts by weight:

[0030] 5 parts of sepiolite powder, 25 parts of modified clay, 6 parts of polyacrylamide, 15 parts of kaolin, 20 parts of cross-linked rectorite, 3 parts of chitosan, 5 parts of shell, 1 part of lotus seed shell, 2 parts of hazelnut shell , 1 part of ginkgo shell, 1 part of macadamia nut shell, 15 parts of compound microorganism;

[0031] The preparation method of described modified clay comprises the following steps:

[0032] S1. Raise the temperature of the clay from room temperature to 500°C at 10°C / min and keep it for 2h; then raise the temperature to 750°C at 5°C / min and keep it for 10h, cool to room temperature, wash until neutral, dry, and pass through 200 mesh screen;

[0033] S2. Add the clay passed through a 200-mesh sieve into a hydrochloric acid solution with a mass fraction of 5%, stir at a temperature of 60°C for 8 hours, filter, wash, and dry...

Embodiment 2

[0047] A bacterial agent for industrial wastewater treatment, comprising the following components in parts by weight:

[0048] 8 parts of sepiolite powder, 30 parts of modified clay, 7 parts of polyacrylamide, 18 parts of kaolin, 23 parts of cross-linked rectorite, 5 parts of chitosan, 8 parts of shell, 2 parts of lotus seed shell, 3 parts of hazelnut shell , 2 parts of ginkgo shell, 2 parts of macadamia nut shell, 18 parts of compound microorganism;

[0049] The preparation method of described modified clay comprises the following steps:

[0050] S1. Raise the temperature of the clay from room temperature to 530°C at 13°C / min and keep it for 3h; then raise the temperature to 780°C at 6°C / min and keep it for 13h, cool to room temperature, wash until neutral, dry, and pass through 200 mesh screen;

[0051] S2. Add the clay passed through a 200-mesh sieve into a hydrochloric acid solution with a mass fraction of 8%, stir for 10 hours at a temperature of 65°C, filter, wash, and...

Embodiment 3

[0065] A bacterial agent for industrial wastewater treatment, comprising the following components in parts by weight:

[0066] 10 parts of sepiolite powder, 35 parts of modified clay, 7 parts of polyacrylamide, 20 parts of kaolin, 25 parts of cross-linked rectorite, 6 parts of chitosan, 10 parts of shell, 2 parts of lotus seed shell, 3 parts of hazelnut shell, 2 parts of ginkgo shell, 2 parts of macadamia nut shell, 20 parts of compound microorganism;

[0067] The preparation method of described modified clay comprises the following steps:

[0068] S1. Raise the temperature of the clay from room temperature to 550°C at 15°C / min and keep it for 3h; then raise the temperature to 800°C at 8°C / min and keep it for 15h, cool to room temperature, wash until neutral, dry, and pass through 200 mesh screen;

[0069] S2. Add the clay passed through a 200-mesh sieve into a hydrochloric acid solution with a mass fraction of 10%, stir for 12 hours at a temperature of 70°C, filter, wash, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com