Vanadium tantalum/niobate photocatalyst and preparation method and application of vanadium tantalum/niobate photocatalyst

A technology of photocatalyst and niobate, applied in the direction of physical/chemical process catalyst, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of not being able to make full use of sunlight and the utilization rate of sunlight Low, no catalytic activity, etc., to achieve the effect of easy modification and application, simple preparation method, and good particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Prepare Nb by high temperature solid phase method 9 VO 25 .

[0035] (1) According to the chemical formula Nb 9 VO 25 The stoichiometric ratio of each element in , respectively weighed Nb 2 o 5 : 5.962 g, NH 4 VO 3 : 0.585g, ground in an agate mortar and mixed well;

[0036] (3) Pre-calcine the mixture obtained in step (2) in an air atmosphere in a muffle furnace at 350°C for 5 hours, after natural cooling, take out the sample, mix and grind the mixture thoroughly again;

[0037] (3) Calcinate the mixture obtained in step (2) again at 930°C for 3 hours in an air atmosphere, cool to room temperature, take it out and grind it sufficiently to obtain Nb 9 VO 25 Photocatalyst powder.

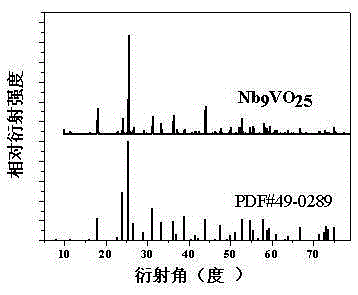

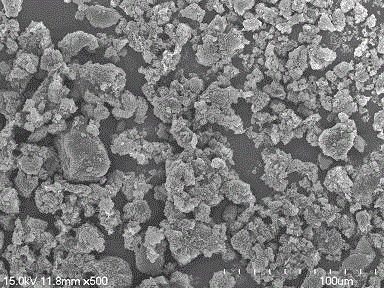

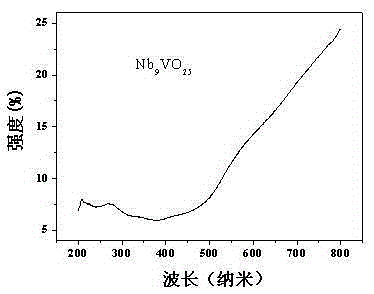

[0038] Such as figure 1 Shown, the Nb prepared in Example 1 9 VO 25 The X-ray powder diffraction pattern of the sample is exactly the same as the standard structure card, and the prepared vanadate Nb in the XRD experiment 9 VO 25It is a single-phase material withou...

Embodiment 2

[0043] Embodiment 2: Prepare Nb by high temperature solid phase method 9 VO 25 .

[0044] (1) According to the chemical formula Nb 9 VO 25 The stoichiometric ratio of each element in , respectively weighed Nb 2 o 5 : 4.77 g, V 2 o 5 : 0.364 g, carefully ground in an agate mortar until the powder sample is evenly mixed;

[0045] (3) Pre-calcine the mixture obtained in step (2) in an air atmosphere in a muffle furnace at 450°C for 2 hours, after natural cooling, fully mix and grind the mixture again;

[0046] (3) Calcinate the mixed sample obtained in step (2) again at 850°C for 8 hours in an air atmosphere, cool to room temperature, take it out and grind it sufficiently to obtain Nb 9 VO 25 Photocatalyst powder.

[0047] Known through experiment, the Nb that present embodiment obtains 9 VO 25 Photocatalyst has pure phase, X-ray powder diffraction pattern embodiment 1 obtains figure 1 Same. Sample Nb 9 VO 25 The main structure and morphology of the photocatalyst,...

Embodiment 3

[0048] Embodiment 3: adopt chemical solution method to prepare Nb 9 VO 25 .

[0049] (1) According to the chemical formula Nb 9 VO 25 The stoichiometric ratio of each element in the NbCl 5 : 6.0752 g, NH 4 VO 3 : 0.293 grams, respectively dissolved in deionized or dilute nitric acid, and add an appropriate amount of citric acid for complexation, after stirring, A and B solutions are obtained, after heating and stirring, mix the two solutions, and continue stirring until forming a gel;

[0050] (2) Place the obtained gel in an oven at 85°C for 12 hours;

[0051] (3) Naturally cool the product obtained in the previous step, take out the precursor, and calcine it in an air atmosphere at a calcination temperature of 800°C and a calcination time of 20 hours. After taking it out and fully grinding it, the Nb 9 VO 25 Photocatalyst powder.

[0052] Known through experiment, the Nb that present embodiment obtains 9 VO 25 Photocatalyst has pure phase, X-ray powder diffraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com