Preparation method and applications of porous composite material with peroxidase activity

A porous composite material, peroxidase technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, oxidized water/sewage treatment, etc., can solve the problem of high cost, difficult purification, unstable It can improve the peroxidase activity, efficient catalytic degradation, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

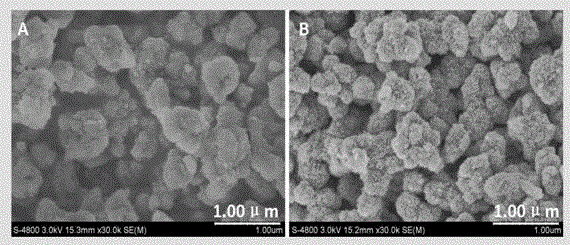

[0020] A preparation method of a porous composite material with peroxidase activity, which uses an acid-free method to hydrothermally synthesize MIL-100(Fe), and obtains a porous composite material derived from MIL-100(Fe) by calcining MIL-100(Fe) materials, the steps are as follows:

[0021] 1) Preparation of MIL-100(Fe)

[0022] 2.5mmolFe(NO 3 ) 3 9H 2 O and 1.675 mmol of trimesic acid were dissolved in 12.5 mL of distilled water, ultrasonically dissolved, then transferred to a reaction kettle with a Teflon liner, reacted at 160 ° C for 12 h, centrifuged to separate the solid, and successively washed with water, N, N - After washing with dimethylformamide and ethanol, dry under vacuum at 100°C for 12 hours to obtain MIL-100(Fe);

[0023] 2) Preparation of MIL-100(Fe)-derived porous composites

[0024] Put the above-prepared MIL-100(Fe) in a muffle furnace, heat up to 350°C at a rate of 2°C / min in the air, calcinate at this temperature for 120min, and cool the obtained c...

Embodiment 2

[0030] A preparation method of a porous composite material with peroxidase activity, which uses an acid-free method to hydrothermally synthesize MIL-100(Fe), and obtains a porous composite material derived from MIL-100(Fe) by calcining MIL-100(Fe) materials, the steps are as follows:

[0031] 1) Preparation of MIL-100(Fe)

[0032] 2.5mmolFe(NO 3 ) 3 9H 2 O and 1.675mmol of trimesic acid were dissolved in 37.5mL of distilled water, ultrasonically dissolved, then transferred to a reaction kettle with a Teflon liner, reacted at 160°C for 12h, centrifuged to separate the solid, followed by water, N, N - After washing with dimethylformamide and ethanol, dry under vacuum at 100°C for 12 hours to obtain MIL-100(Fe);

[0033] 2) Preparation of MIL-100(Fe)-derived porous composites

[0034] The above-prepared MIL-100(Fe) was placed in a muffle furnace, heated to 600°C in argon at a rate of 5°C / min, calcined at this temperature for 60min, and the obtained composite material was coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com