Battery pack case and battery pack

A battery pack and box body technology, applied to battery pack parts, circuits, electrical components, etc., can solve the problems of difficult handling, difficult installation, heavy battery pack weight, etc., and achieve the effects of convenient production, beautiful appearance and space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

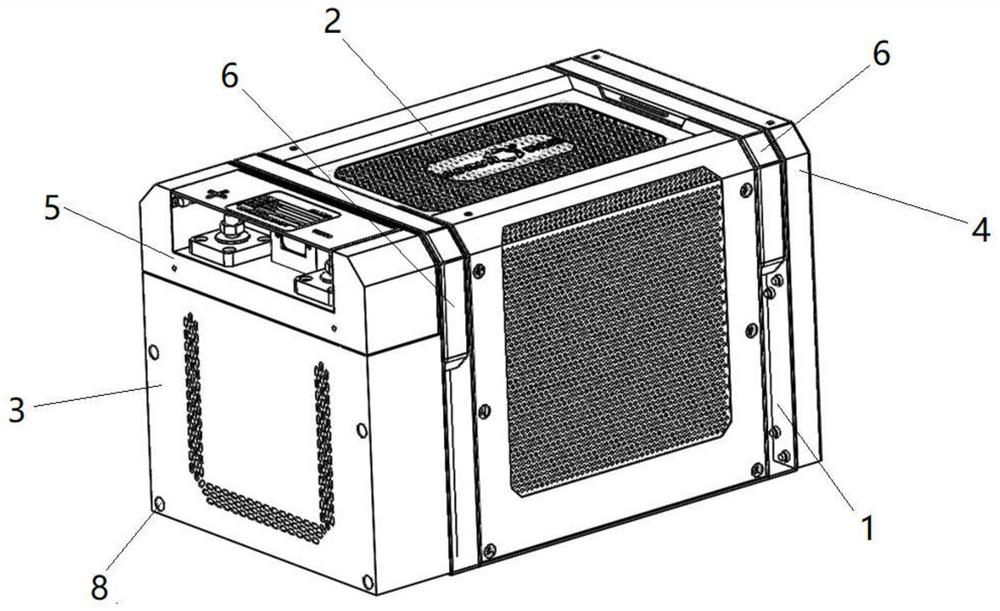

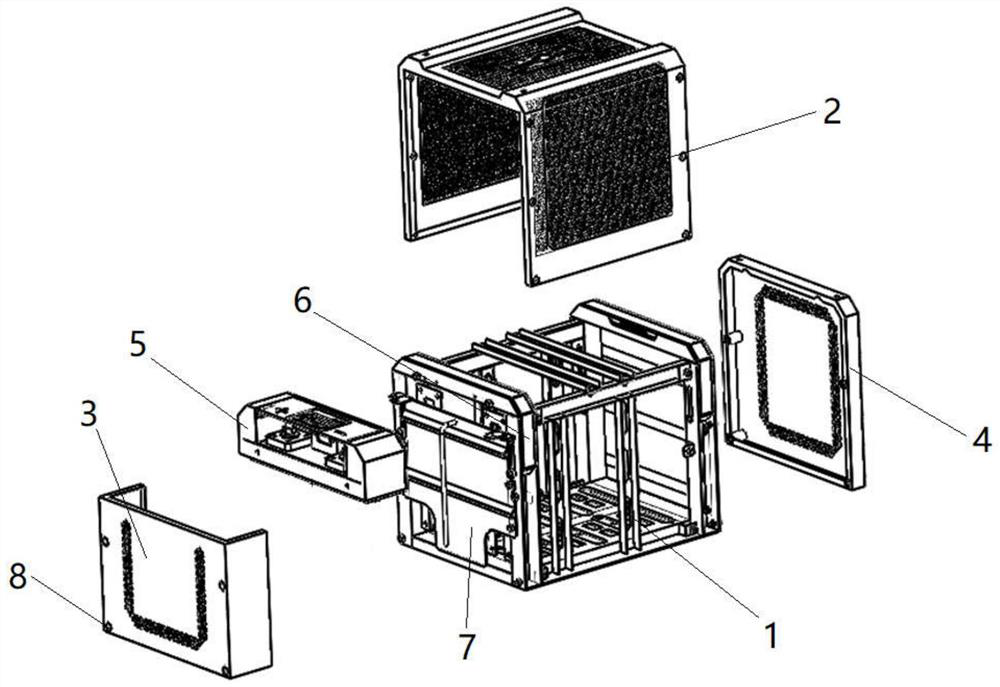

[0027] A battery pack case, such as figure 1 , figure 2 As shown, it includes battery pack module fixing frame 1, top cover 2, left end cover 3, right end cover 4 and outlet box 5;

