Preparation method for MnO2-CeO2-CoO/AC ternary supported catalyst for treatment of phenolic wastewater

A mno2-ceo2-coo, supported catalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of affecting the catalytic performance and service life of catalysts , high loss rate of active components, rapid decline in catalytic activity, etc., to avoid deactivation, improve oxidation efficiency, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

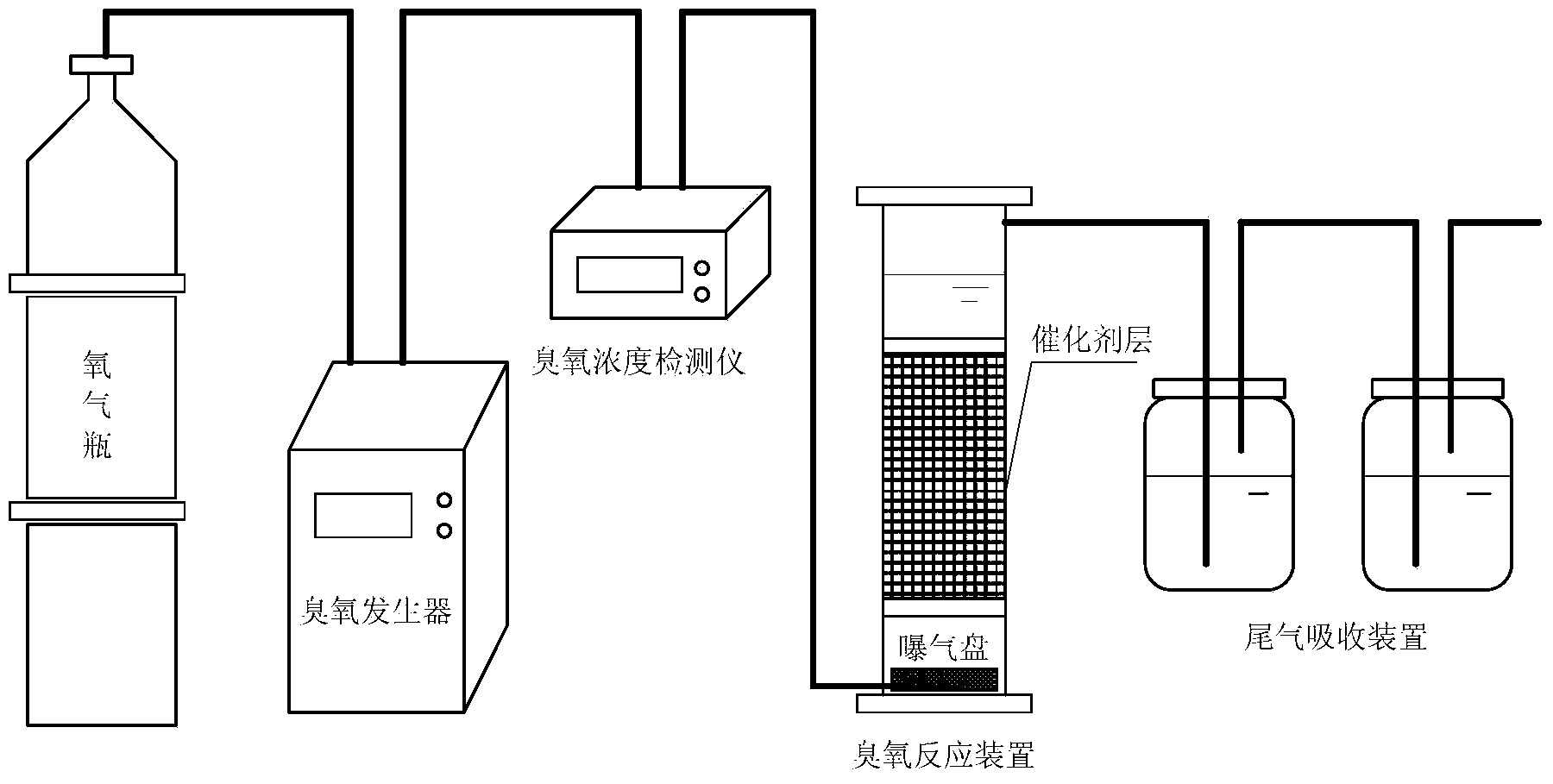

Method used

Image

Examples

Embodiment 1

[0027] 11.55gC 4 h 6 MnO 4 , 2.12gCe(C 2 h 3 o 2 ) 3 ·nH 2 O, 1.66gC 4 h 6 o 4 Co 4H 2 O is formulated into a mixed solution with a mass concentration of 15%, wherein the ratio of manganese, cerium, and cobalt is 10:1:1. Grind 100g of anthracite into a fineness of more than 90% and pass through 200 mesh raw coal powder, add the mixed solution and 25g of coal tar, knead and pulverize in two stages, after uniform mixing, pelletize through a pelletizing machine, after pelletizing After sieving, the carbon balls with qualified particle size are dried by hot air to complete the secondary