Ciba processing device based on reciprocating secondary hammering action force

A processing device and force technology, which is applied in the field of glutinous rice cake processing devices based on reciprocating secondary hammering force, can solve the problems of not being able to soften the glutinous rice cake, damage the flexibility of the glutinous rice cake, etc., and achieve the effect of being convenient for comprehensive hitting and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

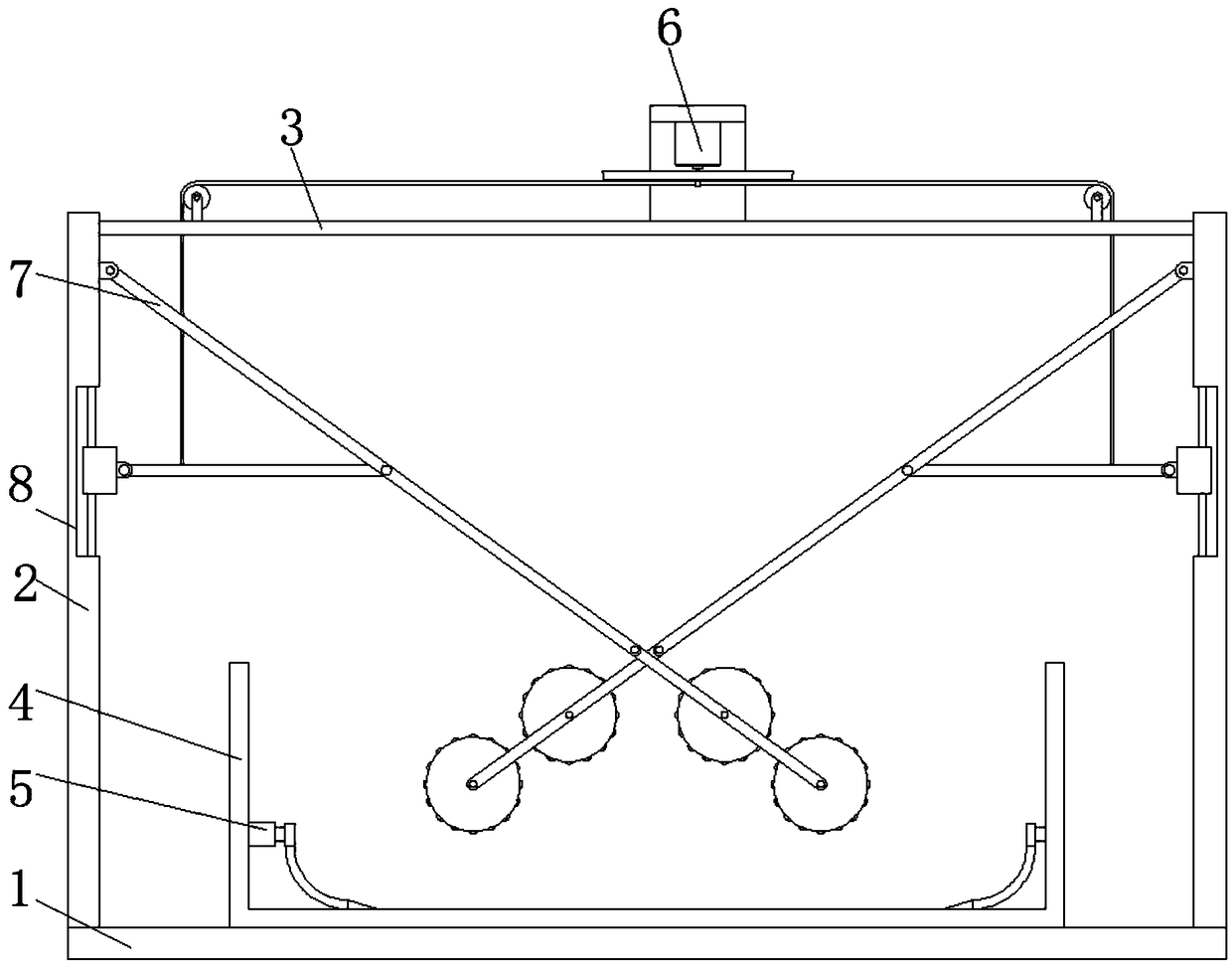

[0043] Such as figure 1 As shown, the present invention provides a technical solution: a glutinous rice cake processing device based on the reciprocating secondary hammering force, comprising a base plate 1, the left and right sides of the top of the base plate 1 are fixedly connected with side plates 2, and the top of the side plate 2 is fixed The top plate 3 is connected, and the top of the bottom plate 1 is fixedly connected with the pressing cylinder 4. The left and right sides of the inner wall of the pressing cylinder 4 are provided with left and right buffer extrusion mechanisms 5, and a notch 8 is opened between the two side plates 2, and the opening of the notch 8 An eccentric wheel rotation mechanism 6 is provided on the inner wall and between the top plate 3, and a reciprocating secondary hammering mechanism 7 is provided on the side close to the side plates 2 on both sides, and the reciprocating secondary hammering mechanism 7 is located above the notch 8 , the rec...

