Quick insertion clamping frame of concrete blinding and method for clamping concrete blinding

A technology of concrete formwork and clamping frame, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc. It can solve the problems of bending deformation, difficulty in cleaning, and dimensional errors, etc., and achieves convenient assembly. Easy handling and high deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

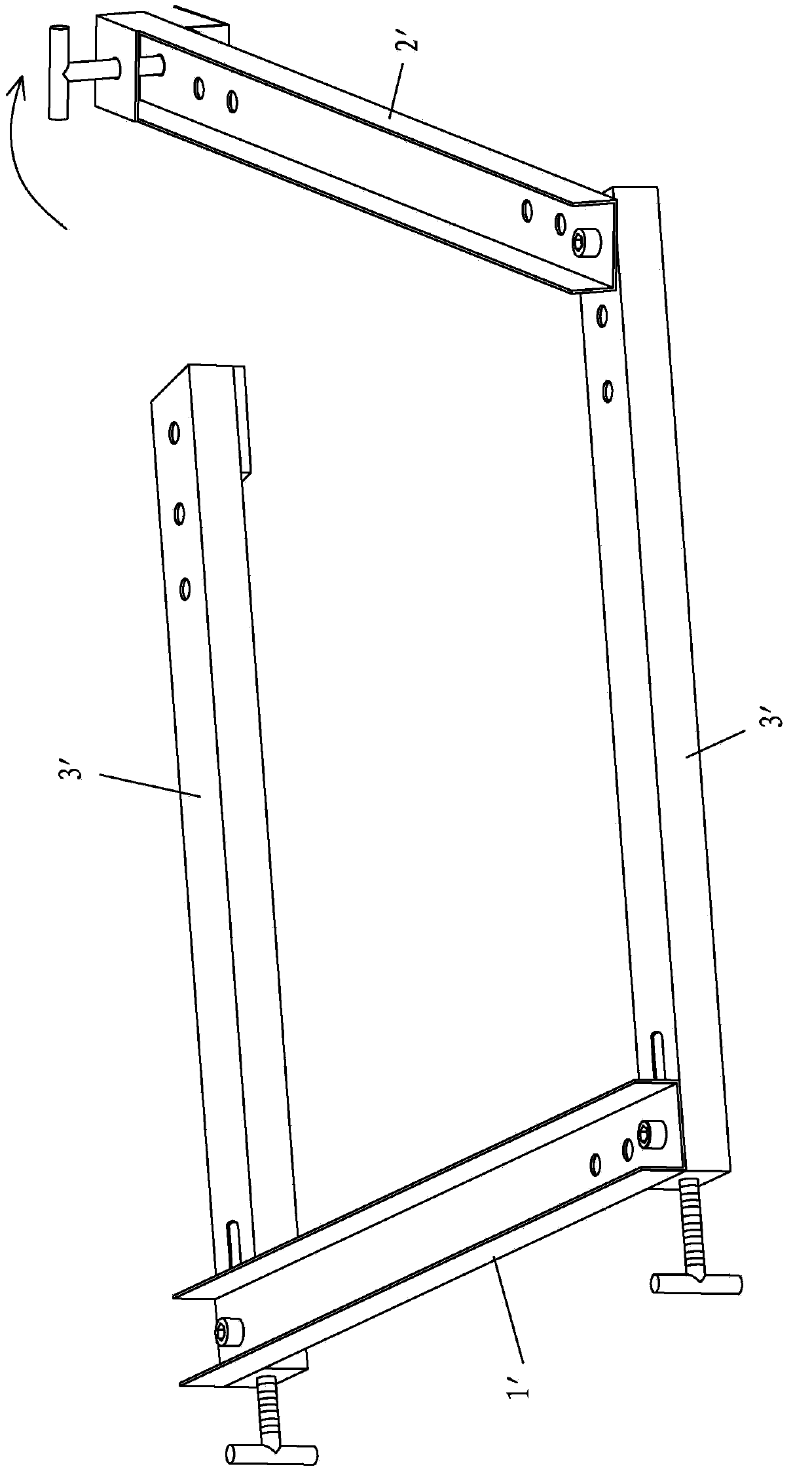

