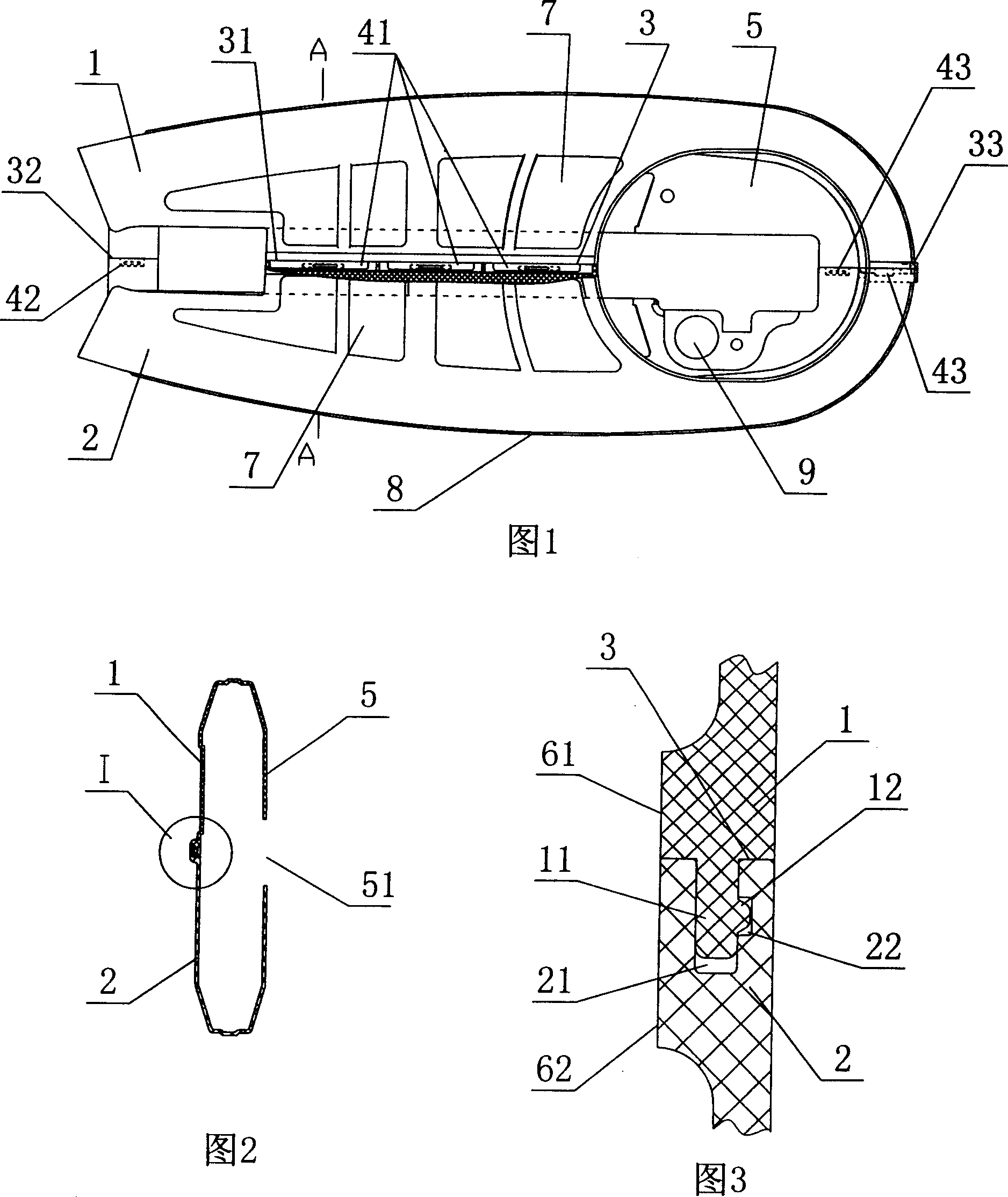

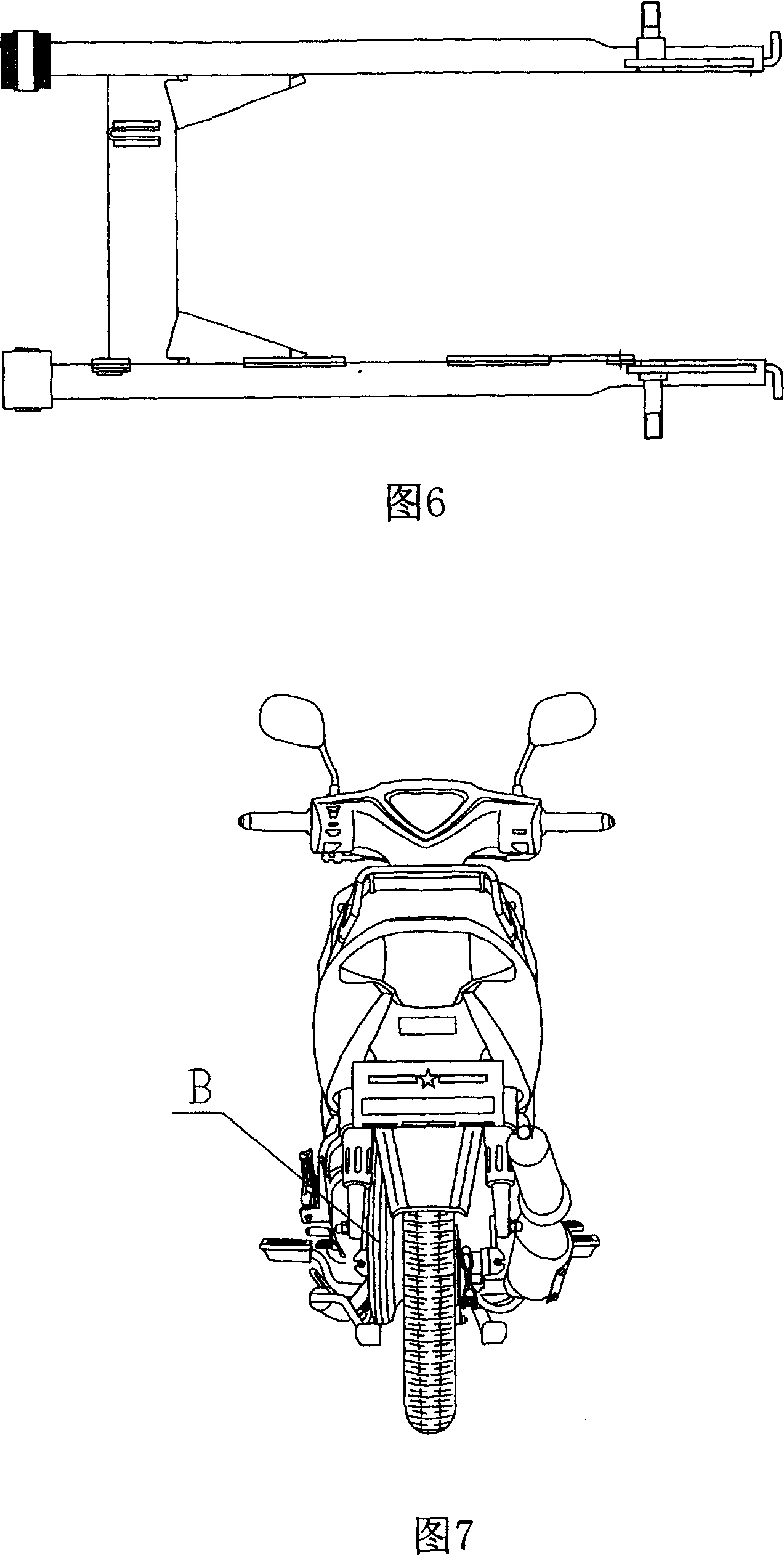

[0002] Generally, the chain box of a motorcycle is stamped with sheet metal and installed on the lower side of the motorcycle body to cover the engine output

sprocket, the rear wheel sprocket and the chain in between. The rear wheel is supported on the flat fork and is swinging. , when the motorcycle is running, the friction between the chain and the metal chain box is easy to make abnormal noises, and the metal chain box is composed of multiple parts, which requires surface treatment, high manufacturing costs, large dimensional tolerances of each part, and difficult to assemble

