Nanometer carbon coated cobaltous oxide, and preparation method and applications thereof

A technology of cobaltous oxide and nano-carbon, which is applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems that hinder the practical application, the preparation process of the adsorbent is complicated, and the adsorption capacity remains to be determined. Improvement and other issues, to achieve the effect of strong ferromagnetism, easier recovery, and short equilibrium time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of a kind of nano-carbon-coated cobaltous oxide of the present embodiment, the specific preparation steps are as follows:

[0039] (1) Calculated according to the mass ratio, the ratio of citric acid particles: cobalt acetate powder is 10:3, weigh 1g of citric acid particles and 0.3g of cobalt acetate powder and pour them into the magnetic boat, and accurately add 2mL of Distilled water, placed the magnetic boat in an ultrasonic cleaner to ultrasonically dissolve the experimental drug, and after it was completely dissolved, placed the magnetic boat in an oven at 80°C for 3 hours to obtain a mixed colloid.

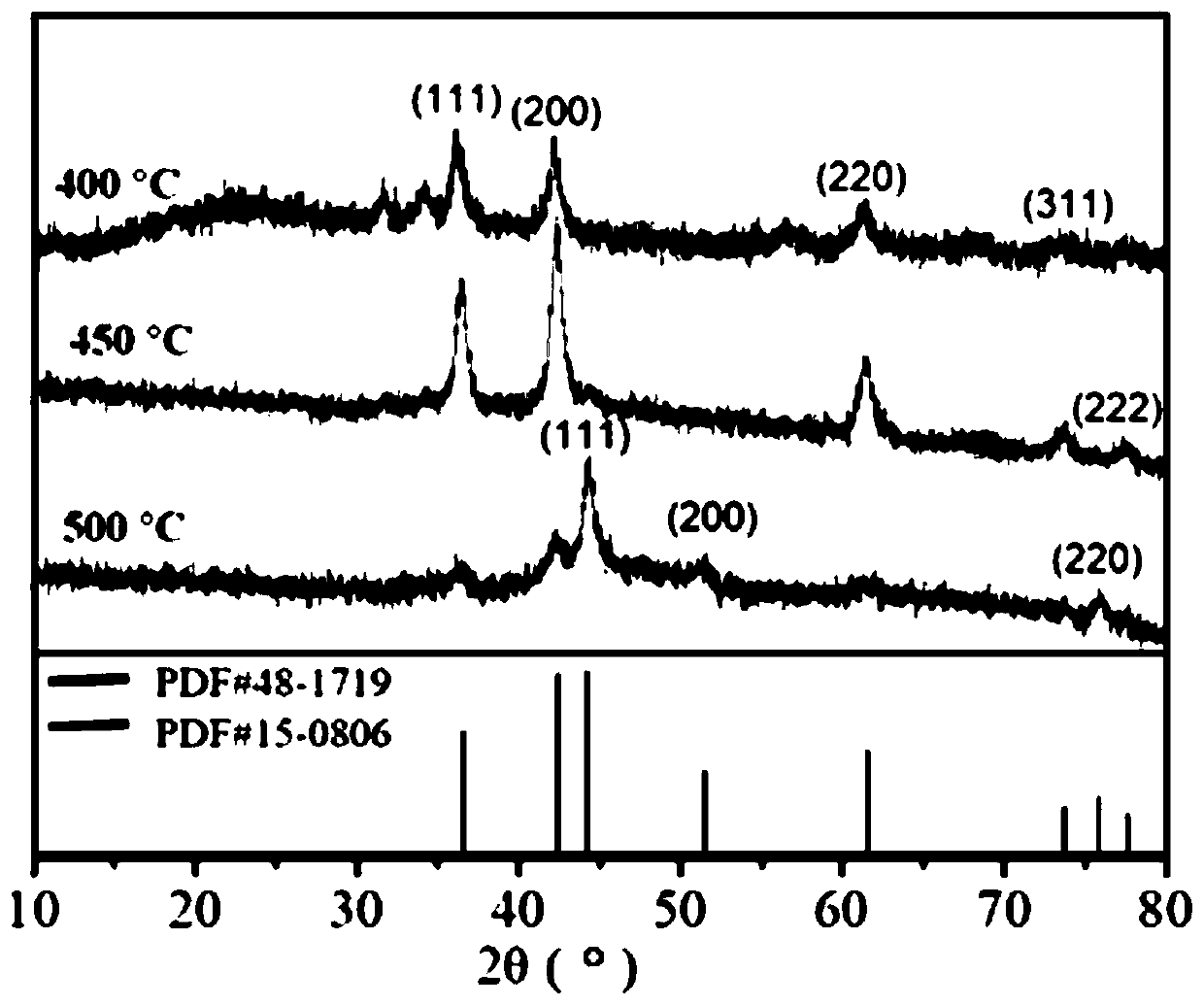

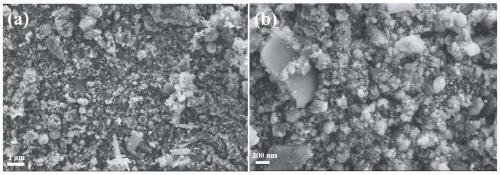

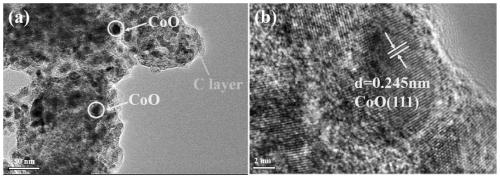

[0040] (2) The resulting mixed colloid is put into a tube furnace, under Ar / H 2 Under the protective effect of (5% Ar), the calcination temperature was raised from room temperature to 450° C. over 5 hours, and then the temperature drop program was started and the ventilation was continued, and then cooled to room temperature. The burnt sample ...

Embodiment 2

[0043] The preparation method of a kind of nano-carbon-coated cobaltous oxide of the present embodiment, the specific preparation steps are as follows:

[0044] (1) Calculated according to the mass ratio, the ratio of citric acid particles: cobalt acetate powder is 10:3, weigh 1g of citric acid particles and 0.3g of cobalt acetate powder and pour them into the magnetic boat, and accurately add 2mL of Distilled water, placed the magnetic boat in an ultrasonic cleaner to ultrasonically dissolve the experimental drug, and after it was completely dissolved, placed the magnetic boat in an oven at 80°C for 3 hours to obtain a mixed colloid.

[0045] (2) The resulting mixed colloid is put into a tube furnace, under Ar / H 2 Under the protective effect of (5% Ar), the calcination temperature was raised from room temperature to 400° C. over 4 hours, and then the cooling procedure was started and the ventilation was continued, and then cooled to room temperature. The burnt sample is put ...

Embodiment 3

[0048] The preparation method of a kind of nano-carbon-coated cobaltous oxide of the present embodiment, the specific preparation steps are as follows:

[0049] (1) Calculated according to the mass ratio, the ratio of citric acid particles: cobalt acetate powder is 10:3, weigh 1g of citric acid particles and 0.3g of cobalt acetate powder and pour them into the magnetic boat, and accurately add 2mL of Distilled water, placed the magnetic boat in an ultrasonic cleaner to ultrasonically dissolve the experimental drug, and after it was completely dissolved, placed the magnetic boat in an oven at 80°C for 3 hours to obtain a mixed colloid.

[0050] (2) The resulting mixed colloid is put into a tube furnace, under Ar / H 2 Under the protective effect of (5% Ar), the temperature was raised from room temperature to 500° C. for calcination over 6 hours, and then the temperature drop program was started and the ventilation was continued, and then cooled to room temperature. The burnt sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com