Mounting structure of gas control valve of cutting machine

A technology of gas control valve and installation structure, which is applied in the direction of gas flame welding equipment, manufacturing tools, welding equipment, etc. It can solve the problems of inconvenient operation and adjustment, occupying a lot of space, and unintuitive operation, and achieves beautiful production, simple assembly, and easy installation. The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with the embodiment of accompanying drawing:

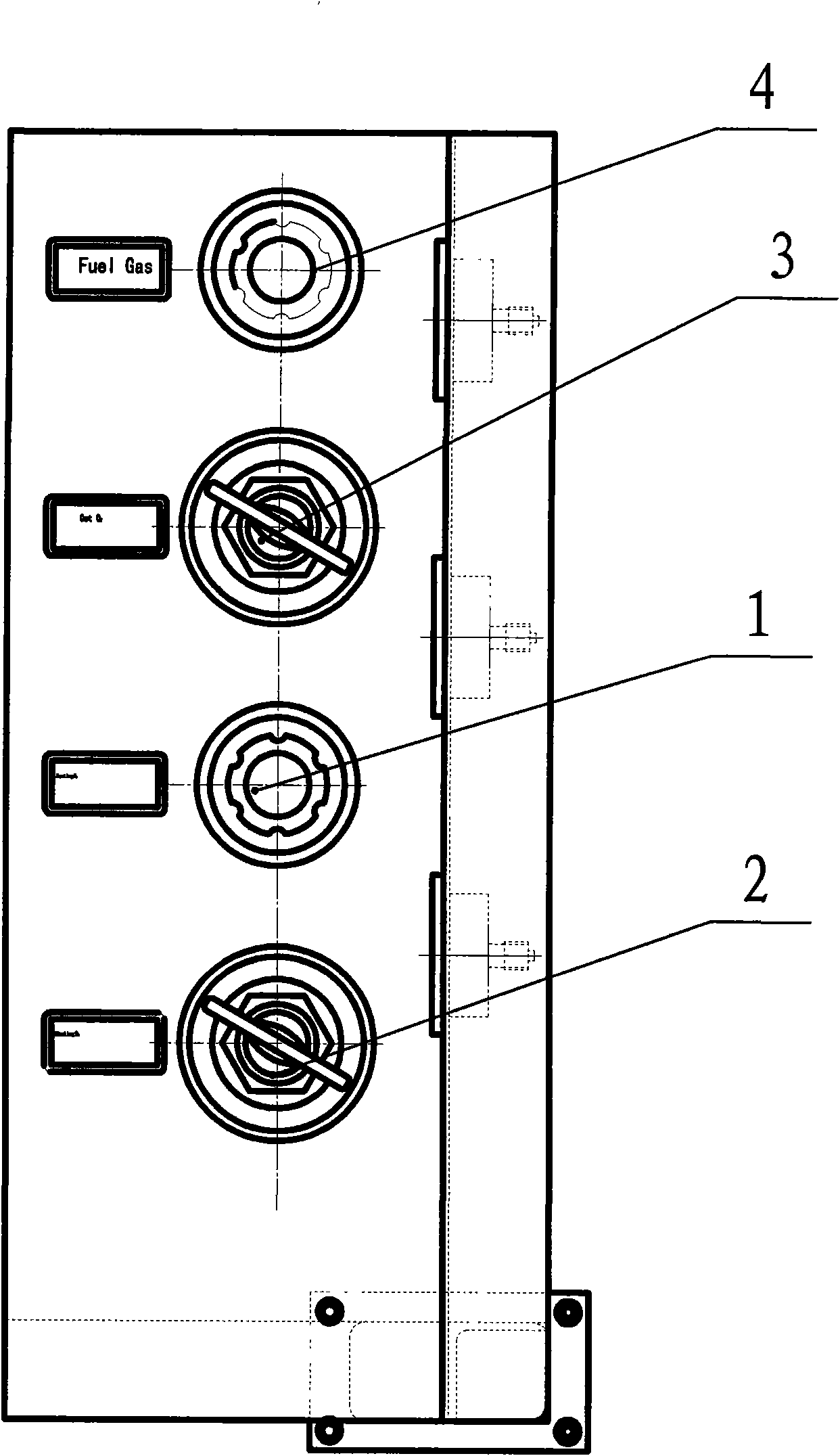

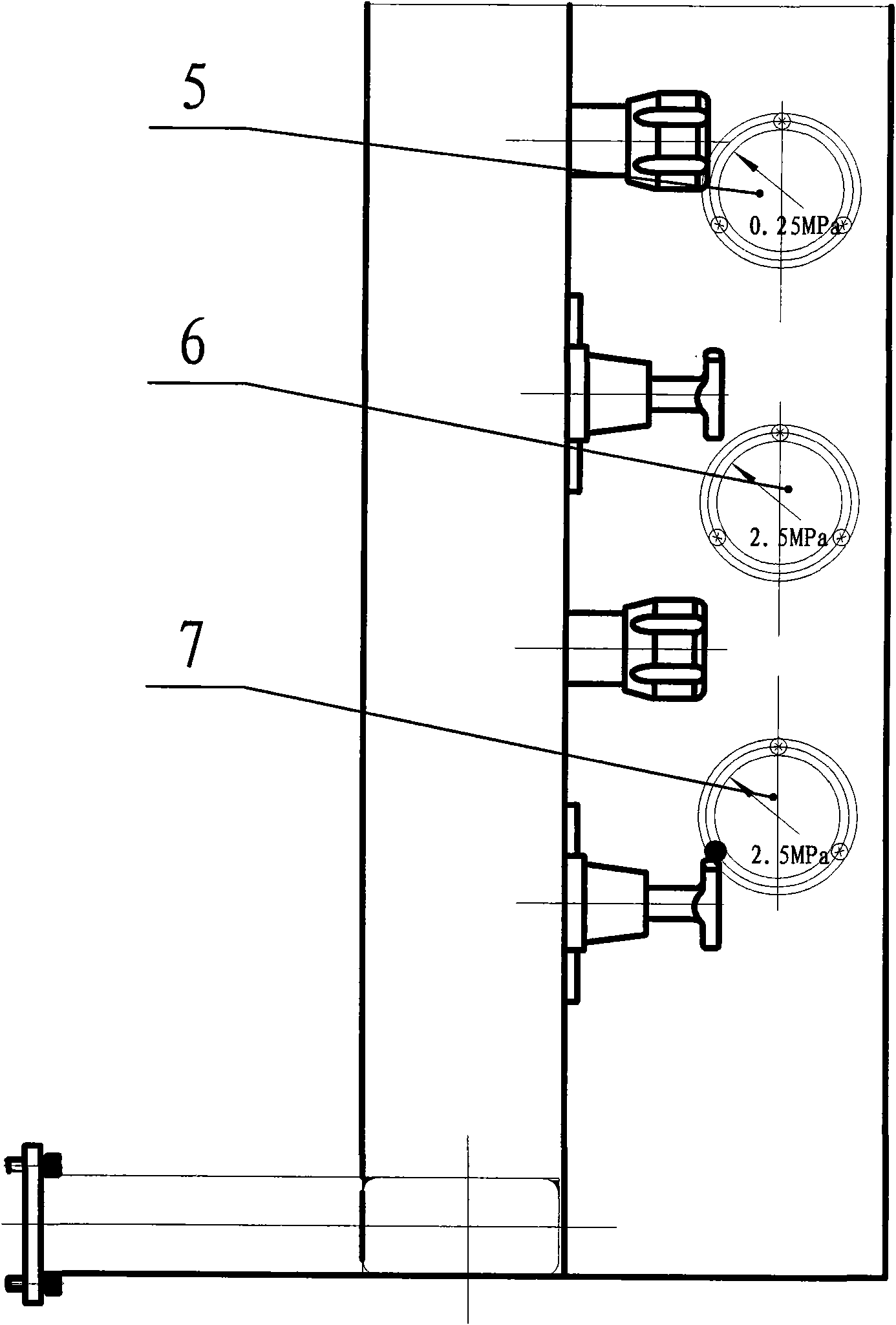

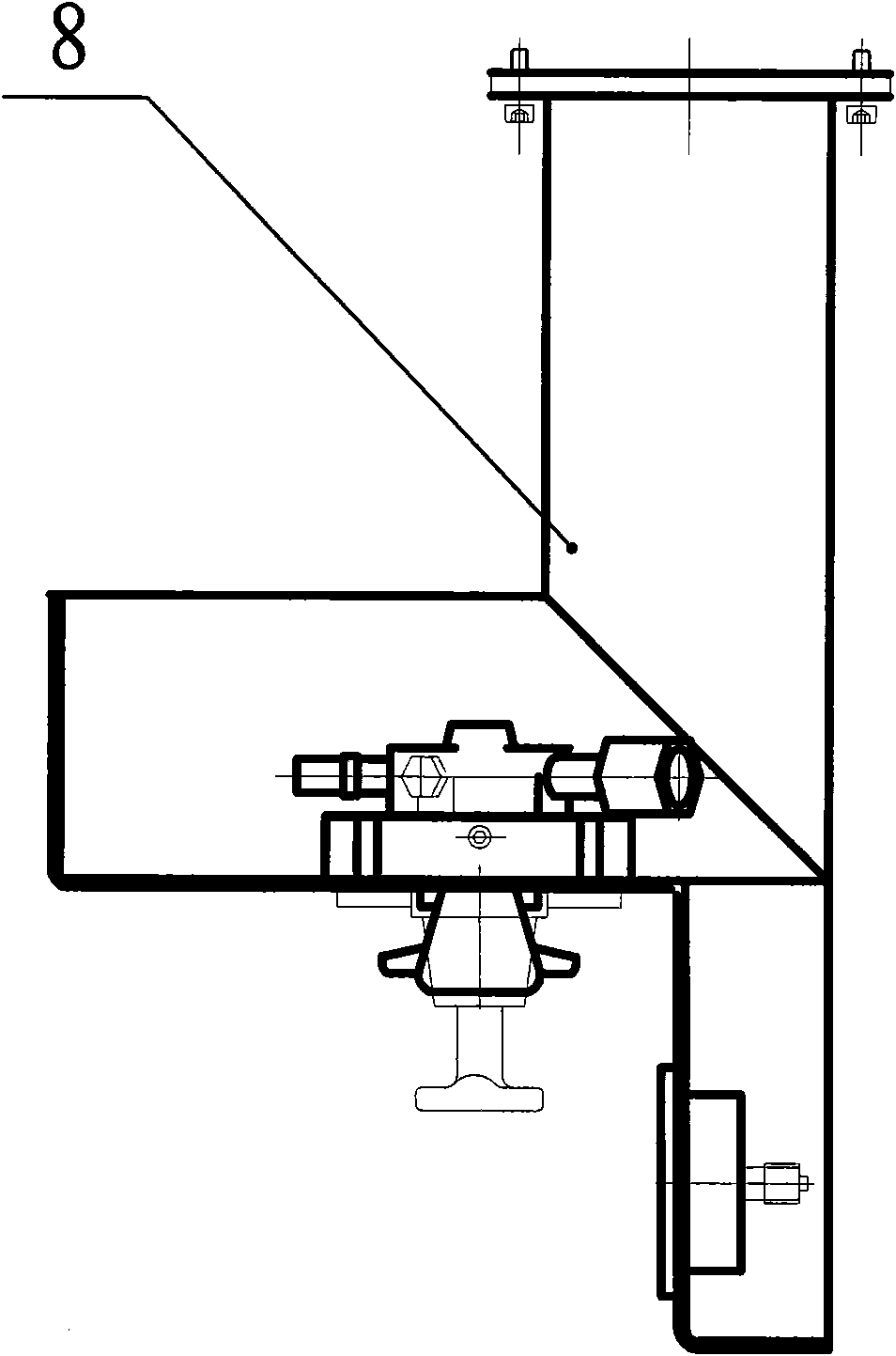

[0012] Such as Figure 1 ~ Figure 3 As shown, including low preheating oxygen pressure reducing valve 1, high preheating oxygen pressure reducing valve 2, cutting oxygen pressure reducing valve 3, gas pressure reducing valve 4, preheating oxygen pressure gauge 5, cutting oxygen pressure gauge 6, gas pressure Table 7, the composition of the mounting plate 8 and so on.

[0013] The installation structure of the gas control valve of the CNC cutting machine of the present invention mainly adopts the side of the installation plate 8 to respectively install various pressure reducing valves: low preheating oxygen pressure reducing valve 1, high preheating oxygen pressure reducing valve 2, cutting oxygen pressure reducing valve 3, gas pressure reducing valve Pressure reducing valve 4, various pressure gauges are installed on the front of mounting plate 8: preheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com