pelletizing, and form carbon balls with a particle size of 4mm, which are laid on the smooth cement floor with a thickness of 3-5cm and air-dried for 5 hours; The air-dried charcoal spheres were in N 2 Carbonization is carried out in the atmosphere, the carbonization temperature rise rate is 5°C / min, the final temperature is controlled at about 600°C, and the temperature is kept constan...

Embodiment 2

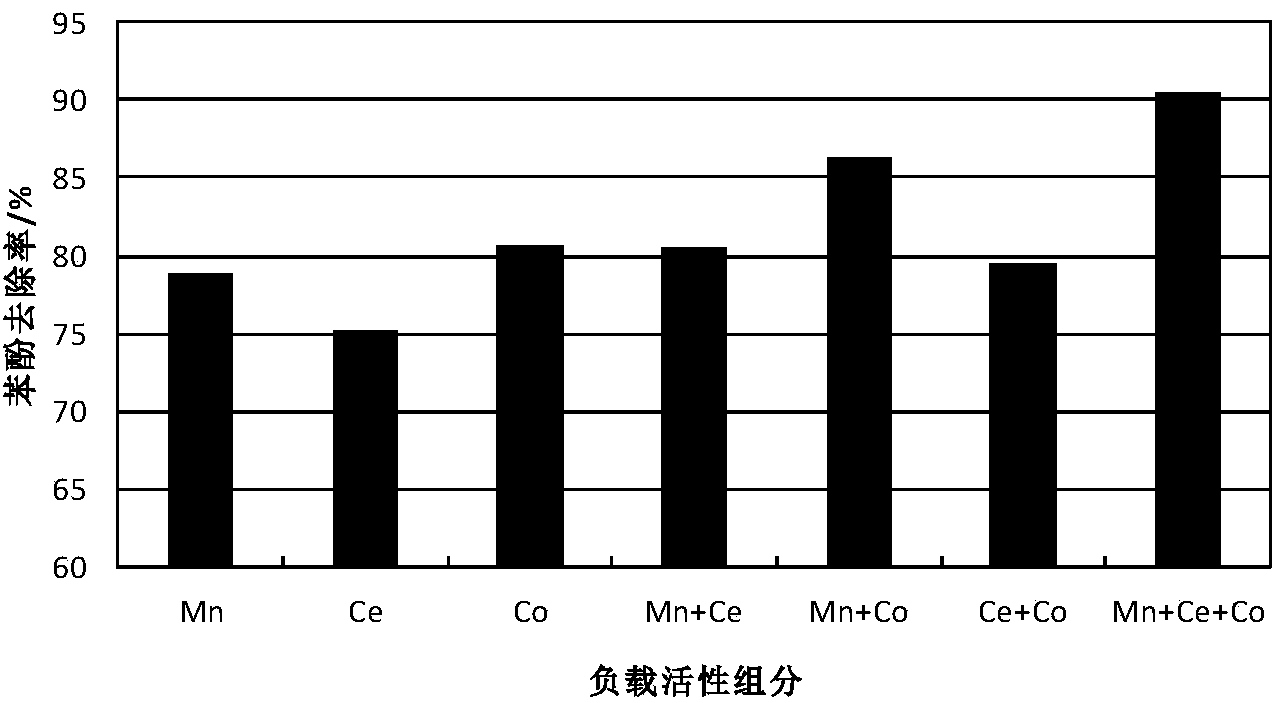

[0033] In order to compare the effects, under the same process conditions as in Example 1, the following groups of catalysts were compared with the catalysts in Example 1 for comparative experiments.

[0034] 15.73gC 4 h 6 MnO 4 Make a solution with a mass concentration of 15%. Grinding 100g of anthracite into a fineness of more than 90% and passing through 200 meshes of raw coal powder, adding manganese acetate solution and 25g of coal tar, the following preparation steps are different from Example 1 only in that the activator is flue gas The temperature is 900°C, the activation time is 10h, and MnO is obtained 2 / AC supported activated carbon catalyst, the loading of Mn is 5%.

