Method of preparing sludge-based Fe-Zn three-dimensional particle catalyst by residual sludge

A technology of excess sludge and catalyst, applied in the field of solid waste resource utilization and sewage treatment, can solve the problems of large randomness of metal types and quantities, limited number of active components, unstable catalytic activity, etc., and achieve good environmental benefits and Economic benefits, easy operation and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

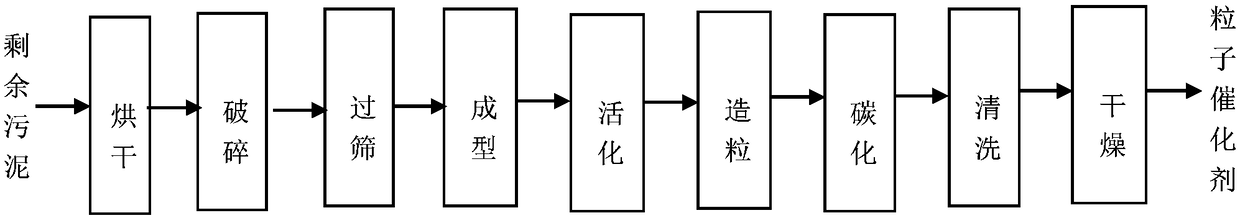

Method used

Image

Examples

Embodiment

[0032] Take the dewatered sludge from the sewage treatment plant that has been conditioned by polyferron, dry it at 110°C for 24 hours, grind it with a pulverizer and pass it through a 150-mesh sieve to obtain a dry sludge powder; add 1% carboxymethyl to the sludge powder Cellulose sodium, and fully mixed evenly; activate with zinc chloride solution with a mass concentration of 5mol / L as the activator, the dosage is 40% by mass fraction, and the sludge base and the activator are uniformly mixed and then made by a granulator Solid balls with a diameter of 8mm were dried at 110°C; the sludge balls were placed in a carbonization furnace with nitrogen as a protective gas, heated to 600°C at a heating rate of 15°C / min, and pyrolyzed for 120 minutes After cooling to room temperature; soak the sludge charcoal spheres after the carbonization step in 90°C water until the pH of the effluent is 7; dry the sludge charcoal spheres after the cleaning step at 110°C to obtain the sludge-based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com