Method for preventing PCB solder mask oil leakage

A solder mask and oil printing technology, which is applied to non-printed masks, circuit covers, and the formation of electrical connections of printed components, can solve the problems of high cost of exposure machines, oil leakage, and repeated oil leakage, so as to reduce the scrap rate and ensure The effect of developing and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

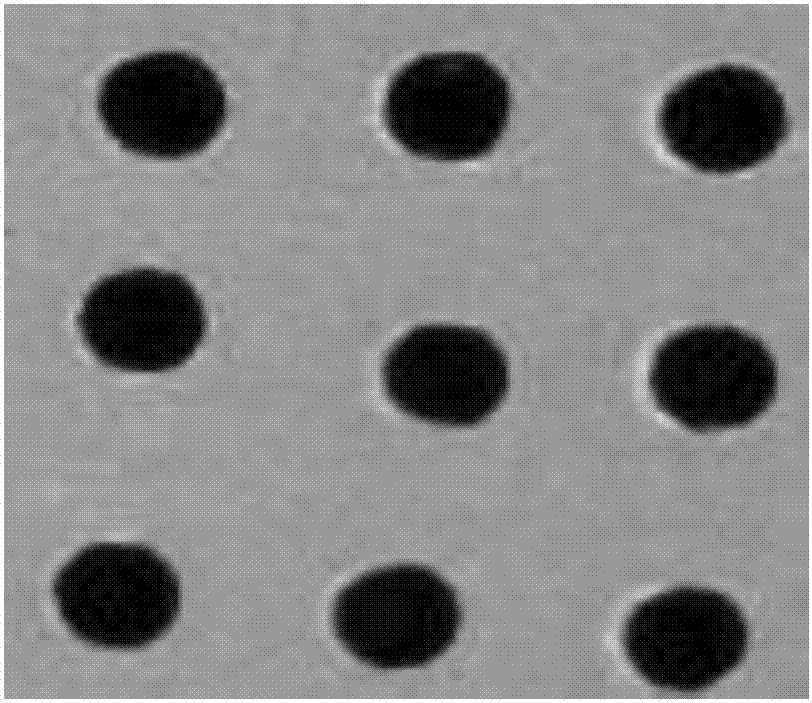

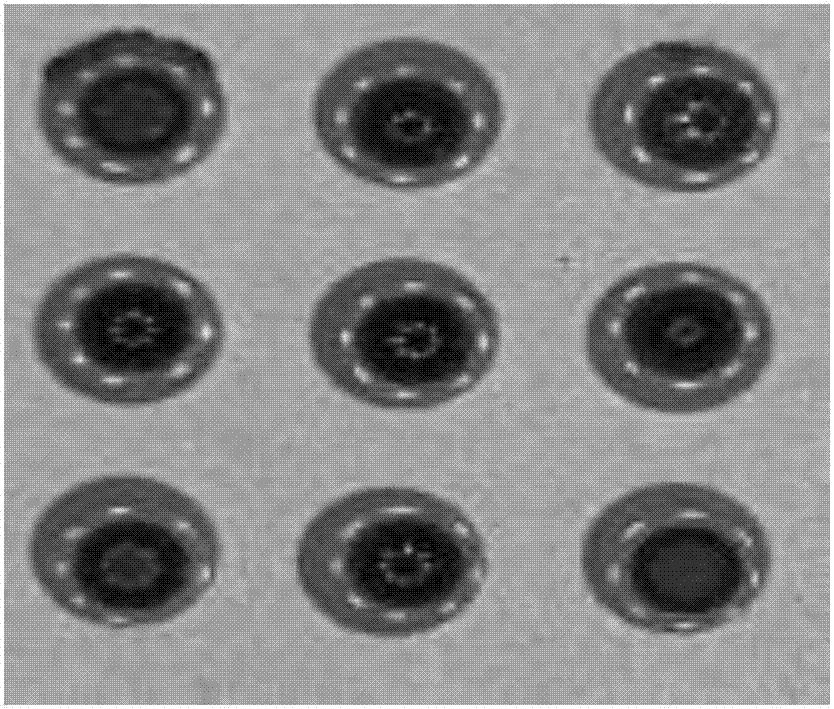

Image

Examples

Embodiment 1

[0030] A method for improving PCB anti-soldering oil emission, which is used to significantly improve oil emission at the position of opening a window on one side after PCB alignment development, comprising the following steps:

[0031] (1) Ink preparation

[0032] Add 10mL plug thinner to 1kg plug oil and mix well; add 40mL top oil thinner to 1kg top oil and mix well.

[0033] (2) Surface treatment

[0034] The board enters the anti-soldering process to brush the board. The current of the A-line brushing board is 2.2A, and the speed is 2.5m / min, and the B-line brushing current is 3.4A, and the speed is 2.5m / min for control.

[0035] (3) Plug holes and ink.

[0036] Plug the hole first, and then print the entire board, and plug the hole oil from the opposite side of the oil emitting surface. The plugging and ink printing process is carried out in 10 steps.

[0037] (4) Pre-baked

[0038] The PCB board is pre-baked, and the parameters of the pre-baking are controlled as fol...

Embodiment 2

[0050] A method for improving PCB anti-soldering oil emission, which is used to significantly improve oil emission at the position of opening a window on one side after PCB alignment development, comprising the following steps:

[0051] (1) Ink preparation

[0052] Add 20mL plug thinner to 1kg plug oil and mix well; add 30mL top oil thinner to 1kg top oil and mix well.

[0053] (2) Surface treatment

[0054] The board enters the anti-soldering process to brush the board. The current of the A-line brushing board is 2A, and the speed is 2m / min. The current of the B-line brushing board is 3A, and the speed is 2m / min for control.

[0055] (3) Plug hole and ink

[0056] Plug the hole first, and then print the entire board, and plug the hole oil from the opposite side of the oil emitting surface. The plugging and ink printing process is carried out in 8 steps.

[0057] (4) Pre-baked

[0058] The PCB board is pre-baked, and the parameters of the pre-baked are controlled as follow...

Embodiment 3

[0070] A method for improving PCB anti-soldering oil emission, which is used to significantly improve oil emission at the position of opening a window on one side after PCB alignment development, comprising the following steps:

[0071] (1) Ink preparation

[0072] Add 15mL plug hole diluent to 1kg plug hole oil and mix well; add 50mL top oil thinner to 1kg top oil and mix well.

[0073] (2) Surface treatment

[0074] The board enters the anti-soldering process to brush the board. The brushing current of the A line is 2.5A and the speed is 3m / min, and the current of the B line brushing board is 3.6A and the speed is 3m / min for control.

[0075] (3) Plug hole and ink

[0076] Plug the hole first, and then print the entire board, and plug the hole oil from the opposite side of the oil emitting surface. The plugging and ink printing process is carried out in two steps.

[0077] (4) Pre-baked

[0078] The PCB board is pre-baked, and the parameters of the pre-baking are control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com