[0035] 11.33gCe(C 2 h 3 o 2 ) 3 ·nH 2 O is made into a solution with a mass concentration of 15%. Grinding 100g of anthracite coal into a fineness of more than 90% and passing through 200 meshes of raw coal powder, adding the cerium acetate solution and 25g of coal tar, the following prepar...

Embodiment 3

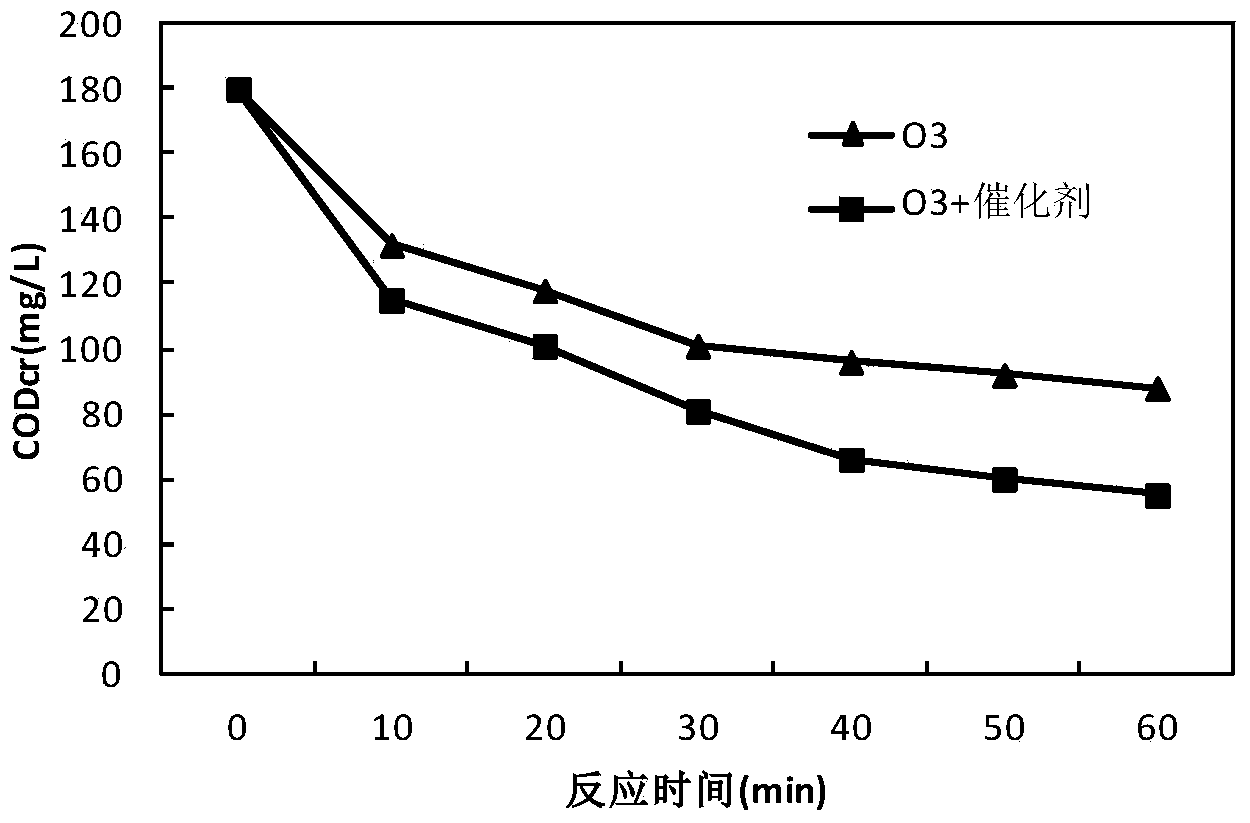

[0042] Adopt the MnO that embodiment 1 prepares 2 -CeO 2 -CoO / AC ternary supported activated carbon catalyst catalyzed the degradation of phenolic wastewater by ozonation oxidation. The experimental water is taken from the secondary biochemical effluent of a petrochemical plant containing phenolic wastewater. The wastewater quality: pH value is 7.5, CODcr is 180mg / L; experimental conditions: static small test experiment, catalyst dosage is 100g / L, ozone dosage 50mg / L, the reaction time is 60min, the supernatant is taken every 10min and filtered to measure CODcr, and the single ozone oxidation is used as a comparative effect under the same experimental conditions. See the experimental results image 3 . It can be seen that adding MnO 2 -CeO 2 - The ozone catalytic oxidation system of the CoO / AC three-way supported activated carbon catalyst has a significantly higher removal effect on the CODcr of phenol-containing wastewater than the ozone oxidation system without a cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com