Overturning-free coating jig frame of conventional steel structure building component

A technology for building components and steel structures, applied in the direction of spraying devices, etc., can solve the problems that the position of the tire frame cannot be completed at one time, the area of the bonding surface increases, and the aesthetics of the finish paint decreases, achieving low cost and increased contact area. , easy replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

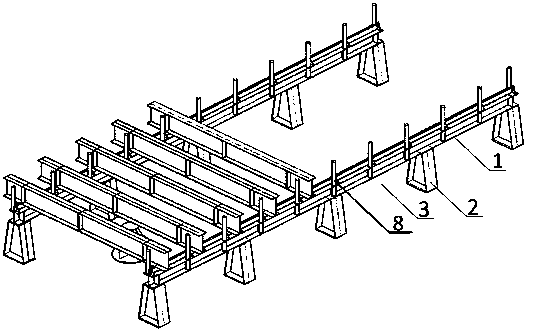

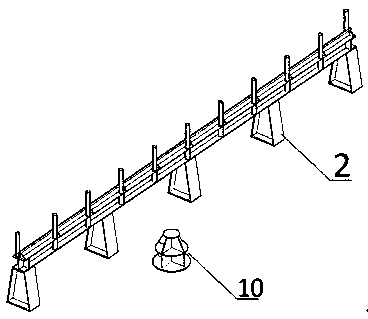

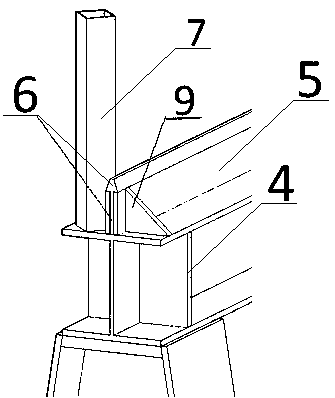

[0019] Conventional steel structure building components free from turning over and coating the frame, including the frame body 1 and the round stool 9, the frame leg 2 is provided on the lower surface of the longitudinal lower flange of the frame body 1, and the frame frame adjacent to the lower surface of the frame body 1 The underpass 3 is formed between the legs 2, the web area of the main body 1 of the tire frame is provided with square stiffened plates 4 at intervals, the upper surface of the upper flange of the main body of the tire frame 1 and the upper surface of the other side are provided with longitudinal steel plates 5, the The plate is not welded, and it can be replaced at any time when it is deformed or damaged during use. There is a coating protection pad 6 sandwiched between the longitudinal steel plates 5. The coating protection pad 6 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com