Using a plastic chain box can achieve the purpose of eliminating the above-mentioned abnormal friction between the chain and the chain box. No surface treatment is required, the manufacturing cost is low, the plastic is easy to deform, and the

assembly is relatively easy. For example, two Chinese patents disclose the above-mentioned plastic chain box. Be 1988.04.06 open, announcement number CN87209331U, be called by name: bicycle plastic chain cover, the 2nd,

Chinese patent 1990.11.14 is disclosed, application number 89211443.6, be called by name: plastic full chain cover; above-mentioned two patents divide chain box into The upper and lower chain boxes are connected by inserts and splints to form a complete whole. Although it can solve the abnormal friction

noise between the chain and the chain box, there are still many parts in the product. The upper and lower chain boxes The installation or

assembly of the synthetic whole is complicated and the manufacturing cost is high, which affects its popularization and use

[0003]

Chinese patent also discloses another kind of chain box, which can be made of plastics. It was disclosed on 1995.05.17, application number 94227366.4, announcement number CN2197287Y, named: full chain cover for variable speed bicycle; the above-mentioned patent divides the chain box into cover body, The chain plate cover and cover

tail, etc., are mainly to divide the chain box into two pieces on the left and right sides. The edges of the two pieces are bent or bent out of the flanges, and the flanges are fastened to connect, and then the chain plate and screws are used to connect the chain plate and the cover. The cover

tail, etc., become a complete whole. Although the above-mentioned chain box can solve the abnormal friction

noise between the chain and the chain box if it is made of plastic, there are still many parts. Deformation, complex installation or

assembly, high manufacturing cost

[0004]

