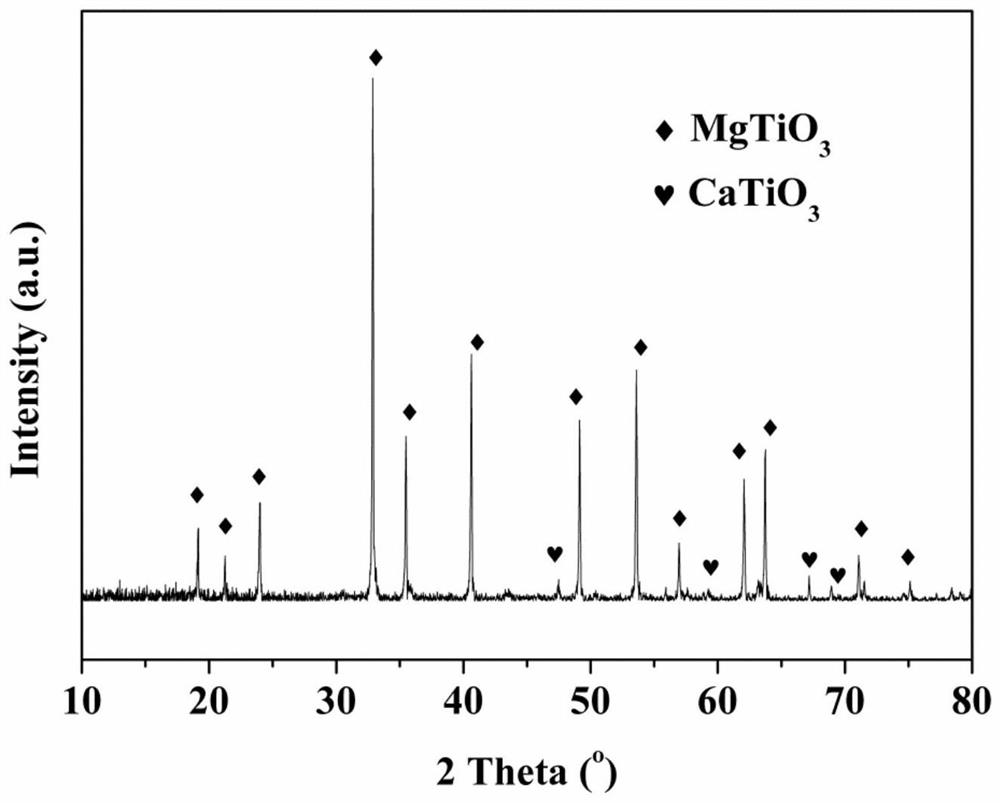

a mgtio 3 Microwave-based dielectric ceramics and preparation method thereof

A microwave dielectric ceramic, 2sm1 technology, applied in the direction of ceramics, inorganic insulators, etc., can solve the problems of lower sintering temperature, high sintering temperature, poor temperature stability, etc., improve the temperature coefficient of resonance frequency, simple preparation process, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

