Injection moulding font advertisement lamp box device and its making method

A technology for advertising light boxes and fonts, which is applied to lighting devices, display devices, and damage prevention measures for lighting devices. It can solve the problems of easy damage, high cost, and low efficiency, and achieve stable and reliable use. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

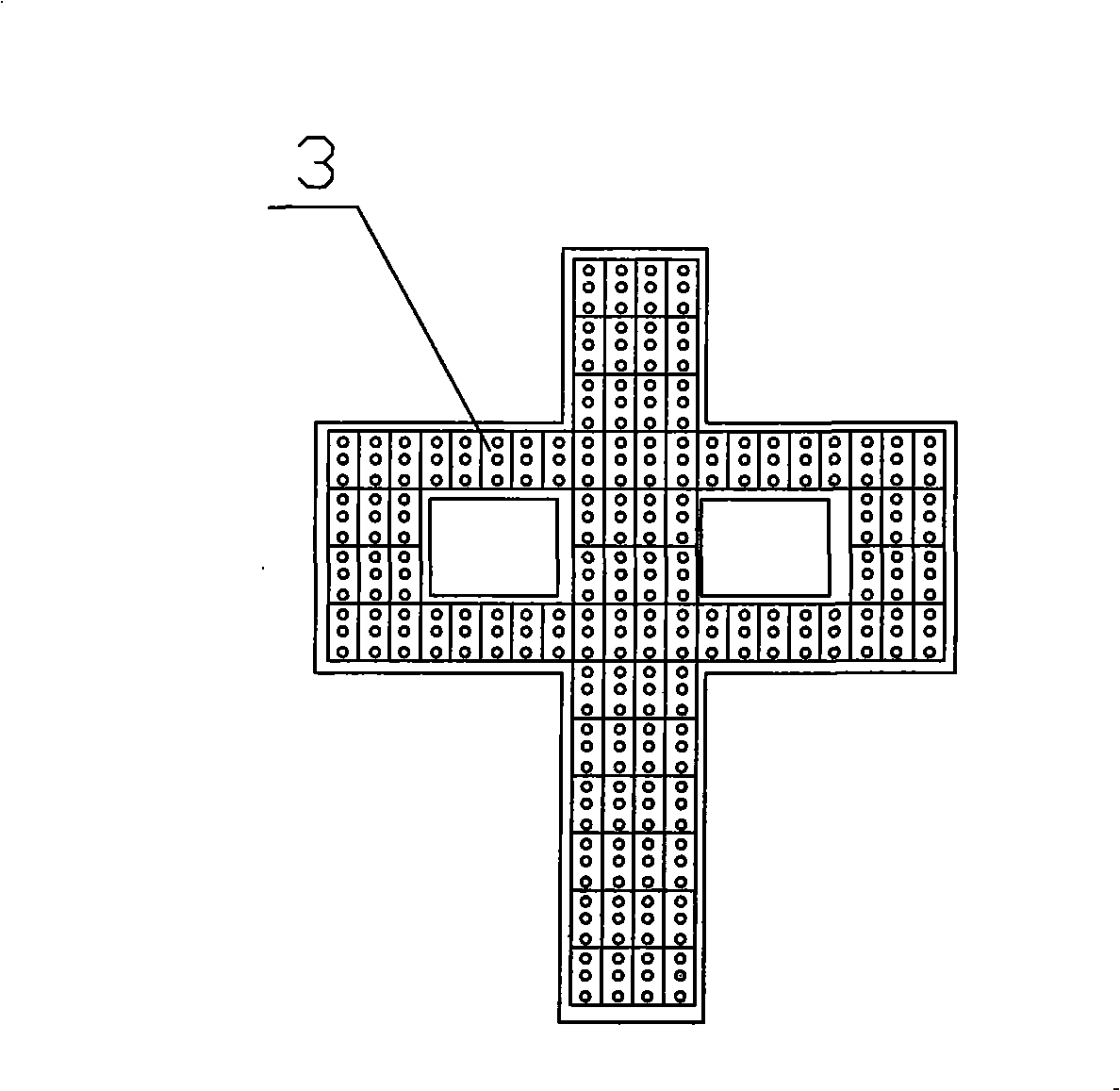

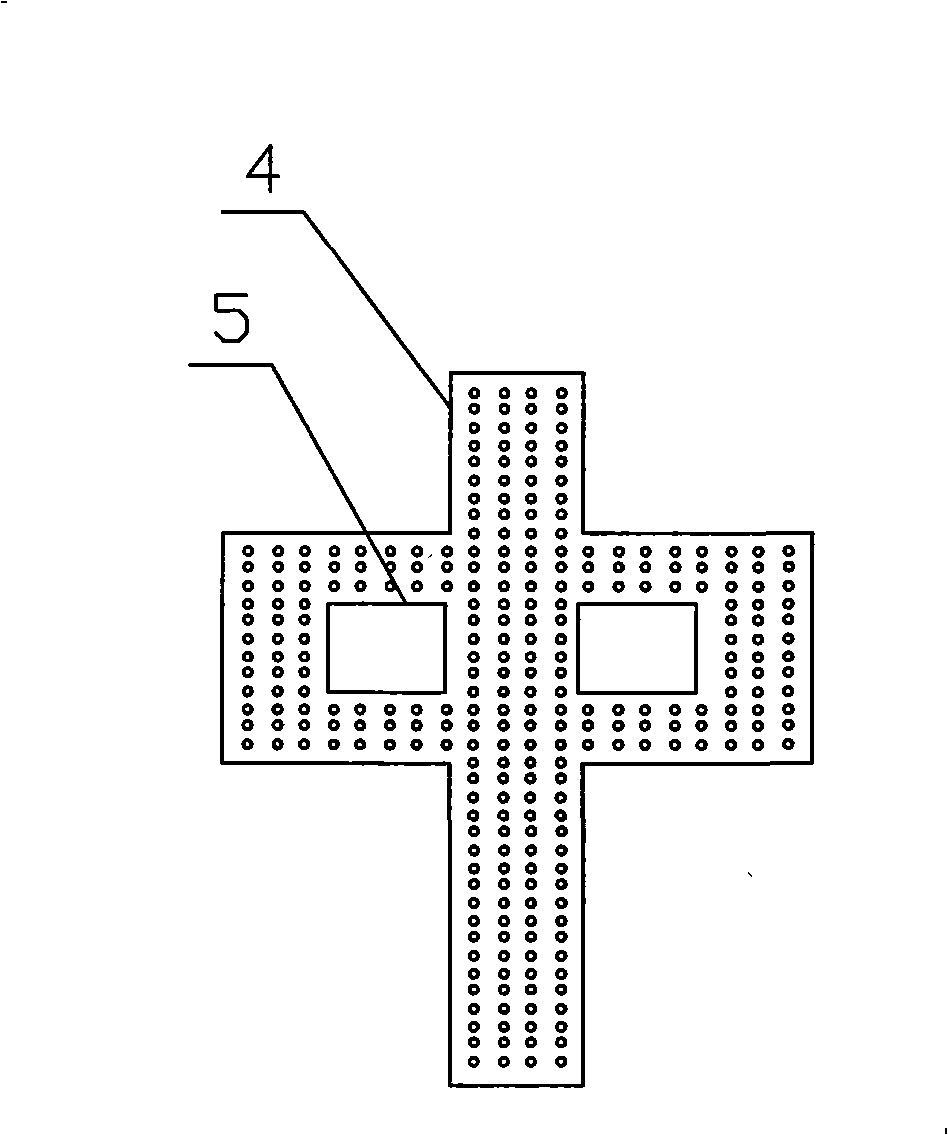

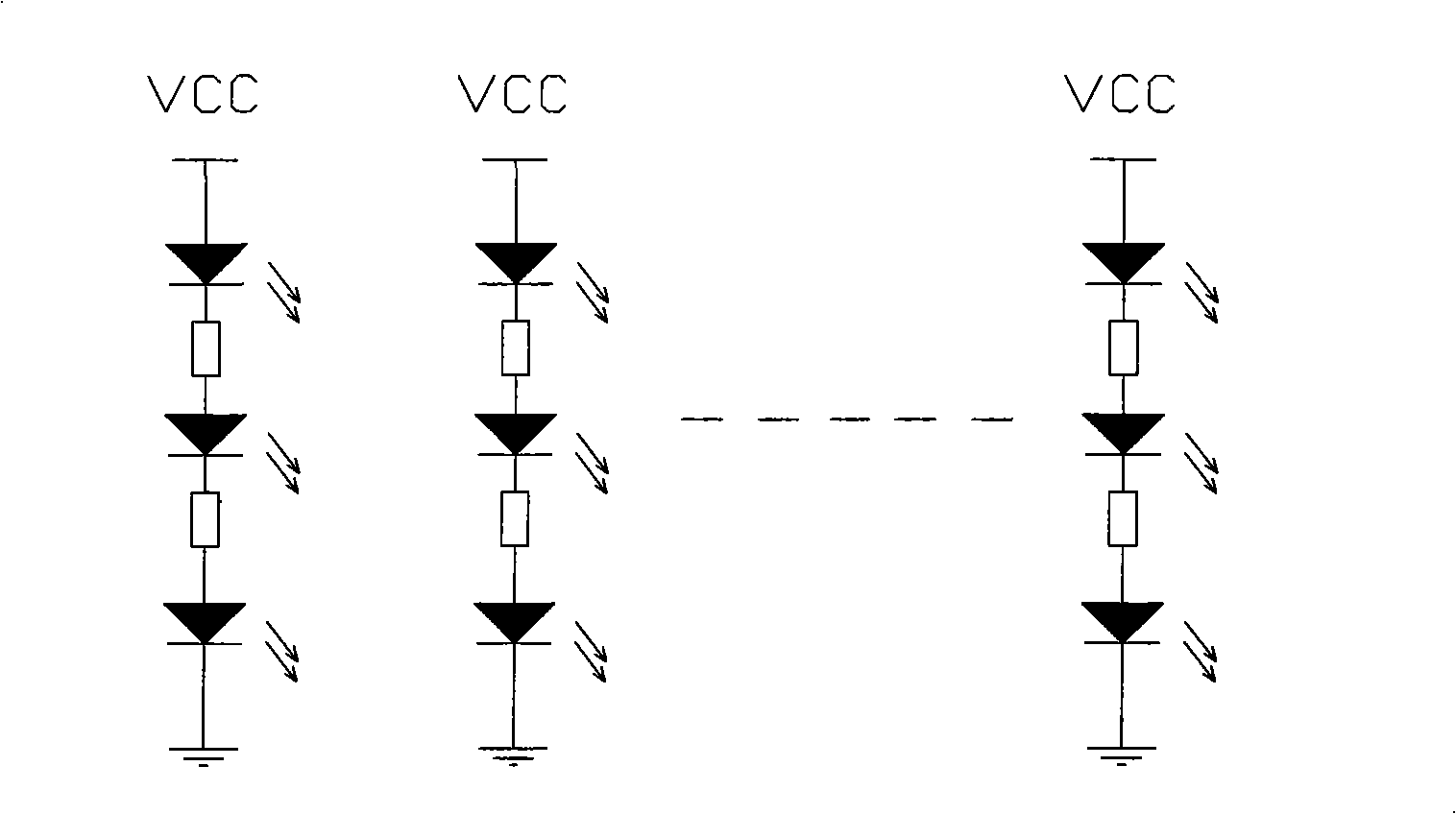

[0011] The injection molded font advertising light box device of the present invention includes a closed outer profile casting frame 4 for forming fonts and several built-in closed casting small frames 5, and LED lamp circuit boards 2 are arranged in the font cavity. The front of the cavity is covered with a light-transmitting plate 6, and the bottom is provided with a bottom plate 7. The LED lamp circuit board 2 is an integral LED lamp circuit board made according to the font shape. The circuit of the LED lamp circuit board is composed of multiple groups of LED lamp series connection units connected in parallel on the whole circuit board. The LED lamp series connection unit consists of three Two LED lamps connected in series and a resistor arranged between two adjacent LED lamps are used. The resistors are arranged between two adjacent LED lamps, which greatly reduces the probability of LED lamps being burned during the manufacturing process and improves production. Efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com