Cobaltous oxide nanocrystal-graphene composite material and preparation method and application thereof

A cobaltous oxide nano-composite material technology, which is applied in electrical components, battery electrodes, non-aqueous electrolyte storage batteries, etc., can solve the problems of easy aggregation of cobaltous oxide nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention also provides a preparation method of the cobaltous oxide nanocrystal-graphene composite material, comprising the following steps:

[0037] 1), graphite oxide is added in the first organic solvent and dispersed;

[0038] 2) Add cobalt acetylacetonate and octadecylamine, heat the mixture to 120°C-140°C, keep it for 20-50 minutes, then raise the temperature until the solution boils and reflux, and keep it for 1-5 hours;

[0039] The ratio of the mass of graphite oxide to the amount of cobalt acetylacetonate is 10 mg / mmol to 40 mg / mmol; the mass ratio of graphite oxide to octadecylamine is 1:80 to 1:25;

[0040] 3), adding a second organic solvent to quench the reaction, separating the solid, washing and drying the solid;

[0041] 4) Heat-treating the dried solid in an inert gas for 1 hour to 3 hours; wherein, the temperature of the heat treatment is 350° C. to 450° C.

[0042] Wherein, the above-mentioned graphite oxide refers to a ...

Embodiment 1

[0054] Add 40mg of graphite oxide to 40mL of N-methylpyrrolidone, and disperse ultrasonically to obtain a uniformly dispersed brown solution;

[0055] Add 2mmol cobalt acetylacetonate and 2g octadecylamine to the above brown solution, first heat the mixture to 120°C and keep it warm for 30 minutes; then raise the temperature to 202°C and keep it warm for 2 hours; keep magnetic stirring during this process;

[0056] The reaction was quenched by adding 20 mL of ethanol, the solid was separated by centrifugation, washed alternately with n-hexane and acetone, and dried under vacuum at 40°C;

[0057] The dried solid was heat-treated at 400° C. for 1 hour in an argon atmosphere to obtain a cobaltous oxide nanocrystal-graphene composite material.

