Low-temperature co-fired microwave dielectric ceramic material and preparation method thereof

A technology of microwave dielectric ceramics and low-temperature co-firing, which is applied in the field of electronic ceramic materials, can solve the problems of high energy consumption, high equipment requirements, and high sintering temperature, and achieve the effect of adjustable temperature coefficient of resonance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

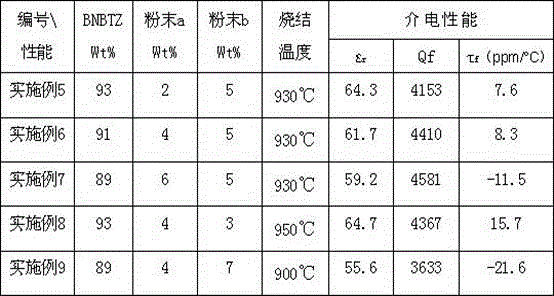

[0017] According to the general chemical formula Ba 4 (Nd 1.0-X Bi x ) 9.33 (Ti 0.9 Zr 0.1 ) 18 o 54 Weigh BaCO 3 、Nd 2 o 3 、 Bi 2 o 3 , ZrO 2 、TiO 2 Raw materials, where x is taken according to the value in Table 1, using absolute ethanol as the medium, planetary ball milling for 3 hours, drying after taking out, and pre-burning in the atmosphere at 1100°C for 2 hours to make the BNBTZ base material; the raw materials BaO, CuO and B 2 o 3 The molar ratio is 1:1:1, with absolute ethanol as the medium, the planetary ball is milled for 3 hours, taken out, dried, and pre-fired in the atmosphere at 700°C for 3 hours to make a powder b pre-fired block for later use; in BNBTZ Add powder b accounting for 5wt% of the total mass percentage to the base material, use absolute ethanol as the medium, planetary ball mill for 12 hours, take it out and dry it, add PVA solution to granulate, press and shape, and then sinter at a temperature of 930°C for 4 Hours, using a network...

Embodiment 5~9

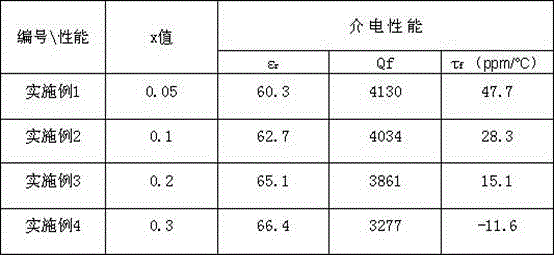

[0021] According to the general chemical formula Ba 4 (Nd 0.8 Bi 0.2 ) 9.33 (Ti 0.9 Zr 0.1 ) 18 o 54 Weigh BaCO 3 、Nd 2 o 3 、 Bi 2 o 3 , ZrO 2 、TiO 2 Raw materials, using absolute ethanol as the medium, planetary ball milling for 3 hours, drying after taking out, and pre-burning in the atmosphere at 1100°C for 2 hours to make BNBTZ base material; the raw material Nd 2 o 3 with Al 2 o 3 According to the molar ratio of 1:1 ingredients, with anhydrous ethanol as the medium, the planetary ball mill for 3 hours, take it out and dry it, and pre-fire it in the atmosphere at 1200 ° C for 3 hours to make a powder a pre-fired block for later use; the raw materials BaO, CuO with B 2 o 3 The molar ratio is 1:1:1, with absolute ethanol as the medium, the planetary ball is milled for 3 hours, taken out, dried, and pre-fired in the atmosphere at 700°C for 3 hours to make a powder b pre-fired block for later use; in BNBTZ Add powder a and powder b in different percentages o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com