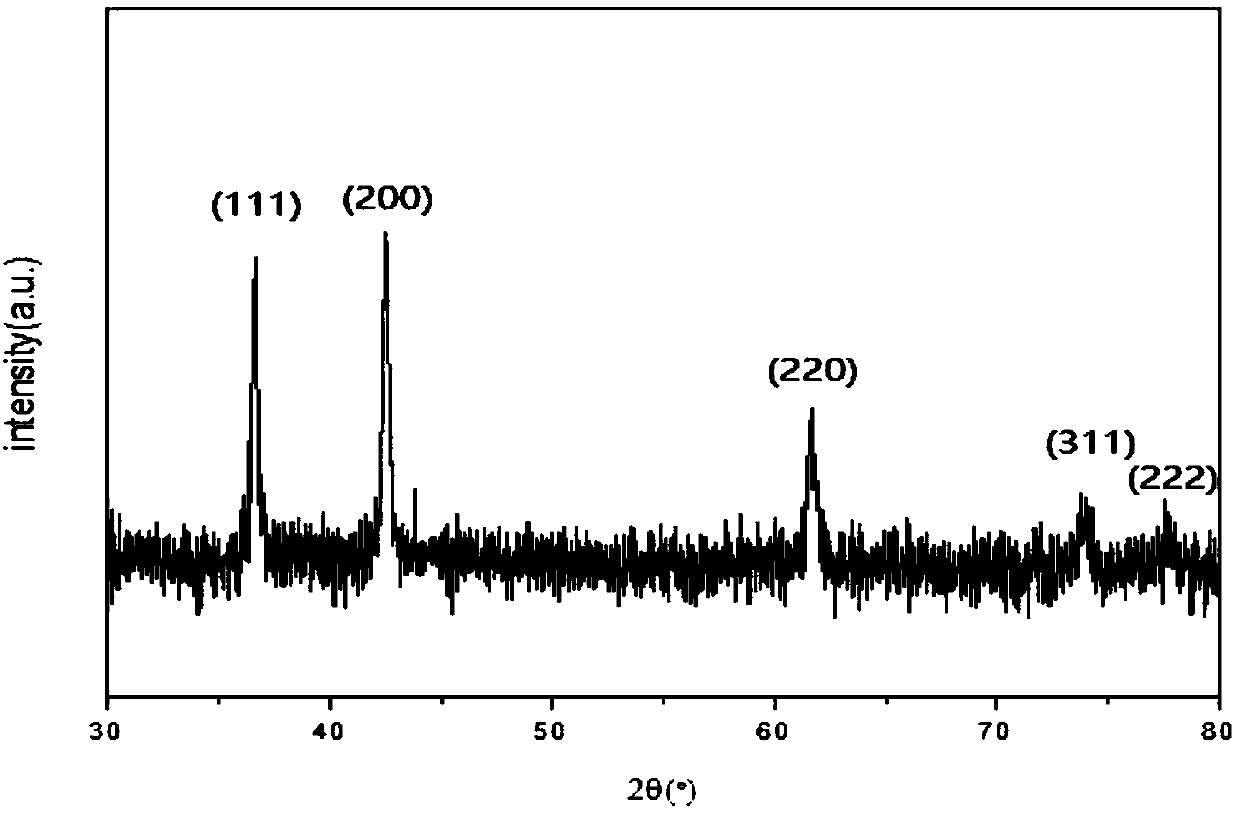

Nitrogen-doped graphene/cobaltous oxide composite material and preparation method thereof

A technology of cobaltous oxide composite materials and nitrogen-doped graphene, which is applied to electrical components, battery electrodes, circuits, etc., to achieve the effects of improving catalytic efficiency, improving electrical conductivity and stability, and improving catalytic efficiency of oxygen reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of nitrogen-doped graphene / cobaltous oxide composite material, its preparation method comprises the steps:

[0040] 1) Add 100 mg of graphite oxide into deionized water, ultrasonically disperse for 1 hour, stir for 0.5 hour, and then ultrasonically disperse for 1 hour to form a GO dispersion;

[0041] 2) Dissolve 100mg of cobalt acetate tetrahydrate and 4g of ammonium carbonate in deionized water to prepare a homogeneous aqueous solution. Add the prepared cobalt acetate solution and ammonium carbonate solution to the GO dispersion and stir for 0.5h. The resulting mixed solution (The concentration of graphene oxide is 0.5mg / ml) into a 500ml two-necked flask, put the flask into a water bath preheated to 80°C, continue to stir and condense and reflux for 10h; after the water bath is over, take out the flask and continue to stir And let the solution cool down naturally; put the cooled solution into the polytetrafluoroethylene liner, put the liner into the reaction ke...

Embodiment 2-4

[0048] The preparation method of nitrogen-doped graphene / cobaltous oxide composite material described in embodiment 2-4 is roughly the same as embodiment 1, and difference is: the consumption of ammonium carbonate in step 2) is respectively 1g (embodiment 2), 2g (Example 3) and 3g (Example 4).

Embodiment 5-8

[0051] Other parameter steps of embodiment 5-8 are identical with embodiment 1, difference is: in the step (2), the consumption of tetrahydrate cobalt acetate is respectively 150mg (embodiment 5), 200mg (embodiment 6) 250mg (embodiment 7 ) and 300 mg (Example 8).

[0052] Comparing Example 1 with Examples 5-8, the results show that too much content of cobaltous oxide will affect the electrical conductivity of the composite material and affect the enhancement trend of the oxygen reduction catalytic performance of the composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com