Neutron shielding fireproof silicone adhesive and preparation method thereof

A silicone glue, neutron technology, applied in shielding, reactor, nuclear engineering and other directions, can solve the problem of undisclosed shielding neutron radiation performance, etc., to achieve the effect of protecting penetrations, improving mechanical properties, and inhibiting volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

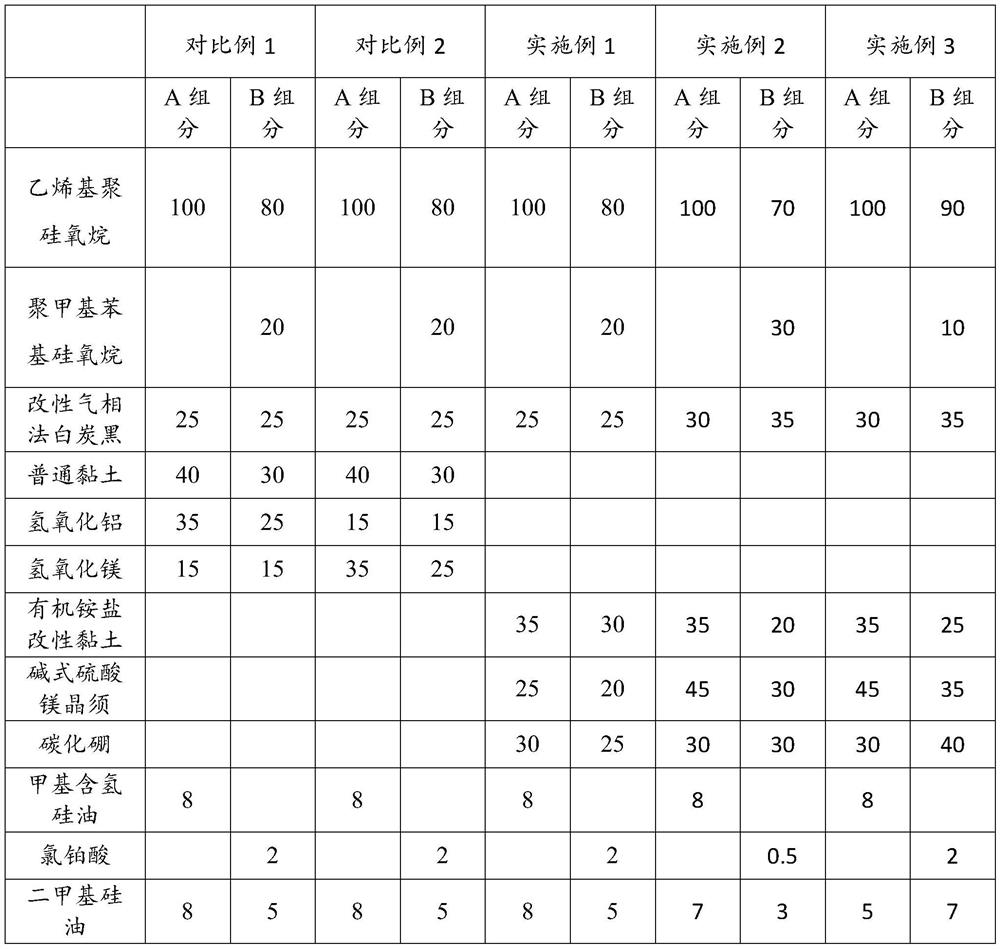

Embodiment 1

[0030] This embodiment provides a neutron shielding fireproof silicone glue, which is composed of component A and component B with a mass ratio of 1:0.8;

[0031] Component A contains 100 parts of vinyl polysiloxane, 10 parts of methyl hydrogen silicone oil, 40 parts of basic magnesium sulfate whiskers, 25 parts of ammonium salt modified clay, 30 parts of boron carbide, and 30 parts of modified gas phase 8 parts of white carbon black and plasticizer.

[0032] Component B contains 80 parts of vinyl polysiloxane, 20 parts of polymethylphenylsiloxane, 0.5 parts of chloroplatinic acid, 25 parts of basic magnesium sulfate whiskers, 15 parts of organic ammonium salt modified clay, 30 parts Boron carbide, 20 parts of modified fumed silica, 3 parts of dimethyl silicone oil.

[0033] Concrete preparation steps are:

[0034] 1. Add vinyl polysiloxane, fumed silica, basic magnesium sulfate whiskers, organic ammonium salt modified clay, methyl hydrogen-containing silicone oil, boron car...

Embodiment 2

[0038] This embodiment provides a neutron shielding fireproof silicone glue, which is composed of component A and component B with a mass ratio of 1:0.8;

[0039] Component A contains 100 parts of vinyl polysiloxane, 8 parts of methyl hydrogen silicone oil, 45 parts of basic magnesium sulfate whiskers, 35 parts of ammonium salt modified clay, 30 parts of boron carbide, and 30 parts of modified fumed white Carbon black, 7 parts of simethicone.

[0040] Component B contains 70 parts of vinyl polysiloxane, 30 parts of polymethylphenylsiloxane, 0.5 parts of chloroplatinic acid, 30 parts of basic magnesium sulfate whiskers, 20 parts of organic ammonium salt modified clay, 30 parts Boron carbide, 35 parts of modified fumed silica, 3 parts of dimethyl silicone oil.

[0041] Concrete preparation steps are:

[0042]1. Add vinyl polysiloxane, modified fumed silica, basic magnesium sulfate whiskers, organic ammonium salt modified clay, methyl hydrogen silicone oil, boron carbide, and d...

Embodiment 3

[0046] This embodiment provides a neutron shielding fireproof silicone glue, which is composed of component A and component B with a mass ratio of 1:0.8;

[0047] Component A contains 100 parts of vinyl polysiloxane, 8 parts of methyl hydrogen silicone oil, 45 parts of basic magnesium sulfate whiskers, 35 parts of ammonium salt modified clay, 30 parts of boron carbide, and 30 parts of modified fumed white Carbon black, 5 parts of simethicone.

[0048] Component B contains 90 parts of vinyl polysiloxane, 2 parts of chloroplatinic acid, 10 parts of polymethylphenylsiloxane, 35 parts of basic magnesium sulfate whiskers, 25 parts of organic ammonium salt modified clay, 40 parts Boron carbide, 35 parts of modified fumed silica, 7 parts of dimethyl silicone oil.

[0049] Concrete preparation steps are:

[0050] 1. Add vinyl polysiloxane, fumed silica, basic magnesium sulfate whiskers, organic ammonium salt modified clay, methyl hydrogen-containing silicone oil, boron carbide, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com