Preparation method of cobalt oxide nanocrystal and prepared cobalt oxide nanocrystal

A technology of cobaltous oxide nanometer and cobalt salt, which is applied in the direction of cobalt oxide/cobalt hydroxide, nanotechnology, nanotechnology, etc., which can solve the problems of uneven crystal grains, low crystallinity, and impurities mixed in, and achieve uniform particle size distribution , the grain development is complete, and the effect of avoiding the mixing of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

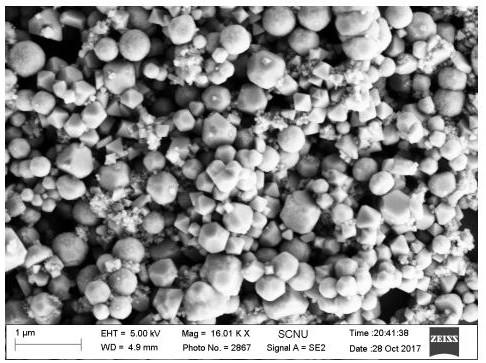

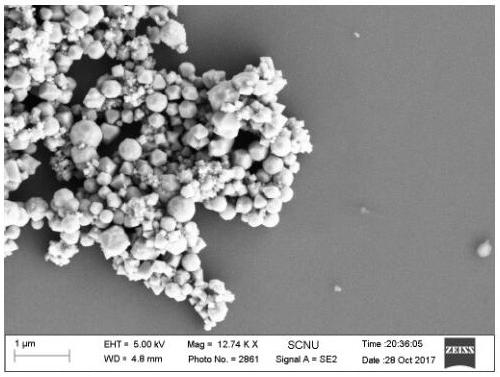

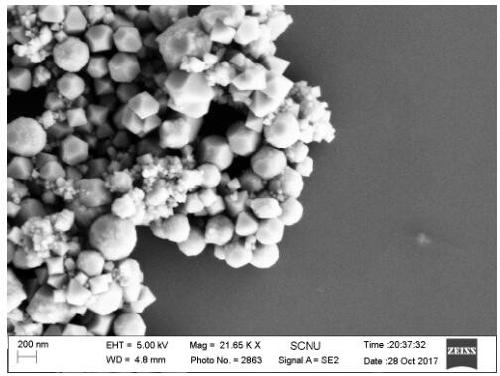

[0027] A method for preparing cobaltous oxide nanocrystals, using cobalt acetate tetrahydrate (purity 99.5%) and triphenylphosphine (purity 98%) as precursors, completely dissolving the precursors in oleylamine, and reacting in a closed environment 18h, the reaction temperature is 180°C, and the heating rate is 10°C / min. Pour the hydrothermal reaction mixture into a centrifuge tube, centrifuge at 5000r / min for 5min, then wash and centrifuge twice with absolute ethanol, and dry at 60°C to obtain oxidation Subcobaltous nanocrystals, wherein the mass ratio of cobalt acetate tetrahydrate and triphenylphosphine is 1:10, and the consumption of oleylamine is 35mL.

Embodiment 2

[0029] A method for preparing cobaltous oxide nanocrystals, using cobalt acetate tetrahydrate (purity 99.5%) and triphenylphosphine (purity 98%) as precursors, completely dissolving the precursors in oleylamine, and reacting in a closed environment 18h, the reaction temperature is 180°C, and the heating rate is 10°C / min. Pour the hydrothermal reaction mixture into a centrifuge tube, centrifuge at 5000r / min for 5min, then wash and centrifuge twice with absolute ethanol, and dry at 60°C to obtain oxidation Subcobaltous nanocrystals, wherein the mass ratio of cobalt acetate tetrahydrate and triphenylphosphine is 1:20, and the consumption of oleylamine is 35mL.

Embodiment 3

[0031] A method for preparing cobaltous oxide nanocrystals, using cobalt acetate tetrahydrate (purity 99.5%) and triphenylphosphine (purity 98%) as precursors, completely dissolving the precursors in oleylamine, and reacting in a closed environment 18h, the reaction temperature is 180°C, and the heating rate is 10°C / min. Pour the hydrothermal reaction mixture into a centrifuge tube, centrifuge at 5000r / min for 5min, then wash and centrifuge twice with absolute ethanol, and dry at 60°C to obtain oxidation Subcobaltous nanocrystals, wherein the mass ratio of cobalt acetate tetrahydrate and triphenylphosphine is 1:25, and the consumption of oleylamine is 35mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com