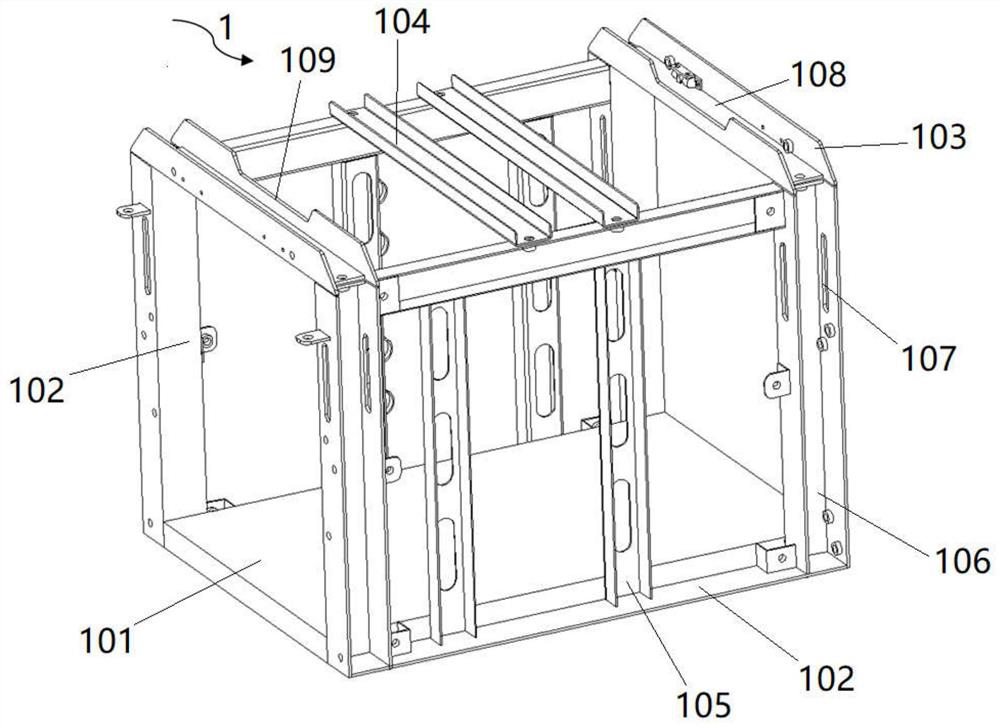

[0028] Such as image 3 As shown, the battery pack module fixing frame 1 includes a bottom plate 101, side support frames 102 are vertically arranged on both sides of the bottom plate 101, and the two ends of the top of the two side support frames 102 are fixed together by cross beams 103 respectively. The top of the side support frame 102 is located between the two cross beams 103 and is provided with two reinforcement cross bars 104 across. The side support frame 102 is provided with two reinforcement vertical bars 105. The two ends of the two side support frames 102 face Grooves 106 are respectively arranged on the outer side, and chute holes 107 are respectively provided on both sides of the grooves 106, through grooves 108 are arranged on the top of the crossbeam 103, and the grooves 106 a...

Embodiment 2

[0033] A battery pack case, the structure of which is similar to that of the battery pack case in Example 1, the difference is that: at the position between the first bolt installation hole and the second bolt installation hole of the right end cover The protective tube is not installed.

Embodiment 3

[0035] A battery pack, comprising a battery pack module and the battery pack case as described in Embodiment 1, the battery pack module is placed in the battery pack module fixing frame of the battery pack case, the main positive line and the main negative line of the battery pack module and control lines are respectively connected to the outlet box. Specifically, the main positive line of the battery pack module is connected to the positive adapter seat in the main positive and negative line inlet cavity of the outlet box, and the main negative line of the battery pack module is connected to the To the negative adapter seat in the total positive and negative wire inlet cavity of the outlet box, the control wire of the battery pack module is connected to the connector installed in the connector mounting hole of the outlet box.

[0036] During production, the battery pack module is placed in the battery pack module fixing frame, and then battery protection baffles are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com