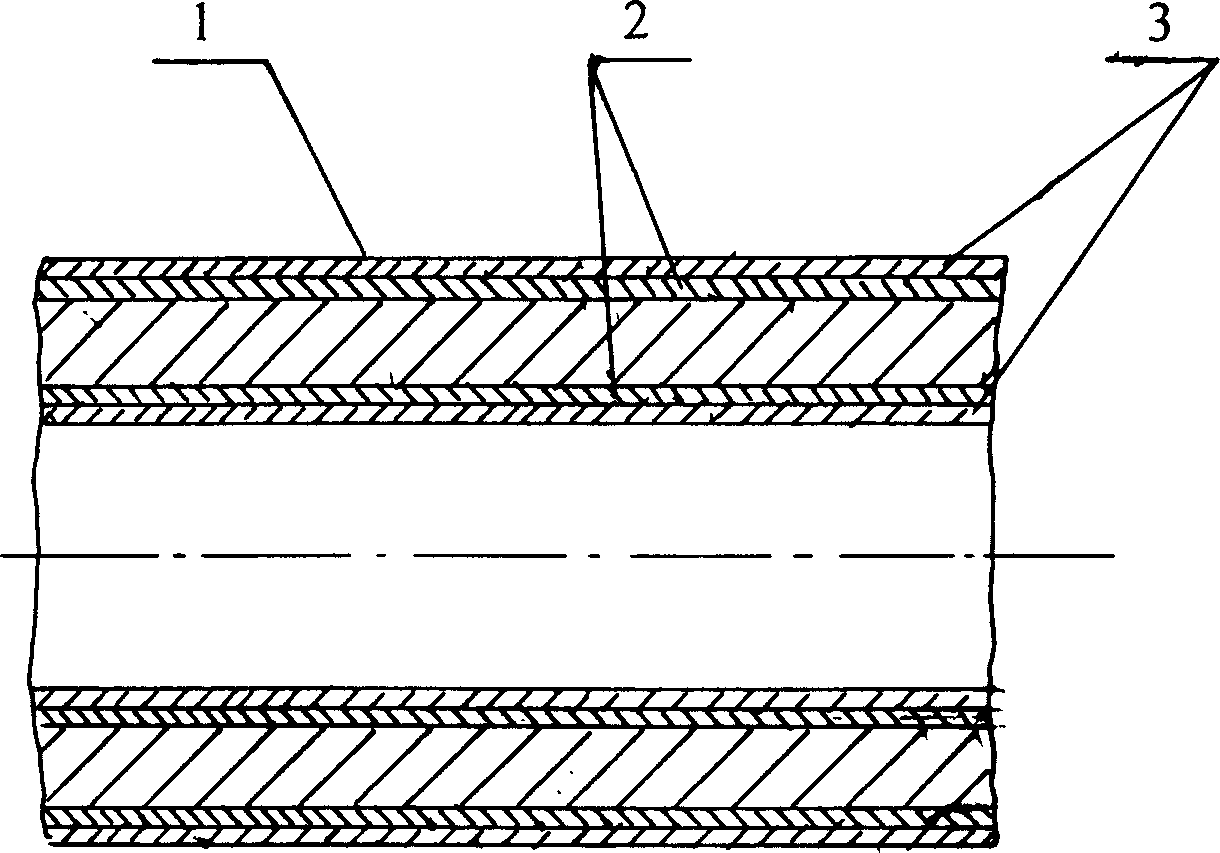

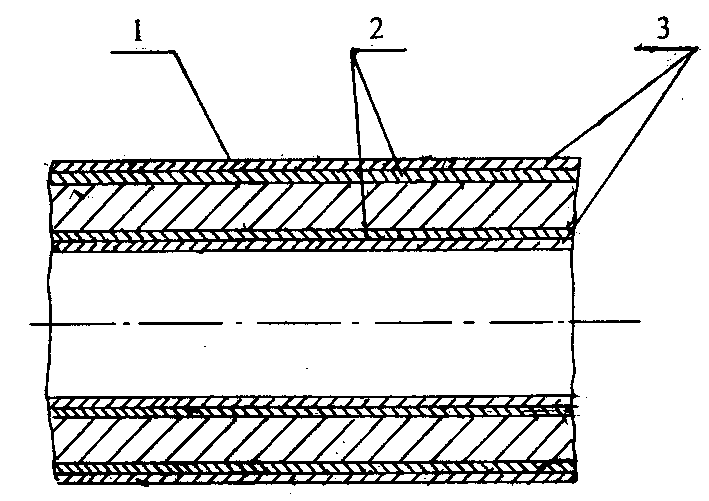

Anti-pitting abrasion-resistant oil pipe and manufacture thereof

A technology for oil pipe and pitting corrosion, which is used in mechanical equipment, pipeline protection, pipeline damage/wear prevention, etc. Deformation resistance, effect of short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) J55 oil pipe, sand blasting reaches Sa2.5 level;

[0017] 2) Carry out nitrocarburizing with a deep-well gas nitriding furnace, the infiltration agent is ammonia and ethanol, the temperature is 560℃, and the holding time is 5hr, to obtain 15μm carbon-containing iron nitrogen compound;

[0018] 3) Soak the tubing in 20% hydrochloric acid solution for 5 minutes after it comes out of the furnace, and then clean it with distilled water;

[0019] 4) Put it into an electroless nickel plating solution at a temperature of 90℃, the composition of the plating solution is: nickel sulfate 20g / L, sodium hypophosphite: 25g / L, sodium citrate: 25g / L, sodium acetate: 13g / L, Pb 2+ : 1mg / L, sodium lauryl sulfate: 20mg / L, pH value: 5.5, take it out for cleaning after 1hr reaction, the thickness of the coating is 10μm, the nickel content is 93%wt, the phosphorus content is 7%wt;

[0020] Result: The surface hardness is Hv480, the porosity of the coating is 0 measured by the red blood salt-so...

Embodiment 2

[0022] 1) N80 oil pipe, degreasing agent for 30 minutes at room temperature and then rinsed, immersed in 20% hydrochloric acid solution for 15 minutes;

[0023] 2) Carry out nitriding with a deep-well gas nitriding furnace, the infiltration agent is ammonia gas, the temperature is 620℃, and the temperature is kept for 1hr to obtain a 5μm iron nitrogen compound layer;

[0024] 3) After the tubing comes out of the furnace, it is immersed in 20% hydrochloric acid solution for 1 min, and then washed with distilled water;

[0025] 4) Put it into an electroless nickel plating solution at 85℃, the composition of the plating solution is: nickel sulfate 30g / L, sodium hypophosphite: 35g / L, sodium citrate 25g / L, sodium acetate 21g / L, thiourea 2mg / L, sodium dodecyl sulfonate 200mg / L, pH value: 4.5, take it out for cleaning after 2hr reaction, the thickness of the coating is 20μm, the nickel content is 89%wt, the phosphorus content is 11%wt;

[0026] Results: The surface hardness is Hv500, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com