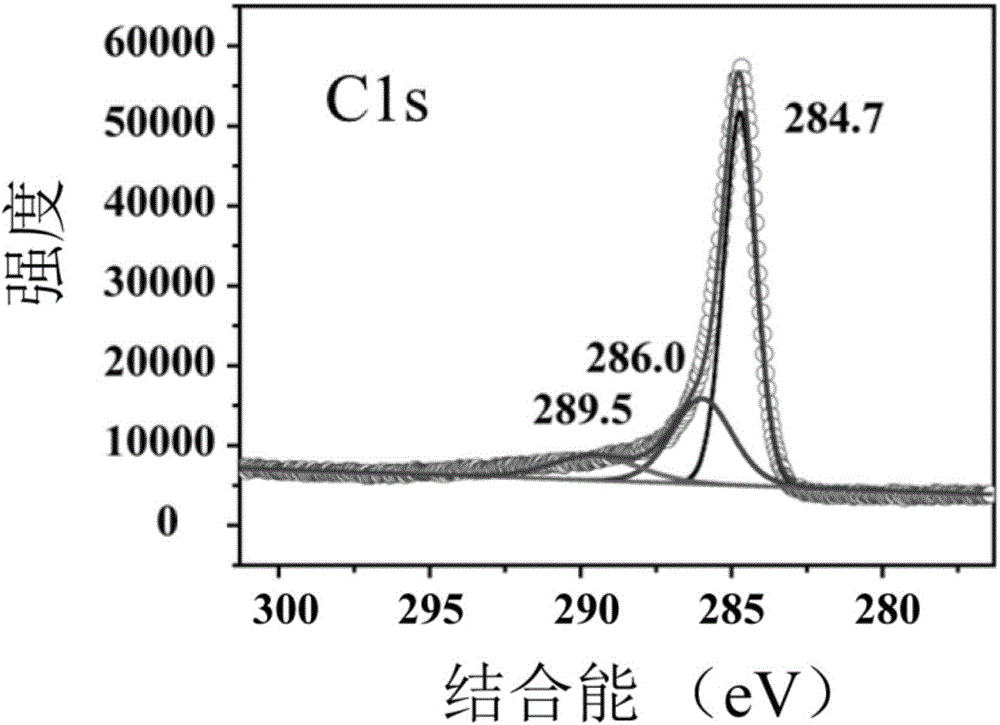

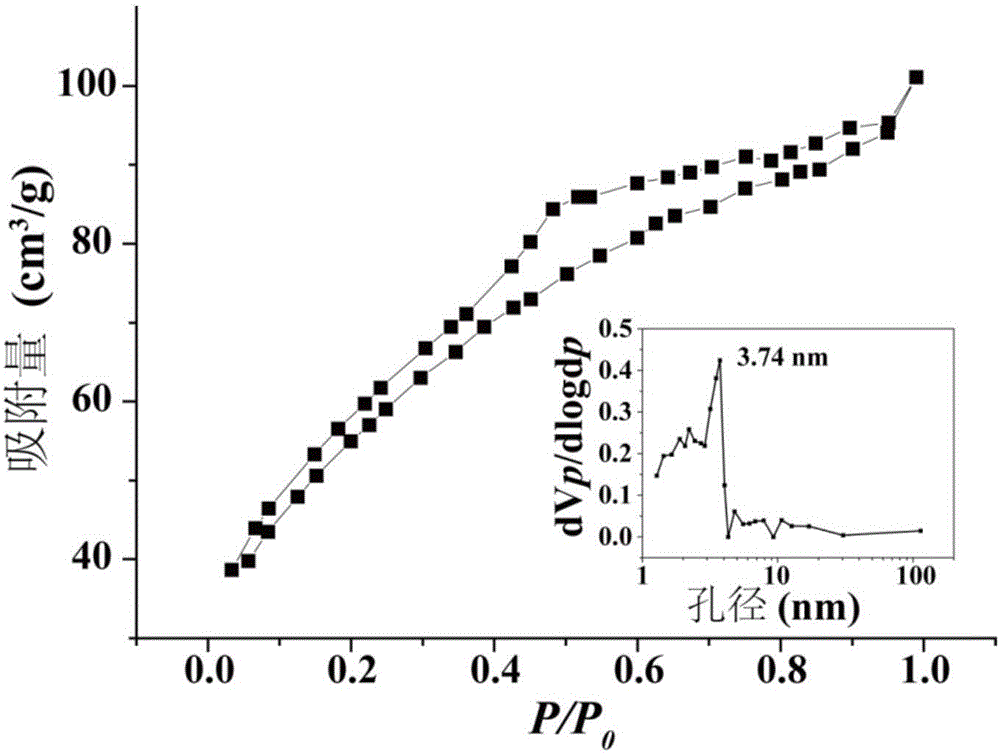

[0058] The cobaltous oxide nanocrystal-graphene composite material prepared in Example 1 of the present invention is analyzed below, and the analysis results obtained are as follows:

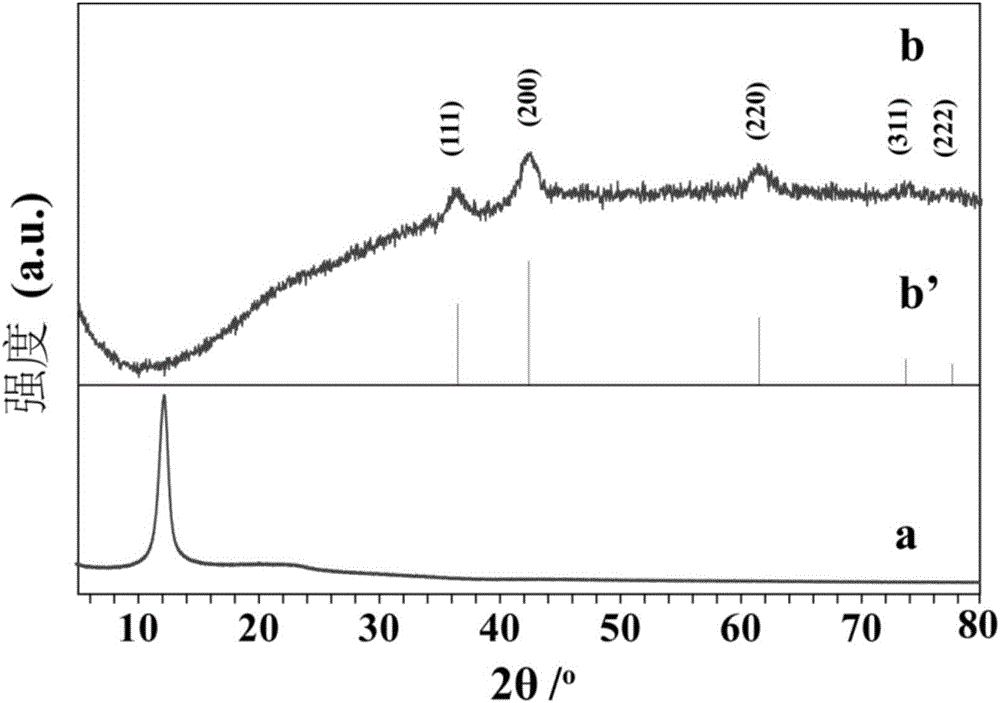

[0059] XRD analysis

[0060] figure 1 The XRD patte...

Embodiment 2

[0076] Add 40mg of graphite oxide to 40mL of oleylamine, and ultrasonically disperse to obtain a uniformly dispersed brown solution;

[0077] Add 1mmol cobalt acetylacetonate and 3.2g octadecylamine to the above brown solution, first heat the mixture to 120°C and keep it warm for 50 minutes; then raise the temperature to 290°C and keep it warm for 1 hour; keep magnetic stirring during this process;

[0078] The reaction was quenched by adding 20 mL of ethanol, the solid was separated by centrifugation, washed alternately with n-hexane and acetone, and dried under vacuum at 40°C;

[0079] The dried solid was heat-treated at 350° C. for 3 hours in an argon atmosphere to obtain a cobaltous oxide nanocrystal-graphene composite material.

[0080] XRD and XPS analysis show that the composite material is a cobaltous oxide nanocrystal-graphene composite material. Electron microscope image analysis shows that the graphene in the composite material is a sheet structure, and the cobaltou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com