Low-temperature sintering microwave medium ceramic material and preparation method thereof

A low-temperature sintering technology for microwave dielectric ceramics, applied in the field of functional ceramics, can solve the problems of small Qf value and large dielectric loss, and achieve the effect of no pollution in the process, simple process, and excellent microwave dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

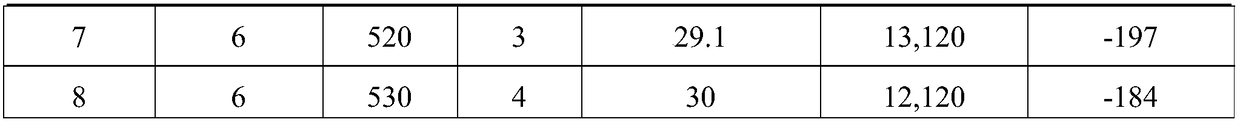

Embodiment 1-8

[0035] Using chemical raw material Bi with a purity greater than 99.9% 2 o 3 、WO 3 , TeO 2 Preparation of BiW 0.5 Te 3 o 12 Microwave dielectric ceramics, the specific implementation is as follows:

[0036] (1) will Bi 2 o 3 、WO 3 , TeO 2 Weigh the ingredients according to the molar ratio of 1:0.5:3, specifically weigh 3.9908 grams of Bi 2 o 3 , 1.9856 g WO 3 , 9.0236 g TeO 2 After mixing, the raw materials are added to the nylon tank, and ball milled for 4 to 6 hours. The specific ball milling time of Examples 1-8 is shown in Table 1; the ball milled raw materials are placed in an infrared drying oven to dry and sieve;

[0037] (2) Calcining the sieved raw materials at 400° C. for 3 hours;

[0038] (3) adding a mass percentage of 5% PVA aqueous solution to the calcined powder for granulation, sieving after drying, and pressing into a cylindrical shape of Φ12mm×6mm with a powder tablet press;

[0039] (4) sintering the cylinder of step (3) at 480-530° C., and ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com