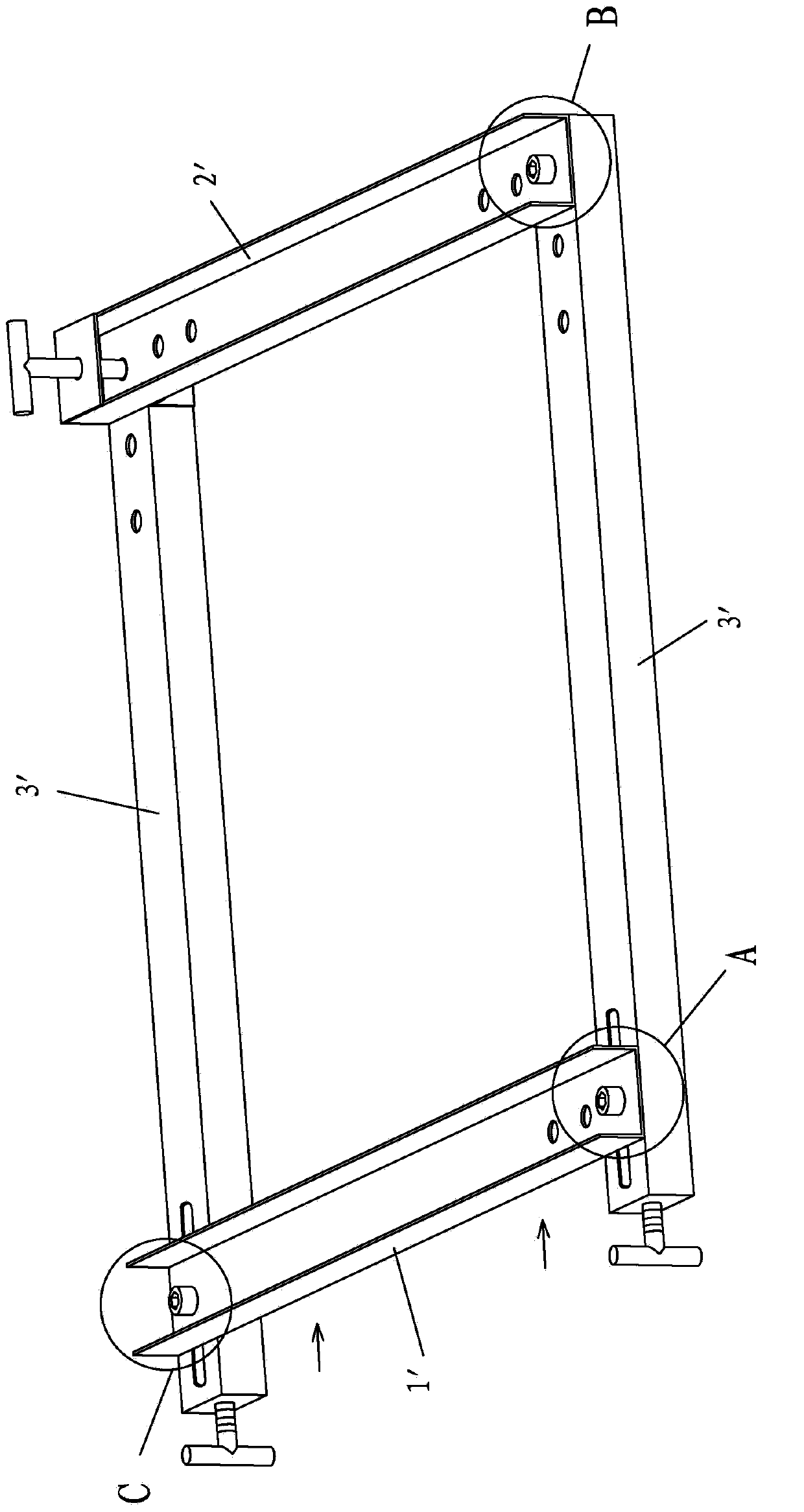

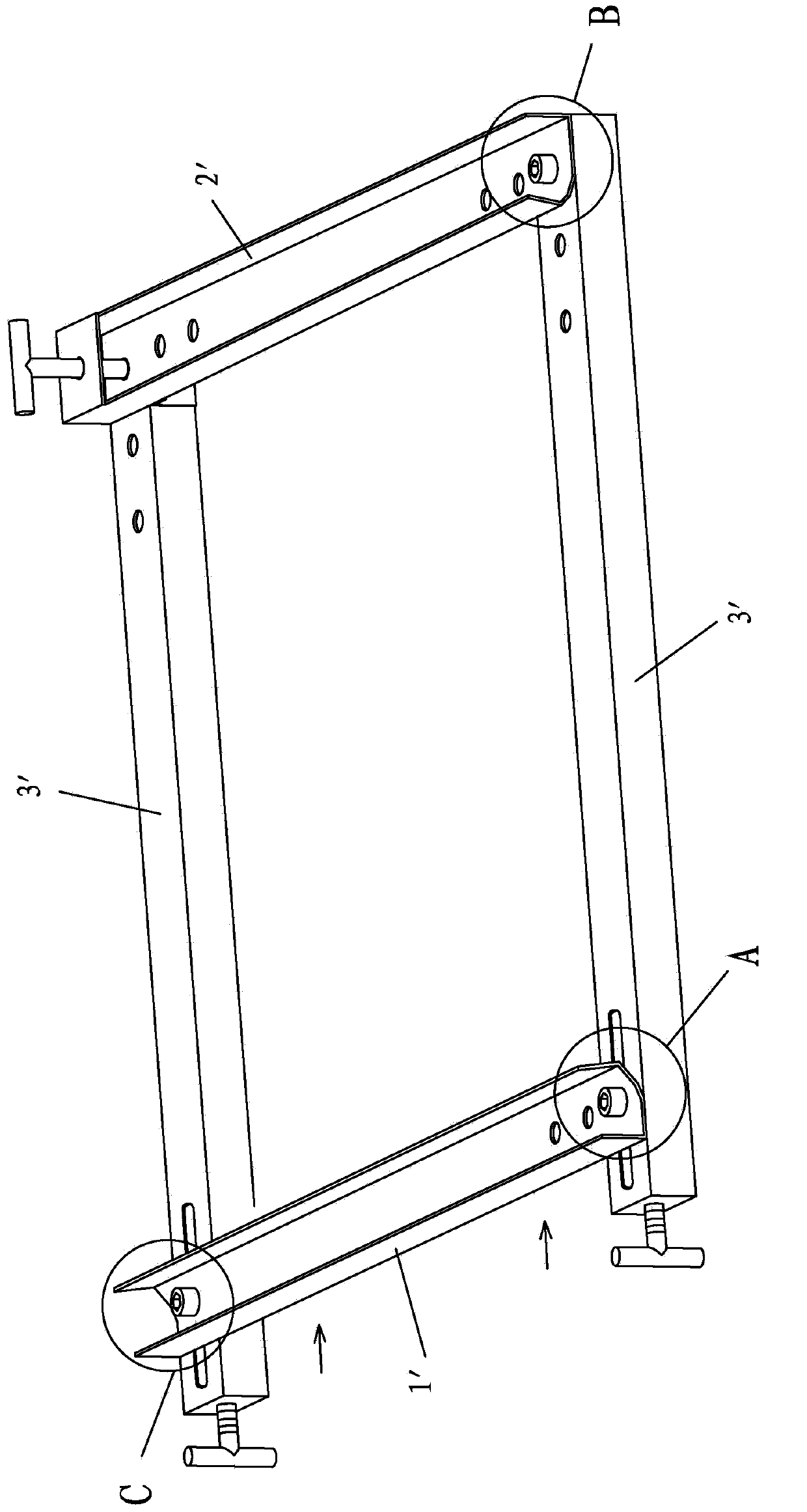

[0045] Such as Figures 4 to 7 As shown, a quick plug-in concrete form clamping frame of the present invention includes a first square pipe 1 , a second square pipe 2 , a third party pipe 3 and a fourth square pipe 4 .

[0046] Both ends of the first square pipe 1 and the third party pipe 3 are respectively provided with jacks 11, 31 for plugging, through which the first square pipe 1, the second square pipe 2, the third party pipe 3 and the fourth square pipe 4 pass. The sockets 11 and 31 are plugged together in turn to form a square frame.

[0047]The jacks 11, 31 at one end of the first square pipe 1 and the third party pipe 3 are respectively multiple, and the multiple jacks 11, 31 are arranged along the length direction of the square pipe respectively, so that they can be quickly plugged into clips of var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com