Embodiment 2

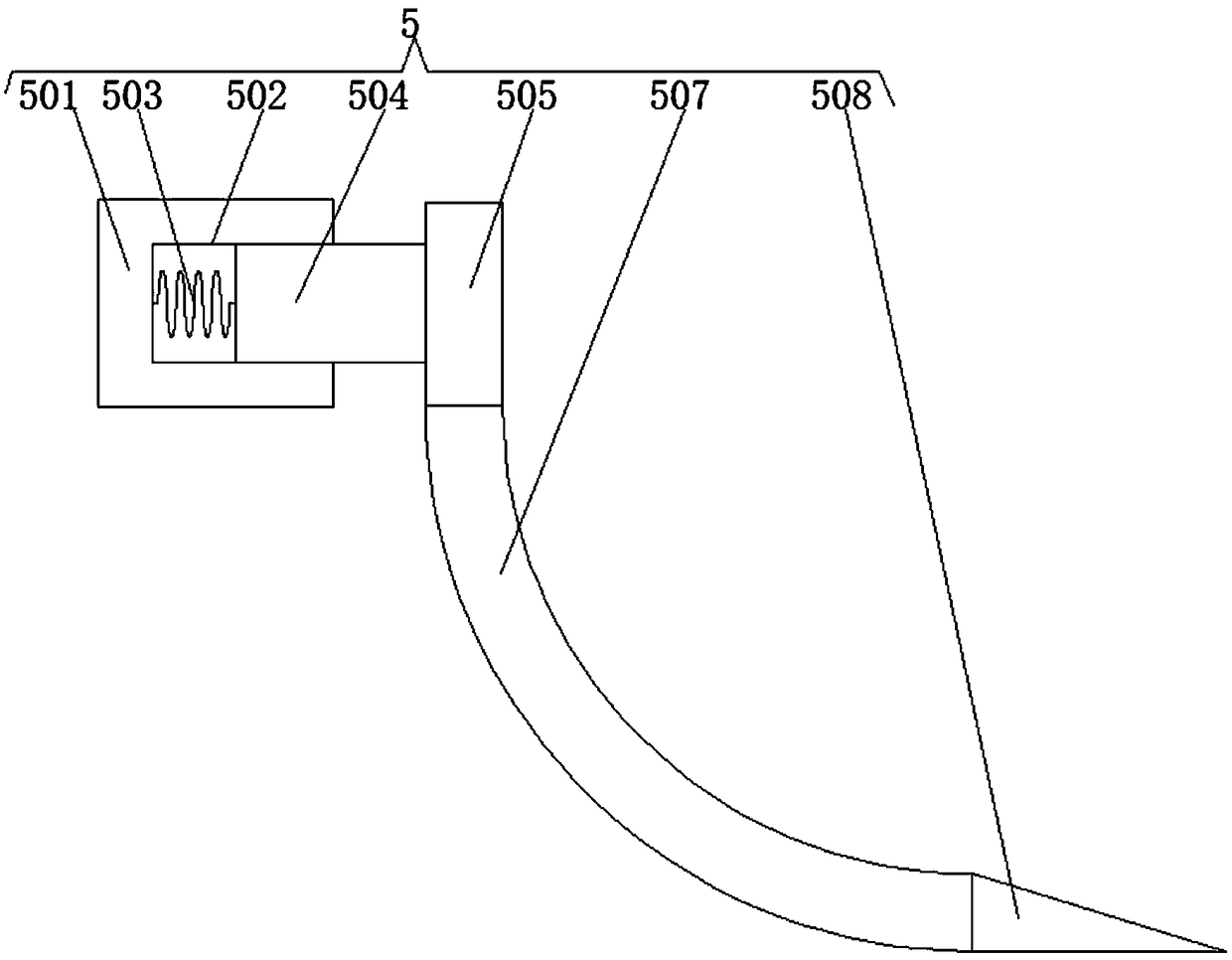

[0046] Such as Figure 1-2 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the left and right buffer extrusion mechanism 5 includes a fixed rod 501 fixedly connected to the inner wall of the pressing cylinder 4, and one end of the fixed rod 501 away from the pressing cylinder 4 is opened There is a circular groove 502, the inner wall of the circular groove 502 is fixedly connected with a compression spring 503, the other end of the compression spring 503 is fixedly connected with a compression rod 504, and the other end of the compression rod 504 is fixedly connected with a riser 505, the bottom of the riser 505 A quarter arc-shaped plate 506 is fixedly connected, and the other end of the quarter arc-shaped plate 506 is fixedly connected with an inclined shovel 507, and the angle between the inclined shovel 507 and the horizontal plane is 10-20°, preferably The shoveling plate 507 is set at 15 degrees, so that the extra glutinous ri...

Embodiment 3