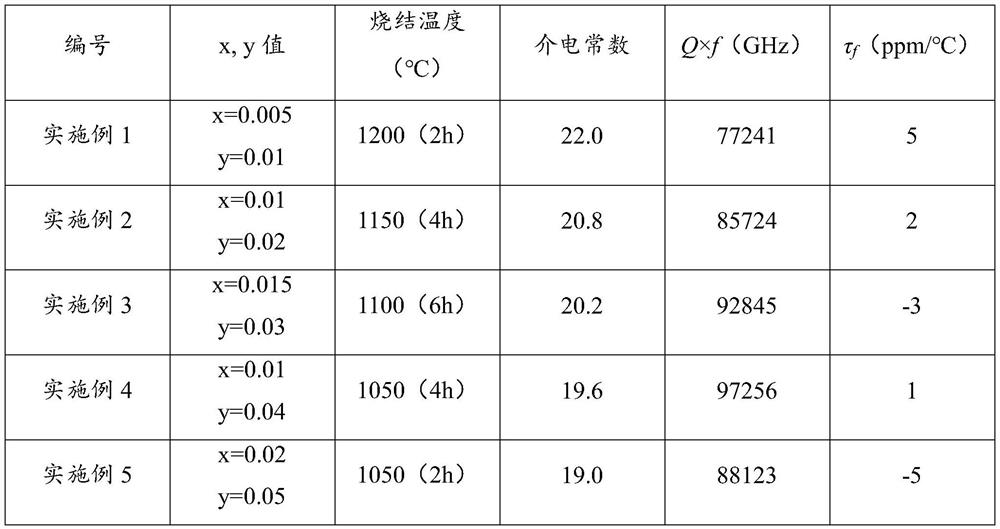

Embodiment 1

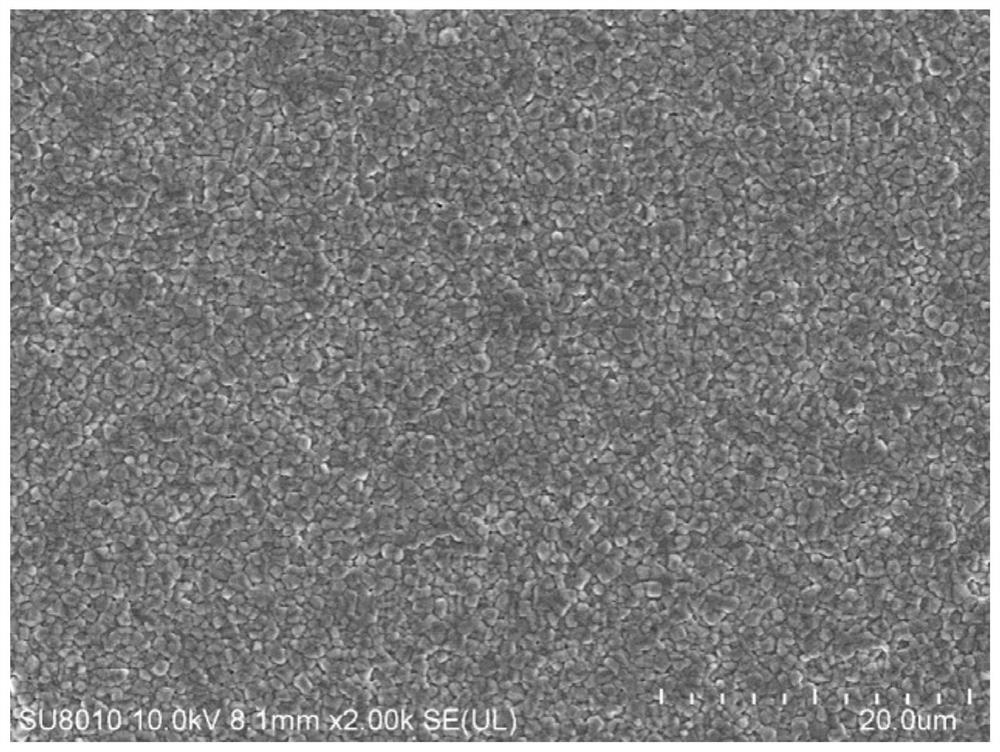

[0024] Will analyze pure raw materials MgO, TiO 2 , GeO 2 According to Mg(Ti 0.995 Ge 0.005 )O 3 The stoichiometric ratio was weighed and the ingredients were weighed, then the above powder was put into a ball mill jar, after adding deionized water and zirconia grinding balls, the ball mill jar was sealed, and wet ball milled on a roller mill for 12 hours. The ball-milled raw materials were dried in a drying oven at 100°C, and passed through an 80-mesh sieve after drying. The sieved ceramic powder was put into a crucible and calcined at 900° C. for 3 hours. According to the chemical formula 0.95Mg(Ti 0.995 Ge 0.005 )O 3 -0.05Ca 0.99 (K 1 / 2 SM 1 / 2 ) 0.01 TiO 3 will analyze pure raw CaCO 3 、TiO 2 、K 2 CO 3 、Sm 2 o 3Mix with the calcined powder, add deionized water and zirconium dioxide grinding balls, material: water: ball = 1:2:4, and ball mill on a vertical planetary ball mill for 4 hours. The ball-milled raw materials were placed in a drying oven and drie...

Embodiment 2

[0026] Will analyze pure raw materials MgO, TiO 2 , GeO 2 According to Mg(Ti 0.99 Ge 0.01 )O 3 The stoichiometric ratio weighs the ingredients, then puts the above powder into a ball mill jar, adds deionized water and zirconium dioxide grinding balls, seals the ball mill jar, and wet ball mills on a roller mill for 16 hours. The ball-milled raw materials were dried in a drying oven at 110°C, and passed through a 100-mesh sieve after drying. The sieved ceramic powder was put into a crucible and calcined at 950° C. for 4 hours. According to the chemical formula 0.95Mg(Ti 0.99 Ge 0.01 )O 3 -0.05Ca 0.98 (K 1 / 2 SM 1 / 2 ) 0.02 TiO 3 Raw material CaCO 3 、TiO 2 、K 2 CO 3 、Sm 2 o 3 Mix the ingredients with the calcined powder, add deionized water and zirconium dioxide grinding balls, material: water: ball = 1.5:2:5, and ball mill on a vertical planetary ball mill for 6 hours. The ball-milled raw materials were placed in a drying oven and dried at 110°C, and passed t...

Embodiment 3

[0028] Will analyze pure raw materials MgO, TiO 2 , GeO 2 According to Mg(Ti 0.985 Ge 0.015 )O 3 Weigh the ingredients according to the stoichiometric ratio, then put the above powder into the ball mill jar, add deionized water and zirconium dioxide grinding balls, seal the ball mill jar, and wet ball mill on the roller mill for 24 hours. The ball-milled raw materials were dried in a drying oven at 120°C, and passed through a 150-mesh sieve after drying. The sieved ceramic powder is put into a crucible and calcined at 1000°C for 3-5 hours. According to the chemical formula 0.95Mg(Ti 0.985 Ge 0.015 )O 3 -0.05Ca 0.97 (K 1 / 2 SM 1 / 2 ) 0.03 TiO 3 Raw material CaCO 3 、TiO 2 、K 2 CO 3 、Sm 2 o 3 Mix with the calcined powder, add deionized water and zirconium dioxide grinding balls, material: water: ball = 1:2:6, and ball mill on a vertical planetary ball mill for 8 hours. The ball-milled raw materials were placed in a drying oven and dried at 120°C, and passed throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com