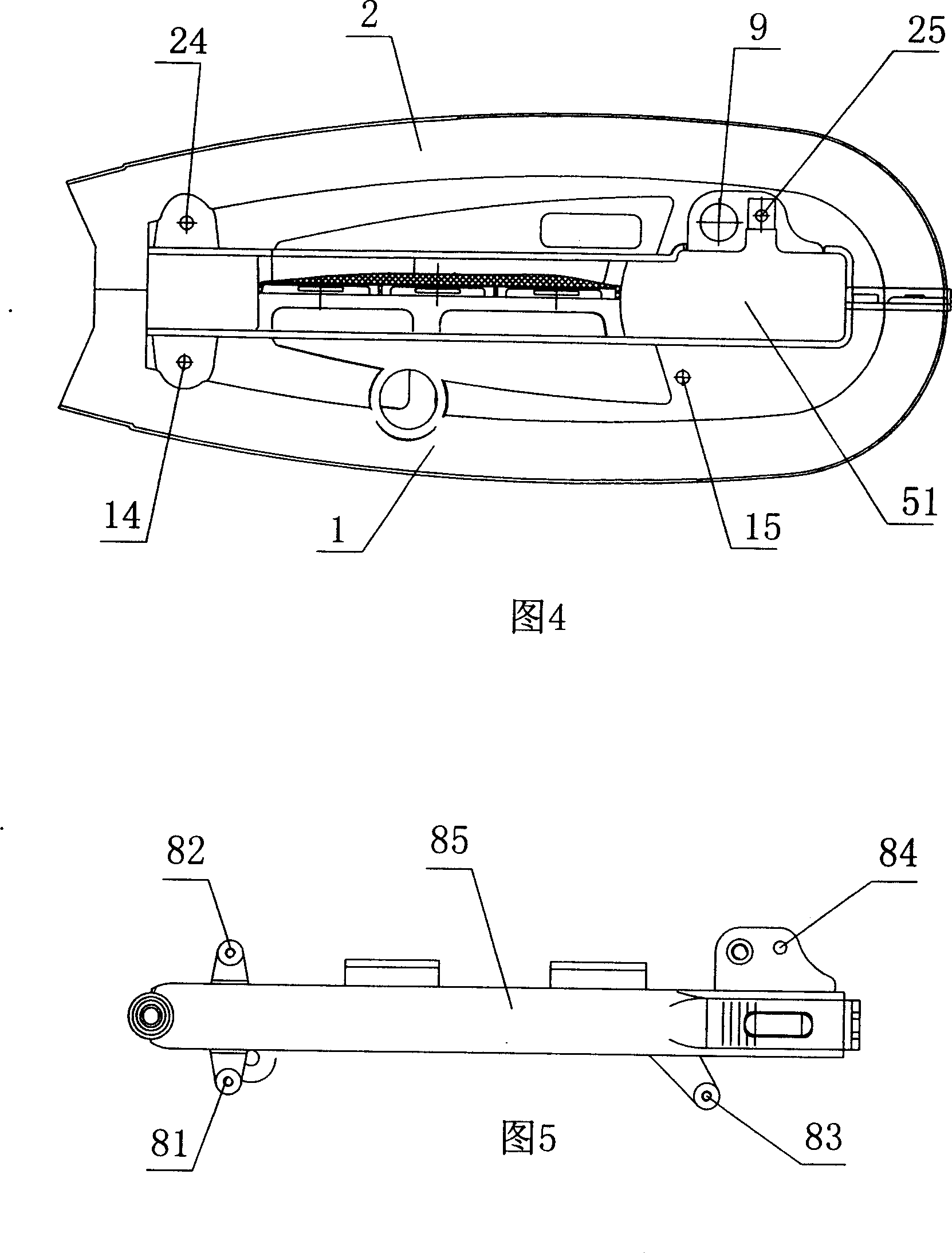

Chinese patent 1997.11.12 also discloses another kind of plastic chain box that solves the above-mentioned problem, announcement number CN1164492A, application number 97103386.2, is called by name: the chain box of motor two-wheeled vehicle; The patent divides the chain box into upper and lower chain boxes, The middle part of the upper and lower chain boxes is provided with a bifurcated part, a

coupling hole and a

coupling claw, and an insert plate is arranged on the flat fork (referred to as a rear swing arm in the

patent literature), and the above-mentioned bifurcated part, the

coupling hole and the coupling are used between the upper and lower chain boxes. The claws are connected during assembly by the insert plate of the flat fork, and the assembly becomes a complete whole. Although it can also solve the abnormal friction noise of the chain and the chain box and reduce the number of parts, the upper and lower chain boxes can never be synthesized separately. It can be used as a whole or as a part, and the structure of the flat fork needs to be changed if the technical solution of this patent is used, otherwise the upper and lower chain boxes will be difficult to close and there will be problems such as excessive deformation. The manufacturing cost of the frame is also difficult to popularize and use

However, for motorcycle chain boxes, the dimensions in the length and width directions are relatively large, and the transverse dimensions are relatively small, and a considerable part of the housing is open, so the housing itself is quite easy to deform even if it is a whole. The strength and rigidity will naturally be greatly reduced, and it is very difficult to maintain the expected shape, which will affect the appearance, and seriously even affect the performance; at the same time, the motorcycle chain box also has certain disassembly requirements for easy maintenance; the choice of connection parts and connection methods It directly affects the complexity and life of the plastic chain box membrane, directly affects the simplicity and complexity of the manufacturing process, and ultimately affects the cost. Therefore, the choice of connection method has become a long-term problem in the structural design and manufacture of motorcycle plastic chain boxes.

Login to View More

Login to View More  Login to View More

Login to View More