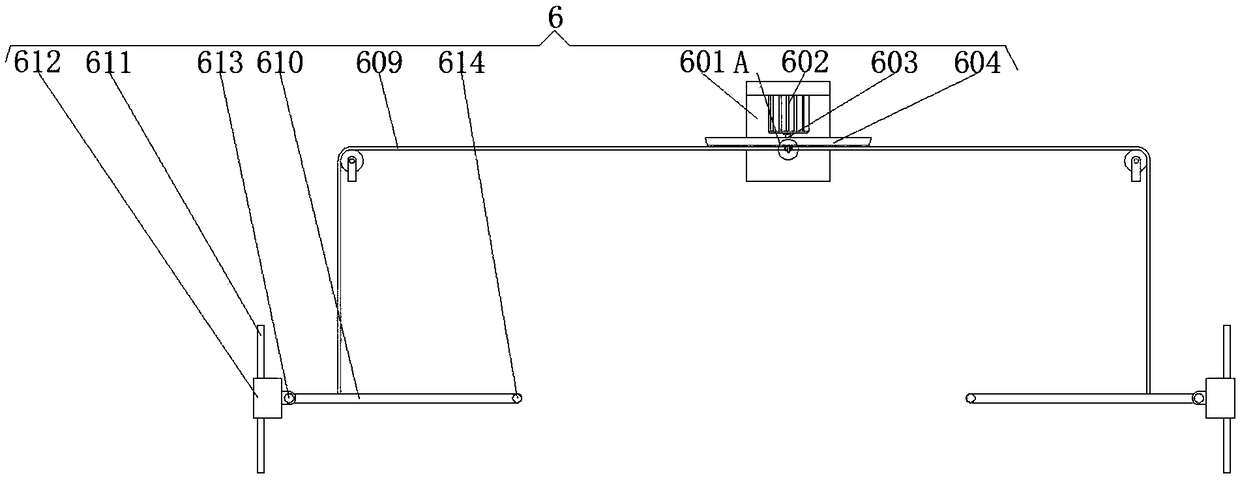

[0048] Such as Figure 1-5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the eccentric wheel rotating mechanism 6 includes an L-shaped plate 601 fixedly connected to the top center of the top plate 3, and the eccentric wheel rotating mechanism 6 also includes The sliding bar 611 is fixedly connected between the top and bottom of the inner wall of the notch 8, and the lower surface above the L-shaped plate 601 is fixedly connected with a three-phase asynchronous motor 602, and the output end of the bottom of the three-phase asynchronous motor 602 is fixedly connected with a rotating shaft through a flat key A603, the bottom of the rotating shaft A603 is fixedly connected with an eccentric circular plate 604, and the distance between the center of the eccentric circular plate 604 and the rotating shaft A603 is 3 cm, and the front of the bottom of the eccentric circular plate 604 is provided with a three-quarter spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com