Multifunctional filtering material and preparation method thereof

A filter material and multi-functional technology, applied in the direction of filtration separation, membrane filter, separation method, etc., can solve the problems of limited antibacterial effect of non-woven fabrics, insufficient antibacterial effect, complicated preparation process, etc., to achieve excellent adsorption, preparation The method is simple and the filtering effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

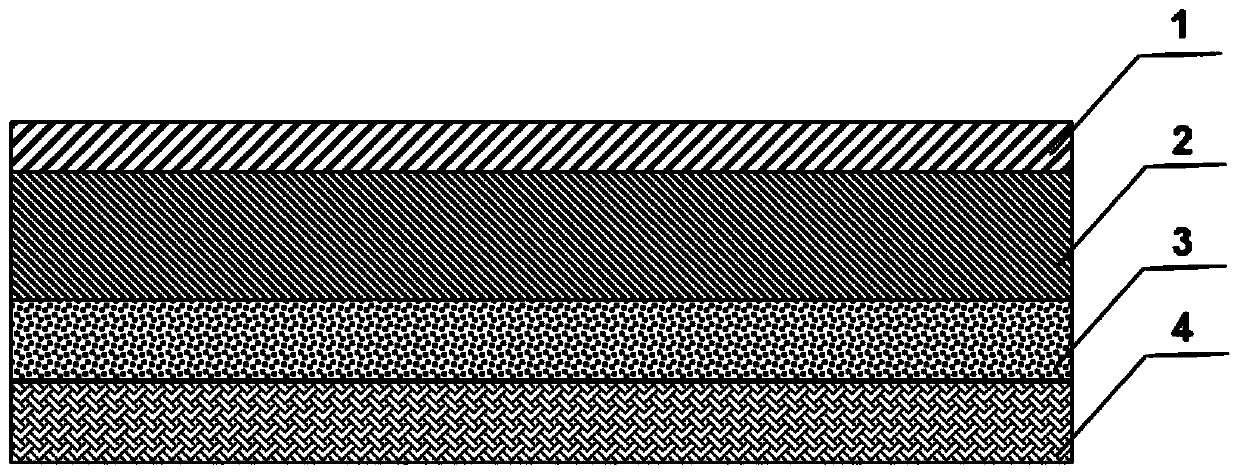

[0030] The invention provides a kind of preparation method of multifunctional filter material, comprises the steps:

[0031] S1, prepare the support layer non-woven fabric, and carry out antibacterial treatment to it;

[0032] S2, after superimposing the upper surface of the filter layer non-woven fabric and the lower surface of the protective layer non-woven fabric, perform ultrasonic compounding; S3, unwind the support layer non-woven fabric after the antibacterial treatment, and place it on the support layer non-woven fabric Spray hot melt adhesive evenly on the upper surface of the upper surface, then evenly sprinkle activated carbon particles on the upper surface of the support layer non-woven fabric sprayed with hot melt adhesive, and then evenly spray hot melt adhesive on the upper surface of the activated carbon particles;

[0033] S4. Superimpose the lower surface of the non-woven fabric of the filter layer on the upper surface of the activated carbon particles spraye...

Embodiment 1

[0046] The present embodiment provides a kind of preparation method of multifunctional filter material, comprises the following steps:

[0047] S1. Add the mixed solution of 10mL silver nitrate (30mmol / L) and 15mL copper nitrate (40mmol / L) into 30mL carboxymethyl chitosan aqueous solution (50mmol / L), and adjust the pH value to 6, sonicate at room temperature Oscillate for 1 hour to prepare an antibacterial finishing solution. At this time, the molar ratio of silver nitrate, copper nitrate and carboxymethyl chitosan in the antibacterial finishing solution is 1:2:5, and silver nitrate, copper nitrate and carboxymethyl chitosan The total mass of the total mass accounts for 1.7% of the total mass of the antibacterial finishing solution; the grammage obtained by the acupuncture method is 70g / m 2 1. The polypropylene needle-punched non-woven fabric with a thickness of 0.4mm is used as the support layer non-woven fabric, which is immersed in the prepared antibacterial finishing solut...

Embodiment 2~8 and comparative example 1~4

[0067] Embodiment 2~8 and comparative example 1~4 provide a kind of preparation method of multifunctional filter material respectively, compared with embodiment 1, difference is that the pH value of antibacterial finishing liquid and the ratio of each raw material are changed, each The pH value of the antibacterial finishing solution corresponding to the embodiment and the comparative example and the molar ratio of silver nitrate, copper nitrate and carboxymethyl chitosan in the antibacterial finishing solution and their percentages in the antibacterial finishing solution are shown in Table 4.

[0068] The pH value of antibacterial finishing solution and the ratio of each raw material in table 4 embodiment 2~8 and comparative example 1~4

[0069]

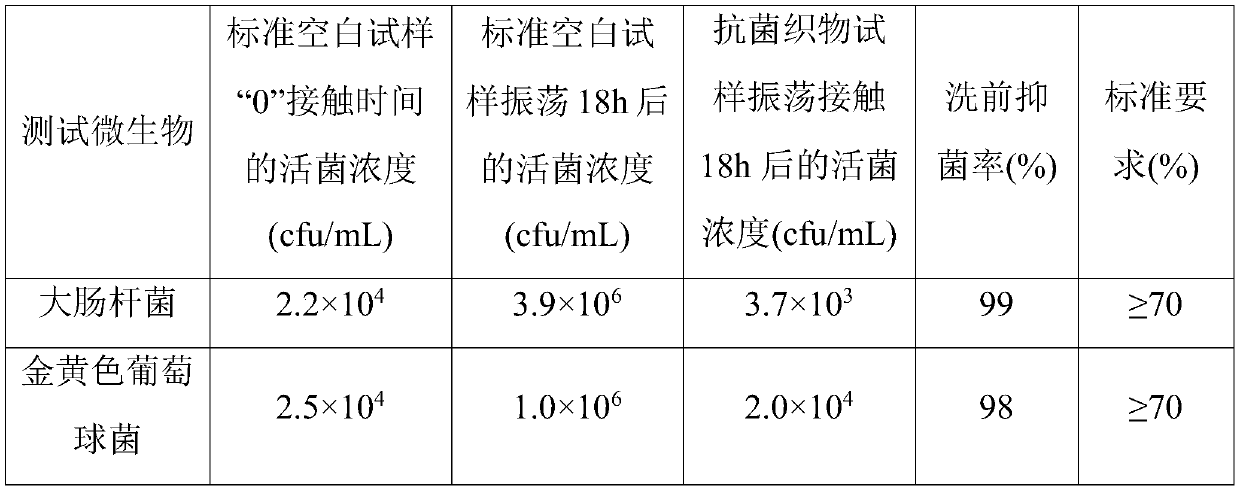

[0070] The antibacterial and antiviral effects of the multifunctional filter materials prepared in Examples 2-8 and Comparative Examples 1-4 were tested, and the results are shown in Table 5.

[0071] The bacteriostasis rate and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com