Repairing method for deformation of inner hole in rear end of intermediate case

A repair method and intermediary technology, which is applied in the field of aero-engine intermediary casing repair, can solve problems such as unusable components and no repair experience, and achieve low cost, innovative ideas, and obvious application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

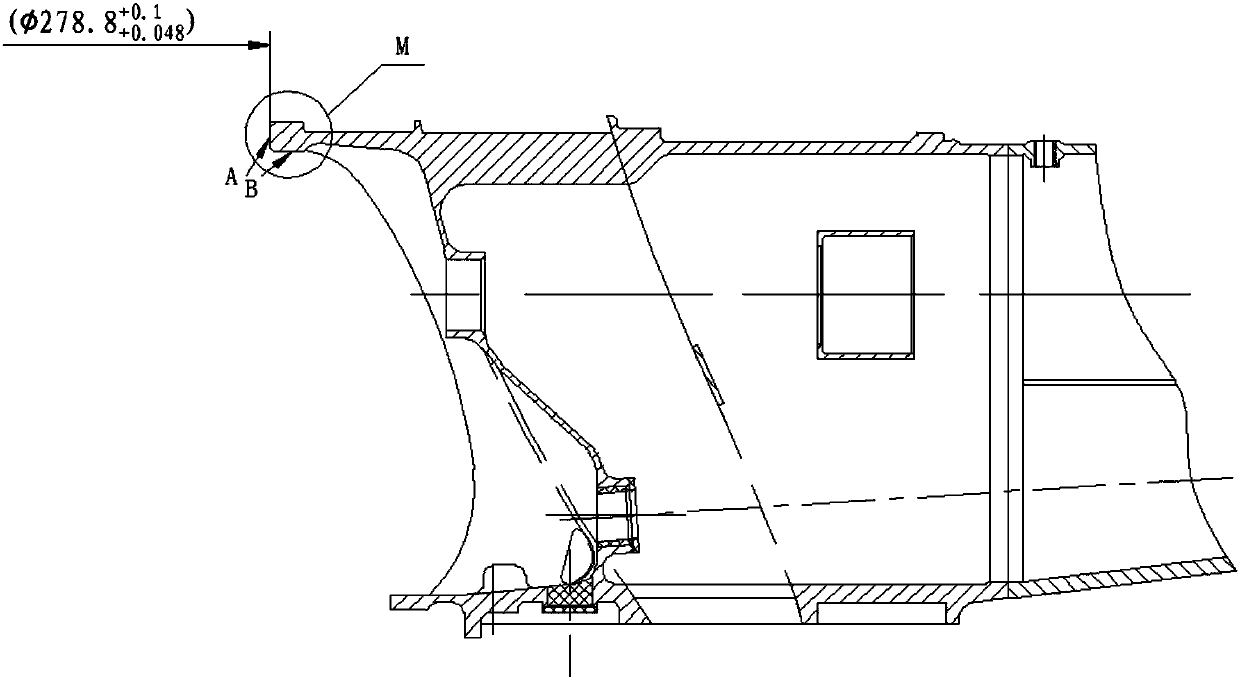

[0028] refer to Figure 1-6 The embodiments of the present invention are further described.

[0029] Step 1: Turn the intermediate casing positioning surface, and process the A and B surfaces of the parts to be repaired; the processing parameters are φ278.8, see figure 1 ;

[0030] Step 2: Remove the processing burr of the intermediate casing, the sharp edge is blunt by 0.2±0.1, and the surface of the part is not allowed to be damaged;

[0031] Step 3: Clean the surface and inner cavity of the part with alcohol to remove all dirt and excess;

[0032] Step 4: Carry out fluorescent inspection on the repaired area after the machining of the intermediate casing, that is, the A-side and B-side areas;

[0033] Step 5: Clean the surface and inner cavity of the part with alcohol again to remove all dirt and excess.

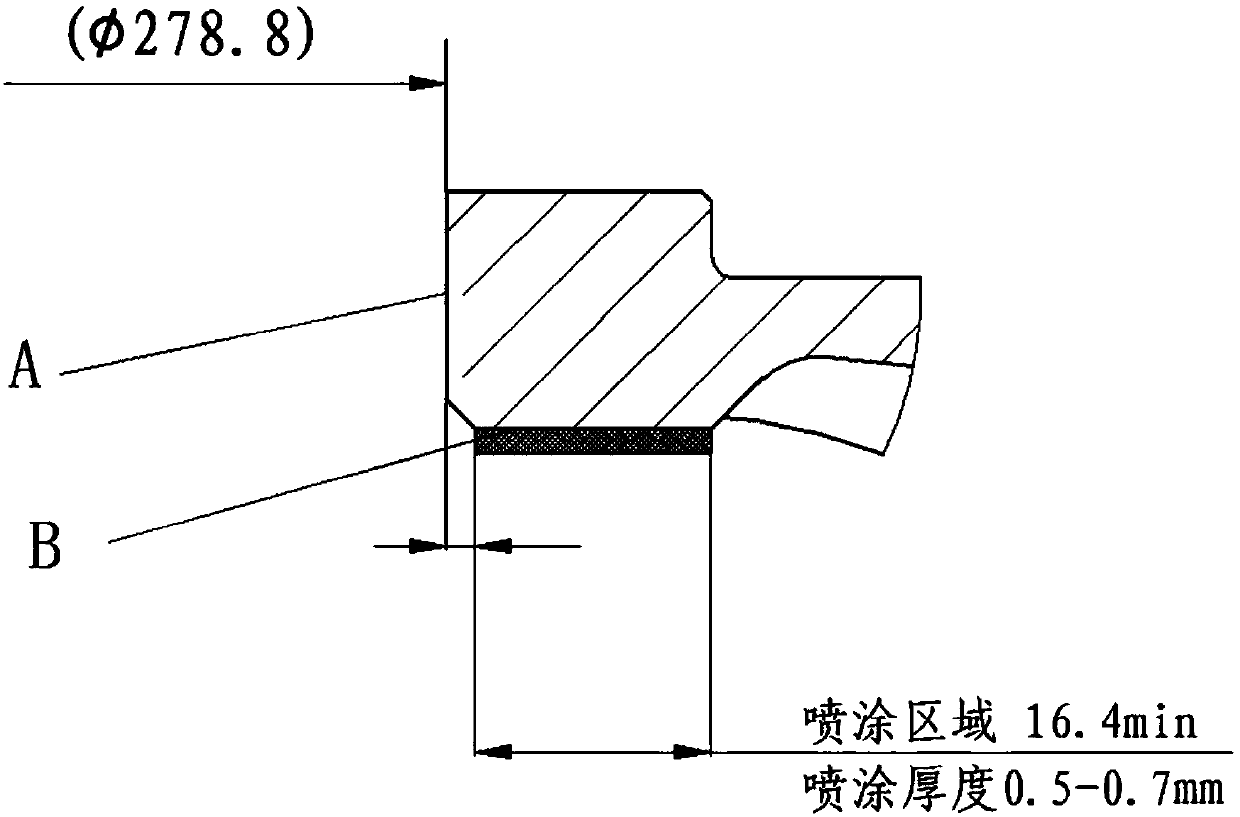

[0034] Step 6: Plasma spray nickel-aluminum coating on surface B; see figure 2 ;

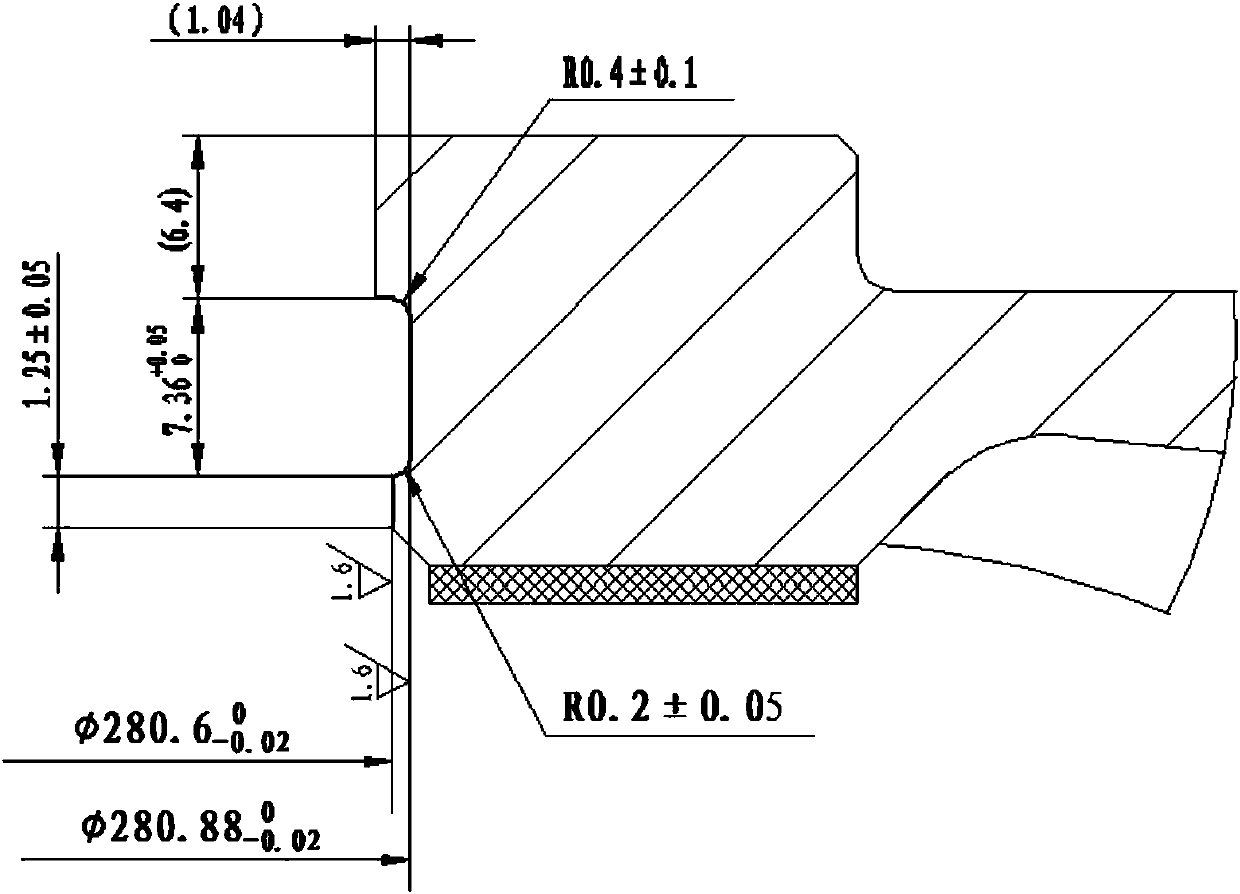

[0035] Step 7: Machining the inner ring groove (the groove for the titanium ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com